Patents

Literature

37results about How to "Reduced purification process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

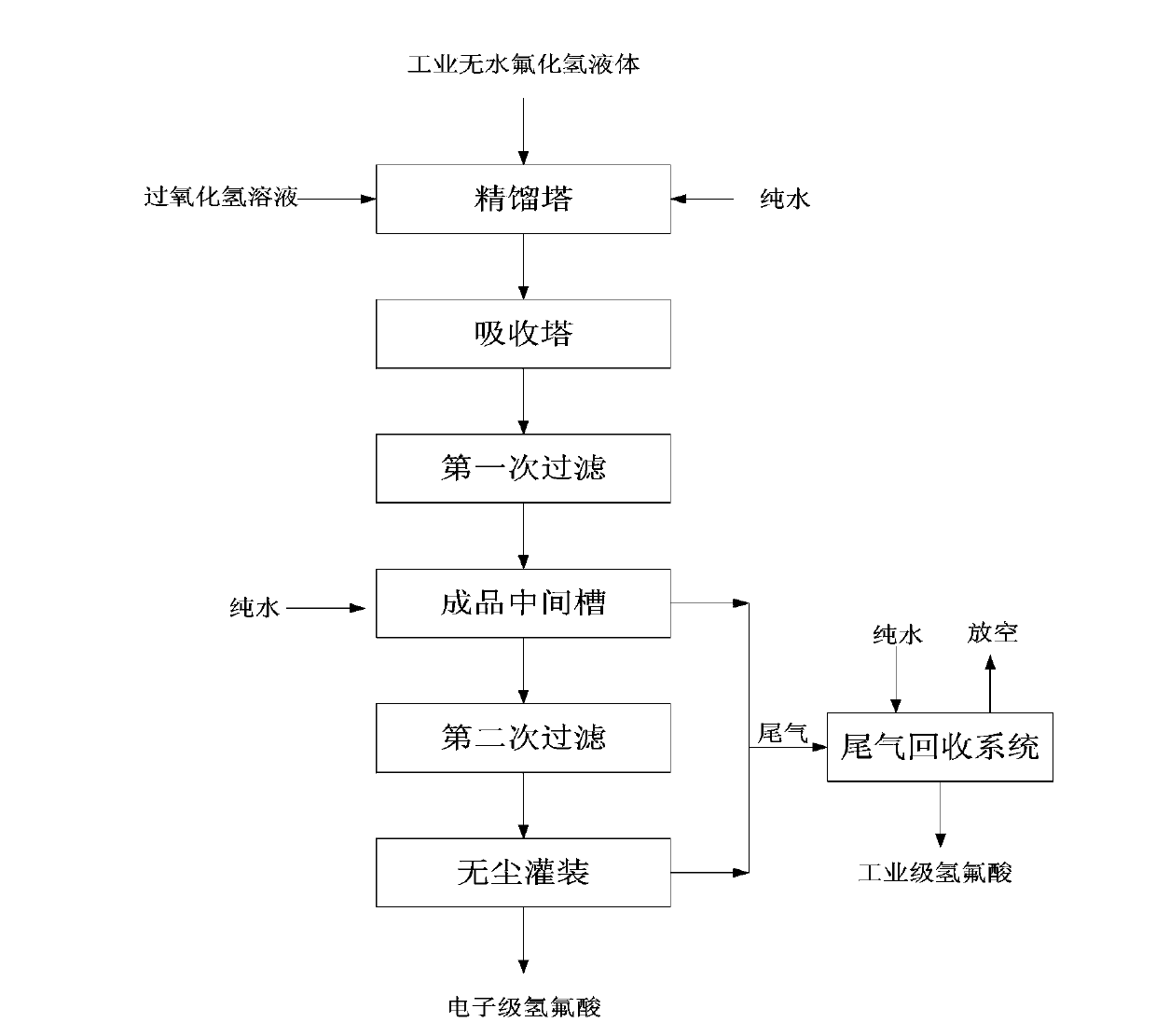

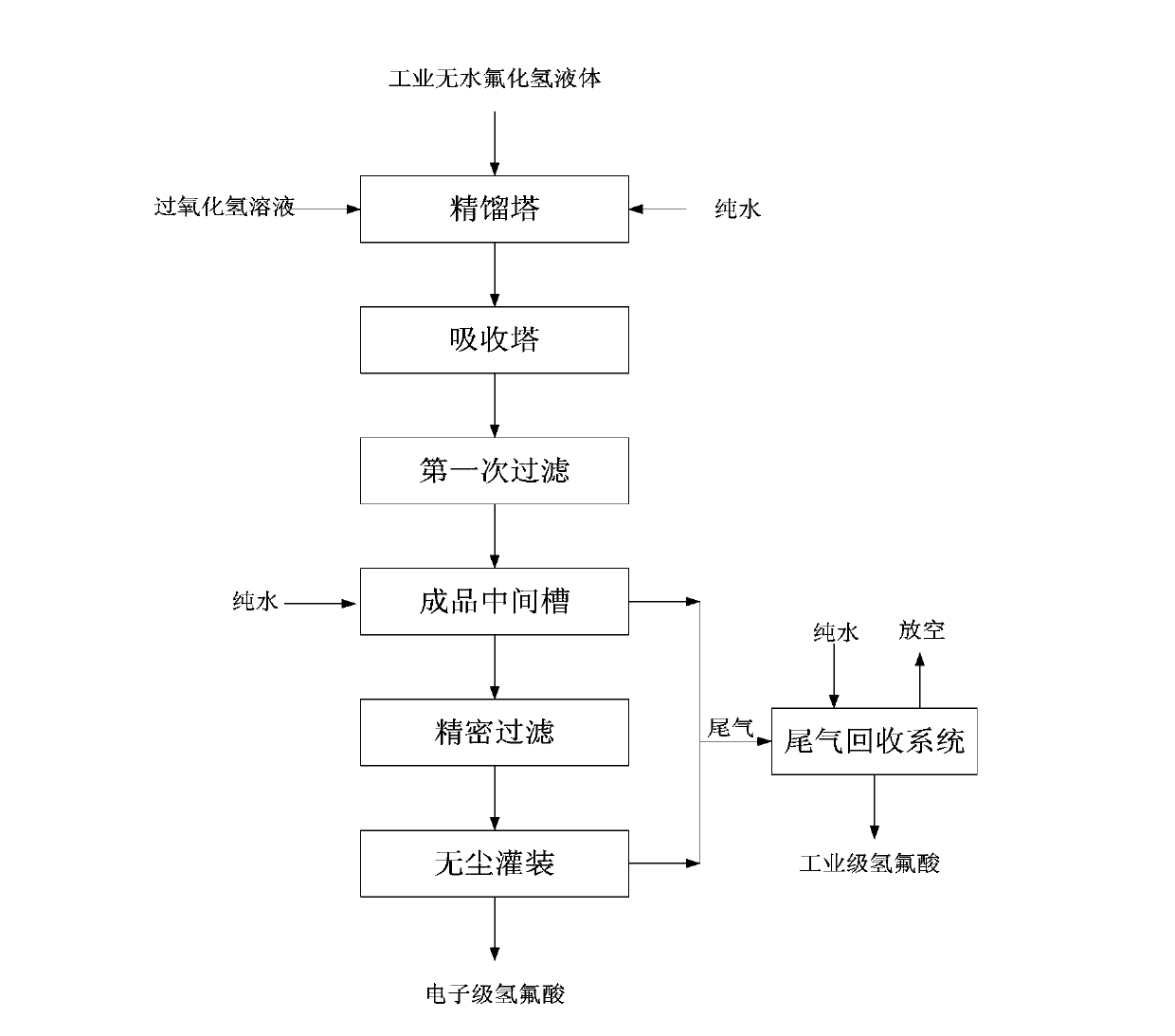

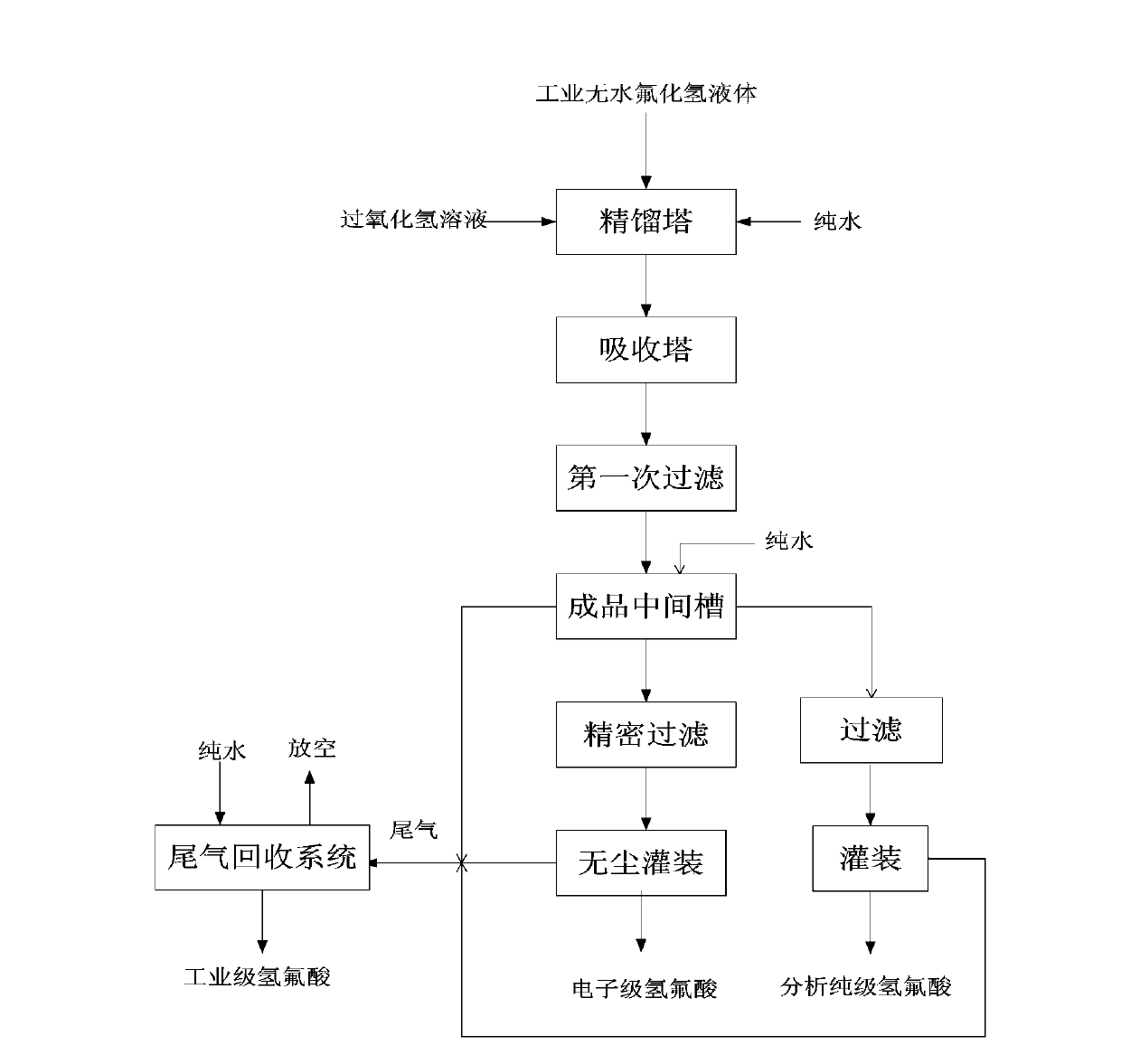

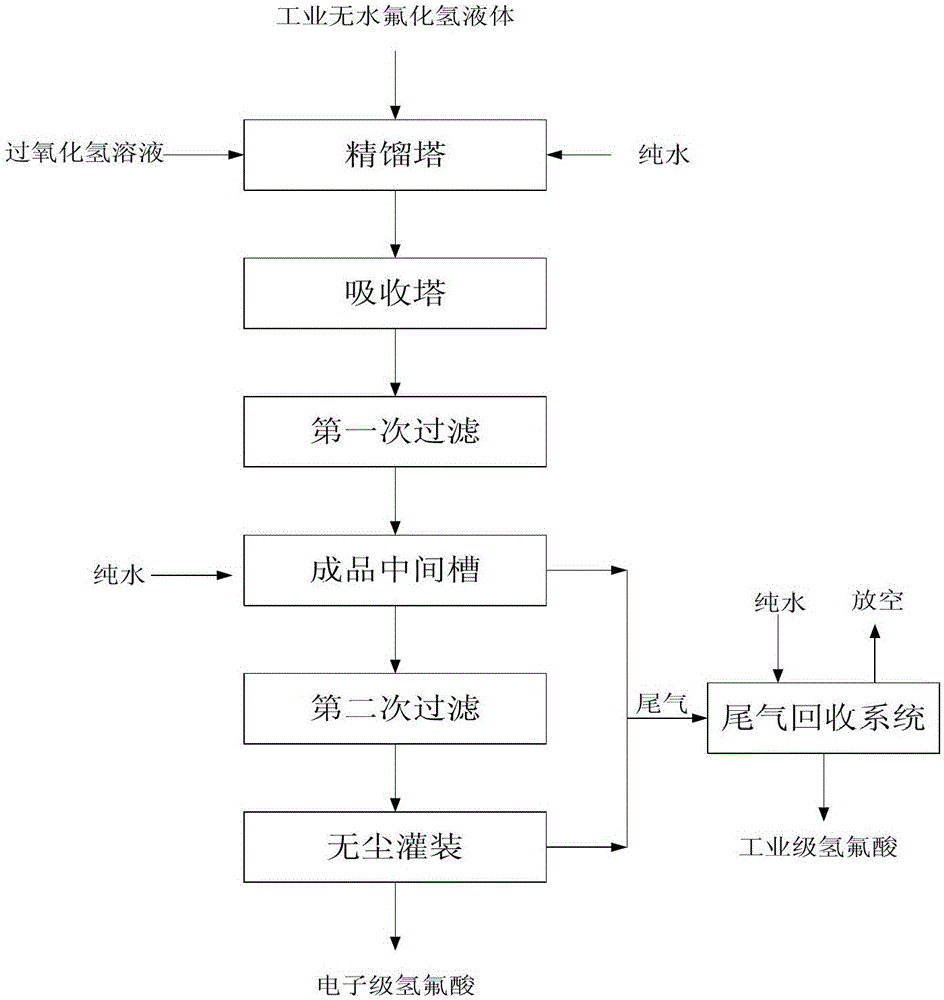

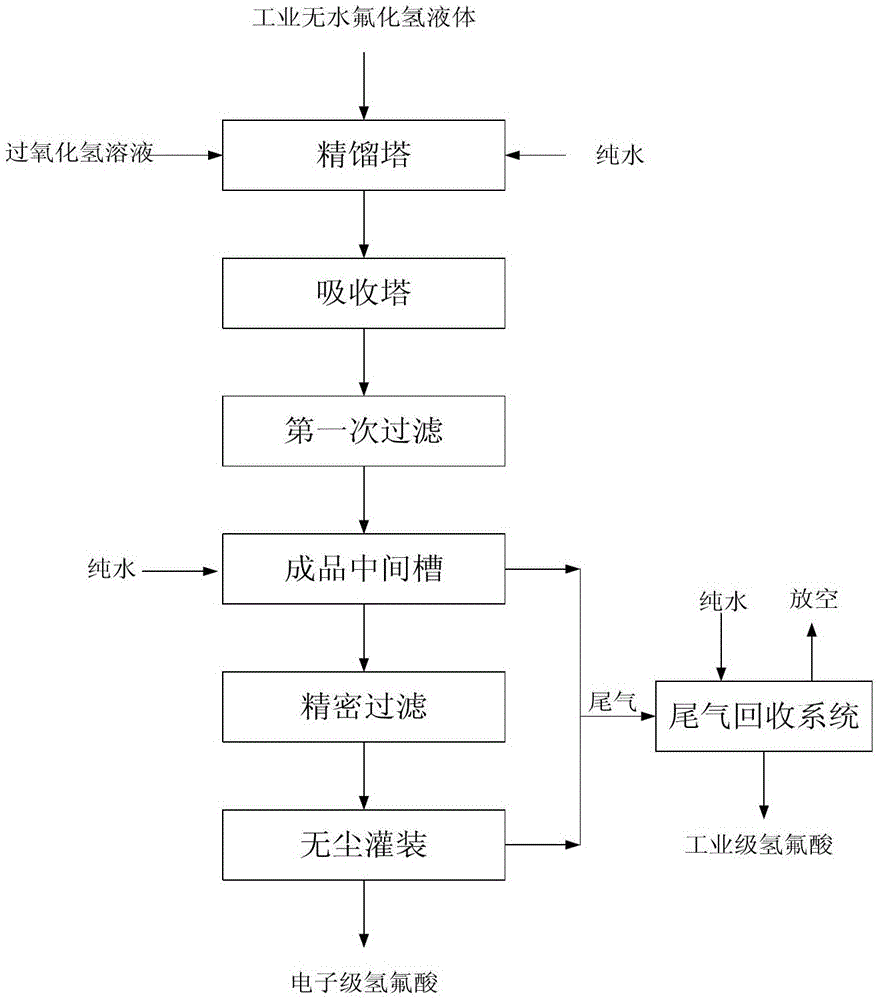

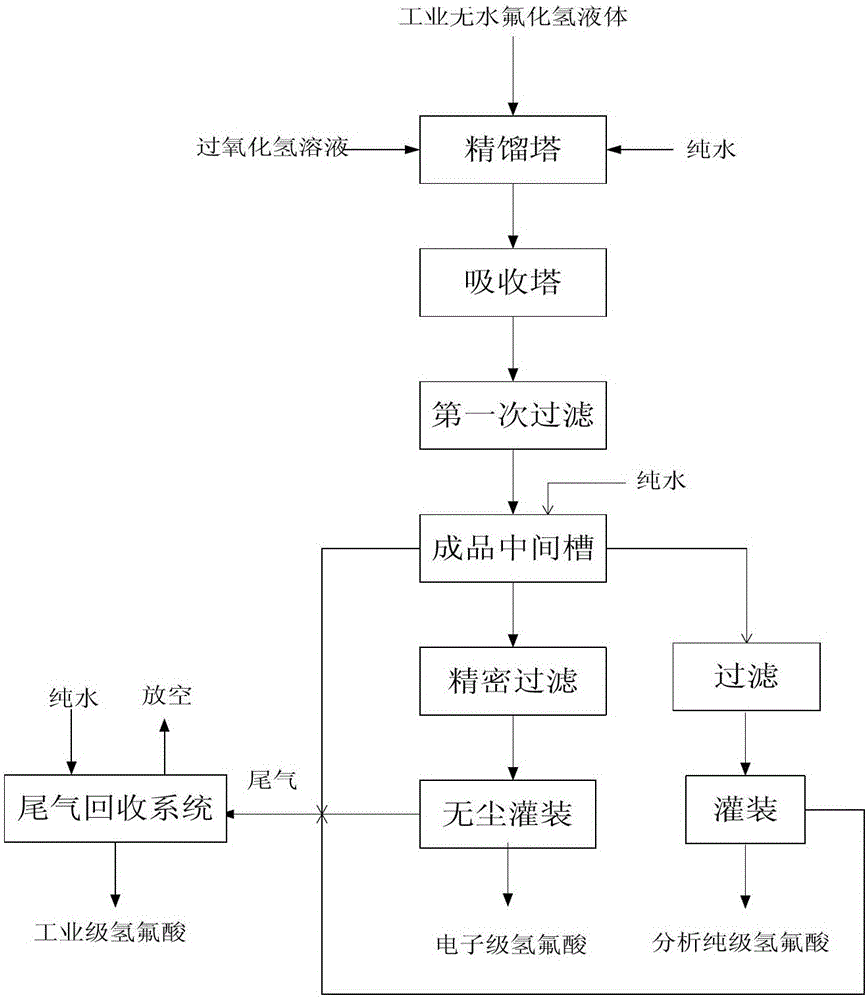

Preparation method for electron-grade hydrofluoric acid

ActiveCN103991847AReduced purification processFluorine/hydrogen-fluorideHydrogen fluorideHydrofluoric acid

A preparation method for electron-grade hydrofluoric acid comprises the following steps: introducing an industrial waterless hydrogen fluoride liquid and pure water into a rectifying tower, so as to form hydrofluoric acid with a first concentration; then adding a hydrogen peroxide solution for obtaining arsenic and silicon impurities in hydrofluoric acid, and then performing rectification; condensing the hydrogen fluoride gas obtained through rectification to form a hydrofluoric acid liquid, performing first filtration, and performing absorbing by utilizing pure water to form hydrofluoric acid with a second concentration, and performing second filtration, so as to obtain the electron-grade hydrofluoric acid product; and absorbing tail gas with pure water, so as to prepare industrial-grade hydrofluoric acid. The preparation technology is simple, and no extra impurities are introduced; the prepared electron-grade hydrofluoric acid reaches international standard SEMI-C7 standard of semiconductor equipment and materials; the yield is high and the cost is low; and by employing one production process, the electron-grade hydrofluoric acid and analytically-pure-grade hydrofluoric acid can be both prepared.

Owner:FUJIAN YONGJING TECH CO LTD

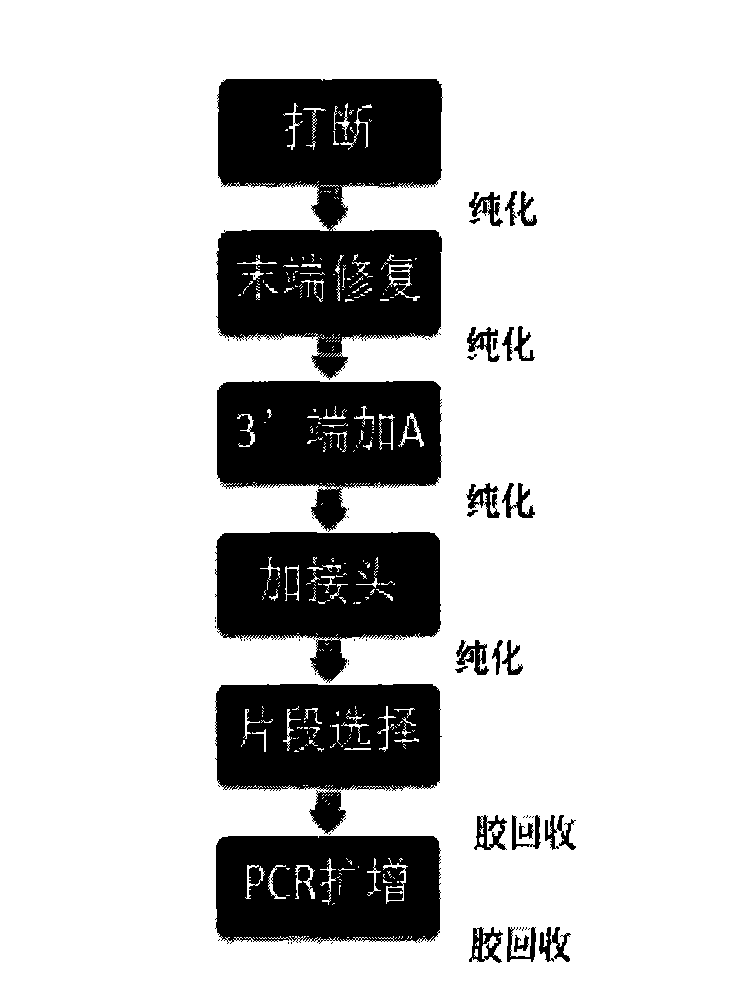

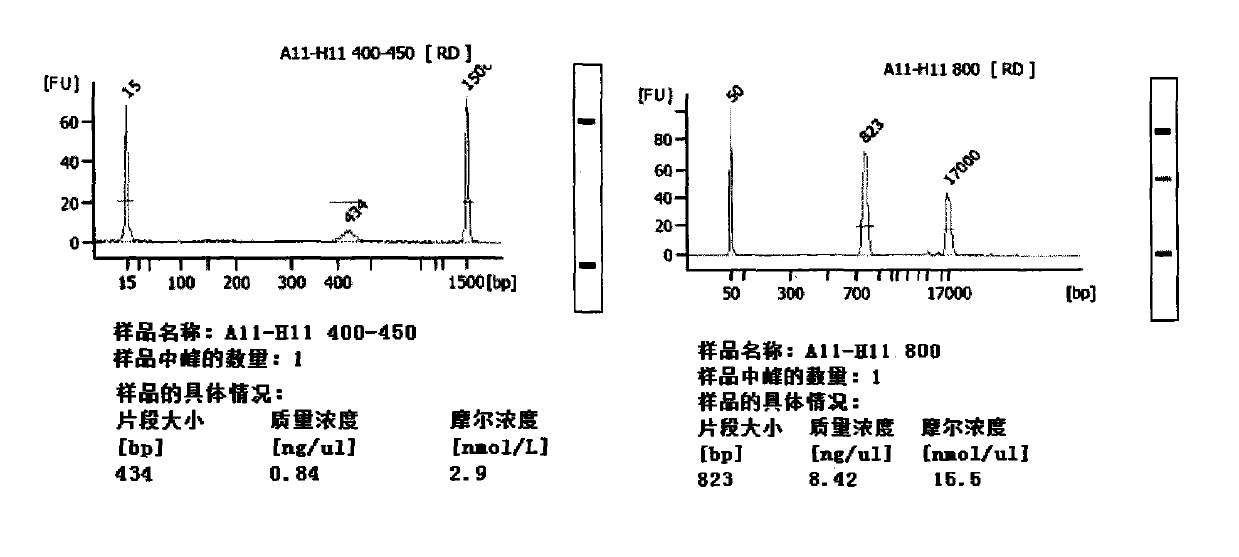

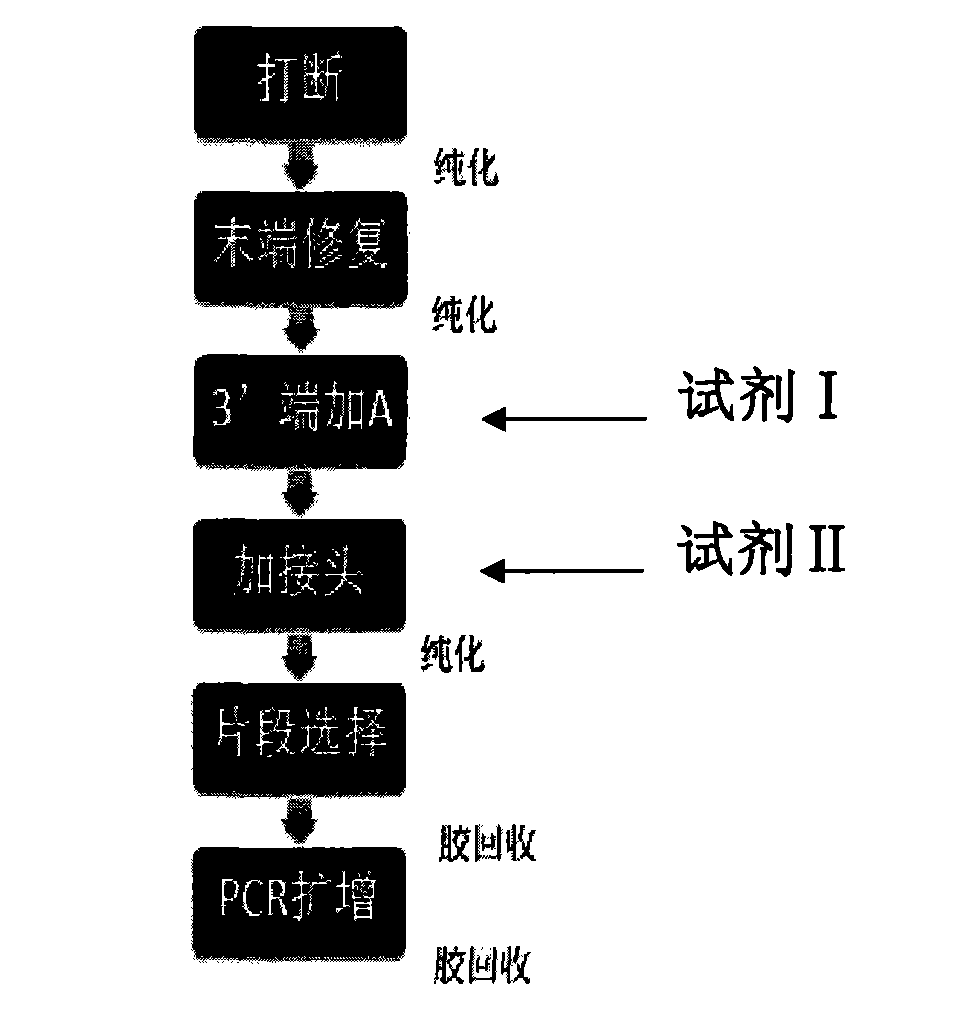

Novel library construction method based on illumina sequencing platform

ActiveCN102560688AReduced purification processShorten experiment timeMicrobiological testing/measurementLibrary creationSmall fragmentDNA

