Patents

Literature

56results about How to "Reduce purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel aldolase, and method for producing optically active IHOG and monatin

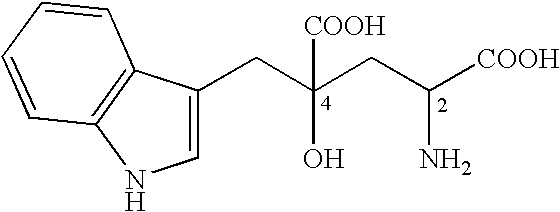

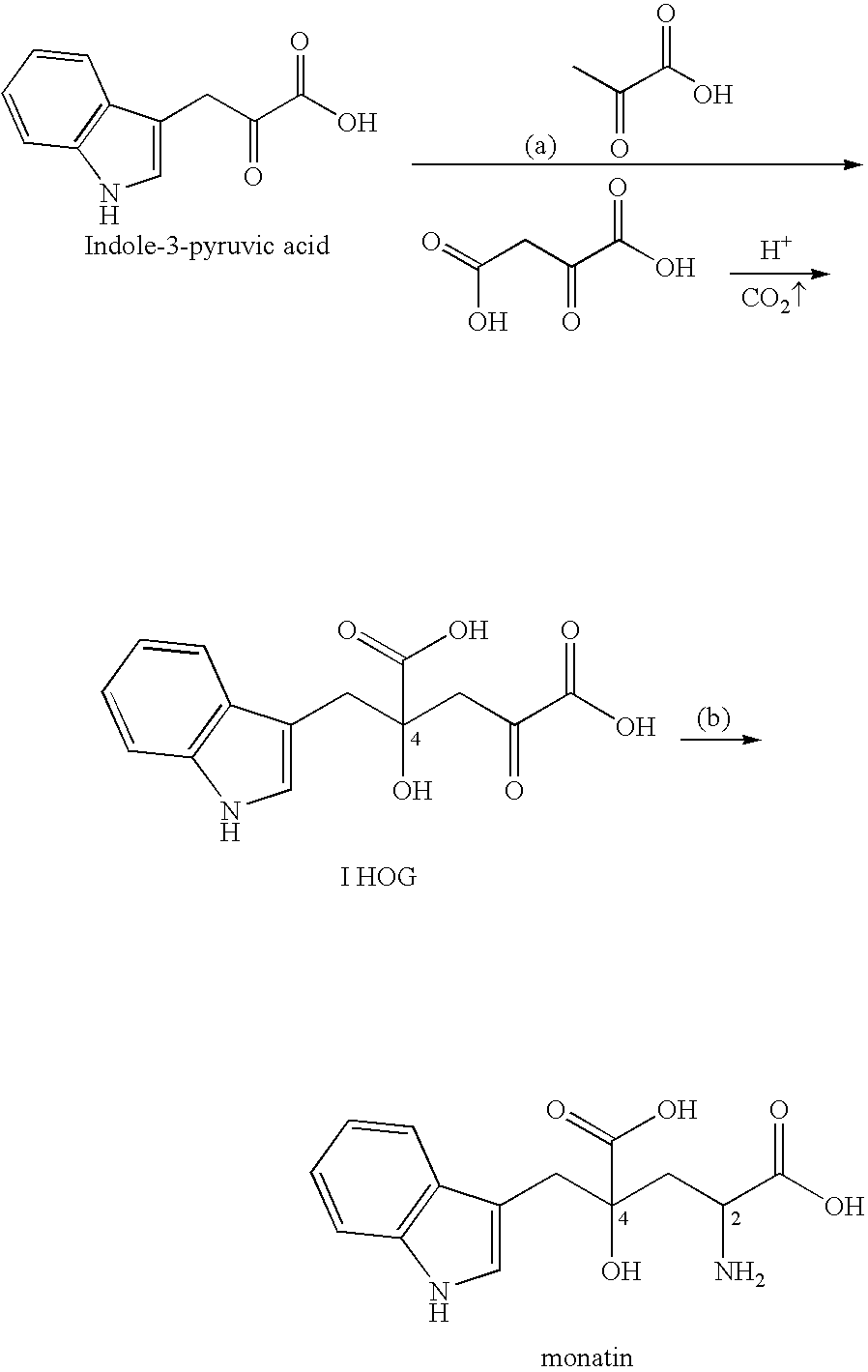

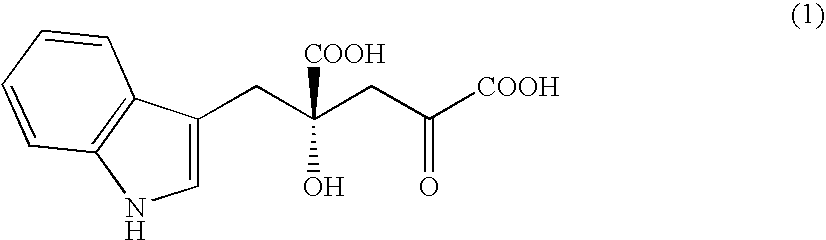

The present invention relates to a method for producing optically active IHOG, which can in turn be used for the production of monatin. The present invention further relates to a method for producing optically active monatin, and aldolase used for these methods. As such, the present invention enables the synthesis of 4-(Indole-3-ylmethyl)-4-hydroxy-2-oxoglutaric acid with high optical purity, which is useful as an intermediate in the synthesis of optically active monatin, from indole pyruvic acid and pyruvic acid (or oxaloacetic acid).

