Flywheel type energy-saving turning and throwing machine

An energy-saving, turning and polishing machine technology, which is applied in the fields of organic fertilizer, application, climate change adaptation, etc., can solve the problems of high energy consumption, increased weight, expensive purchase cost, etc., and achieves high drying efficiency, simple structure and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

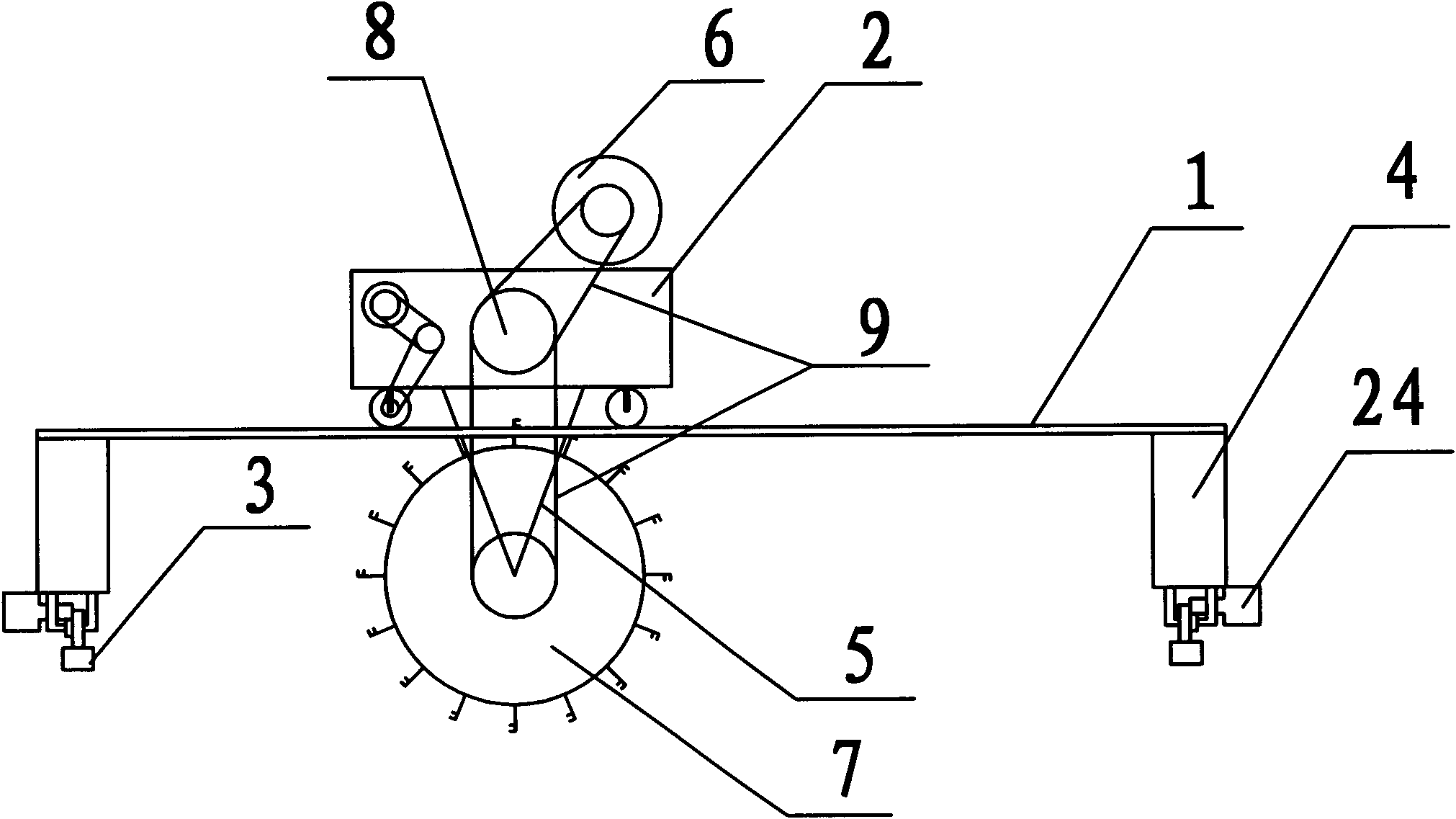

[0030] A wheel-knife energy-saving turning and polishing machine, such as figure 1 As shown, it includes a walking mechanism and a turning and throwing mechanism. The turning and throwing mechanism is fixedly connected with the walking mechanism. The walking mechanism is composed of a horizontal walking mechanism and a longitudinal walking mechanism. 2 is set on the horizontal guide rail 1 and moves back and forth along the horizontal guide rail; the longitudinal traveling mechanism includes the longitudinal guide rail 3 and the longitudinal monorail moving vehicle 4, the longitudinal monorail moving vehicles 4 are connected by the horizontal guide rail 1, and the longitudinal monorail moving vehicle 4 is arranged on the longitudinal The guide rail 3 reciprocates along the longitudinal guide rail 3; the horizontal guide rail 1 is fixed on the longitudinal monorail moving car 4; Fixed connection.

