Method of recycling lead and zinc ore from high-sulfur lead and zinc ore tailings

A technology of lead-zinc ore and tailings, which is applied in the field of mineral processing engineering, can solve problems such as difficult high-efficiency separation of lead and zinc, poor recovery effect of zinc oxide, and low added value of products, so as to improve zinc recovery rate, facilitate industrial implementation, and improve The effect of comprehensive utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

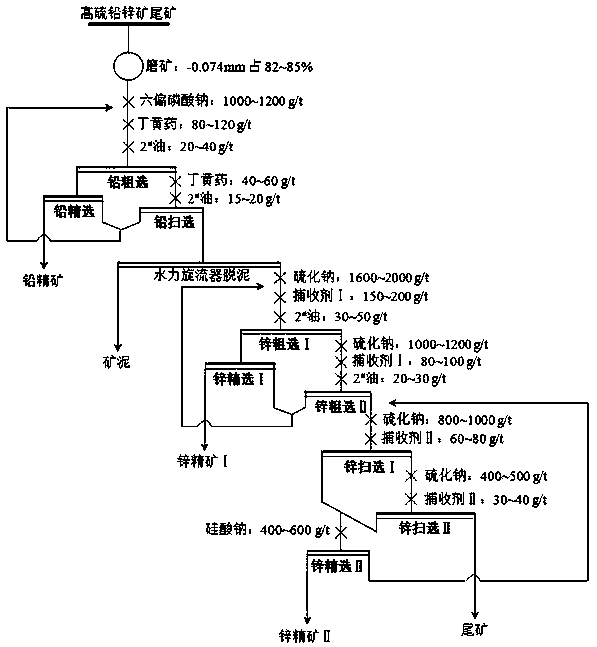

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the method for reclaiming lead-zinc minerals from high-sulfur lead-zinc ore tailings, the selected tailings sample is taken from the old tailings pool of Huize high-sulfur lead-zinc mine in Yunnan, and the tailings contain Pb 0.84%, Zn 3.67%, S 1.89%, Fe 2.94%, of which the lead minerals are mainly galena and white lead minerals, and the zinc minerals are mainly sphalerite, smithsonite and zinc silicate.

[0035] (1) Add the tailings to the rod mill, add water to adjust the pulp concentration to 62%, and then grind the ore until the particle size is less than 0.074mm by mass, accounting for 83.2%;

[0036] (2) Adjust the slurry concentration of the grinding product obtained in step (1) to 24%, and then add dispersant sodium hexametaphosphate 1000g / t, collector butyl xanthate 100g / t, foaming agent 2 # Oil 30g / t is used for lead roughing to obtain lead roughing concentrate and lead roughing tailings;

[0037] (3) Perform lead concentration on the lead rough...

Embodiment 2

[0047] Embodiment 2: This method for reclaiming lead-zinc minerals from high-sulfur lead-zinc ore tailings, the tailings sample used is taken from the tailings pond of Yiliang lead-zinc mine in Zhaotong, Yunnan, and the tailings contain Pb 1.02%, Zn 2.83%, S 3.14%, Fe 5.28%, Ag 4.2g / t, Ge 3.05g / t, of which the lead-containing minerals are mainly galena with fine particle size, and the zinc-containing minerals are mainly smithsonite.

[0048] (1) Put the tailings into the rod mill, add water to adjust the slurry concentration to 65%, and then grind the ore until the particle size is less than 0.074mm by mass, accounting for 82%;

[0049] (2) Adjust the slurry concentration of the grinding product obtained in step (1) to 23%, and then add dispersant sodium hexametaphosphate 1200g / t, collector butyl xanthate 80g / t, foaming agent 2 # Oil 20g / t is used for lead roughing to obtain lead roughing concentrate and lead roughing tailings;

[0050] (3) Perform lead concentration on the l...

Embodiment 3

[0060] Embodiment 3: This method for recovering lead-zinc minerals from high-sulfur lead-zinc mine tailings, the tailings sample used is taken from the tailings pond of Guangdong Fankou lead-zinc mine, and the tailings contain Pb 0.97%, Zn 1.94%, S 2.27%, Fe 3.22%, SiO 2 32.84%, of which the lead minerals are mainly galena, the zinc minerals are mainly smithsonite, sphalerite and willemite, and the main gangue minerals are quartz and dolomite.

[0061] (1) Put the tailings into the rod mill, add water to adjust the slurry concentration to 60%, and then grind the ore until the particle size is less than 0.074mm by mass, accounting for 85%;

[0062] (2) Adjust the slurry concentration of the grinding product obtained in step (1) to 25%, and then add dispersant sodium hexametaphosphate 1100g / t, collector butyl xanthate 120g / t, foaming agent 2 # Oil 40g / t is used for lead roughing to obtain lead roughing concentrate and lead roughing tailings;

[0063] (3) Perform lead concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com