Advanced treatment and zero emission process for coking wastewater

A coking sewage and advanced treatment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of direct discharge, supplementary dilution water, etc., to ensure water quality, The effect of reducing the amount of water and reducing the amount of sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

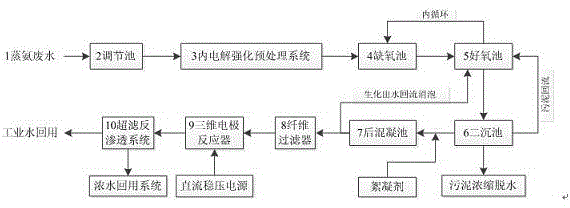

[0026] Attached below figure 1 And the examples illustrate the present invention in detail.

[0027] See attached figure 1 According to a complete process plan of the present invention for the advanced treatment of coking wastewater, the treatment process is carried out as follows:

[0028] (1) The coking wastewater enters the conditioning tank after ammonia removal and dephenolization, and then is pumped to the internal electrolysis pretreatment system for iron-carbon internal electrolysis and biological anaerobic reaction, reducing the COD of the raw water of the coking wastewater and increasing the B of the wastewater. / C ratio.

[0029] (2) The coking sewage after internal electrolysis enters the anoxic tank and aerobic tank for A / O biochemical reaction, and then enters the secondary sedimentation tank and the post-coagulation tank to further remove colloids, turbidity and chroma, and part of the biochemical effluent returns As defoaming water in aerobic pool.

[0030] (3) The bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com