Owner:AJINOMOTO CO INC

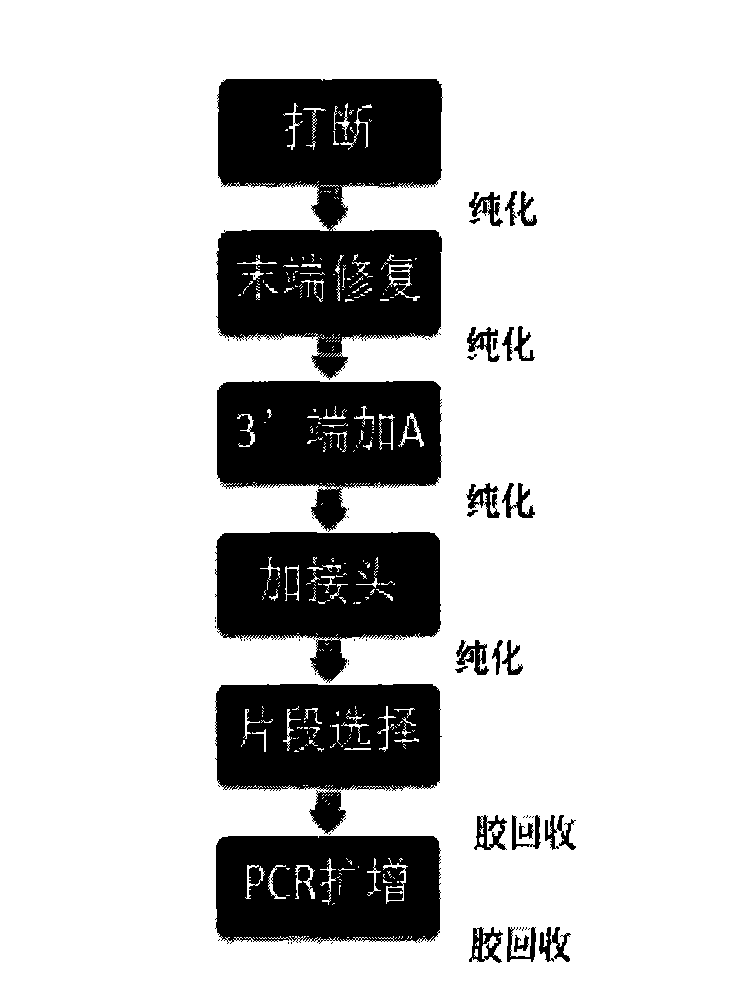

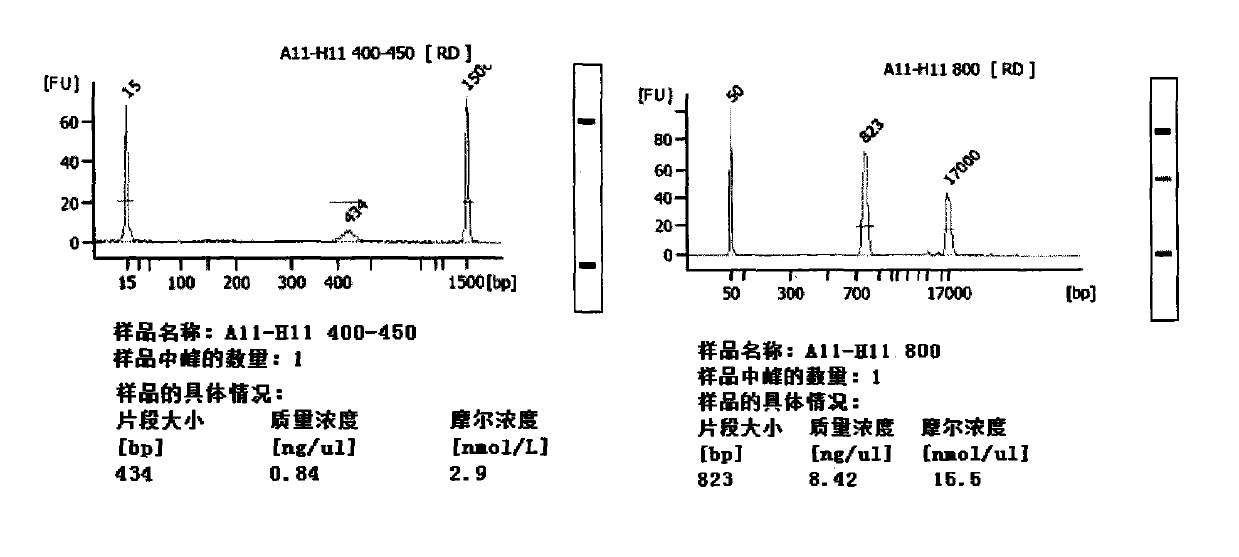

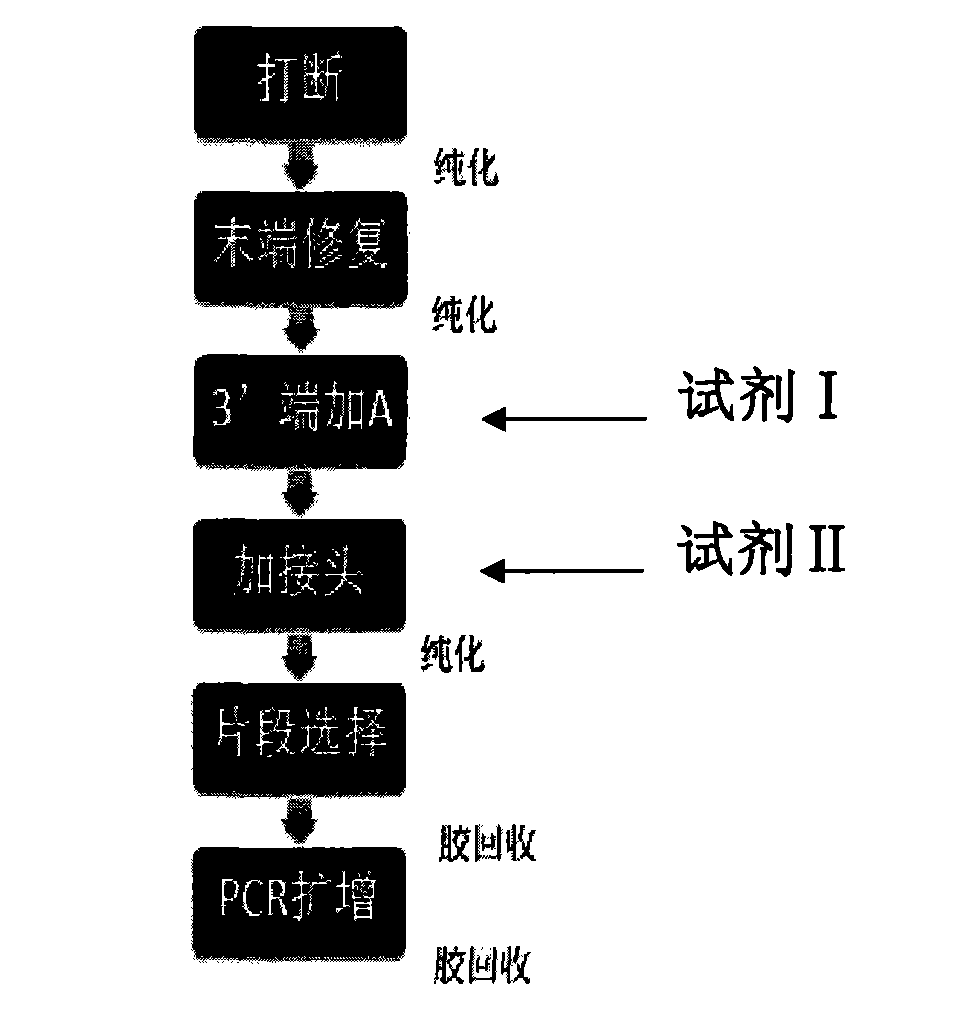

Novel library construction method based on illumina sequencing platform

ActiveCN102560688AReduced purification processShorten experiment timeMicrobiological testing/measurementLibrary creationSmall fragmentDNA

