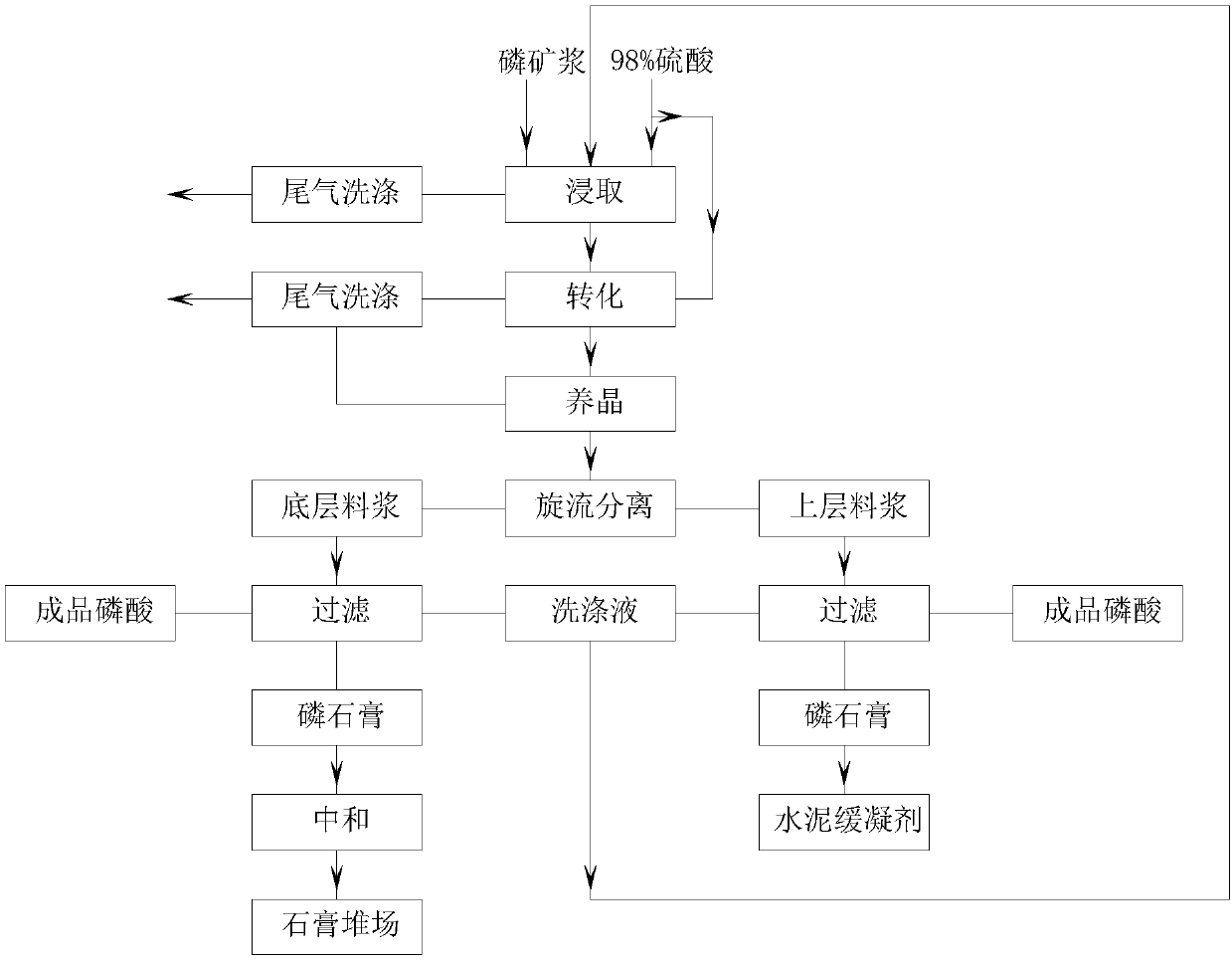

One-step method dihydrate-semi-hydrated wet production process for phosphoric acid

A production process, a water-wet process technology, is applied in the field of one-step dihydrate-semi-aqueous wet process phosphoric acid production process, and can solve the problem that the water balance of the phosphate slurry production system is difficult to solve, the comprehensive utilization rate of phosphogypsum is less than 30%, and the filter The problem of large amount of water for filter cloth washing can reduce the consumption of phosphoric acid concentration steam, improve the comprehensive utilization rate, and reduce the loss of phosphorus resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