The invention provides a novel library construction method based on an illumina sequencing platform, and in particular provides a small-fragment DNA library construction method. Aiming at the defects of the small-fragment DNA library construction of the existing illumina sequencing platform, the purification steps can be reduced, the loss and waste of a library are reduced, the cost is lowered, and the working efficiency is improved.

Owner:WUXI QINGLAN BIOLOGICAL SCI & TECH

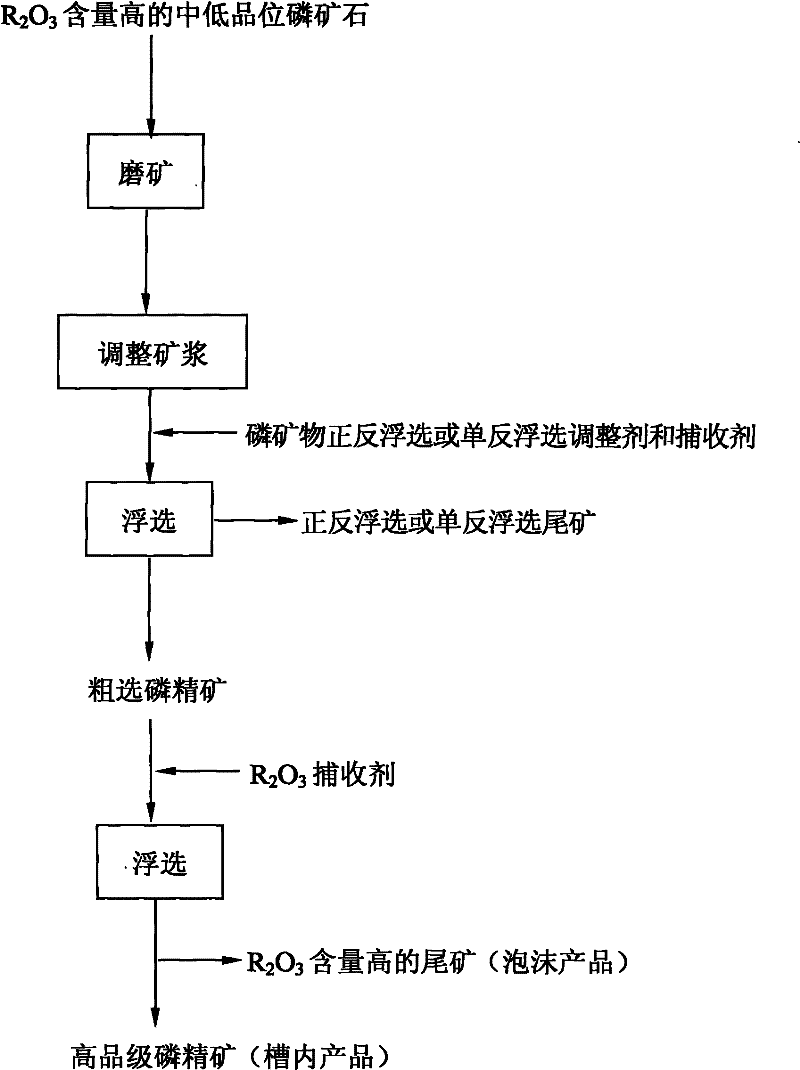

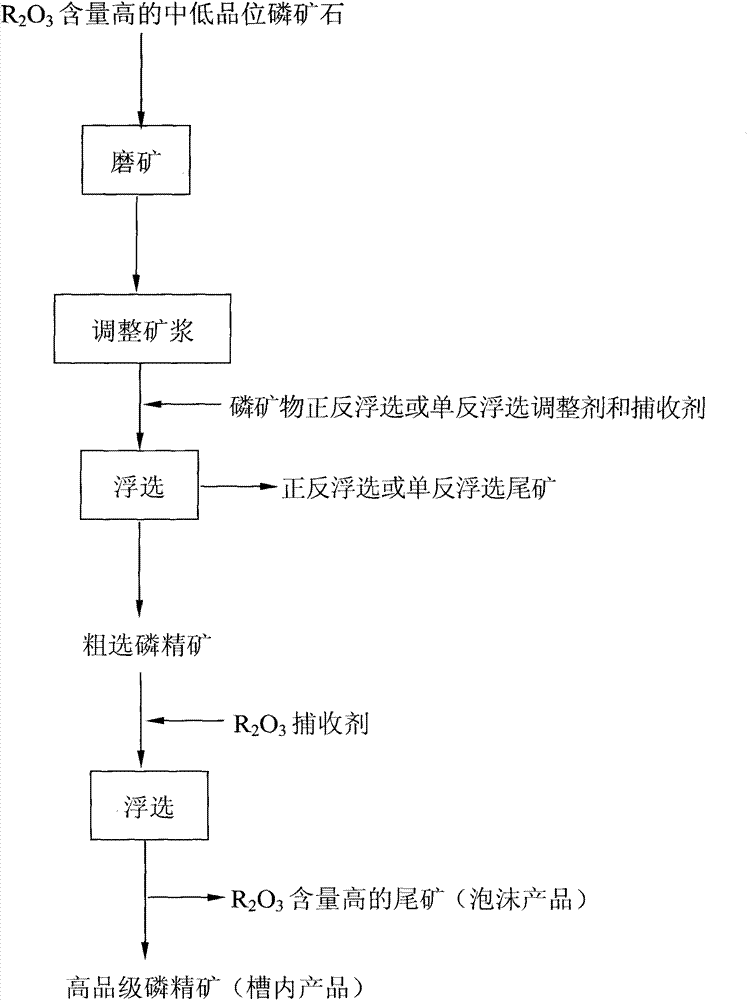

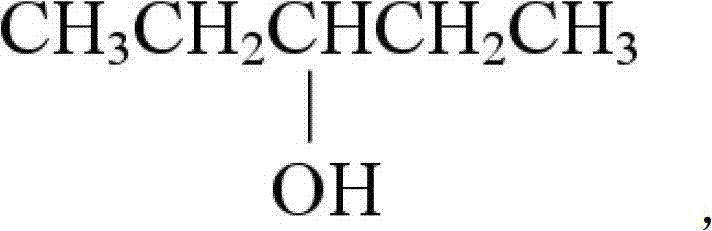

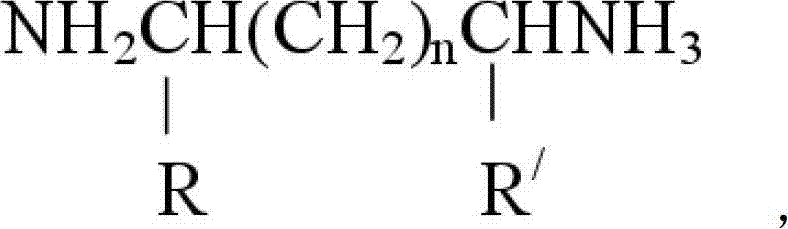

Oredressing method for removing sesquioxide of iron and aluminum

The invention relates to an oredressing method for pertinently reducing content of sesquioxide of iron and aluminum (R2O3) in the collophanite floatation process in advance. The process comprises the following steps of: (1) levigating raw collophanite until grains with the grain size of 0.038mm are more than or equal to 76 weight percent, and controlling the pulp mixing concentration to be 25-40 weight percent; (2) introducing ore pulp into a mineralizing agitation tank of a floatation machine, adding an agent for floating conventional mid-low grade collophanite for pneumatic flotation, ensuring that a spindle speed of the floatation machine is 1,800-2,100r / min, the floating aeration quantity is 0.05-0.10m<3> / h and the floating scraper speed is 20-30r / min, and obtaining phosphate concentrate subjected to rough concentration; and (3) controlling the pH of the phosphate concentrate subjected to rough concentration to be 4.5-5.5, adding a collector for removing R2O3, performing pneumatic flotation for 4 to 8 minutes, removing an impurity of R2O3 from foam, and obtaining base flow, namely a high grade phosphate concentrate product. By the method, the R2O3 content in the concentrate can be obviously reduced, the quality of the phosphate concentrate is improved, and production processes, flows and cost during purification in the subsequent acid making process can be reduced.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