The invention provides a novel library construction method based on an illumina sequencing platform, and in particular provides a small-fragment DNA library construction method. Aiming at the defects of the small-fragment DNA library construction of the existing illumina sequencing platform, the purification steps can be reduced, the loss and waste of a library are reduced, the cost is lowered, and the working efficiency is improved.

Owner:WUXI QINGLAN BIOLOGICAL SCI & TECH

Physical degumming method of ramie

InactiveCN1624213AReduce environmental pollutionReduce degumming costsMechanical treatmentStrong acidsEngineering

This invention relates to a method of degumming Boehmeria nivea. The process is: fresh Boehmeria nivea (or commercial original Boehmeria nivea) ->immersion in warm water-> mechanical hemp knocking and washing ->boiling off in hyperthermia and heavy pressure (or immersion in warm water) -> mechanical hemp knocking and washing -> refined dry hemp. This method, assuming the characteristics of environmental protection, high efficiency and high qualities, greatly reduces the degumming cost, avoids the pollution of strong acid and strong base in waste solution to the environment, for this process makes use of existing machinery of degumming. Instead of using such chemical materials as strong acid and strong base, the method is high-temp high-pressure cooking, immersion in warm water, mechanical beating and washing for removing extraneous cells of Boehmeria nivea liber.

Owner:HUNAN AGRICULTURAL UNIV

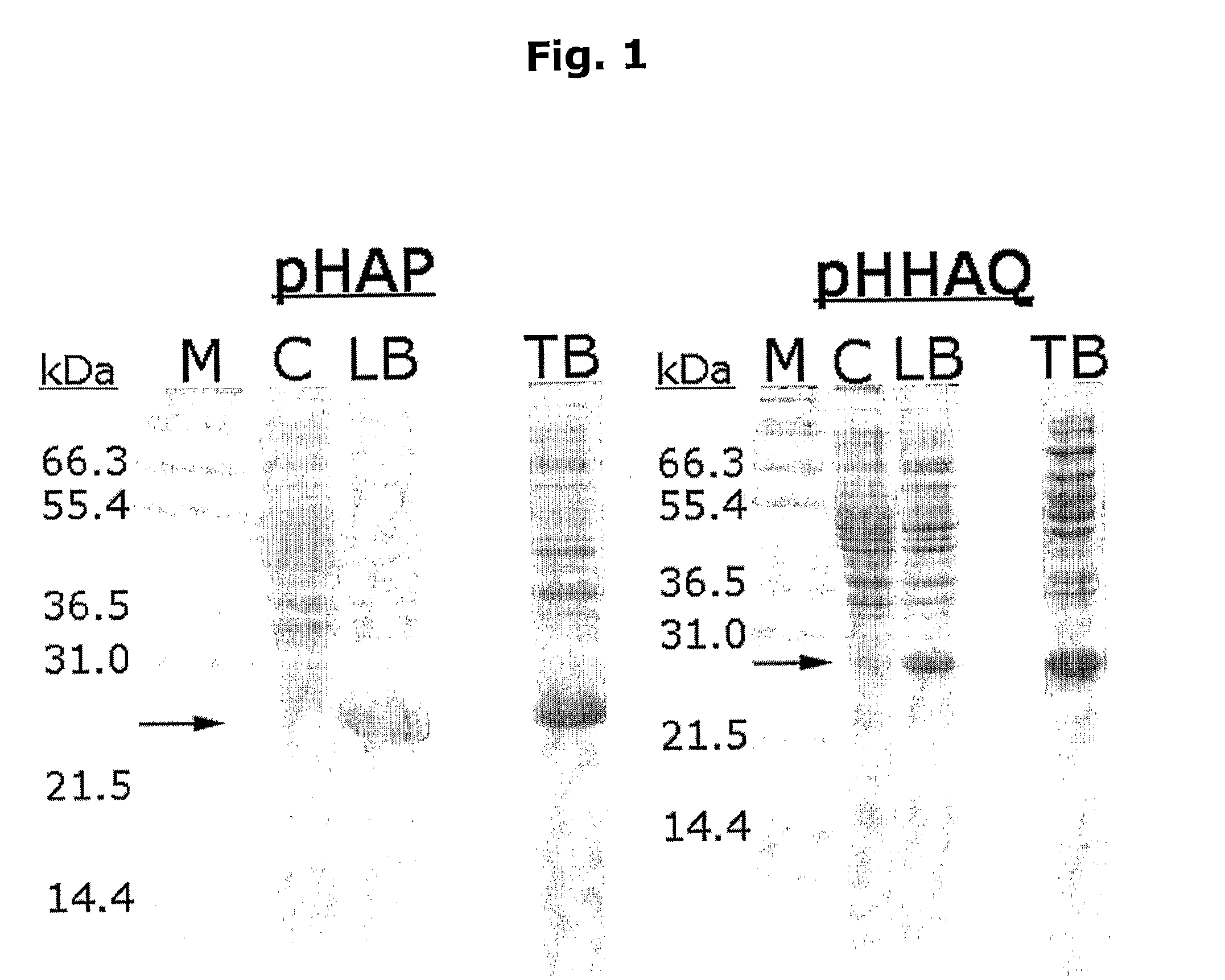

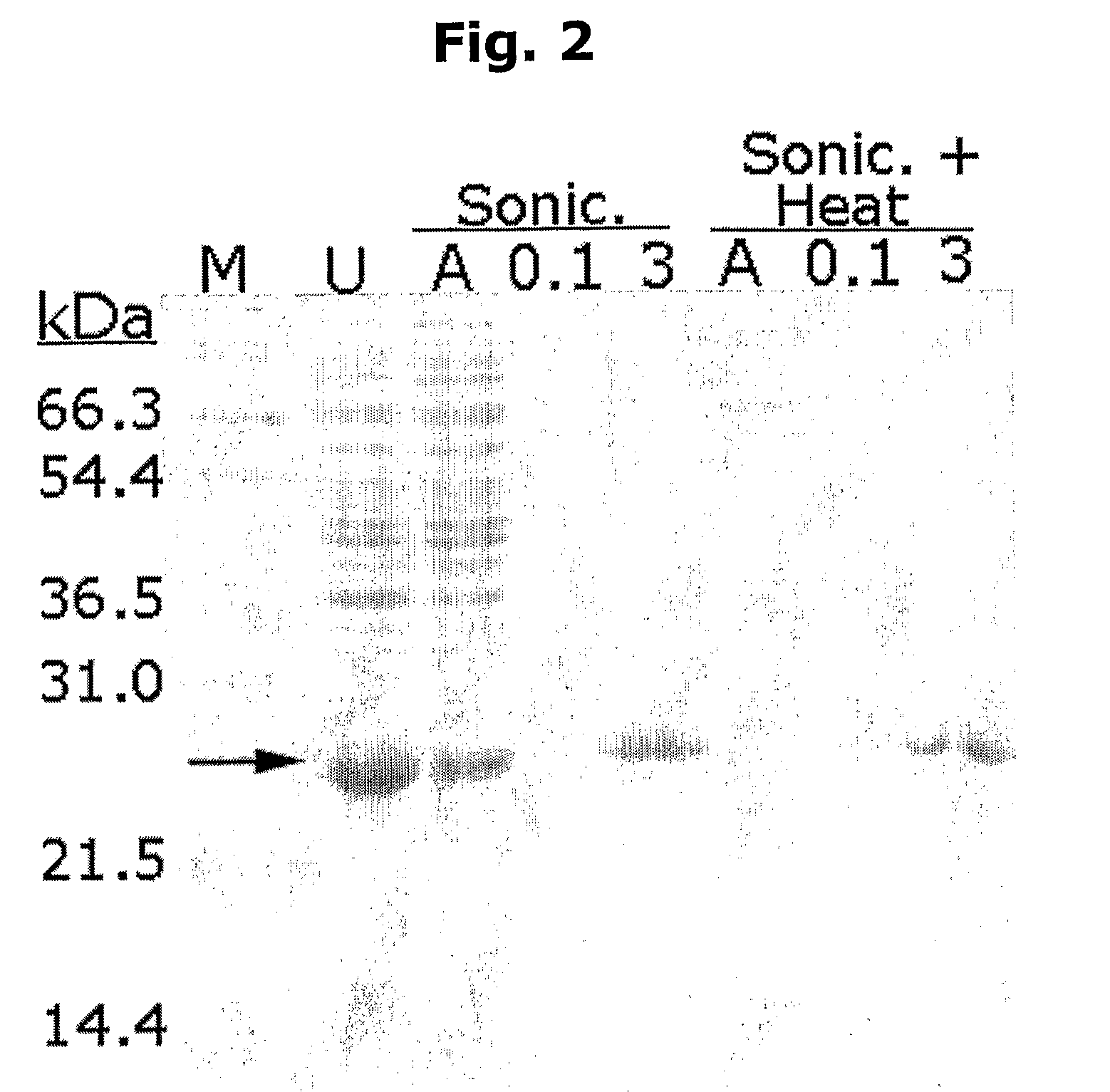

Novel method for protein purification

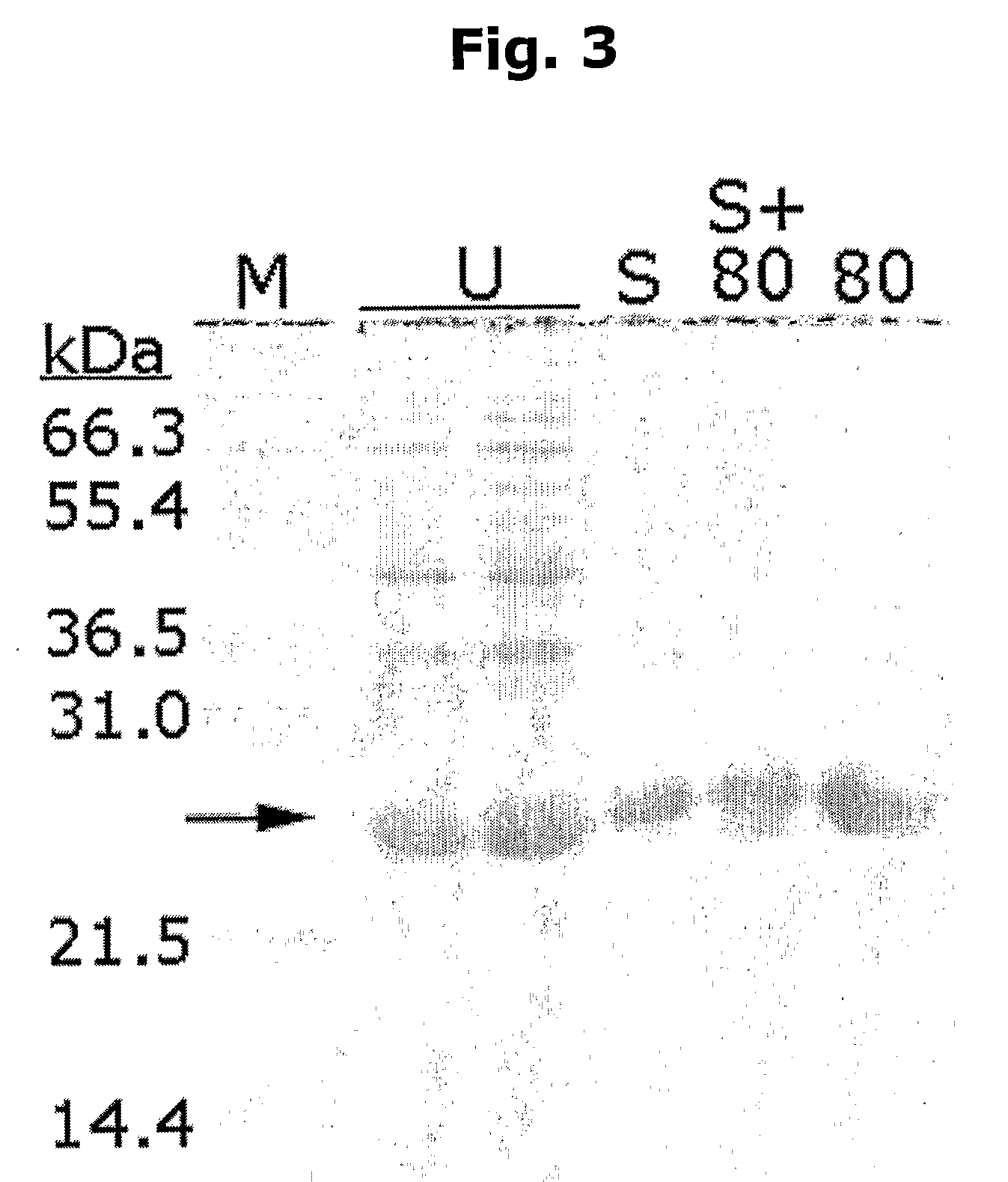

InactiveUS20100233783A1Easy to transcribeEasy translationBacteriaPeptide/protein ingredientsLysisProtein purification

Process for purifying a recombinant protein including one or a few procedural steps only. The process combines the step of lysis of the host cell, with the purification of the protein of interest, allowing for a rapid and much more efficient process of purification. The conditions used during the purification process are those of a high temperature and a low pH, allowing for thermostable and acid-resistant recombinant