Method for treating blast furnace fume and recycling iron and zinc

A soot and blast furnace technology, applied in the field of comprehensive utilization of resources, can solve the problems of spontaneous combustion of zinc gas ash, reduce the service life of cloth bags, and close symbiosis, and achieve the effects of efficient recovery, convenient operation, and comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

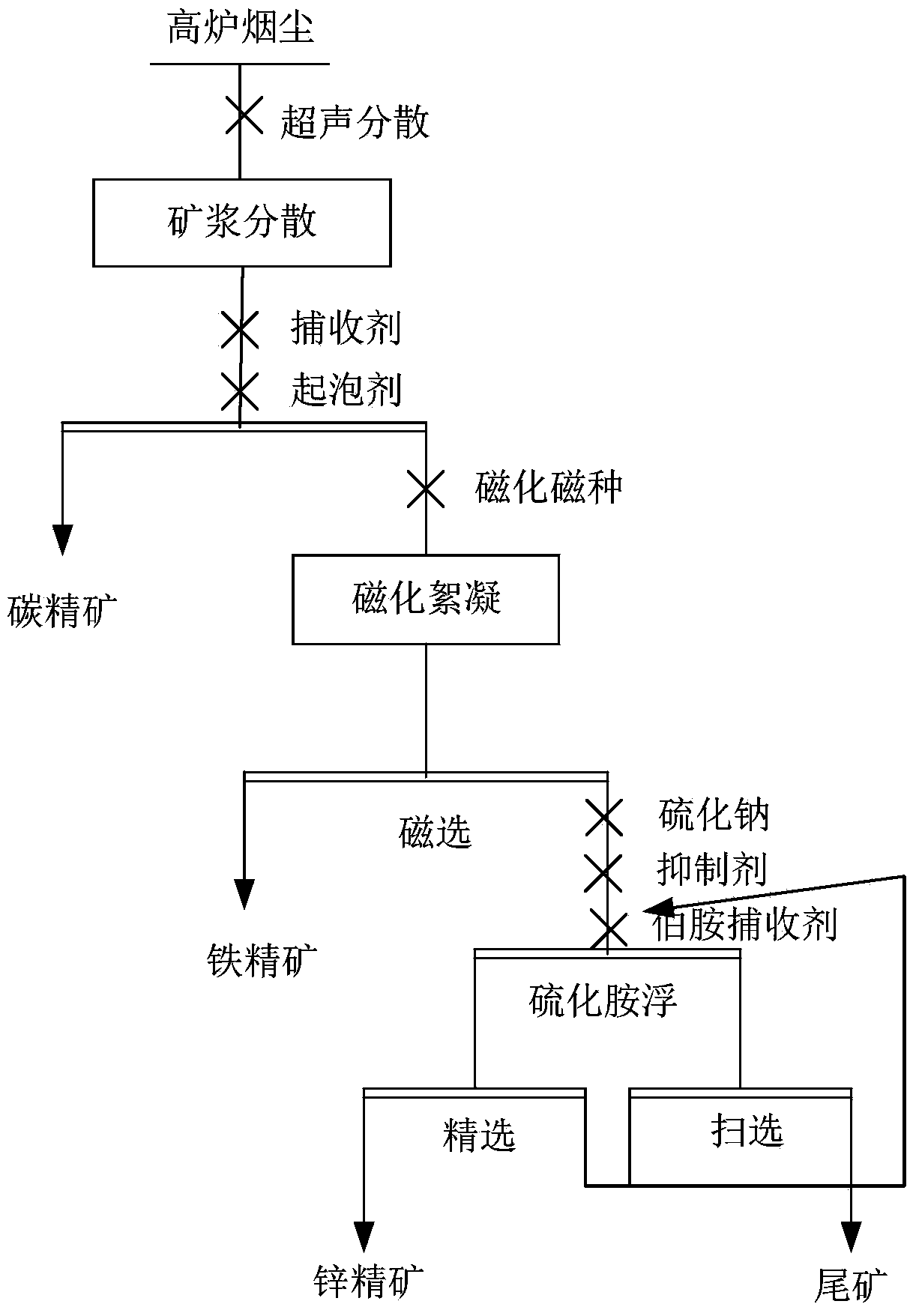

Method used

Image

Examples

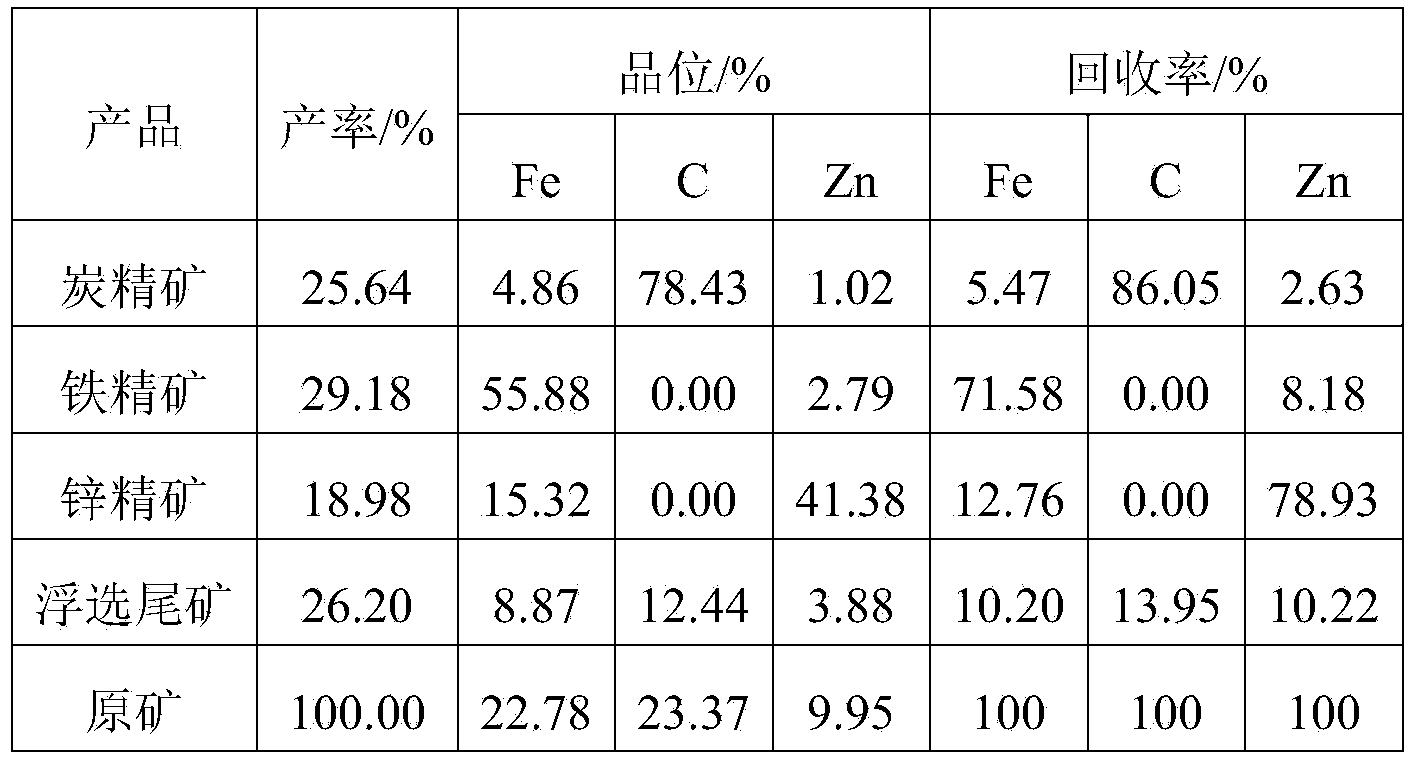

Embodiment 1

[0040] The blast furnace dust containing 22.78% iron, 9.95% zinc and 23.37% carbon is treated by the above method. Take 500g of blast furnace dust and adjust the slurry according to the solid-liquid weight ratio of 1:5, heat to 50°C, stir at a stirring speed of 800r / min for 30 minutes, so that the electrolyte in the blast furnace dust is completely dissolved, filter, the clear liquid is an electrolyte solution, and the filter residue It is iron-containing slag, and the slag is mixed with water until the pulp dispersion concentration is 20%, the stirring speed is 800r / min, and the 80KHz ultrasonic wave is used to disperse, and the dispersant sodium carbonate and sodium hexametaphosphate 600g / t each, 800g / t to obtain dispersed pulp; transfer the dispersed pulp to the flotation tank, use diesel oil 100g / t as collector and terpineol 50g / t as foaming agent to float and remove charcoal in blast furnace dust to obtain carbon fines ore and dispersed ore after decarbonization; take -40...

