Micro-fine particle zinc oxide ore copper ammonia complex cascade activation-enhanced sulfuration flotation method

A copper ammonia complex and zinc oxide ore technology, applied in flotation, solid separation and other directions, can solve the problems of unsatisfactory flotation index, poor vulcanization effect, and difficulty in stable adsorption of collectors, and reduce flotation treatment. cost, solve difficult recovery, and improve the effect of flotation recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

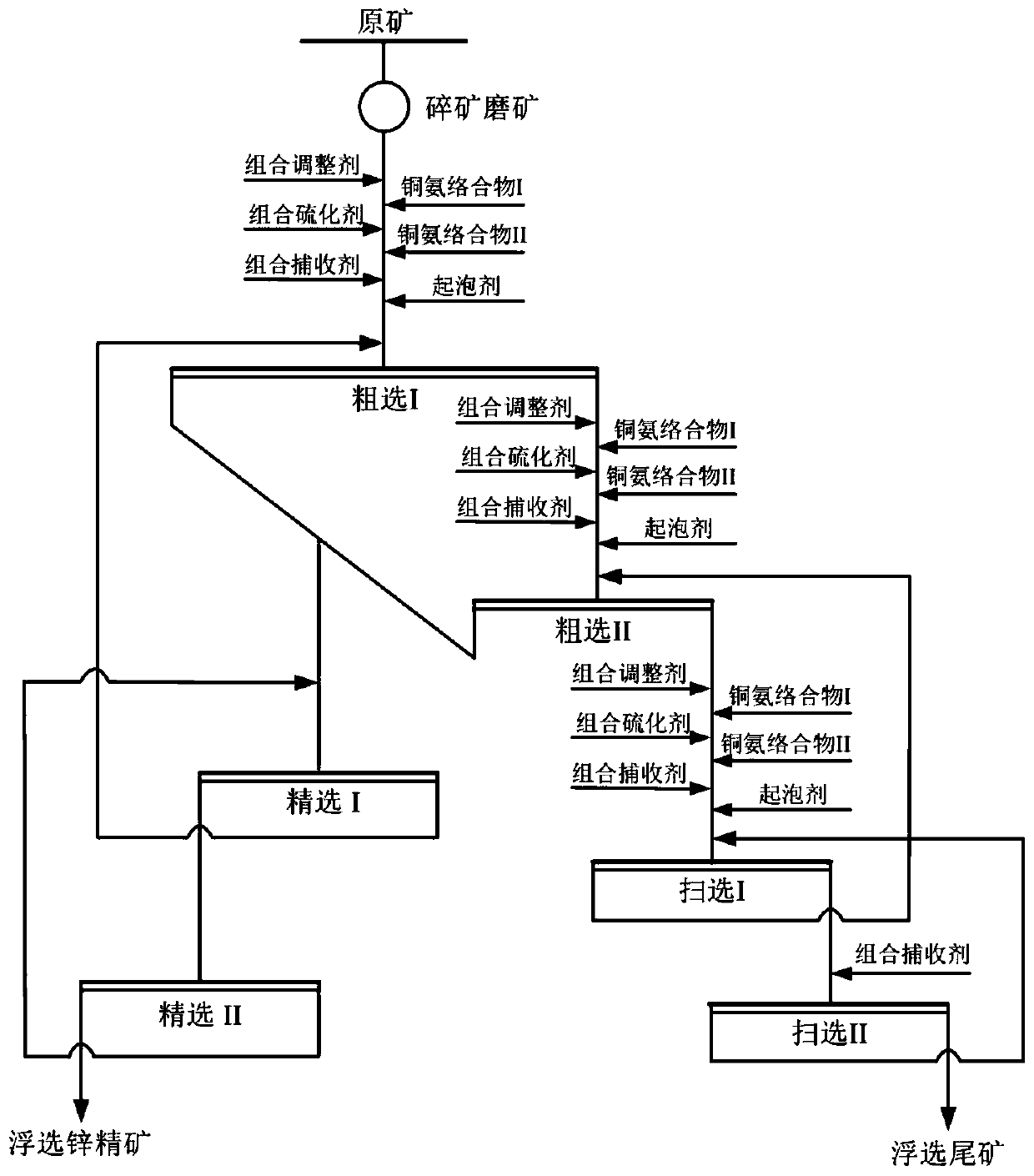

[0036] Example 1: Such as figure 1 As shown, a copper-ammonia complex cascade activation-enhanced sulfide flotation method of fine-grained zinc oxide ore, the specific steps are as follows:

[0037] (1) The mass percentage of zinc oxide ore crushed and fined to -38μm size accounted for 75%, and the slurry was adjusted to a mass percentage of 40%; the mass percentage of zinc in the zinc oxide ore was 8.0% ;

[0038] (2) In step (1), add the combination regulator (sodium hexametaphosphate and water glass), copper ammonia complex I, combined vulcanizing agent (sodium sulfide and sodium polysulfide), copper ammonia complex II in sequence , Combine collectors (isoamyl xanthate, butyl xanthate and butyl ammonium black powder) and foaming agent (terpineol oil), perform a roughing operation to obtain a roughing concentrate and a roughing tailings; Calculated per ton of zinc oxide ore, add 1000g of combined regulator, 400g of copper ammonia complex I, 3000g of combined vulcanizing agent, ...

Embodiment 2

[0043] Example 2: Such as figure 1 As shown, a copper-ammonia complex cascade activation-enhanced sulfide flotation method of fine-grained zinc oxide ore, the specific steps are as follows:

[0044] (1) The mass percentage of zinc oxide ore crushed and fined to -38μm size is 82%, and the mass percentage of the slurry is adjusted to 35%; the mass percentage of zinc in the zinc oxide ore is 14.6% ;

[0045] (2) In step (1), add the combination regulator (sodium hexametaphosphate and water glass), copper ammonia complex I, combined sulfide agent (sodium sulfide and sodium polysulfide), copper ammonia complex II in sequence in step (1) , Combine collectors (isoamyl xanthate, butyl xanthate and butyl ammonium black powder) and foaming agent (terpineol oil), perform a roughing operation to obtain a roughing concentrate and a roughing tailings; Calculated per ton of zinc oxide ore, add 1200g of combined modifier, 600g of copper ammonia complex I, 6000g of combined vulcanizing agent, 300...

Embodiment 3

[0050] Example 3: Such as figure 1 As shown, a copper-ammonia complex cascade activation-enhanced sulfidation flotation method of fine-grained zinc oxide ore, the specific steps are as follows:

[0051] (1) The mass percentage of zinc oxide ore crushed and fined to -38μm size accounted for 90%, and the slurry was adjusted to a mass percentage of 25%; the mass percentage of zinc in the zinc oxide ore was 20.5% ;

[0052] (2) In step (1), add the combination regulator (sodium hexametaphosphate and water glass), copper ammonia complex I, combined sulfide agent (sodium sulfide and sodium polysulfide), copper ammonia complex II in sequence in step (1) , Combine collectors (isoamyl xanthate, butyl xanthate and butyl ammonium black powder) and foaming agent (terpineol oil), perform a roughing operation to obtain a roughing concentrate and a roughing tailings; Calculated per ton of zinc oxide ore, add 1500g of combined regulator, 800g of copper ammonia complex I, 8000g of combined vulcan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com