proteins to be isolated from a suspension. The invention also relates to purifying recombinant proteins which are fusion proteins, wherein one part of the protein may be selected from an enamel matrix protein, such as amelogenin.

Owner:PER HENRIK SVENSSON JOHAN +1

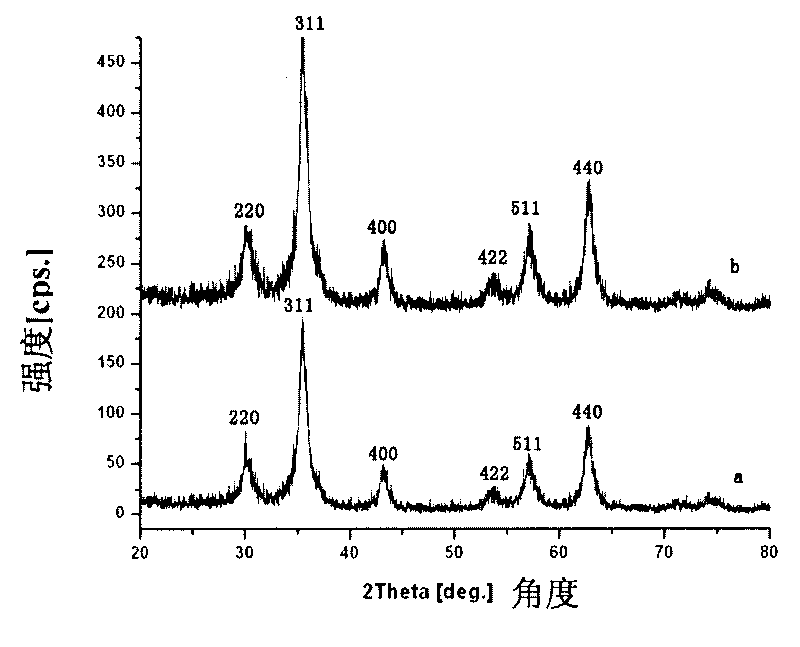

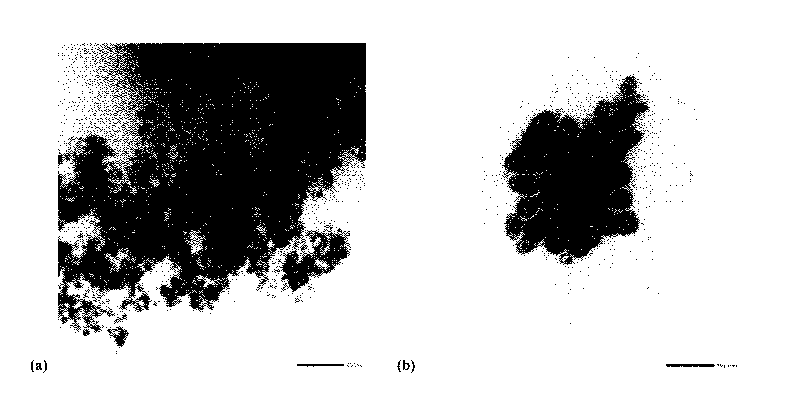

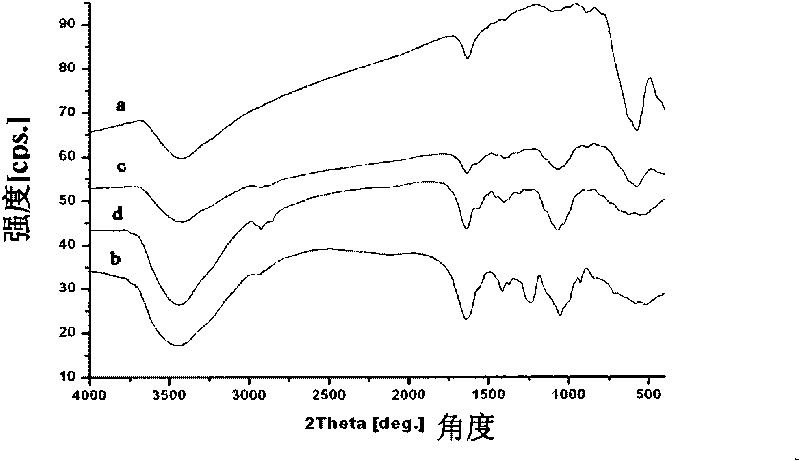

Magnetic compatible microsphere for purifying thrombin and preparation method and application thereof

ActiveCN101716494AHigh yieldEasy to operateOther chemical processesEnzymesMicrosphereCombinatorial chemistry

The invention provides a magnetic compatible microsphere for purifying thrombin and a preparation method and application thereof. The magnetic compatible microsphere for purifying the thrombin comprises a magnetic core, a polymer enwrapping material enwrapped outside the magnetic core, and a ligand coupled with the polymer enwrapping material. The magnetic affinity microsphere is characterized in that the ligand can be specifically compatible with the thrombin.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES