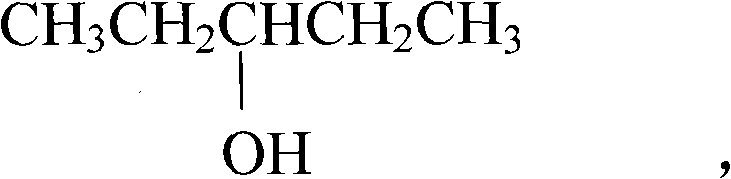

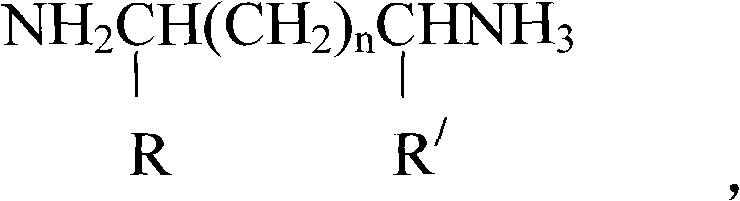

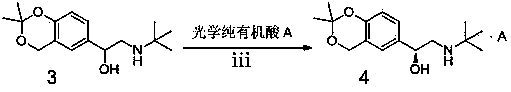

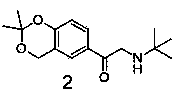

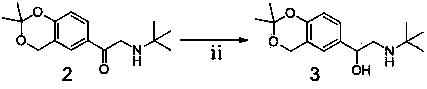

Levalbuterol intermediate and levalbuterol hydrochloride synthesis method

ActiveCN104557572ASimplified post-processing stepsImprove protectionOrganic compound preparationAmino-hyroxy compound preparationSynthesis methodsStructural formula

The invention provides a levalbuterol intermediate and a levalbuterol hydrochloride synthesis method, and relates to a levalbuterol intermediate and a method for preparing levalbuterol hydrochloride from the intermediate. The method comprises steps as follows: 2-halogenate-1-(2,2-dimelthyl-4-hydrogen-benzo [d][1,3] dioxane)-butanone and organic amine have a Hoffman alkylation reaction to prepare a compound in the formula 2, the structural formula of the compound is shown in the specification, and the compound in the formula 2 is subjected to a reduction reaction, optically pure organic acid resolution and deprotection by hydrochloric acid to obtain levalbuterol hydrochloride. The method does not need processes of protection or deprotection and the like of hydroxyl groups on a benzene ring, protection, deprotection and purification processes are reduced, the synthesis route is short, operation is simple, meanwhile, borane-thioether does not need to be used as a reduction agent, and safety and environmental protection are realized.

Owner:SHANGHAI DINGYA PHARM CHEM CO LTD

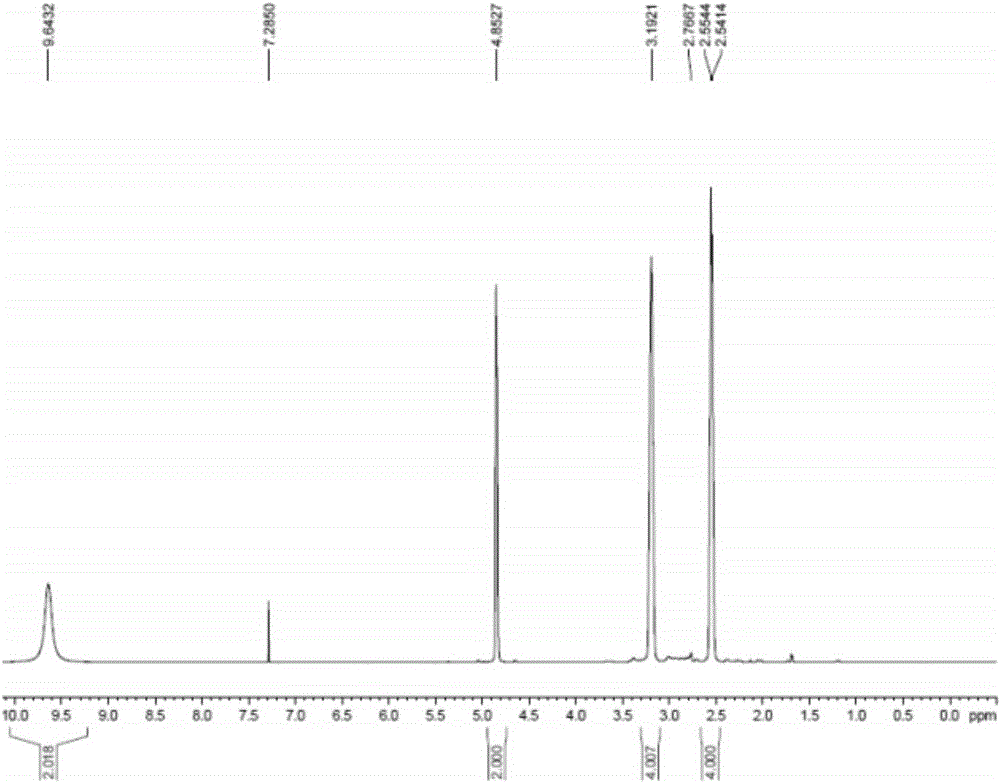

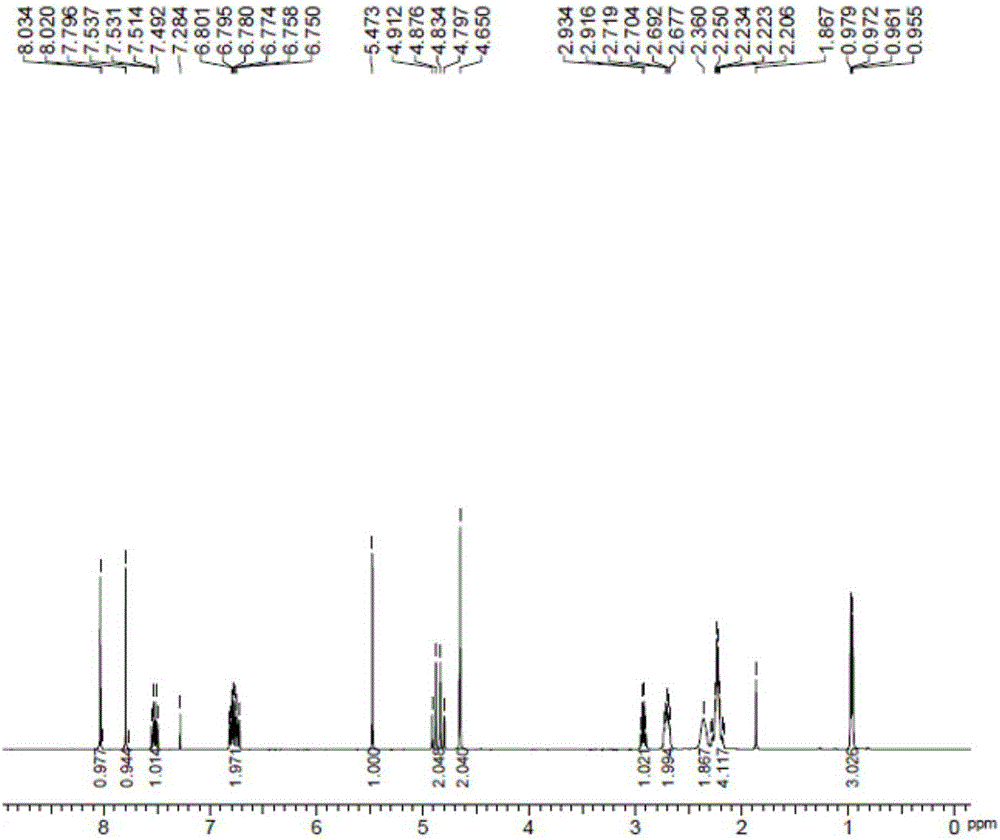

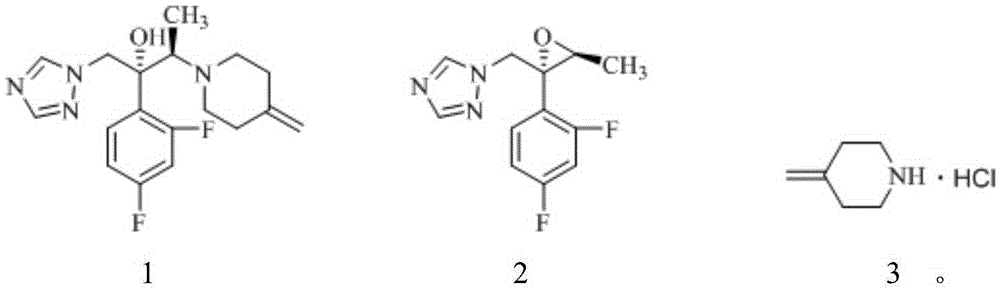

Method for preparation of Efinaconazole

The invention provides a method for preparation of Efinaconazole. The method comprises the following step: in the presence of iodide or its hydrate, in a reaction solvent and alkali, a compound as shown in the formula 2 is contacted with a compound as shown in the formula 3, so as to obtain a compound as shown in the formula 1. By the method, Efinaconazole can be effectively prepared. In addition, the method has advantages of few steps, simple synthesis process and mild reaction conditions. Meanwhile, excessive use of expensive amine can be avoided; yield and purity of the product are high; there are few by-products; production cost is low; corrosion to the reaction vessel during the production process is little; and industrial "three wastes (waste gas, waste water and industrial residue)" are easy to treat. The method is safe and environment-friendly, and is beneficial to industrial production of Efinaconazole.

Owner:WATERSTONE PHARMA WUHAN

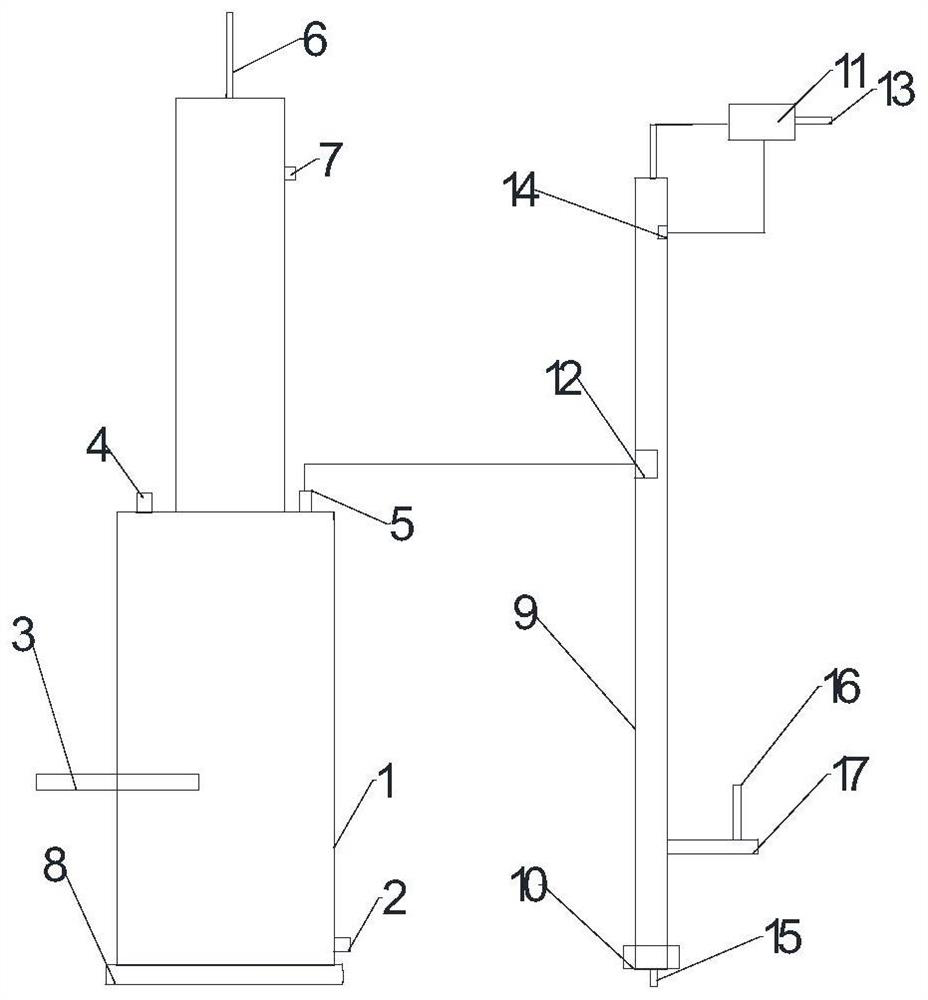

Method and device for removing metal impurities in polycrystalline silicon by electron beam overheat smelting

InactiveCN104556050AReduce the number of timesReduced purification processSilicon compoundsDirectional solidificationPolycrystalline silicon

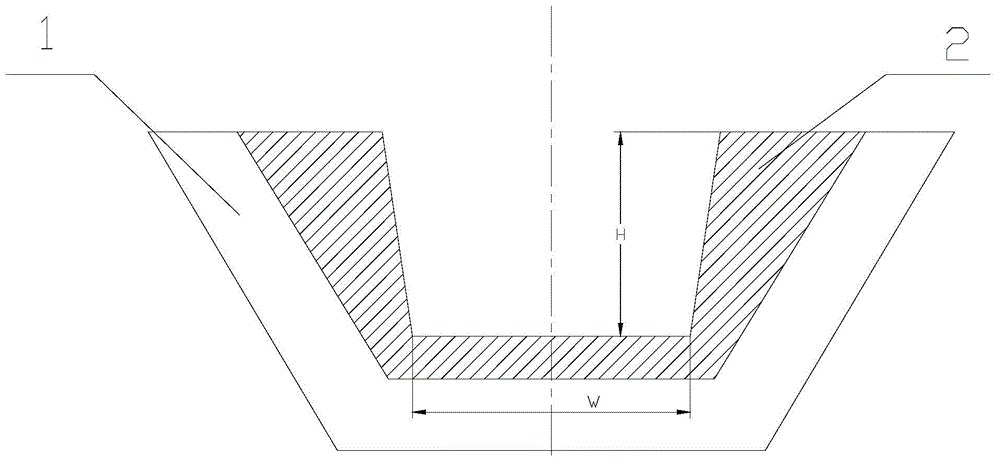

The invention discloses a method and device for removing metal impurities in polycrystalline silicon by electron beam overheat smelting, and belongs to the field of metallurgy. The device comprises a water-cooled copper smelting crucible, wherein an inclined sidewall design is adopted for the water-cooled copper smelting crucible; the inner sidewall of the water-cooled copper smelting crucible forms an included angle of 105 to 120 degrees with the bottom of the water-cooled copper smelting crucible; a graphite bushing is arranged in the water-cooled copper smelting crucible; the outer surface of the graphite bushing is attached to the inner surface of the water-cooled copper smelting crucible to form a close fit design; the bottom of the graphite bushing and the bottom of the water-cooled copper smelting crucible are horizontal, the inner surface sidewall of the graphite bushing forms an included angle of 95 to 100 degrees with the bottom of the graphite bushing. According to the device, the metal impurities are removed by overheat smelting, so that the number of times of subsequent directional solidification and ingot casting can be reduced, a purification process can be eliminated, and the production cost can be reduced; by electron beam overheat smelting for polycrystalline silicon purification, post directional solidification can be reduced by one time or more, and the metal impurities in the polycrystalline silicon can be reduced by 30 percent or more.

