Pallet device and crystallized film growth device

A tray and equipment technology, applied in the field of crystalline film growth, can solve the problems of increasing the tray carrying area, increasing the tray, increasing energy consumption, etc., to ensure process stability and uniformity, ensuring stability and uniformity, The effect of reducing production and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those skilled in the art to better understand the technical solution of the present invention, the tray device and the crystalline film growth equipment provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. In these drawings, the same reference numerals are attached to the same or corresponding parts.

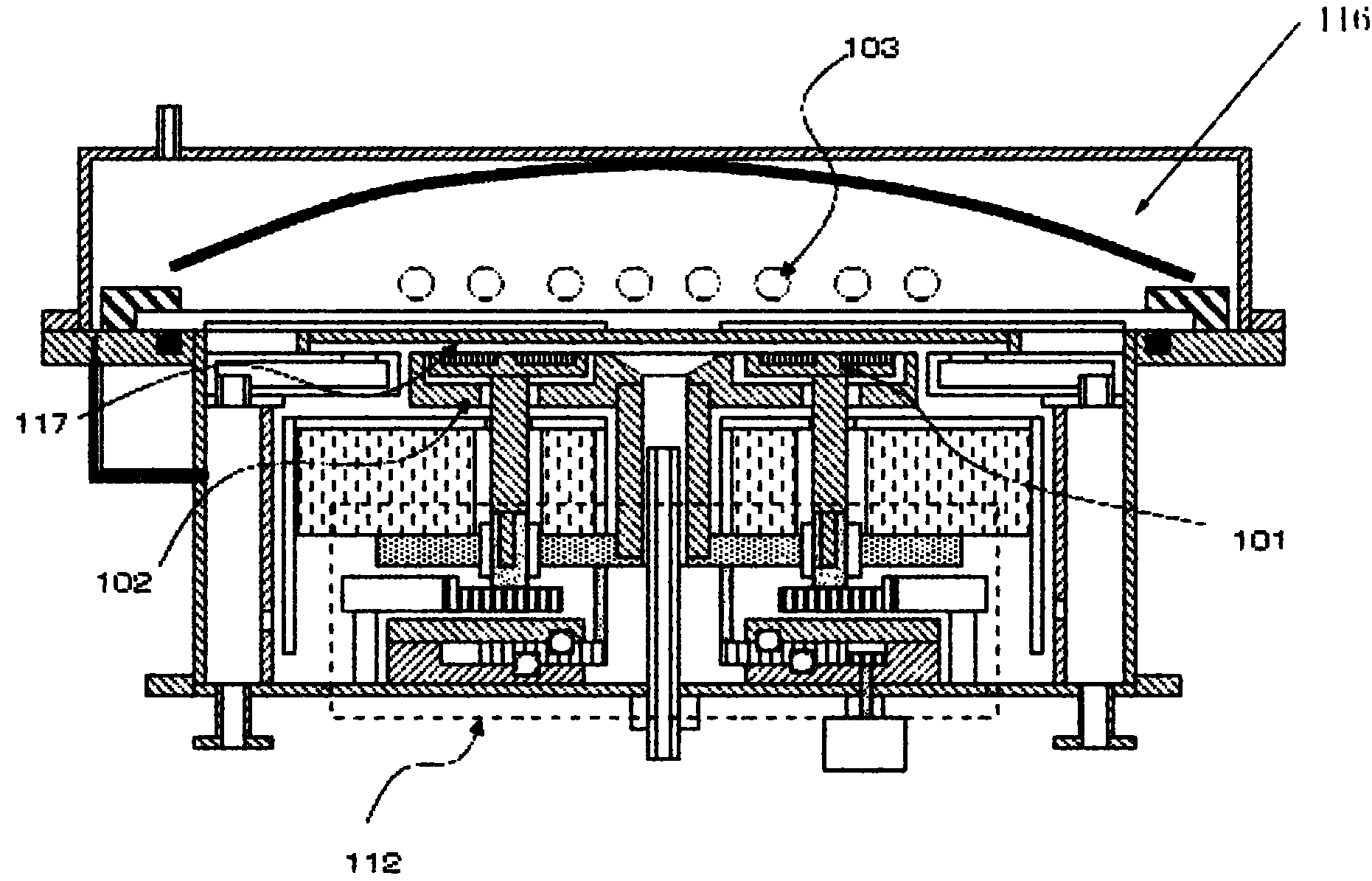

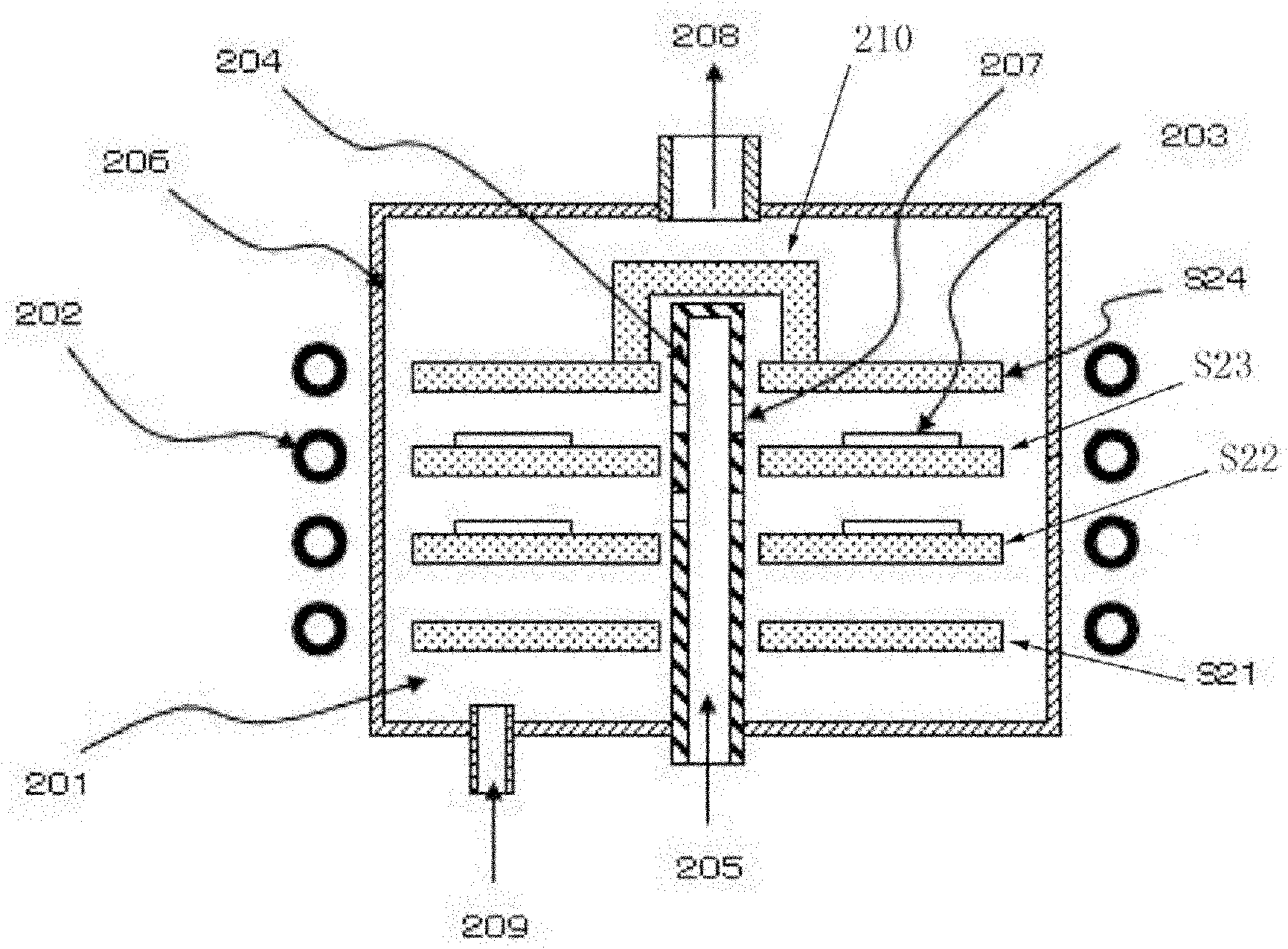

[0052] figure 2 A schematic structural diagram of a pallet device provided by an embodiment of the present invention. In this embodiment, the tray device includes four ring-shaped trays 74-71 that are parallel to each other and stacked in sequence from bottom to top in the longitudinal direction. Each tray 71-74 is fixed thereon. There is a certain distance between adjacent trays, so that workpieces to be processed, such as substrates, are placed on the trays 71-74 and process gases pass through. Usually, the distance can be set at 0.5 cm to 8 cm, preferably 1 cm to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com