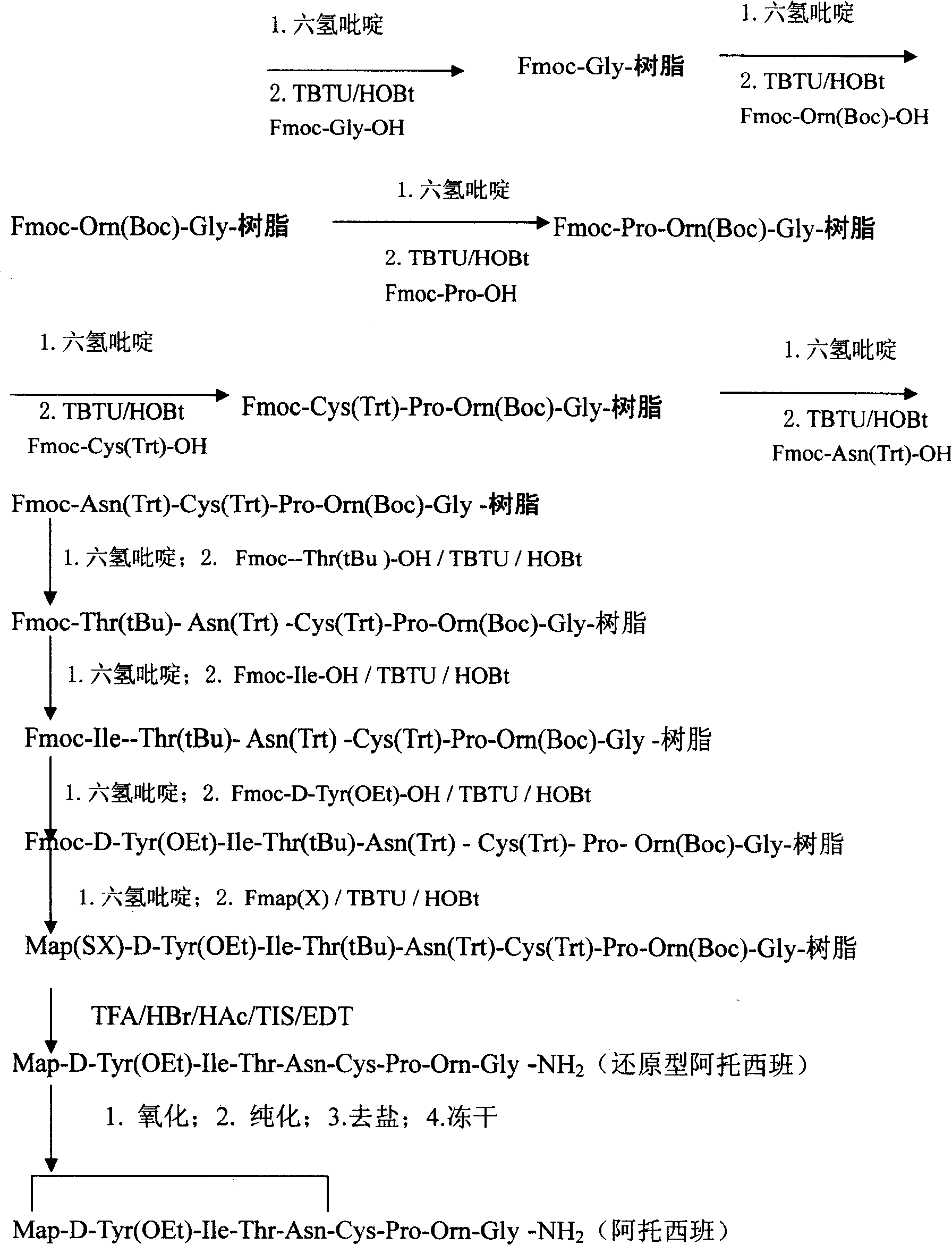

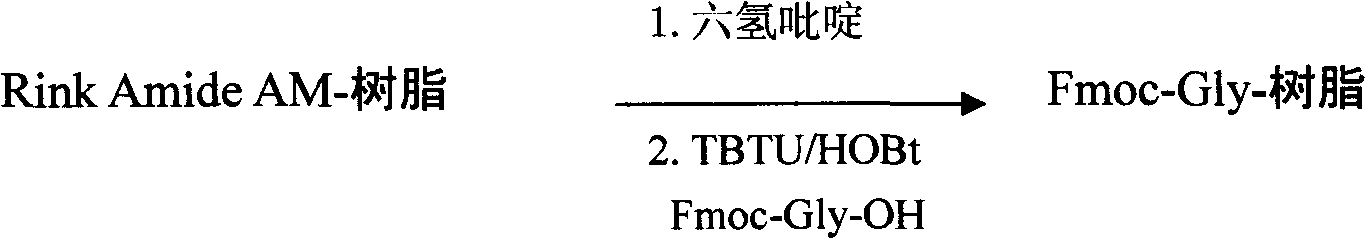

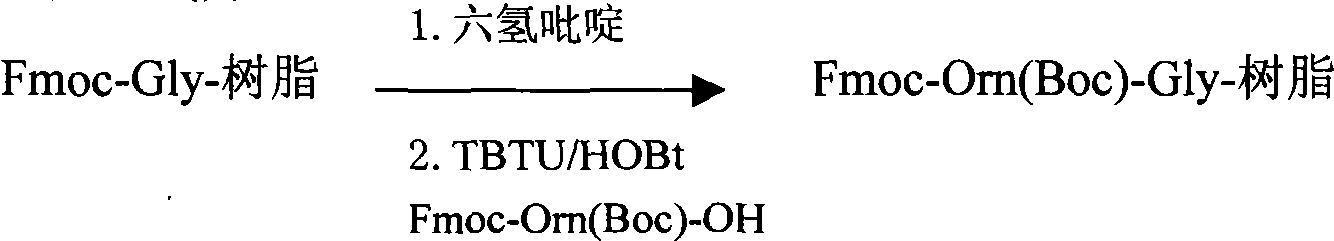

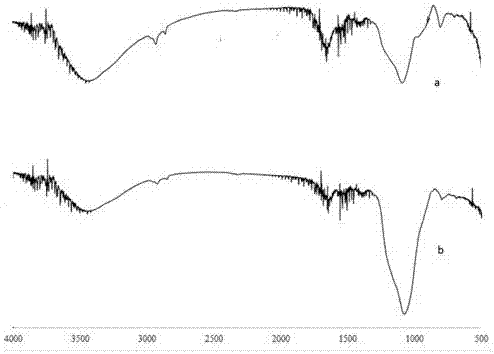

Method for synthesizing atosiban acetate from solid phase polypeptide

ActiveCN101357937AConvenient sourceHigh peptide yieldPeptide preparation methodsBulk chemical productionPreparative hplcSide chain