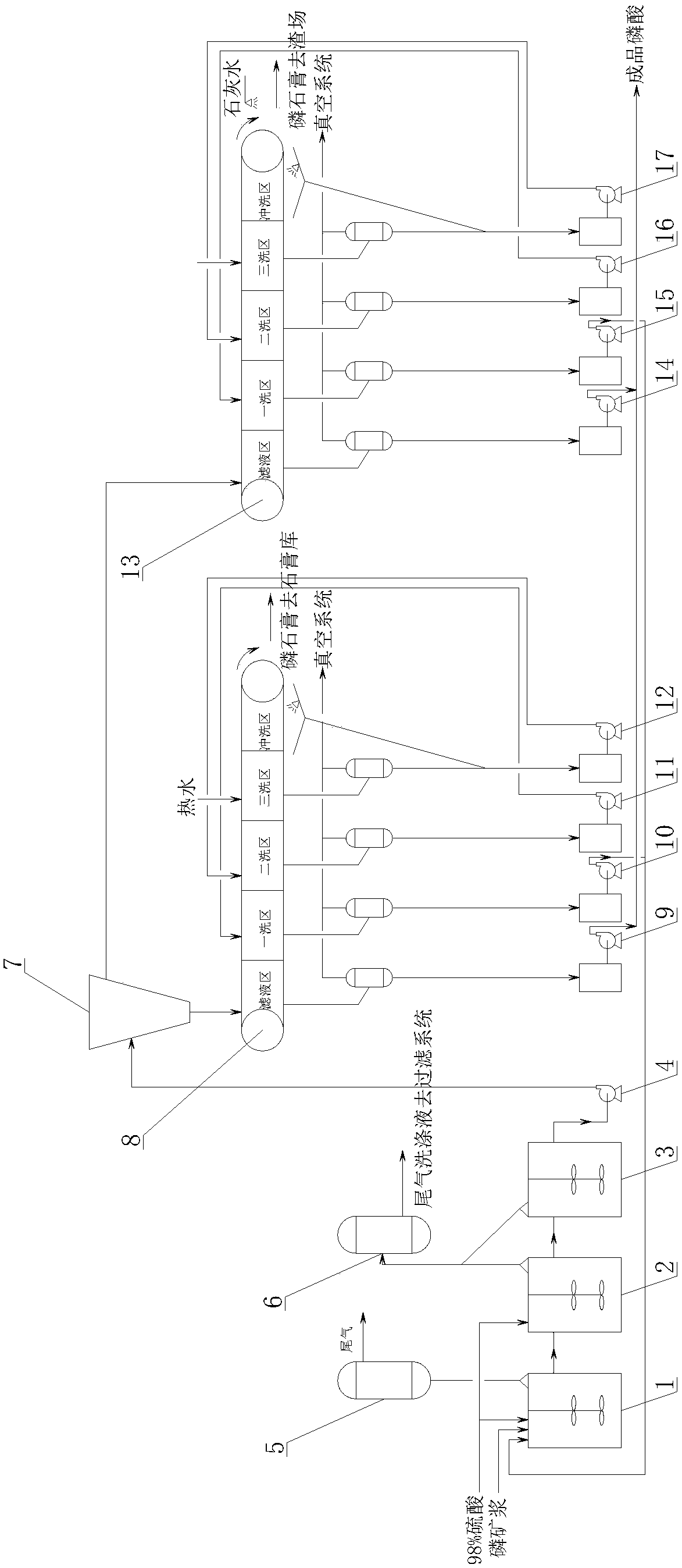

Method used

Image

Examples

Embodiment 1

[0043] S1, leaching reaction:

[0044] 1000 parts of ground phosphate rock are configured into phosphate rock slurry (H 2 O 30%, P 2 o 5 30.02%, CaO 43.62%, MgO1.48%, fineness of 100 mesh ≥ 75%), 240 parts of 98% concentrated sulfuric acid and phosphogypsum washing liquid from the filtration process are continuously mixed and added to the reaction tank for leaching reaction, leaching reaction The temperature is 70-75°C, and the amount of 98% concentrated sulfuric acid accounts for 30% of the total amount of theoretical sulfuric acid (the total amount of sulfuric acid depends on the theoretical mass required for the complete reaction of CaO and MgO in the phosphate rock, and another 562 parts are added to the conversion tank).

[0045] The phosphate rock contained in the phosphate rock slurry, the P contained in the phosphogypsum washing liquid 2 o 5 And the mass ratio of the three reaction slurry is 1000:800:4925.

[0046] Phosphate rock in the reaction tank CaSO 4 -H 3...

Embodiment 2

[0054] S1, leaching reaction:

[0055] 1000 parts of ground phosphate rock are configured into phosphate rock slurry (H 2 O 30%, P 2 o 5 30.02%, CaO 43.62%, MgO1.48%, fineness of 100 mesh ≥ 75%), 224 parts of 98% concentrated sulfuric acid and phosphogypsum washing liquid from the filtration process are continuously mixed and added to the reaction tank for leaching reaction, leaching reaction The temperature is 70-75°C, and the addition of 98% concentrated sulfuric acid accounts for 30% of the total theoretical sulfuric acid (the total sulfuric acid depends on the theoretical mass required for the complete reaction of CaO and MgO in the phosphate rock, and another 578 parts are added to the conversion tank).

[0056] The phosphate rock contained in the phosphate rock slurry, the P contained in the phosphogypsum washing liquid 2 o 5 And the mass ratio of the three reaction slurry is 1000:770:4704.

[0057] Phosphate rock in the reaction tank CaSO 4 -H 3 PO 4 -H 2 SO 4...

Embodiment 3

[0065] S1, leaching reaction:

[0066] 1000 parts of ground phosphate rock are configured into phosphate rock slurry (H 2 O 30%, P 2 o 5 30.02%, CaO 43.62%, MgO1.48%, fineness of 100 mesh ≥ 75%), 256 parts of 98% concentrated sulfuric acid and phosphogypsum washing liquid from the filtration process are continuously mixed and added to the reaction tank for leaching reaction, leaching reaction The temperature is 70-75°C, and the amount of 98% concentrated sulfuric acid accounts for 30% of the total theoretical sulfuric acid (the total sulfuric acid depends on the theoretical mass required for the complete reaction of CaO and MgO in the phosphate rock, and another 540 parts are added to the conversion tank).

[0067] The phosphate rock contained in the phosphate rock slurry, the P contained in the phosphogypsum washing liquid 2 o 5 And the mass ratio of the three reaction slurry is 1000:829:5145.

[0068] Phosphate rock in the reaction tank CaSO 4 -H 3 PO 4 -H 2 SO 4 -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com