Owner:DALIAN UNIV OF TECH

Method for producing rubber vulcanization accelerator CZ (N-Cyclohexyl-Benzothiazole Sulfenamide,) by two-drop method

InactiveCN106632141AReduce dosageReduce M purification processOrganic chemistryFiltrationDistillation

The invention discloses a method for producing a rubber vulcanization accelerator CZ (N-Cyclohexyl-Benzothiazole Sulfenamide) by a two-drop method. The method comprises the following steps of, according to a volume ratio, which is 2 to 1, of methanol to cyclohexylamine, adding the mixed liquid of the methanol and the cyclohexylamine into an oxidation device, in an agitation condition, adding a fused coarse M at a temperature of 170 to 180 DEG C, making the M and the cyclohexylamine generate an M-cyclohexylamine salt, afterwards, dropwise adding a hydrogen peroxide solution into a solution, then, after 80 to 120 minutes, replacing the hydrogen peroxide solution with sodium hypochlorite, dropwise adding the sodium hypochlorite to find an endpoint, carrying out a judgment by using starch-potassium iodide test paper, when the test paper becomes black, stopping dropwise adding the sodium hypochlorite, and starting distillation to recover the methanol; carrying out suction filtration, water scrubbing, filtration and drying on a product, so as to obtain the rubber vulcanization accelerator CZ. The yield of the accelerator CZ reaches 99 percent or above; the use level of the cyclohexylamine in the method is low; an M purification process as well as a pulping procedure and a cyclohexylamine distillation procedure in an old process is reduced; the link of producing the CZ is reduced; produced wastewater is decreased by 70 percent or above compared with that in the old process; the method is easy for industrialized production.

Owner:KEMAI CHEM

Oredressing method for removing sesquioxide of iron and aluminum

The invention relates to an oredressing method for pertinently reducing content of sesquioxide of iron and aluminum (R2O3) in the collophanite floatation process in advance. The process comprises the following steps of: (1) levigating raw collophanite until grains with the grain size of 0.038mm are more than or equal to 76 weight percent, and controlling the pulp mixing concentration to be 25-40 weight percent; (2) introducing ore pulp into a mineralizing agitation tank of a floatation machine, adding an agent for floating conventional mid-low grade collophanite for pneumatic flotation, ensuring that a spindle speed of the floatation machine is 1,800-2,100r / min, the floating aeration quantity is 0.05-0.10m<3> / h and the floating scraper speed is 20-30r / min, and obtaining phosphate concentrate subjected to rough concentration; and (3) controlling the pH of the phosphate concentrate subjected to rough concentration to be 4.5-5.5, adding a collector for removing R2O3, performing pneumaticflotation for 4 to 8 minutes, removing an impurity of R2O3 from foam, and obtaining base flow, namely a high grade phosphate concentrate product. By the method, the R2O3 content in the concentrate can be obviously reduced, the quality of the phosphate concentrate is improved, and production processes, flows and cost during purification in the subsequent acid making process can be reduced.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

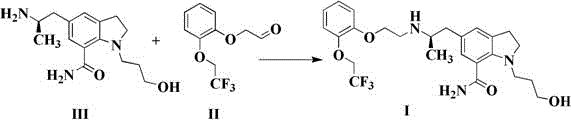

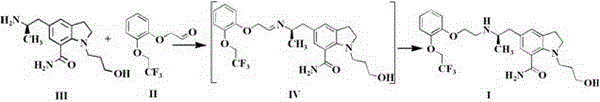

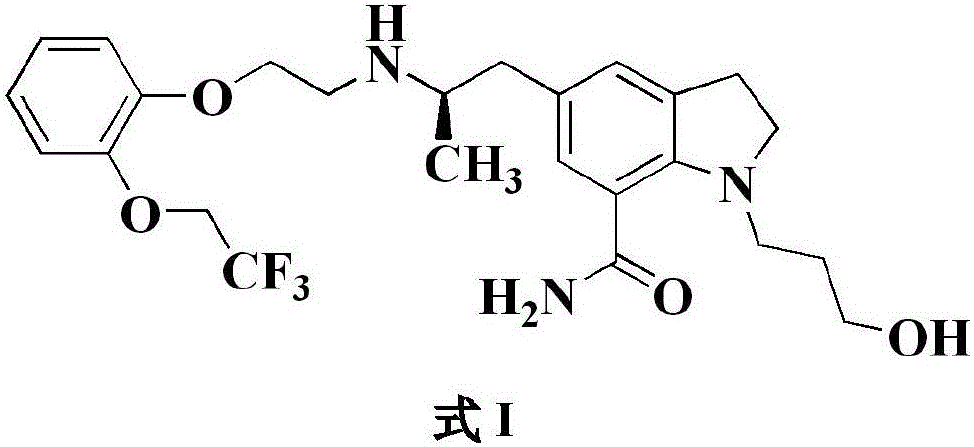

New preparation method of silodosin compound

ActiveCN106083689AReduced purification processReduce contentOrganic chemistryControllabilityImpurity

The invention belongs to the technical field of medical chemistry, and concretely relates to a new preparation method of silodosin. A compound III reacts with a compound II to generate an imine intermediate IV, and the imine intermediate IV is reduced to obtain silodosin, so impurity P1 is effectively removed, the content of the impurity P1 is reduced, and the product quality is improved. The preparation method has the advantages of simplicity in operation, mild reaction conditions, good safety and controllability, good product purity, and suitableness for industrial production.

Owner:QILU PHARMA HAINAN +1

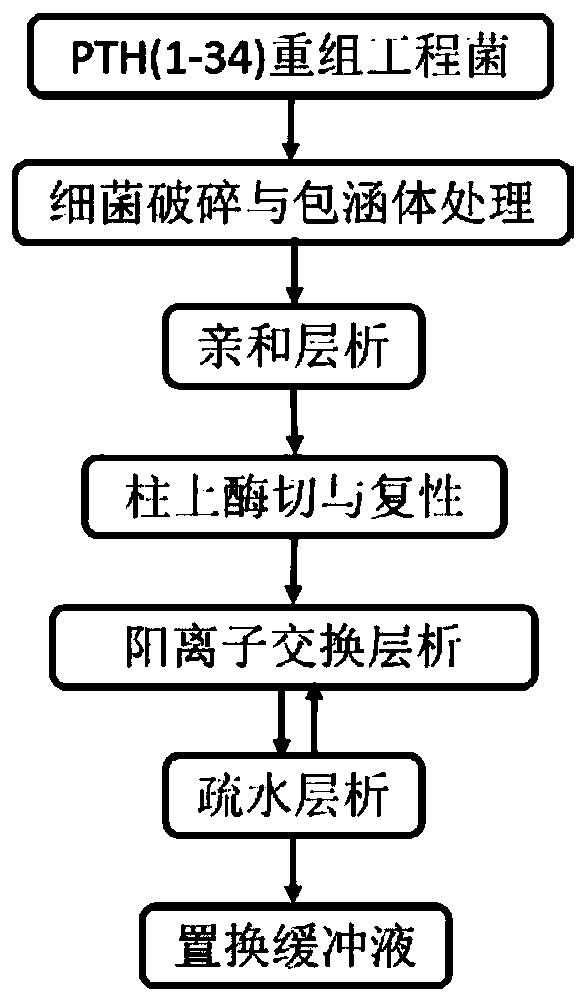

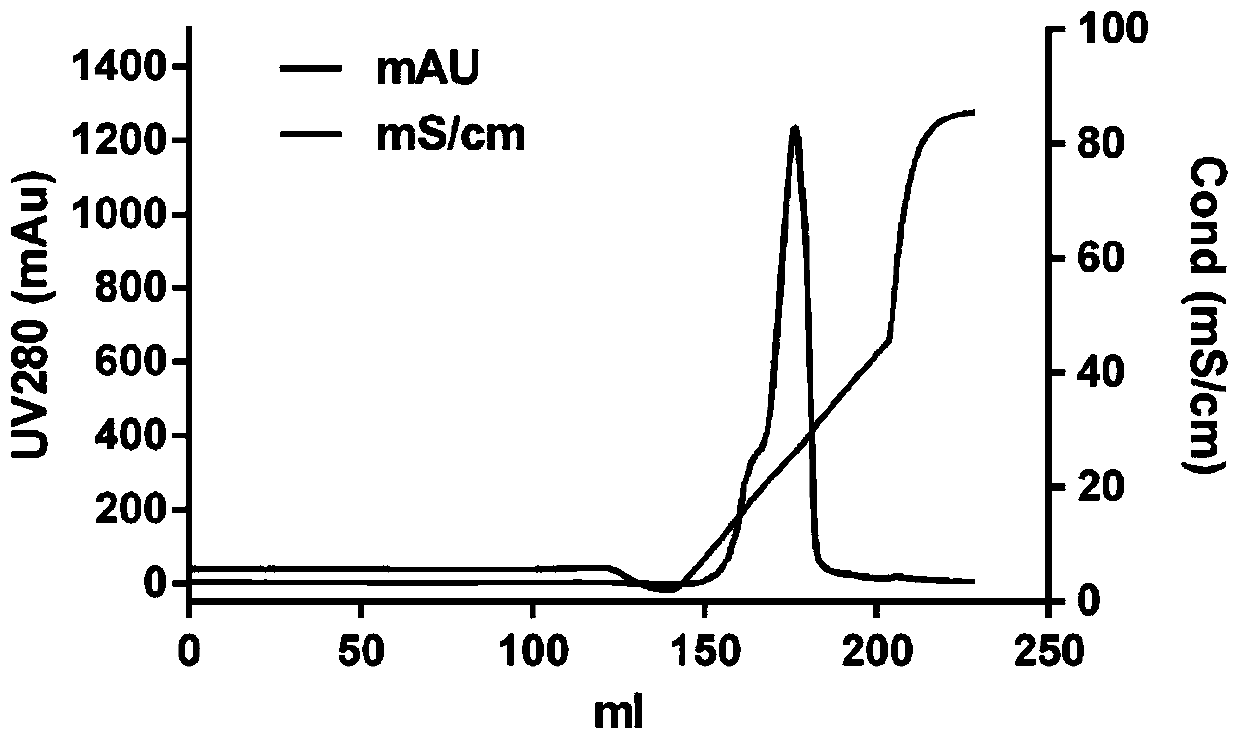

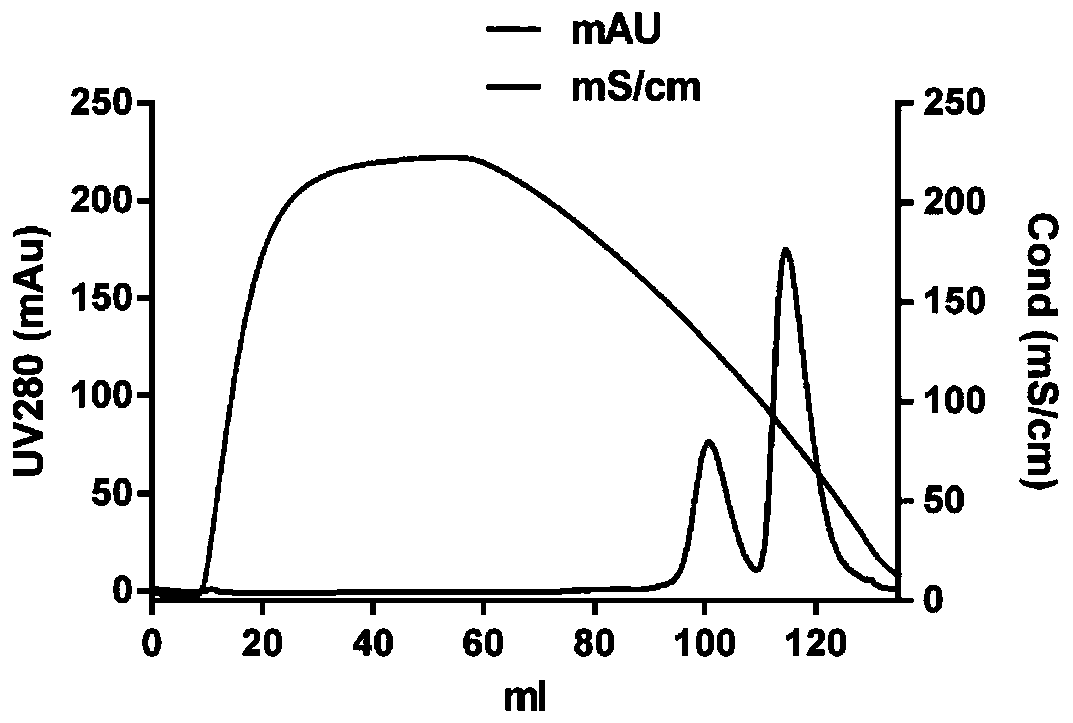

Purification method of recombinant parathyroid hormone PTH (1-34)

ActiveCN111018965AAvoid damageReduced purification processPeptide preparation methodsParathyroid hormonesEnzyme digestionInclusion bodies

The invention discloses a separation and purification method of recombinant parathyroid hormone (PTH), which comprises the following steps: 1) bacterium crushing and inclusion body treatment: carryingout high-pressure homogenization and bacterium crushing, carrying out high-speed centrifugation after bacterium crushing to collect precipitates, carrying out resuspension washing on the precipitates, and mixing and redissolving the precipitates with a redissolved solution; 2) affinity chromatography; wherein a filler is selected from one of Ni-NTA, GST Sepharose and MBP Sepharose; 3) carrying out enzyme digestion and renaturation on a column; 4) carrying out cation exchange chromatography and / or hydrophobic chromatography, and (5) desalting. According to the present invention, through the method, the PTH (1-34) polypeptide with biological activity can be efficiently extracted from an inclusion body so as to make the large-scale industrial production of the PTH (1-34) possible.