The invention discloses a preparation method of solid phase peptide synthesis atosiban which includes the following steps: taking Rink Amide resins, Rink Amide MBHA resins or Rink Amide AM resins as starting materials and taking Fmoc amino acids as monomers, amino acids are grafted one by one and mercaptopropionic acids (Map(SX)) are protected by the last peptide chain; after protected nonapeptide resins are obtained, the acellular side-chain protective groups and cutting peptides are synchronized; then cutting peptides is carried out, and reduced crude atosiban is collected; the pH value is adjusted to 7.5 to 10.0, and oxidized crude atosiban is collected; target products are obtained by the separation and purification by preparative HPLC(C18 or C8 column). The preparation method is convenient in material source, simplifies technology and reduces cost; and the preparation method is low in the pollution of three wastes and is high in yield, and the preparation method is convenient for being industrialized and has good industrialization prospect.

Owner:SHANGHAI SOHO YIMING PHARMA

Preparation method of Salvia miltiorrhiza soft capsule

InactiveCN102772487AHigh dissolution rateGood curative effectCapsule deliveryCardiovascular disorderPEG 400Separation technology

The invention provides a preparation method of a Salvia miltiorrhiza soft capsule, comprising the following steps of: completely mixing Salvia miltiorrhiza extract with glycerine and polyethylene glycol 400 so that liposoluble constituents such as tanshinone II A are dissolved in a liquid substrate so as to achieve certain solubilization and improve the biological availability of liposoluble constituents of Salvia miltiorrhiza. In the preparation process of the Salvia miltiorrhiza soft capsule, a method for preparing Salvia miltiorrhiza water-soluble component extract is provided, a macroporous resin separation technology is adopted, and ethanol solution is concentrated, atomized and dried after elution; in the obtained extract, the total salvianolic acid compounds account for more than 60% of total solid, wherein the content of salvianolic acid compound danshinolic acid B is between 45% and 60%, and the content of danshensu is controlled between 10% and 20%. The content of danshensu is controlled while the yield of salvianolic acids is improved so that the proportion of the main active ingredient danshinolic acid B is obviously improved. The preparation method is safe and efficient, low-toxic and environmentally-friendly, can satisfy the requirement of industrial production, and has wide and practical application value.

Owner:沈阳长秀医药有限公司

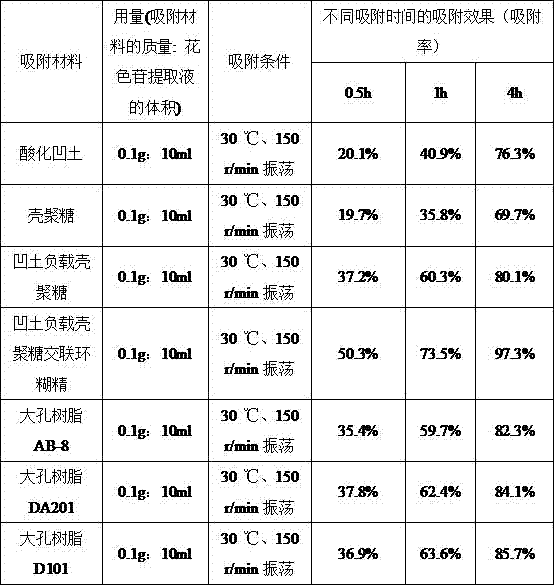

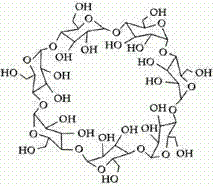

Preparation and application of attapulgite-supported chitosan crosslinked cyclodextrin composite

ActiveCN107312205AImprove adsorption capacityEasy wayNatural dyesActivated attapulgiteChemical synthesis

The invention relates to the field of chemical synthesis and discloses preparation and application of attapulgite-supported chitosan crosslinked cyclodextrin composite; the preparation includes mixing well acid-activated attapulgite with chitosan oxaloacetate sol having volume of V, centrifuging the mixture, performing suction filtering, and drying in vacuum to constant weight to obtain primary attapulgite-supported chitosan; allowing standing, removing supernate, adding alkaline liquor into the remainder until pH is 6.8-7.2, centrifuging, washing, performing suction filtering, and drying in vacuum to constant weight to obtain attapulgite-supposed chitosan; pouring cyclodextrin solution evenly into the attapulgite-supported chitosan, stirring fast and well, dropwise adding a crosslinking agent slowly, filtering after full reaction, washing filtered material to neutrality, and performing ketone washing, alcohol washing, suction filtering and drying to obtain the attapulgite-supported chitosan crosslinked cyclodextrin composite. Compared with macroporous resins, the composite of the invention has good adsorbing effect for plant pigments.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Preparation method of glutathione-enriched yeast

InactiveCN102653722AGood improvementHigh cost of solutionFungiMicroorganism based processesMolecular biologyGlutathione

The invention relates to a preparation method of a glutathione-enriched yeast. Culture conditions, feeding strategy and related techniques are optimized to obtain a glutathione-enriched efficient dough yeast product. The method provided by the invention can effectively solve the problems of low glutathione content and poor improvement effect on the dough in the common dried yeast, and the problems of high cost, high oxidation tendency and the like when independently adding glutathione to improve the dough, thereby enhancing the added value of the product.