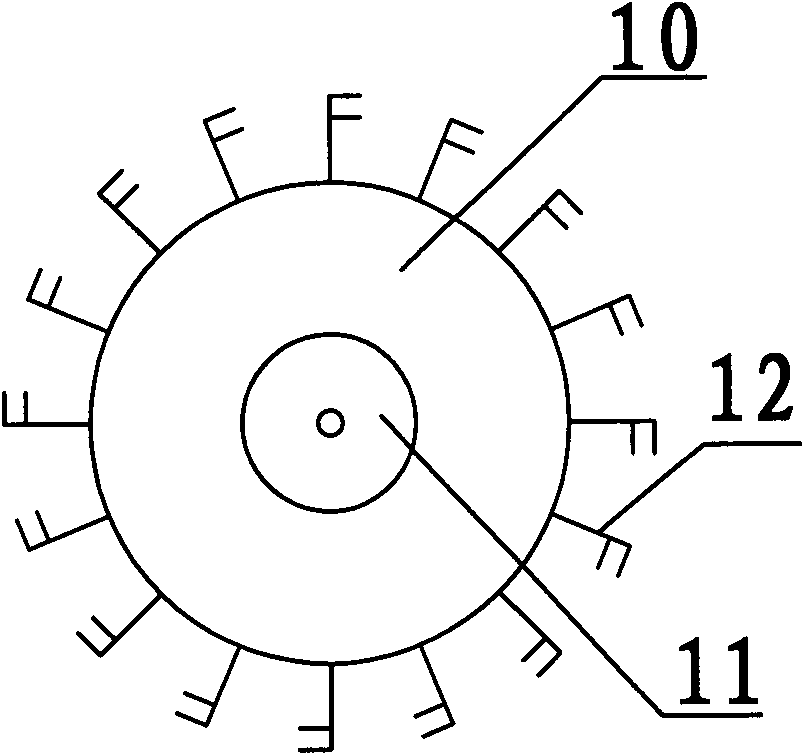

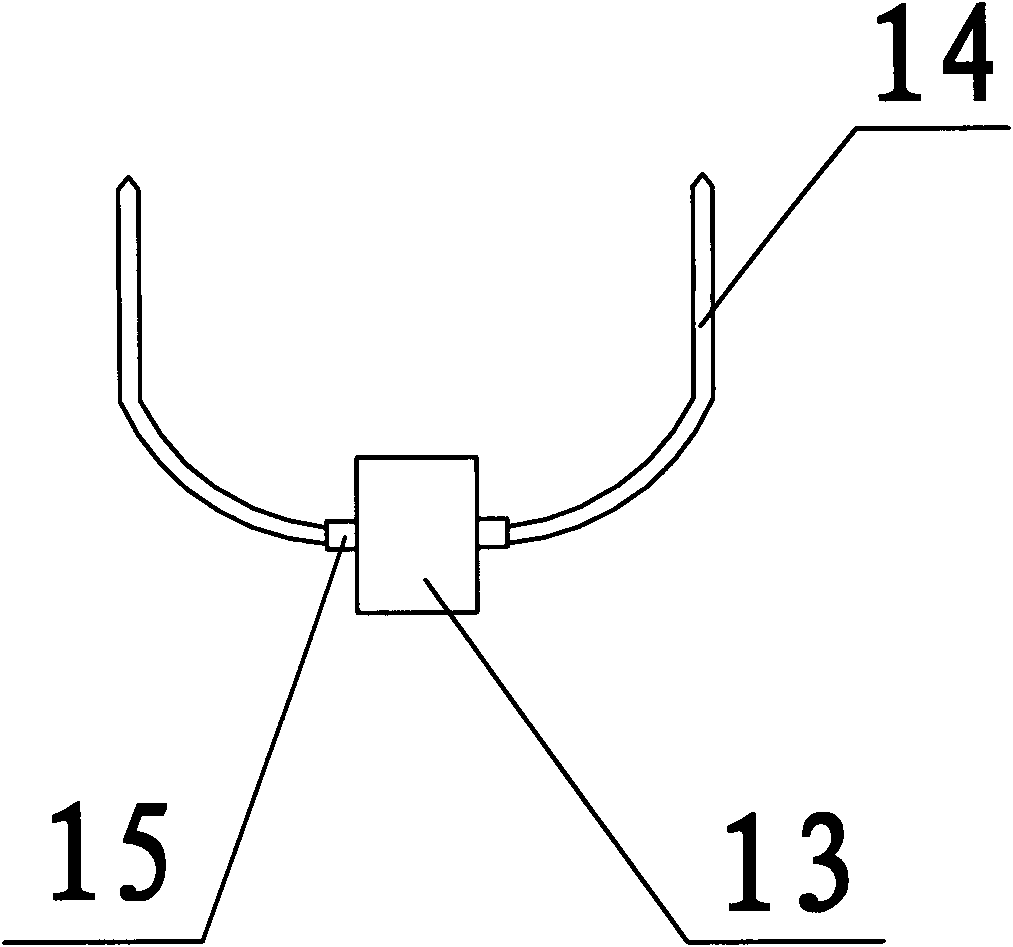

[0031] Described throwing mechanism comprises turning over reduction motor 6, t...

Embodiment 2

[0037]The wheel cutter type energy-saving turning and throwing machine as described in embodiment 1, the difference is that the diameter of the wheel body 10 of the turning and throwing wheel 7 is 3m; the length of the cutter body 14 is 50cm; 13 The included angle 16 of the projection on the plane where the throwing wheel 7 is located is 120 °; the power of the lateral motion vehicle reduction motor 21 is 2.2kw, the power of the longitudinal motion vehicle reduction motor 24 is 1.5kw, and the power of the turning and throwing reduction motor 6 is 7.5 kw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com