Owner:重庆艾力彼生物科技有限公司

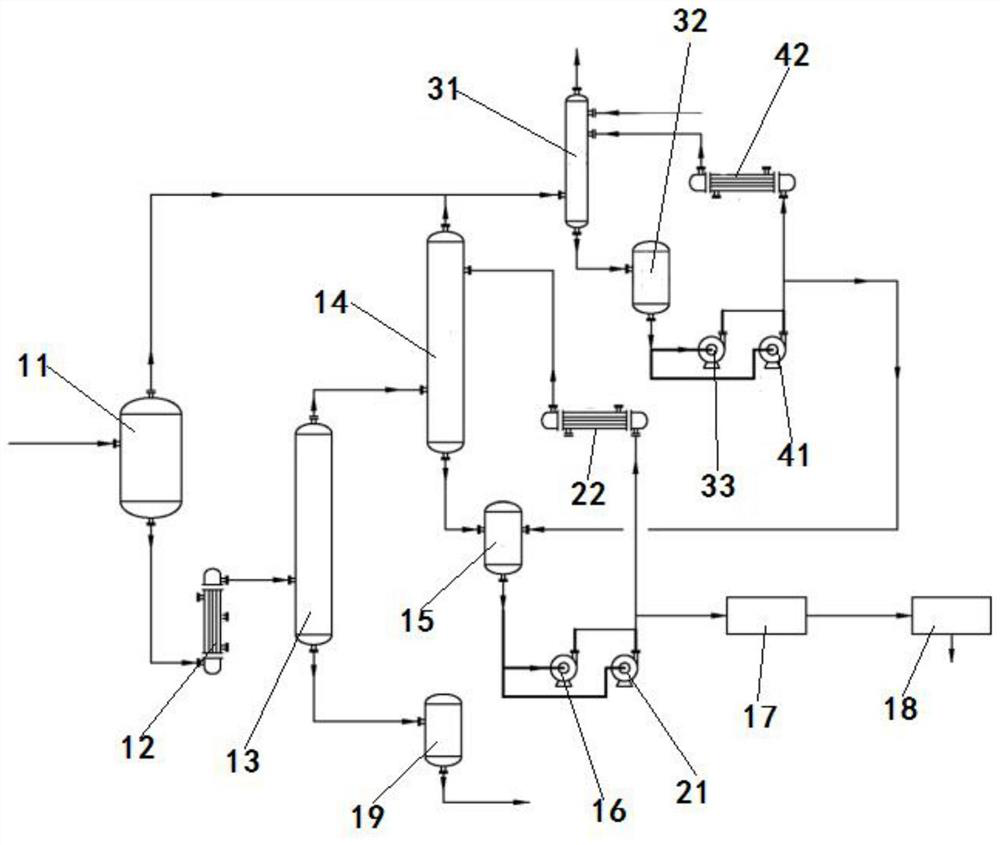

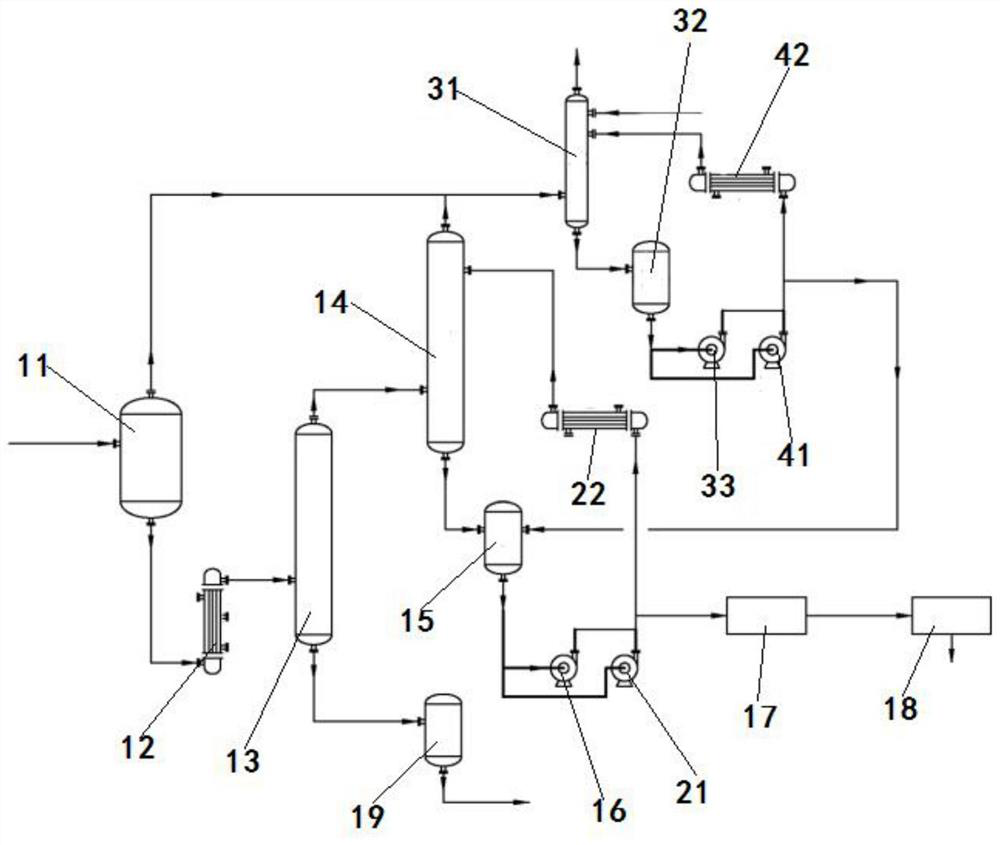

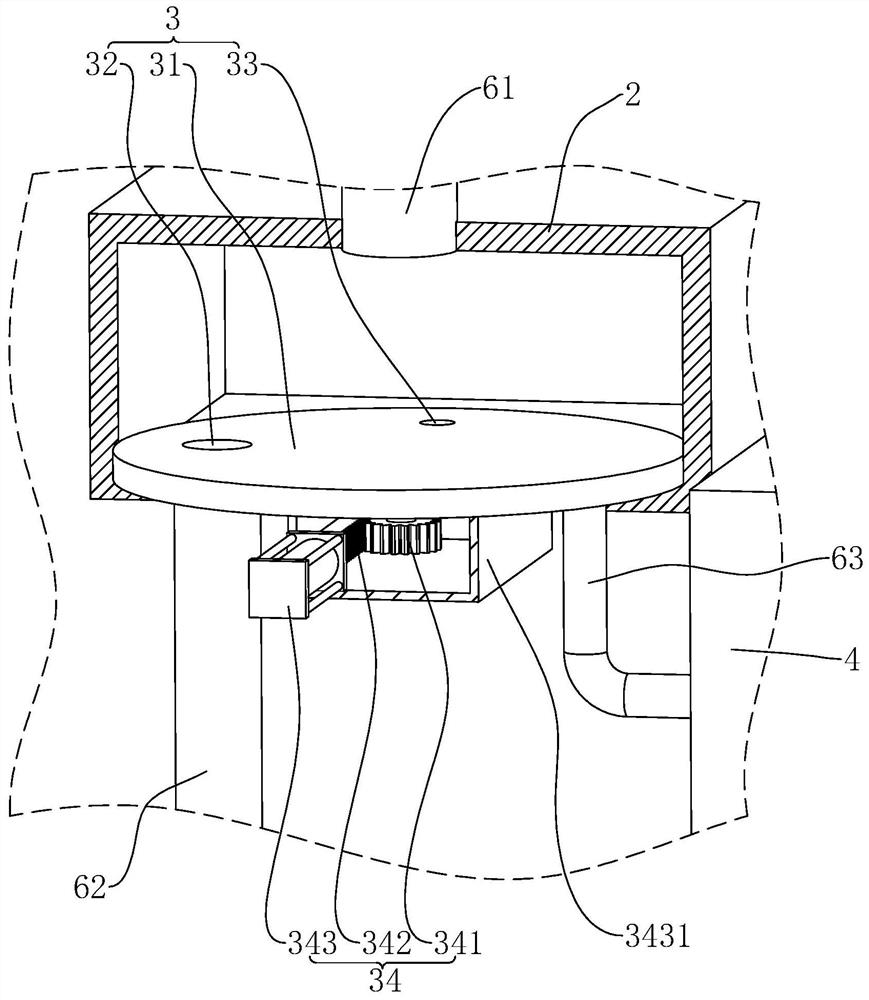

Production device and production method of electronic-grade hydrofluoric acid

ActiveCN112010263AEasy to handleAvoid pollutionGas treatmentDispersed particle separationHydrogen fluorideFluid phase

The invention discloses a production device and a production method of electronic-grade hydrofluoric acid. The production method comprises the following steps: gasifying industrial anhydrous hydrogenfluoride serving as a raw material through an evaporator, conveying the gasified anhydrous hydrogen fluoride to a purification tower, and carrying out rectifying to obtain high-purity hydrogen fluoride gas; conveying the high-purity hydrogen fluoride gas to an absorption tower, and conducting absorbing with a hydrofluoric acid liquid phase having a certain concentration to obtain a crude electronic-grade hydrofluoric acid product; and finally, carrying out ultra-pure filtration to obtain a finished electronic-grade hydrofluoric acid product. The technical problems of low yield and low purity in the prior art are solved in the invention, and the production method meets environmental protection requirements and is suitable for industrial large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing rubber vulcanization accelerator CZ

InactiveCN106699684AReduce dosageReduce M purification processOrganic chemistryVulcanizationSodium chlorate

The invention discloses a method for producing a rubber vulcanization accelerator CZ. The method comprises the following steps: adding a mixed liquid of methanol and cyclohexane in a volume ratio of 2:1 into an oxidizer, under a stirring condition, adding molten crude M of 170-180 DEG C to generate M-cyclohexylamine from crude M and cyclohexane, dropping a sodium hypochlorite solution into the solution, after 80-120 minutes, sampling and observing, judging a reaction final point by using potassium iodide-starch test paper, stopping dropping sodium chlorate when the test paper is black, and starting distillation to recycle methanol; performing suction filtration, water washing, filtration and drying, thereby obtaining a rubber vulcanization accelerator CZ product. The yield of the rubber vulcanization accelerator CZ is up to 99% or greater; by adopting the method, a small amount of cyclohexane is used, an M purification procedure and a pulping procedure and a cyclohexane distillation procedure in a conventional process can be reduced, procedures for producing CZ can be reduced, wastewater of the production can be reduced by 70% or greater when being compared with that of the conventional process, and industrial production can be easily achieved.

