Pipe leaching method and pipe leaching device for solid powder

A technology of solid powder and leaching, which is applied in solid solvent extraction, chemical/physical/physical-chemical process of applying energy, etc., to achieve the effect of broadening the application field, speeding up the leaching speed, and improving the leaching efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

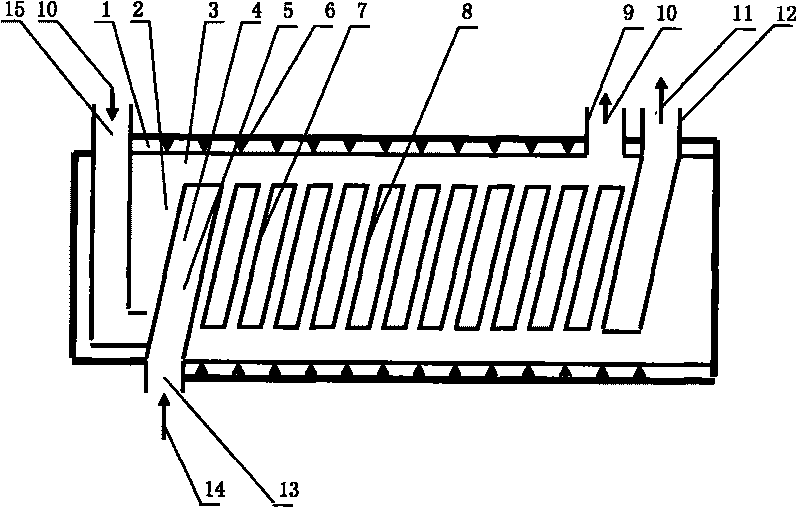

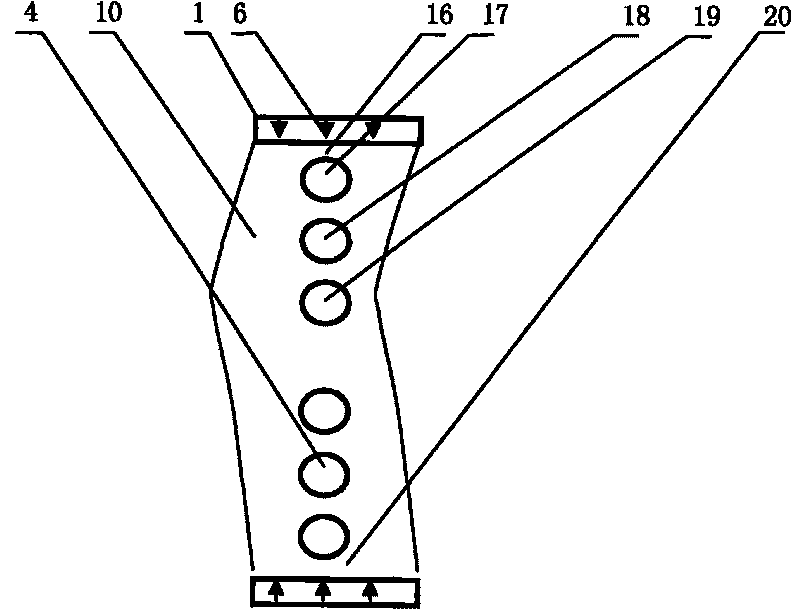

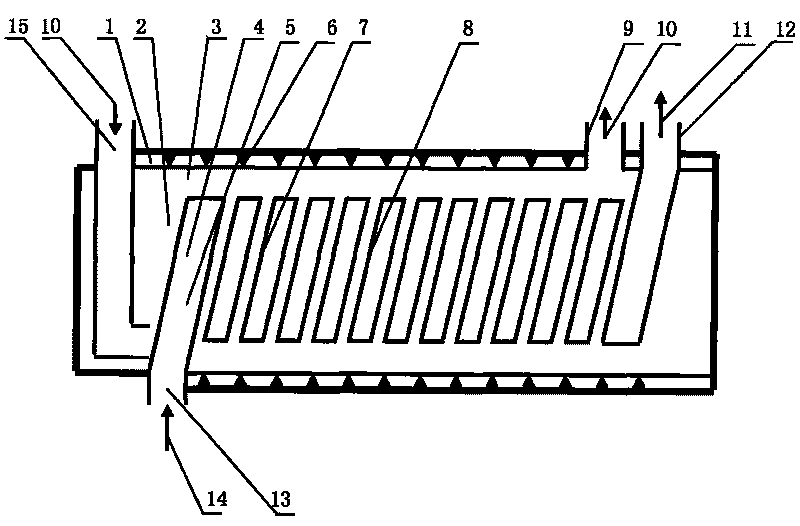

[0051] figure 1 It is an atmospheric pressure tubular leaching device for realizing the tubular leaching method. From figure 1 It can be seen that the atmospheric pressure tubular leaching device is composed of at least one atmospheric pressure open trough container 1 filled with liquid medium 2 and at least one ultrasonic generator 6 arranged inside or outside the trough container. A multi-layer spiral coil 16 filled with flowing solution 14 to be leached is immersed in the open tank container at normal pressure, and the multi-layer spiral coil 16 is an atmospheric pressure spiral coil.

[0052] The leaching process of the atmospheric pressure tube leaching device is an irreversible leaching process. The characteristics of the process are: when the solid powder with a set particle size goes through the same leaching time, the path of most of the particles tends to be equal, and the residual particle mass, particle size and particle target composition also tend to be equal, ...

Embodiment 2

[0063] figure 1 It is a high-pressure tubular leaching device for realizing the tubular leaching method. From figure 1 It can be seen that the high-pressure tubular leaching device is composed of at least one trough container 1 filled with liquid medium 2 and at least one ultrasonic generator 6 arranged inside or outside the trough container. A multi-layer spiral coil 16 filled with flowing solution 14 to be leached is provided, and the multi-layer spiral coil 16 is a high-pressure spiral coil.

[0064] The technical principle of the high-pressure tubular leaching device is the same as that of the first embodiment, which is an irreversible leaching process. The pipeline inlet 13 and the pipeline outlet 12 of the high-pressure spiral coil can be arranged tangentially on the tank wall of the non-open tank vessel 1 at normal pressure, or can be arranged at both ends thereof. The water-based solution 3 filled with the non-open tank container at normal pressure can be the clear ...

Embodiment 3

[0067] An atmospheric-pressure tubular leaching process for zinc oxide ore powder, which adopts the atmospheric-pressure tubular leaching method and device described in Embodiment 1 in the conventional leaching process. The zinc oxide ore powder includes at least zinc oxide ore, zinc calcine, zinc-containing fume and zinc-containing leaching slag.

[0068] The leaching environment of atmospheric pressure tubular leaching of zinc oxide ore powder, such as temperature, acidity, additives, particle size and concentration, etc., can be the same as conventional leaching. The multi-layer spiral coil 16 adopts the improved high-transmission stainless steel spiral coil and the ultrasonic frequency is 20kHz-1×10 6 kHz, ultrasonic sound intensity is 1-50w / cm 2 The ultrasonic generating device 6 can be used to obtain cavitation bubbles with a flow velocity ≥ 100 m / s generated by ultrasonic waves in the solution 14 to be leached. At the set ultrasonic frequency, as the ultrasonic sound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com