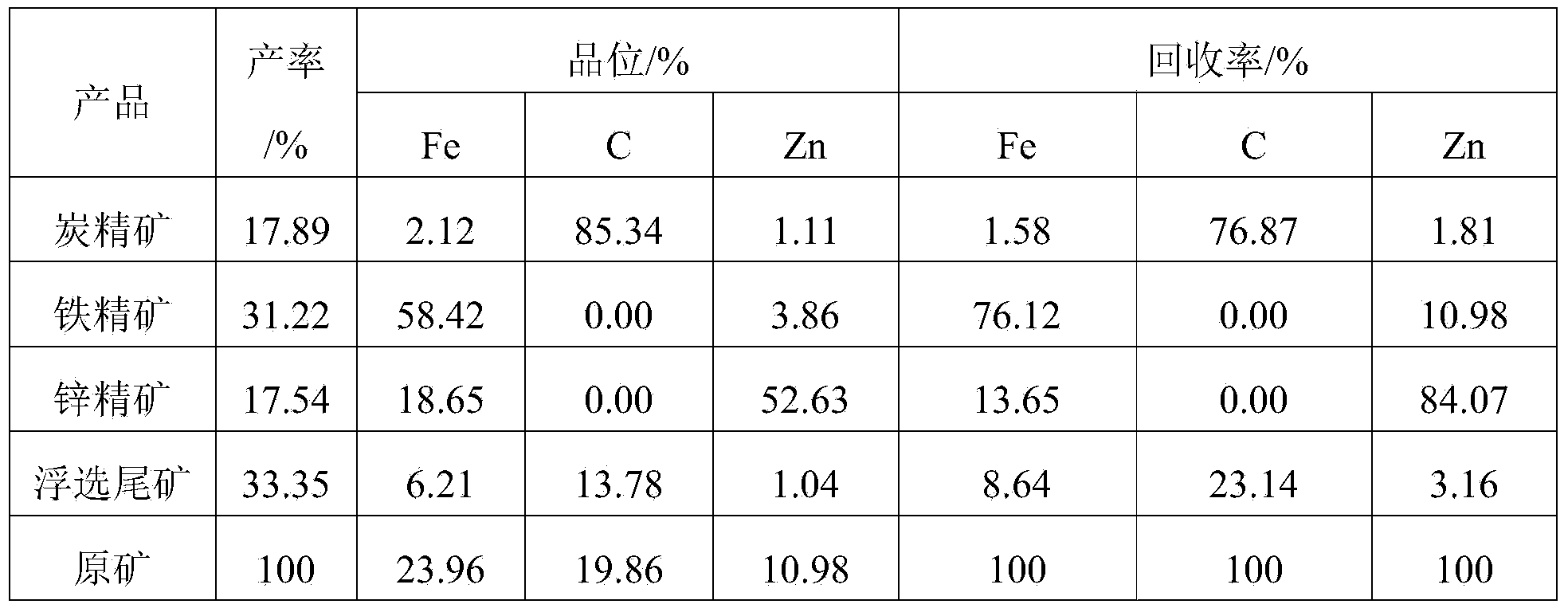

Embodiment 2

[0044] The blast furnace dust containing 23.96% iron, 10.98% zinc and 19.86% carbon is treated by the above method. Take 500g of blast furnace dust and mix it according to the solid-liquid weight ratio of 1:6, heat it to 60°C, stir at a stirring speed of 900r / min for 30 minutes, so that the electrolyte in the blast furnace dust is completely dissolved, filter, the clear liquid is an electrolyte solution, and the filter residue It is iron-containing slag, the slag is mixed with water to adjust the slurry to a concentration of 30%, the stirring speed is 800r / min, and the 80KHz ultrasonic wave is used for dispersion, and the dispersant sodium carbonate and sodium hexametaphosphate are added at 800g / t and 800g / t respectively. Promptly get the dispersed pulp; transfer the dispersed pulp to the flotation cell, use 100g / t of diesel oil as the collector, and 50g / t of terpineol as the foaming agent to remove the charcoal in the blast furnace dust by flotation to obtain the charcoal conc...

Embodiment 3

[0048] The blast furnace dust containing 24.93% iron, 10.17% zinc and 20.50% carbon is treated by the above method. Take 500g of blast furnace dust and mix it according to the solid-liquid ratio of 1:5.5, heat to 55°C, stir at 900r / min for 30 minutes, stir for 30 minutes, so that the electrolyte in the blast furnace dust is completely dissolved, filter, and the clear liquid is an electrolyte solution , the filter residue is iron-containing slag, the slag is mixed with water to a concentration of 25%, and the stirring speed is 900r / min under the stirring condition, stirring, dispersing with 80KHz ultrasonic waves, and adding 800g / t of dispersants sodium carbonate and sodium hexametaphosphate , 800g / t to get the dispersed pulp; transfer the dispersed pulp to the flotation tank, use 100g / t of diesel oil as the collector, and 50g / t of terpineol as the foaming agent to remove the charcoal in the blast furnace dust by flotation Dispersed pulp after carbon eluting; take -400 mesh mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com