Owner:KEMAI CHEM

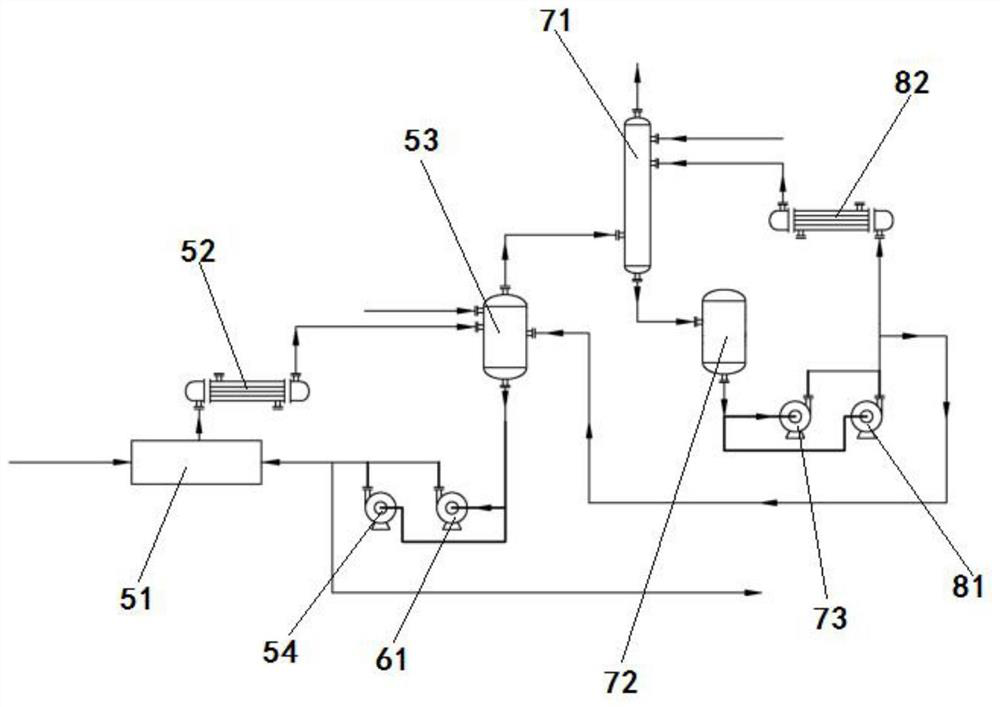

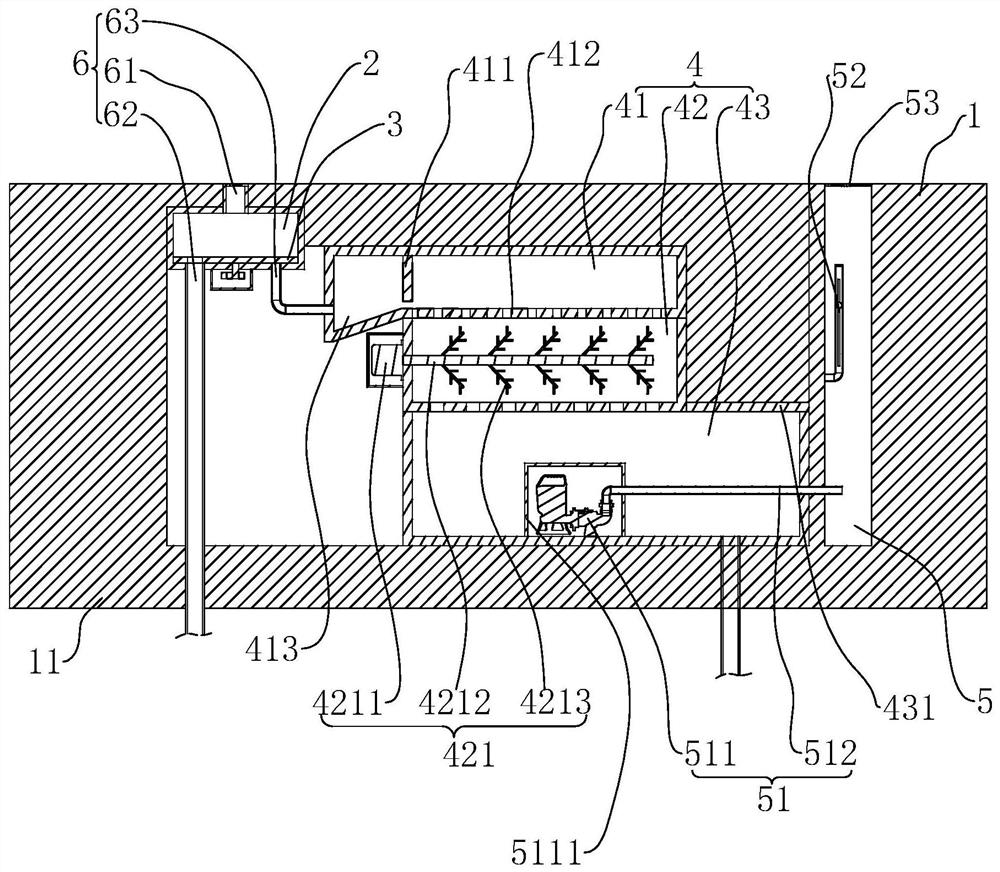

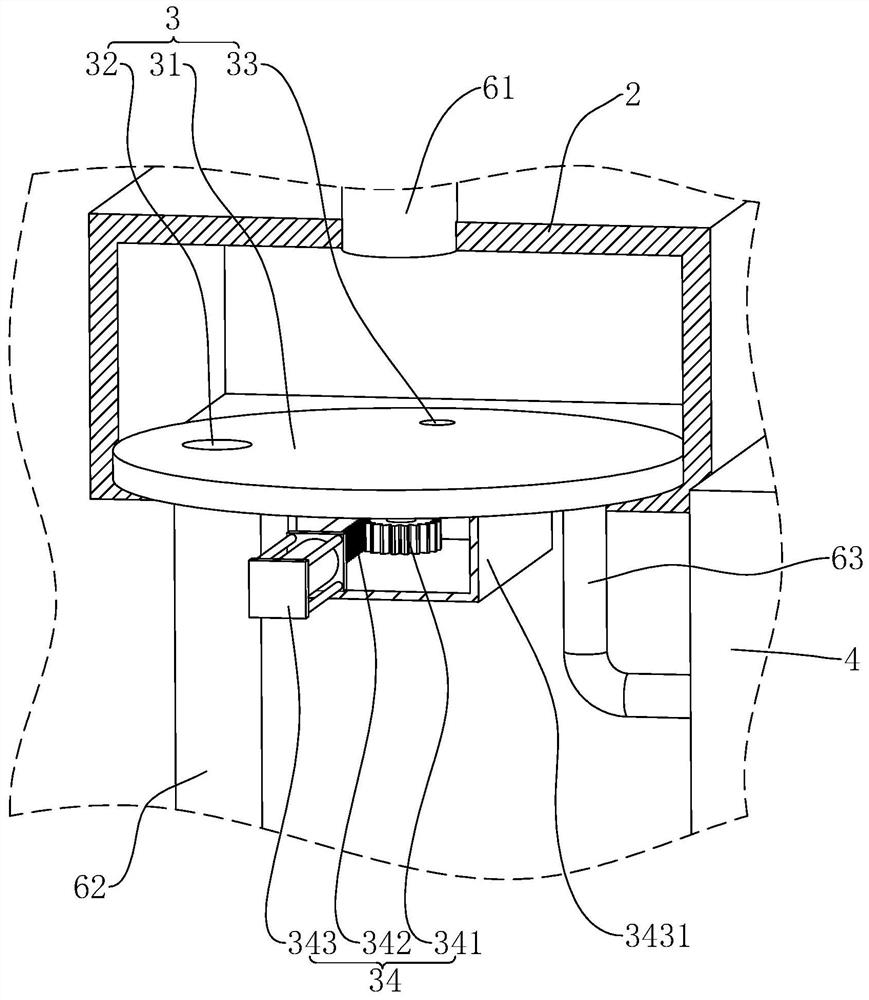

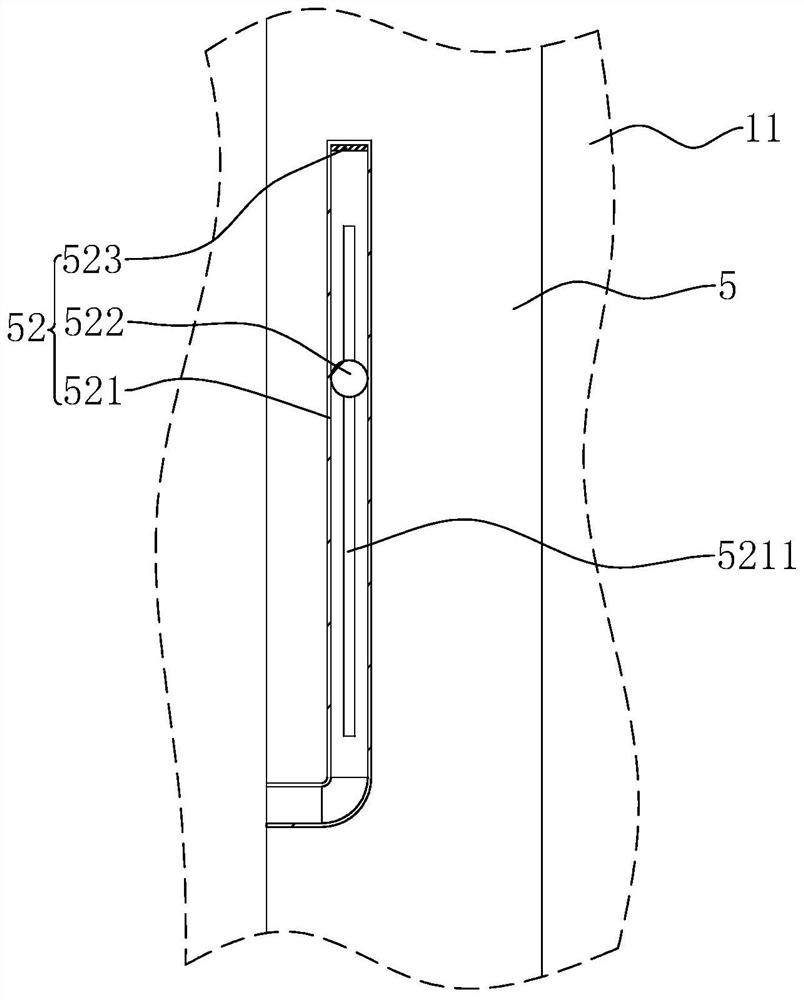

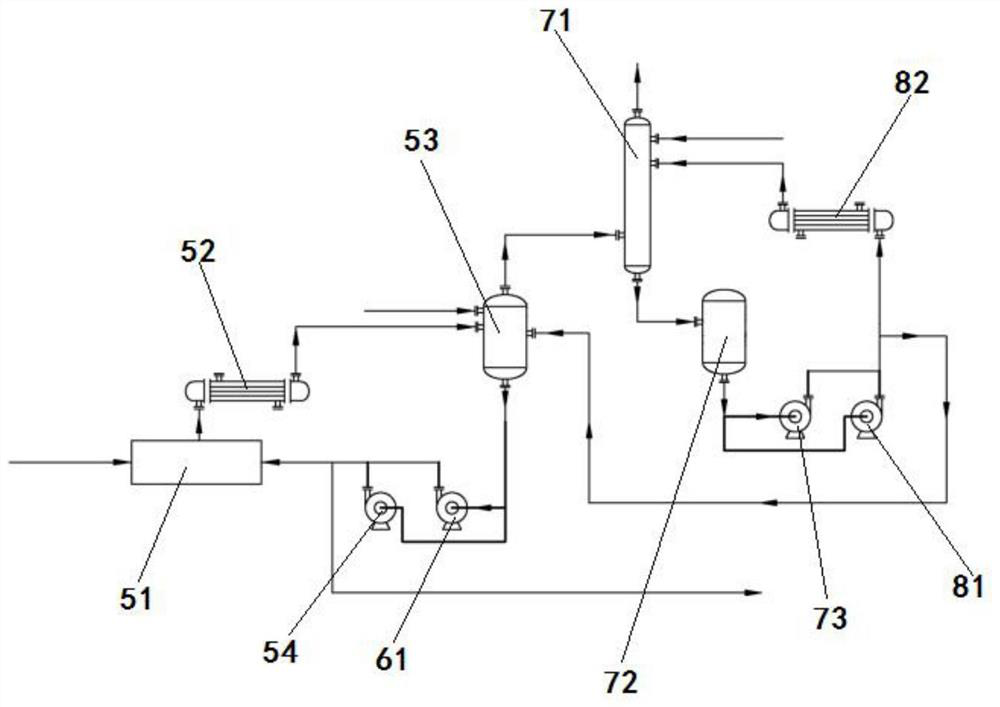

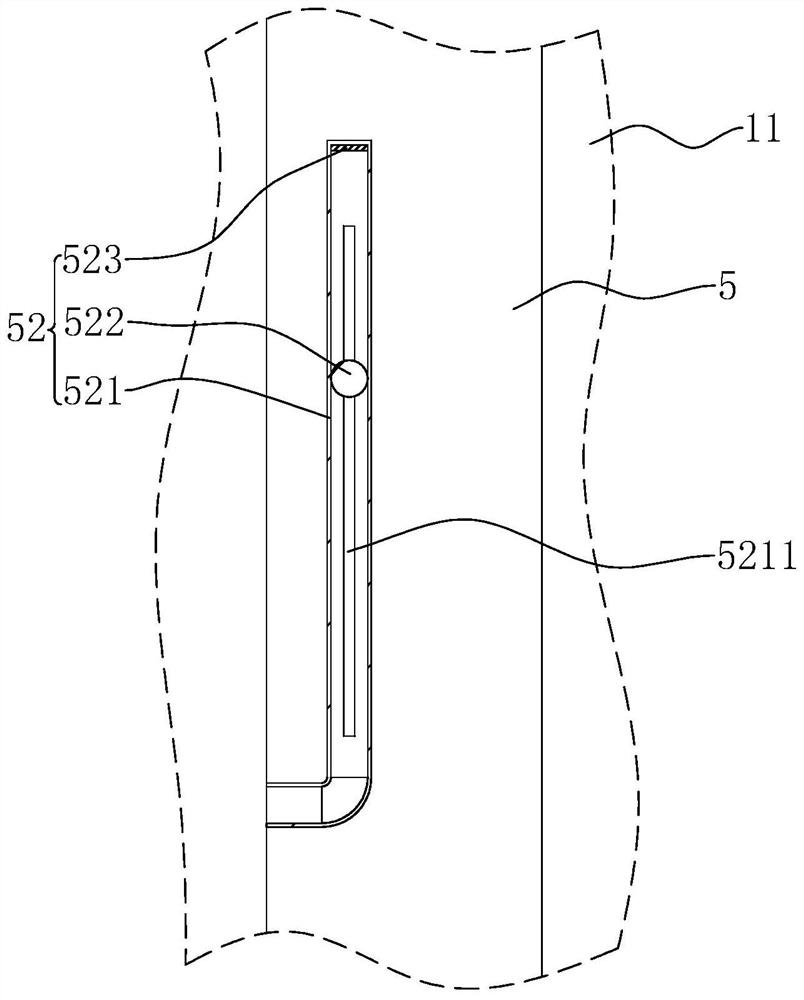

Rainwater sewage treatment system

ActiveCN112922114AReduced purification processRealize shuntFatty/oily/floating substances removal devicesSewerage structuresStormwater treatmentRoad surface

The invention relates to the field of water treatment, and particularly relates to a rainwater sewage treatment system. The rainwater sewage treatment system comprises a discharge pipe, a sewage pipe and a rainwater pipe, wherein a transfer station is arranged between the discharge pipe and the sewage pipe and the rainwater pipe; one end, far away from a road surface, of the discharge pipe is fixedly connected and communicates with the transfer station; one end of the sewage pipe is fixedly connected and communicated with the transfer station, and the other end of the sewage pipe communicates with a sewage treatment plant; one end of the rainwater pipe is fixedly connected and communicates with the transfer station, and the other end of the rainwater pipe communicates with a river channel; the rainwater pipe and the sewage pipe are not opened and closed at the same time; and a conversion device for converting the opening and closing states of the rainwater pipe and the sewage pipe is arranged between the rainwater pipe and the sewage pipe. According to the rainwater sewage treatment system, the opening states of the rainwater pipe and the sewage pipe are converted, sewage and rainwater are separated, the process of purifying the rainwater by the sewage treatment plant is reduced, and the effect of reducing the power consumption waste of the sewage treatment plant is achieved.

Owner:张家港市建筑设计研究院有限责任公司

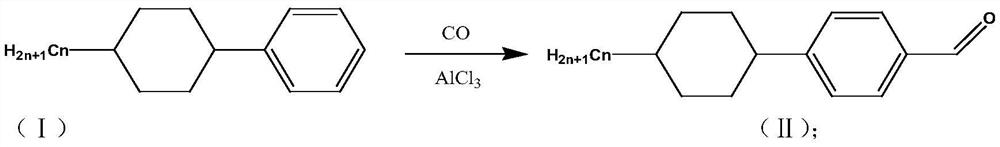

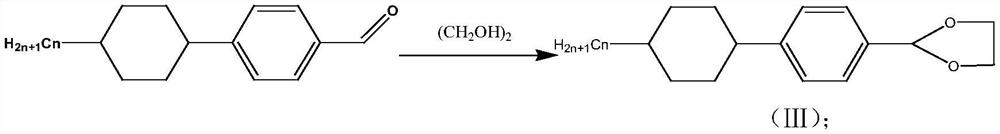

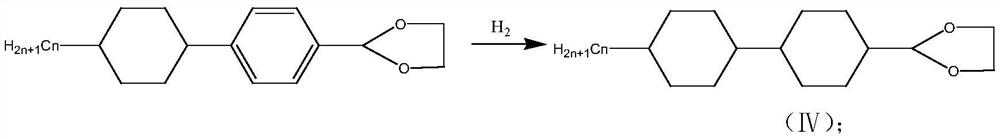

Preparation method of trans-4-(trans-4-alkylcyclohexyl) cyclohexanecarboxaldehyde

PendingCN113372208ALow costHigh yieldOrganic compound preparationOrganic chemistry methodsBenzeneCombinatorial chemistry

The invention discloses a preparation method of trans-4-(trans-4-alkyl cyclohexyl) cyclohexanecarboxaldehyde, and belongs to the technical field of liquid crystal intermediate synthesis methods. The preparation method comprises the following steps: by taking (4-alkyl cyclohexyl) benzene as an initial raw material, carrying out carbonylation reaction, aldehyde group protection hydrogenation and deprotection to obtain the trans-4-(trans-4-alkyl cyclohexyl) cyclohexanecarboxaldehyde. The preparation method of the compound is simple, and the purposes of shortening the route, simplifying post-treatment and saving working hours and cost are achieved.

Owner:山东盛华电子新材料有限公司 +2

Preparation method of electronic grade hydrofluoric acid

ActiveCN103991847BReduced purification processFluorine/hydrogen-fluorideHydrofluoric acidHydrogen fluoride

A preparation method for electron-grade hydrofluoric acid comprises the following steps: introducing an industrial waterless hydrogen fluoride liquid and pure water into a rectifying tower, so as to form hydrofluoric acid with a first concentration; then adding a hydrogen peroxide solution for obtaining arsenic and silicon impurities in hydrofluoric acid, and then performing rectification; condensing the hydrogen fluoride gas obtained through rectification to form a hydrofluoric acid liquid, performing first filtration, and performing absorbing by utilizing pure water to form hydrofluoric acid with a second concentration, and performing second filtration, so as to obtain the electron-grade hydrofluoric acid product; and absorbing tail gas with pure water, so as to prepare industrial-grade hydrofluoric acid. The preparation technology is simple, and no extra impurities are introduced; the prepared electron-grade hydrofluoric acid reaches international standard SEMI-C7 standard of semiconductor equipment and materials; the yield is high and the cost is low; and by employing one production process, the electron-grade hydrofluoric acid and analytically-pure-grade hydrofluoric acid can be both prepared.

Owner:FUJIAN YONGJING TECH CO LTD

A method for removing pigment and impurities in crude lactide

ActiveCN111100107BReduced purification processGuaranteed yieldProductsOrganic chemistryLactidePhysical chemistry

The invention relates to a method for removing pigments and impurities in crude lactide. First, the temperature and pressure in the rectification tower are adjusted, and supercritical CO 2 into the rectification tower; then the crude lactide is crushed or heated and melted, and then sent into the rectification tower for decolorization and impurity removal; the product after rectification and CO 2 Separation to obtain de-impurity and decolorized lactide. The present invention uses supercritical CO 2 The combination of extraction and rectification process can not only effectively remove the pigment and impurities in the crude lactide, but also effectively reduce the operating temperature and difficulty of the rectification process, and reduce the coking, oxidation and polymerization of lactide caused by high temperature And side reactions such as mesization, to ensure the yield and quality of lactide products, is a purification method with high operational feasibility, simple separation process, and high-efficiency removal of impurities.

Owner:CHINA PETROLEUM & CHEM CORP +1

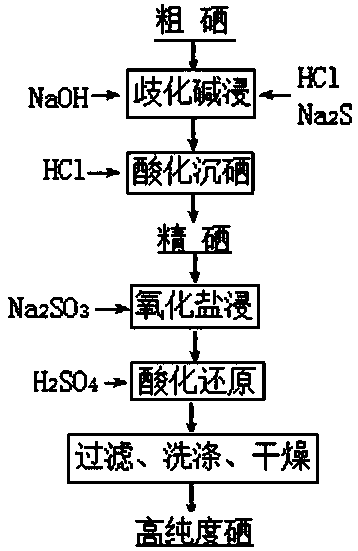

A method for preparing high-purity selenium by a crude selenium wet method

InactiveCN106853959BReduced purification processHigh recovery rateElemental selenium/telluriumSulfite saltSodium sulfite

The invention discloses a method for preparing high-purity selenium through wet-process purification of crude selenium. The method comprises the following steps: a, slowly adding crude selenium into a sodium hydroxide solution at a uniform speed, wherein a liquid-solid mass ratio is 3-5: 1, reaction time is 1.5 to 2 h and complete dissolving and leaching of crude selenium are ensured; b, adjusting a pH value to 6.5 to 7.0 by using hydrochloric acid, adding sodium sulfide, then carrying out uniform mixing under stirring and carrying out standing to remove impurities; c, adjusting the pH value of an alkaline leaching solution obtained in the previous step to 1.0 to 1.5, carrying out ageing for 2.5 to 3 h and then carrying out solid-liquid separation after complete precipitation of selenium; d, oxidizing leached fine selenium by using a sodium sulfite solution, carrying out sufficient stirring and then successively carrying out standing and filtering so as to obtain a selenium-rich solution; and e, slowly adding sulfuric acid into the selenium-rich solution, and successively carrying out acidification and reduction, filtering, washing and drying so as to prepare high-purity selenium. The method provided by the invention realizes preparation of high-purity selenium through two-step leaching and wet-process purification of crude selenium, shortens the purification flow of selenium, improves recovery rate, reduces production cost and mitigates limitation of large-scale production.

Owner:三门峡市有色金属质量科学研究所

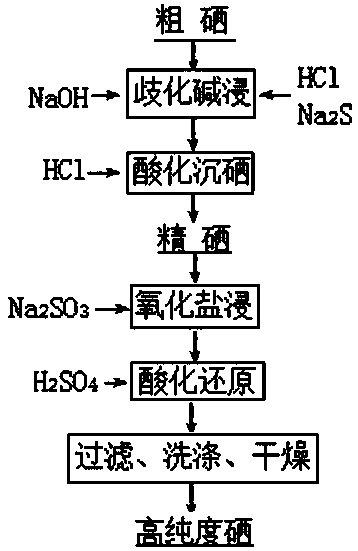

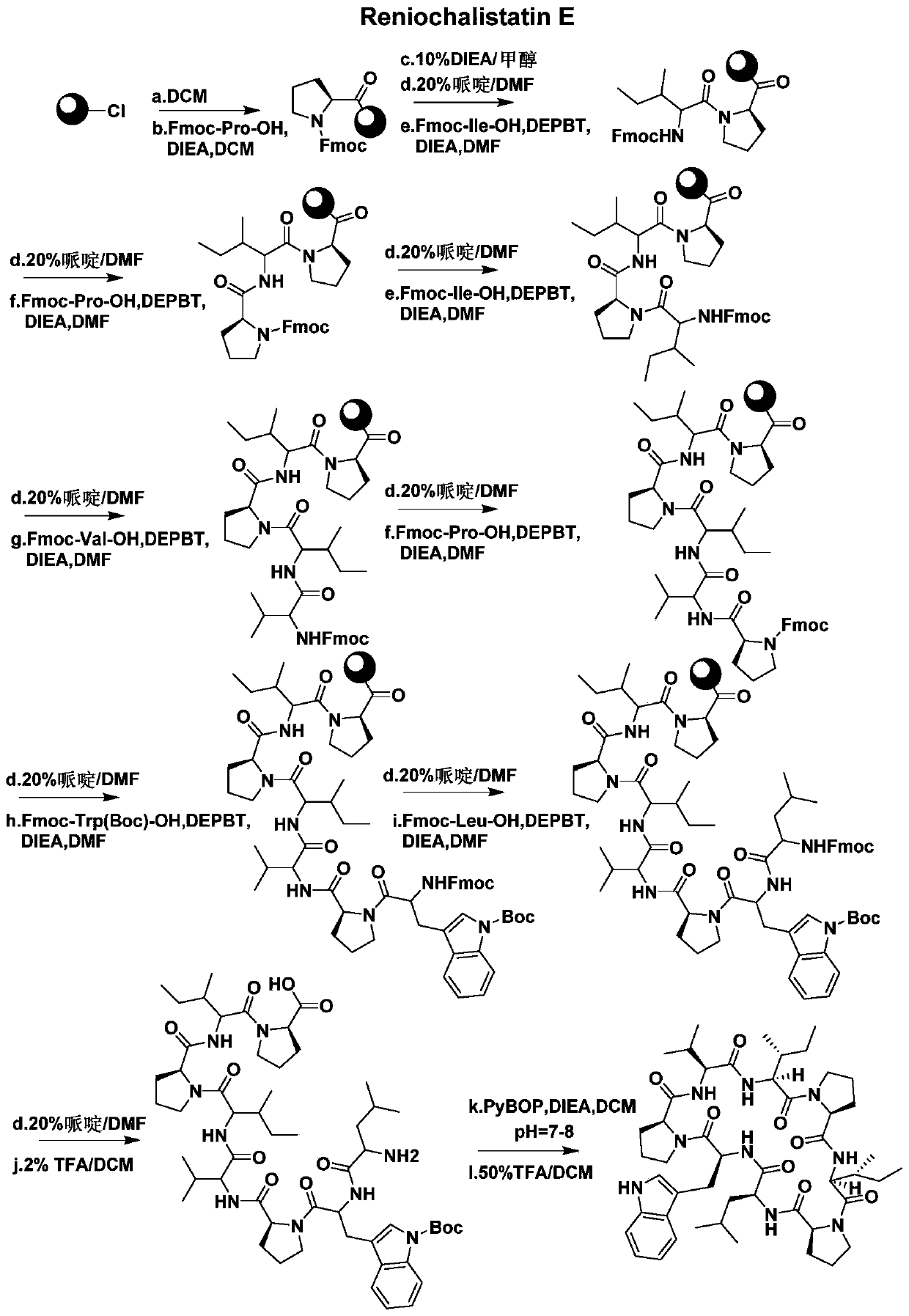

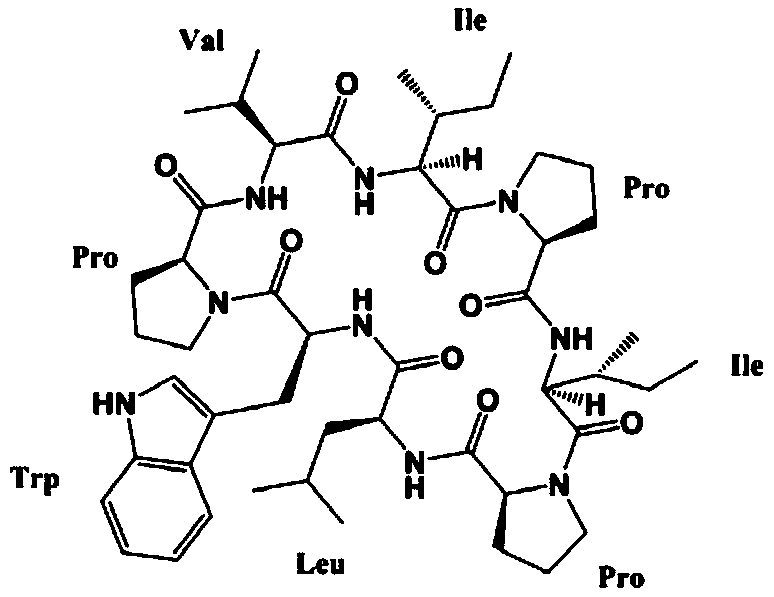

A kind of synthetic method of active cyclic octapeptide reniochalistatin E and its analogs

InactiveCN107827956BLow costShorten the compositing timePeptide preparation methodsBulk chemical productionTryptophanReniochalistatin E

The invention discloses a synthesis method of active cyclic octapeptide Reniochalistatin E and an analogue thereof. A complete synthesis method of the cyclic octapeptide disclosed by the invention adopts a polypeptide solid phase synthesis method, and the synthesis time and purification processes are greatly shortened; in order to prevent the condition that hydrogen on tryptophan indole nitrogen possibly causes decrease of a connection rate and increase of by-products, tryptophan with protection of carbonyl tert-butyl (Boc) on indole is adopted as a raw material, and finally, after cyclizationis finished, a TFA / DCM solution with a high volume ratio is adopted for removing Boc protection to obtain a final product. Compared with traditional condensation reagents and cyclization reagents, condensation reagents DEPBT and DIEA and a cyclization reagent PyBOP adopted by the invention have the advantages of greatly reducing racemization caused by reaction processes and reducing toxicity hazards to the body of a user. The product obtained by the synthesis method provided by the invention is simple in synthesis process, low in raw material cost, mild in reaction condition, high in purity and easy to industrialize, and has broad market prospects.

Owner:JINAN UNIVERSITY

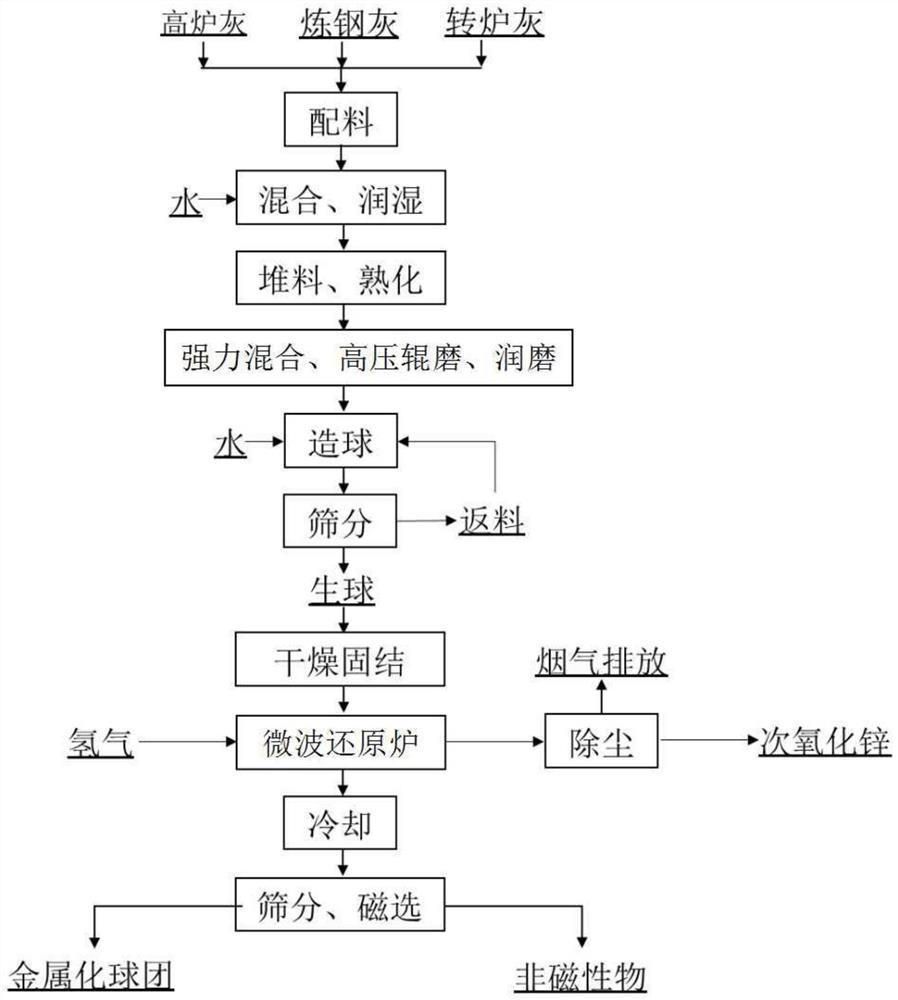

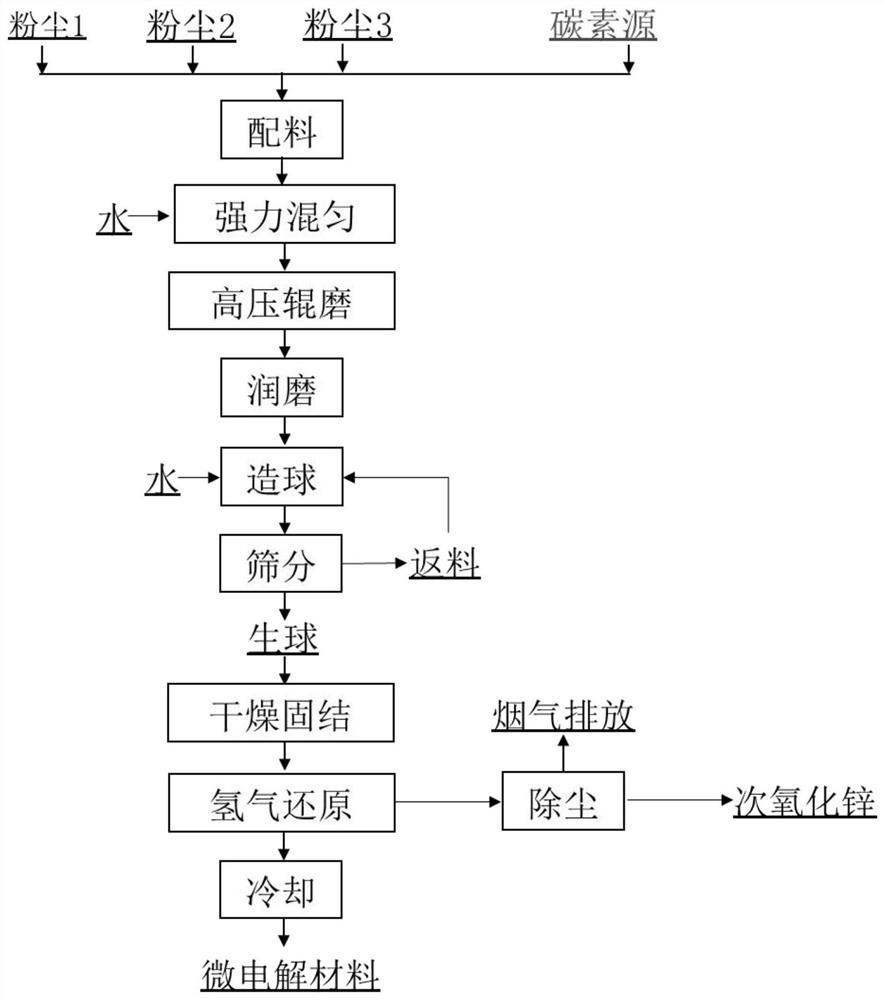

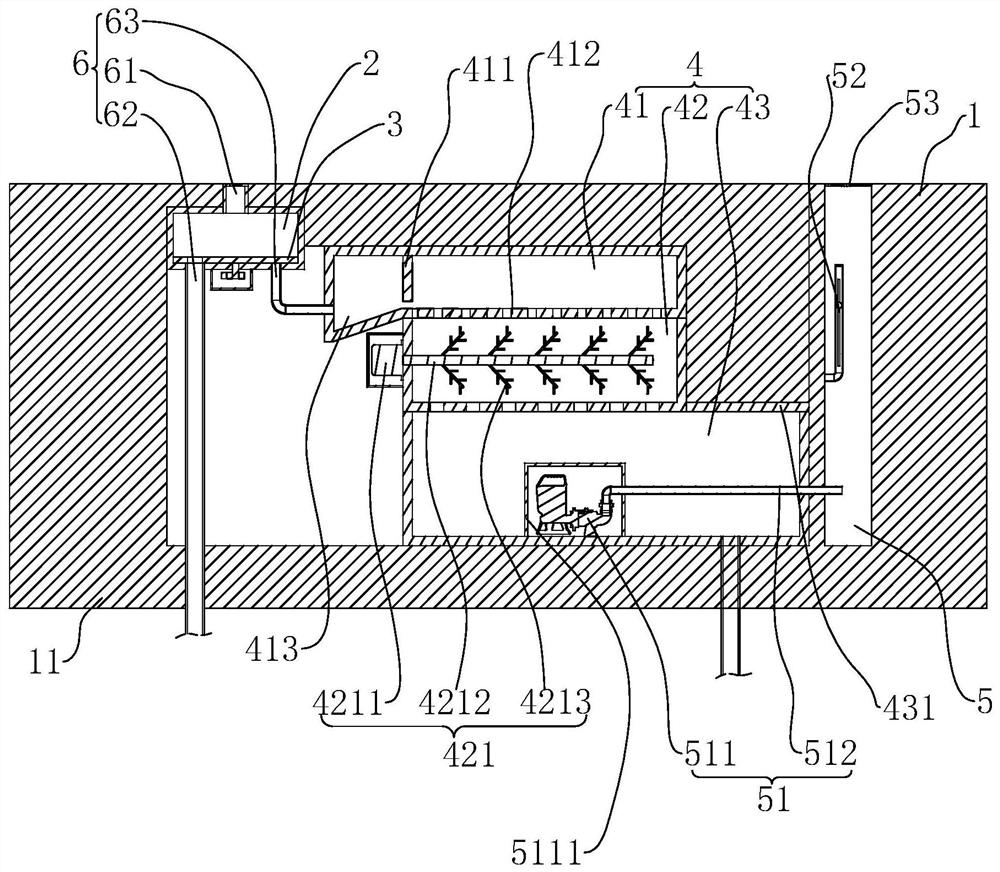

Method for dezincification of zinc-containing dust through microwave hydrogen reduction

PendingCN114525401AHigh carbon contentImprove absorbing performanceProcess efficiency improvementMixed materialsZinc

The invention discloses a method for dezincification of zinc-containing dust through microwave hydrogen reduction, which belongs to the technical field of ferrous metallurgy and comprises the following steps: S1, carrying out optimized ore blending on different types of zinc-containing dust in a steel plant to obtain an ore-blended zinc-containing dust material; s2, a binder is added into the zinc-containing dust material obtained after ore blending, powerful mixing treatment is conducted, then high-pressure roller milling and wet milling combined treatment is conducted, and a uniformly-mixed material is obtained; s3, pelletizing the uniformly mixed material to obtain green pellets, and drying to obtain dry pellets; and S4, the dry balls are put into a microwave reduction furnace to be subjected to hydrogen reduction treatment, cooling is conducted under the protective atmosphere after reduction, and reduced dezincified balls are obtained. Aiming at the characteristics of high carbon content and excellent wave-absorbing performance in the zinc-containing dust of the iron and steel plant and the characteristics of high heating speed, small heat loss, strong penetrating power, convenience in operation and the like of microwave heating, the defects of high energy consumption and serious pollution of traditional heating can be obviously improved when the zinc-containing dust is heated.

Owner:CENT SOUTH UNIV

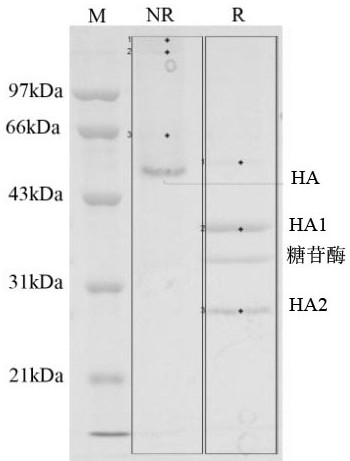

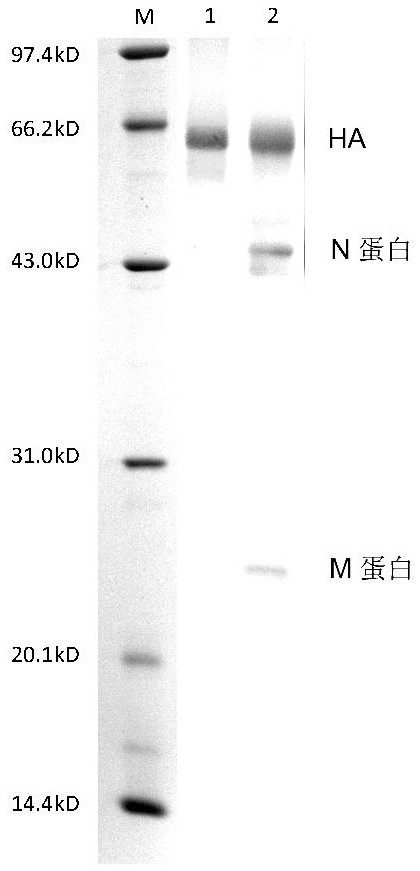

Subunit influenza vaccine split agent and application thereof

ActiveCN111803625AHigh virus contentConvenient purification workSsRNA viruses negative-senseViral antigen ingredientsAntigenSucrose

The invention discloses a subunit influenza vaccine split agent and application thereof, and belongs to the technical field of vaccine production. The subunit influenza vaccine split agent comprises nonoxynol-9 with a mass concentration of 0.1-5%, sodium hydroxide with a mass concentration of 1-5 g / L, sodium dihydrogen phosphate with a mass concentration of 5-20 g / L, sucrose with a mass concentration of 10-60% and the balance distilled water. According to the subunit influenza vaccine split agent and application thereof, the split agent is subjected to a density gradient centrifugation process, due to the fact that the split agent with the formula has the character of efficiently splitting influenza viruses, virus particles do not need to be split in advance, and are split in the centrifugation process instead, that is to say, one-step splitting is achieved, thus a purification treatment process is shortened, no obvious M protein bands or N protein bands appear in a product PAGE electrophoresis, and the purity of a main antigen component HA of a vaccine is higher than 90%, and is higher than those of products which are obtained by adopting aforehand splitting and other split agentformulas.

Owner:天津中逸安健生物科技有限公司

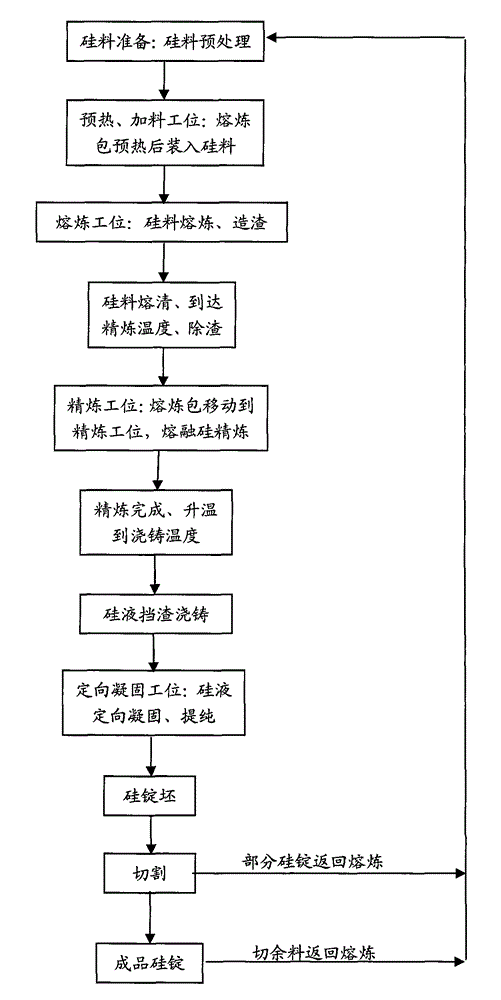

Production method and production equipment for high-purity polysilicon

The invention relates to a production method for high-purity polysilicon and production equipment for producing the high-purity polysilicon by the production method, wherein the production method comprises the following steps: preparing a silicone material, smelting a packaging material, deslagging, smelting silicon refining, casting silicone fluid slag, deairing silicone fluid in vacuum, directionally solidifying, discharging silicon ingots, and peeling and cutting, wherein the silicone material used in the silicone material preparation step is metallurgy level of reduction silicon; and a heating mode adopted in the silicon material smelting step comprises chemical combustion heating. The production equipment comprises at least more than three same ladle structures used for a smelting ladle and a refining ladle, wherein one ladle is used for smelting operation, one ladle is used for refining operation, and another ladle is used for repairing, preheating or loading operation. The production method and the production equipment can produce the high-purity polysilicon on large scale and at low cost.

Owner:沈阳三特真空科技有限公司

A continuous purification method for high-purity tungsten hexafluoride

ActiveCN110510675BWide concentration rangeImprove the purification effectTungsten halidesPurification methodsPhysical chemistry

The invention relates to a continuous purification method of high-purity tungsten hexafluoride, belonging to the field of fluorine-containing fine chemical separation technology. In the method, the impurity gas is firstly sublimated into a solid through a low-temperature purification tower, and then the tungsten hexafluoride with a purity of 99.9999 vol% is obtained through high-efficiency rectification by adjusting the rectification process parameters. The method of the invention can realize the purification of crude tungsten hexafluoride gas with a purity of more than 30 vol%, has wide application range, strong operability, high yield, low cost, high efficiency and is easy for large-scale production.

Owner:PERIC SPECIAL GASES CO LTD

A method of recycling neighbor aminozylene acid from neighboring aminopenzoate wastewater

ActiveCN104016871BAvoid introducingEasy post-processingOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidEnvironmental engineering

The invention provides a method for reclaiming anthranilic acid from methyl anthranilate wastewater, the method is to carry out separation treatment and extraction treatment to methyl anthranilate wastewater, then obtain sodium anthranilate solution, and then Anthranilic acid was obtained after purification. In the present invention, the property that anthranilic acid is soluble in hot water and slightly soluble in cold water is used for purification, which reduces the addition of other substances and the purification process, reduces the cost of purification, and is economical and environmentally friendly.

Owner:BEIJING HUIYU LEBANG ENVIRONMENT PROTECTION TECH CO LTD

Preparation method of carbon-containing micro-electrolysis material

ActiveCN114574692AImprove adsorption capacityAchieve recyclingWater contaminantsDispersed particle separationElectrolysisMixed materials

The invention discloses a preparation method of a carbon-containing micro-electrolysis material, which comprises the following steps: S1, optimally proportioning a zinc-containing dust material, a carbon source and a binder to obtain a mixture; s2, intensively and uniformly mixing the mixture obtained in the step S1, and then carrying out high-pressure roller milling and wet milling combined treatment to obtain a uniformly mixed material; s3, pelletizing the uniformly mixed material obtained in the step S2 to obtain green pellets, and drying to obtain dry pellets; and S4, the dry balls obtained in the step S3 are loaded into a gas-based shaft furnace to be subjected to hydrogen reduction treatment, cooling is conducted under the protective atmosphere after reduction, and the carbon-containing micro-electrolysis material is obtained. According to the preparation method of the carbon-containing micro-electrolysis material, Fe and C contained in zinc-containing dust are fully utilized, dezincification of the zinc-containing dust and preparation of the micro-electrolysis material are achieved in one step through a reduction method, the traditional preparation process of the micro-electrolysis material is changed, and short-process and high-value comprehensive utilization of the zinc-containing dust is achieved.

Owner:CENT SOUTH UNIV

A kind of production device and production method of electronic grade hydrofluoric acid

ActiveCN112010263BEasy to handleAvoid pollutionGas treatmentDispersed particle separationHydrogen fluoridePhysical chemistry

Owner:BEIJING UNIV OF CHEM TECH

A rainwater treatment system

ActiveCN112922114BReduced purification processRealize shuntFatty/oily/floating substances removal devicesSewerage structuresStormwater treatmentSewage

The present application relates to the field of water treatment, in particular to a rainwater treatment system. The rainwater treatment system includes a discharge pipe, a sewage pipe and a rainwater pipe. A transfer station is arranged between the discharge pipe, the sewage pipe and the rainwater pipe. One end of the pipe away from the road is fixedly connected and connected with the transfer station, one end of the sewage pipe is fixedly connected and connected with the transfer station, and the other end is connected with the sewage treatment plant. Open and close at the same time, a conversion device for switching the open and closed states of the rainwater pipe and the sewage pipe is arranged between the rainwater pipe and the sewage pipe. In the present application, the change of the open state of the rainwater pipe and the sewage pipe is realized, the diversion of sewage and rainwater is realized, the process of purifying the rainwater in the sewage treatment plant is shortened, and the effect of reducing the waste of power consumption of the sewage treatment plant is achieved.

Owner:张家港市建筑设计研究院有限责任公司

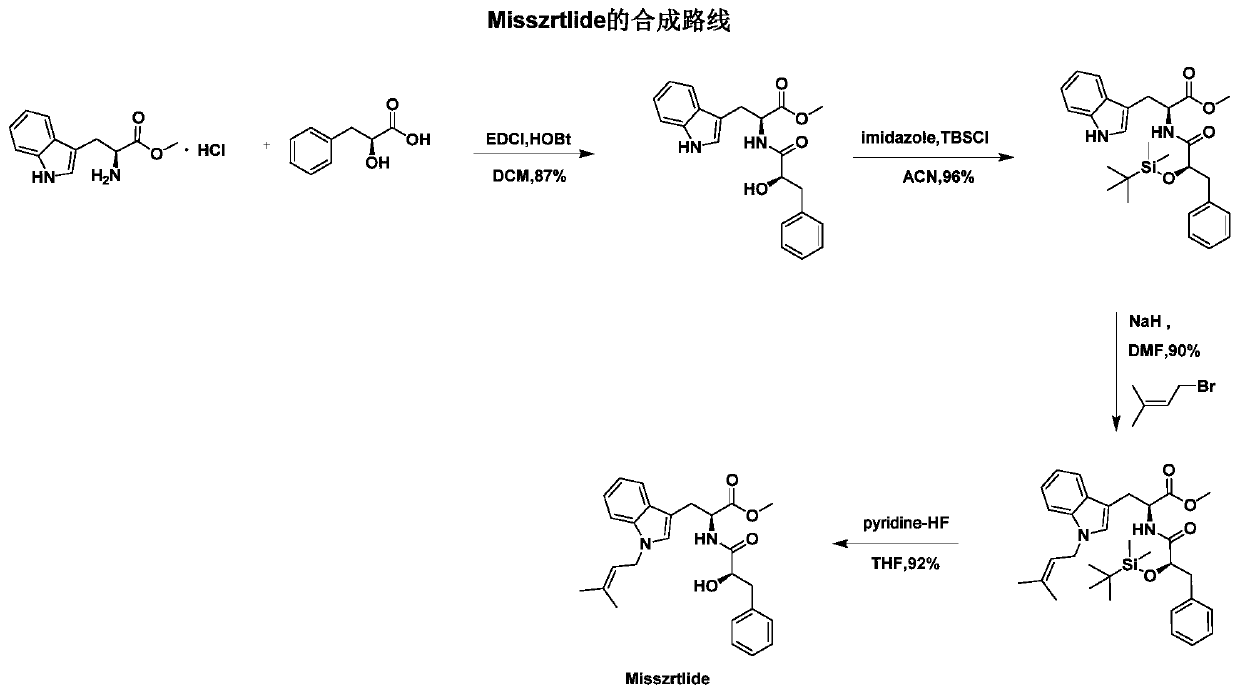

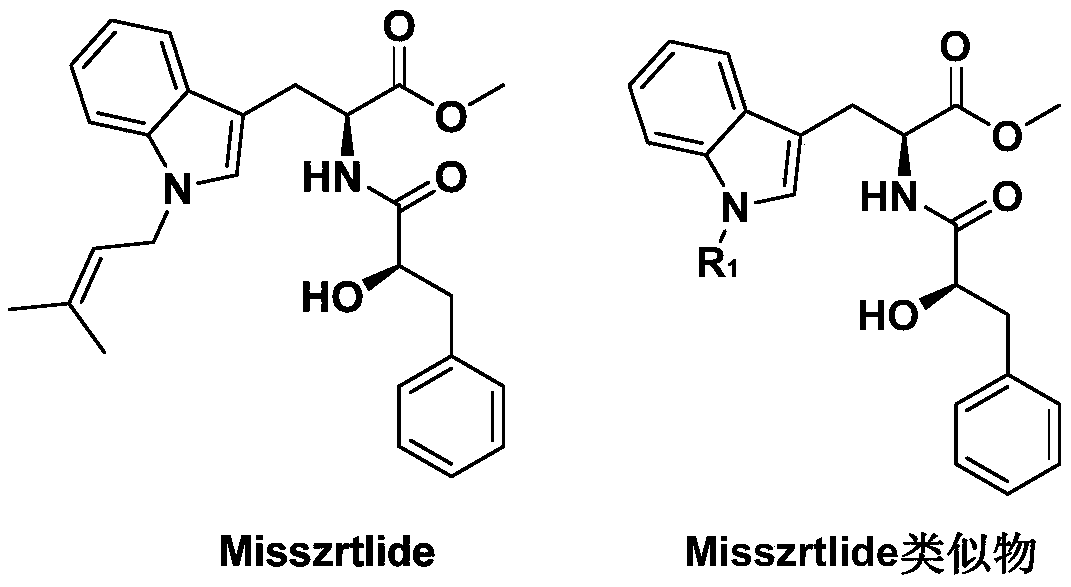

A kind of synthetic method of active alkaloid misszrtlide

InactiveCN108164451BReduced synthesis time and purification stepsThe synthesis process is simpleOrganic chemistryHydroxybenzotriazoleMethyl tryptophan

The invention belongs to the field of alkaloid and discloses a method for synthesizing active alkaloid Misszrtlide and an analogue thereof. The method comprises the following steps: adopting chiral raw materials, namely L-methyl tryptophan hydrochloride and L-phenyl lactic acid as substrates and performing non-racemic amide connection under the condition of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride / 1-hydroxybenzotriazole; subsequently reacting with tert-butyldimethylsilyl chloride under imidazole conditions, so that hydroxyl is promoted, and the competition with N-H on tryptophan indole in the process of reaction with R1Br (R1 can be one of 3,3-dimethylpropenyl, p-toluoyl and decanoyl) under alkaline conditions in the next step is avoided; finally, mildly and efficientlyremoving the tert-butyldimethylsilyl protection with a hydrogen fluoride pyridine solution to obtain the Misszrtlide or the analogue thereof with high yield and easiness in processing through four-step reaction. The method disclosed by the invention is simple, low in raw material cost, mild in reaction conditions, high in purity and easy to industrialize and has wide market prospect.

Owner:JINAN UNIVERSITY

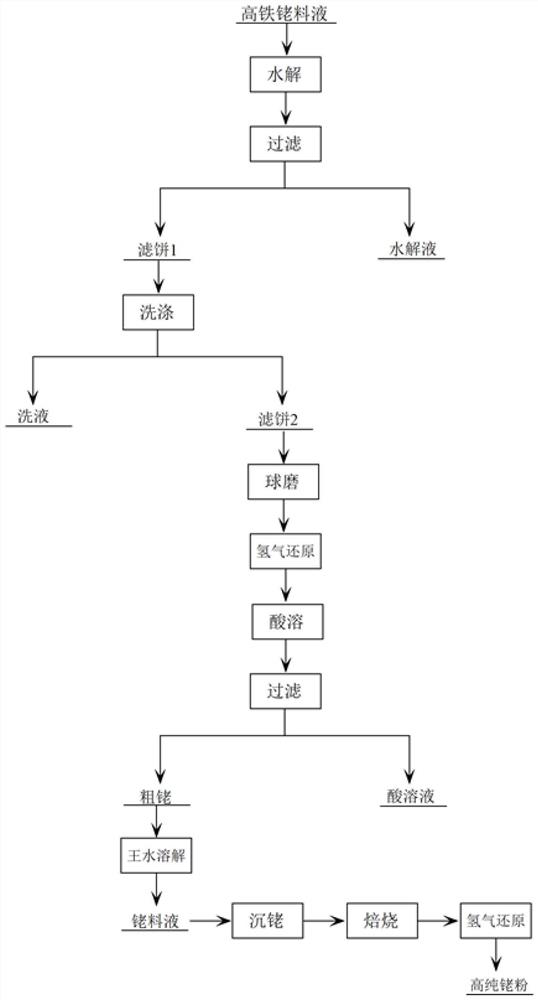

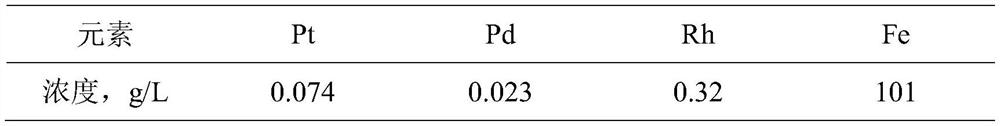

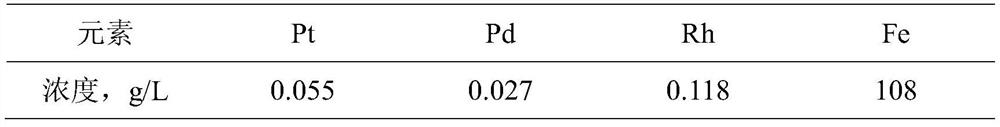

Method for separating and purifying rhodium in high-iron rhodium-containing feed liquid

ActiveCN113832356AAvoid lostReduced purification processProcess efficiency improvementHydrogen atmosphereAqua regia

The invention discloses a method for separating and purifying rhodium in high-iron rhodium-containing feed liquid. The method comprises the following steps of simultaneously adding the high-iron rhodium-containing feed liquid and liquid caustic soda into a reaction kettle, continuously adding the liquid caustic soda to adjust the pH value in the reaction kettle to 8 to 9 after the high-iron rhodium-containing feed liquid is completely added into the reaction kettle, maintaining the pH value in the reaction kettle until no precipitate is generated, and filtering to obtain a first filter cake; stirring and washing the first filter cake with a washing solution with the pH value of 8 to 9, and filtering to obtain a second filter cake; drying the second filter cake, ball-milling, reducing in a hydrogen atmosphere, and separating and filtering in an acid leaching manner to obtain a crude rhodium product; dissolving the crude rhodium product with aqua regia, adding tetraethylenepentamine for rhodium precipitation, and filtering to obtain rhodium salt; dissolving the rhodium salt with aqua regia again, repeating rhodium precipitation-aqua regia dissolution operation for 2 to 3 times, and obtaining high-purity rhodium salt; and roasting the high-purity rhodium salt, and reducing in a hydrogen atmosphere to obtain rhodium powder with the purity of 99 percent or above. The method for separating and purifying the rhodium in the high-iron rhodium-containing feed liquid provided by the invention is high in recovery rate and low in cost.

Owner:GEM CO LTD +1

Preparation method of gingko leaf wine

InactiveCN105087294ALow costHigh nutritional valueAlcoholic beverage preparationActivated carbonAlcohol

A preparation method of gingko leaf wine comprises the following steps of (1) preparation of gingko leaf dry powder: picking green and fresh gingko leaves without being eaten by worms in summers and autumns, drying the green and fresh gingko leaves in the sun, pulverizing the dried gingko leaves, sieving the smashed gingko leaves by using a sieve with mesh of 30-70, and packing the sieved gingko leaves for subsequent use; (2) preparation of extract solvent: diluting wine or alcohol with water until the concentration of the wine or alcohol is 20-36%, adding 1% of activated carbon in the diluted wine or alcohol, performing deodorization treatment for 5-10 days and filtering for subsequent use; (3) preparation of gingko leaf leach liquor: adding 300-900g of gingko leaf dry powder in 100L of extract solvent, stirring the mixture at intervals of 2-3 days for four times to five times, standing for 48-60 hours, and sucking up supernatant liquor by siphoning; and (4) preparation of syrup: preparing 50-60% of liquor by using sugar and water, adding 0-1% of citric acid in the liquor, boiling the mixture, removing bubbles, filtering the hot mixture by using filtering cloth with mesh of 200 to remove residues, weighing 13-95% of gingko leaf leach liquor, 0-10% of syrup, 0-10% of fruit juice and the balanced water according to volume ratio, stirring and standing in a sealed environment for 20-30 days, and filtering, sterilizing and filling to obtain the gingko leaf wine.

Owner:尹连花

Method for purifying inosine from fermentation liquor

InactiveCN113185563AReduce pollutionSave purified raw materialsSugar derivativesSugar derivatives preparationBiotechnologyInosine

The invention provides a method for purifying inosine from fermentation liquor, and relates to the technical field of chemical engineering. The method for purifying inosine from fermentation liquor comprises the following steps: S1, selecting inosine fermentation liquor for treatment; S2, putting the inosine fermentation liquor filtered in the step S1 into a reaction kettle; S3, separately storing the filtrate collected in S2; S4, concentrating, crystallizing and drying the inosine aqueous solution filtered in S2; S5, filtering the filtrate in the step S2 by using a micro-filtration membrane; S6, purifying the filtrate filtered in the step S5 and the wastewater collected in the step S3 by using a sewage treatment device. The inosine fermentation liquor filtrate glycogen is collected, meanwhile, purification and discharge are conducted in a filtrate sewage treatment mode, the environmental protection pressure is small, inosine can be collected to the maximum extent through the arrangement that the inosine fermentation liquor is diluted and filtered at the same time through the nanofiltration membrane, and the device is worthy of being vigorously popularized.

Owner:JINAN MINGXIN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com