Owner:HUBEI UNIV OF TECH

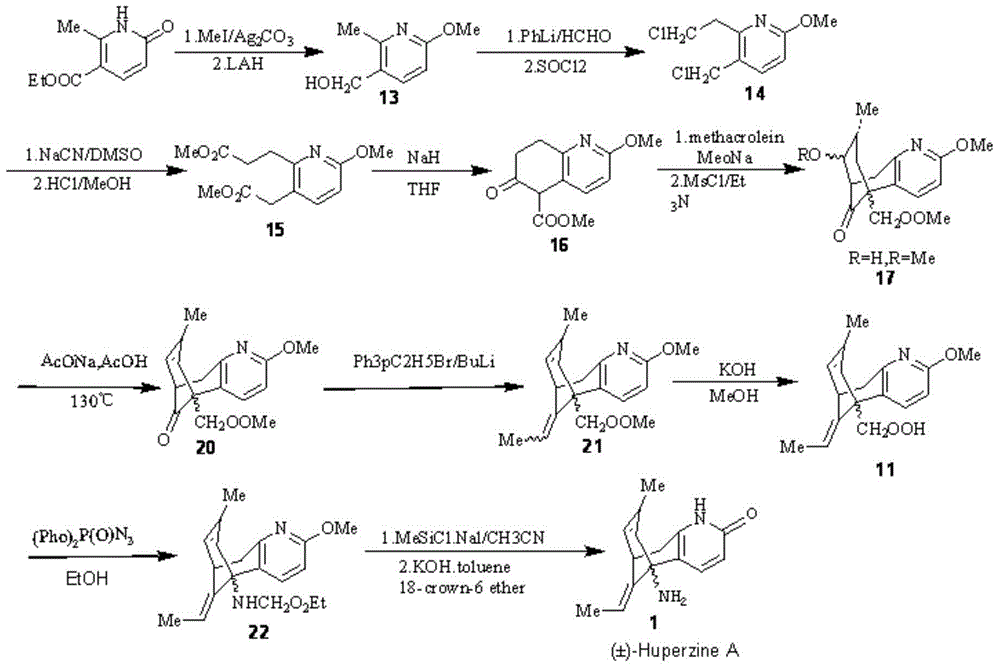

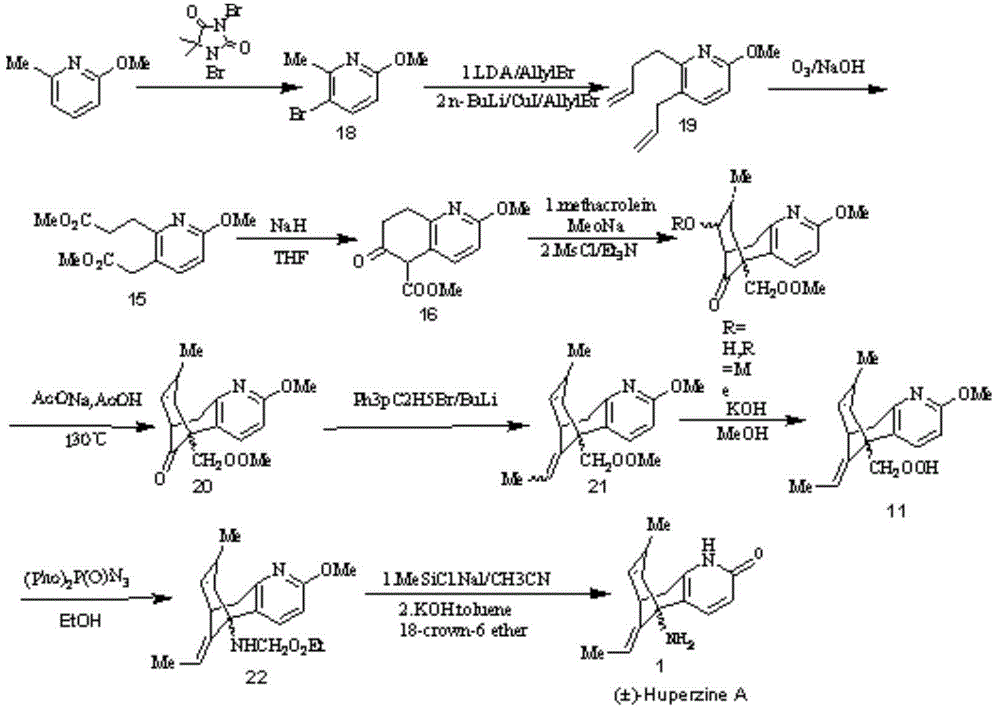

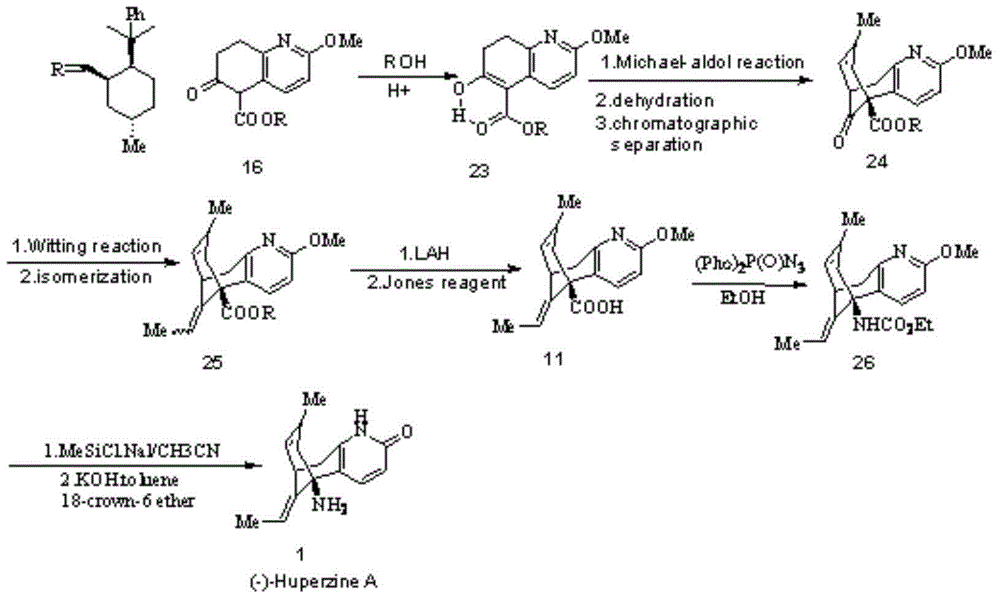

Reversible acetylcholinesterase inhibitor huperzine-A synthesis method

InactiveCN105399672AHigh ee valueLow costOrganic chemistryCholinesterase inhibitionSynthesis methods

The present invention discloses a reversible acetylcholinesterase inhibitor huperzine-A synthesis method, wherein the route is defined in the specification. The method of the present invention has advantages of easily-available raw materials, simple operation, high yield, low cost, high purity of the final product, easy quality control and the like, and is suitable for industrial production.

Owner:SHANGHAI HONGJING BIOTECH CO LTD

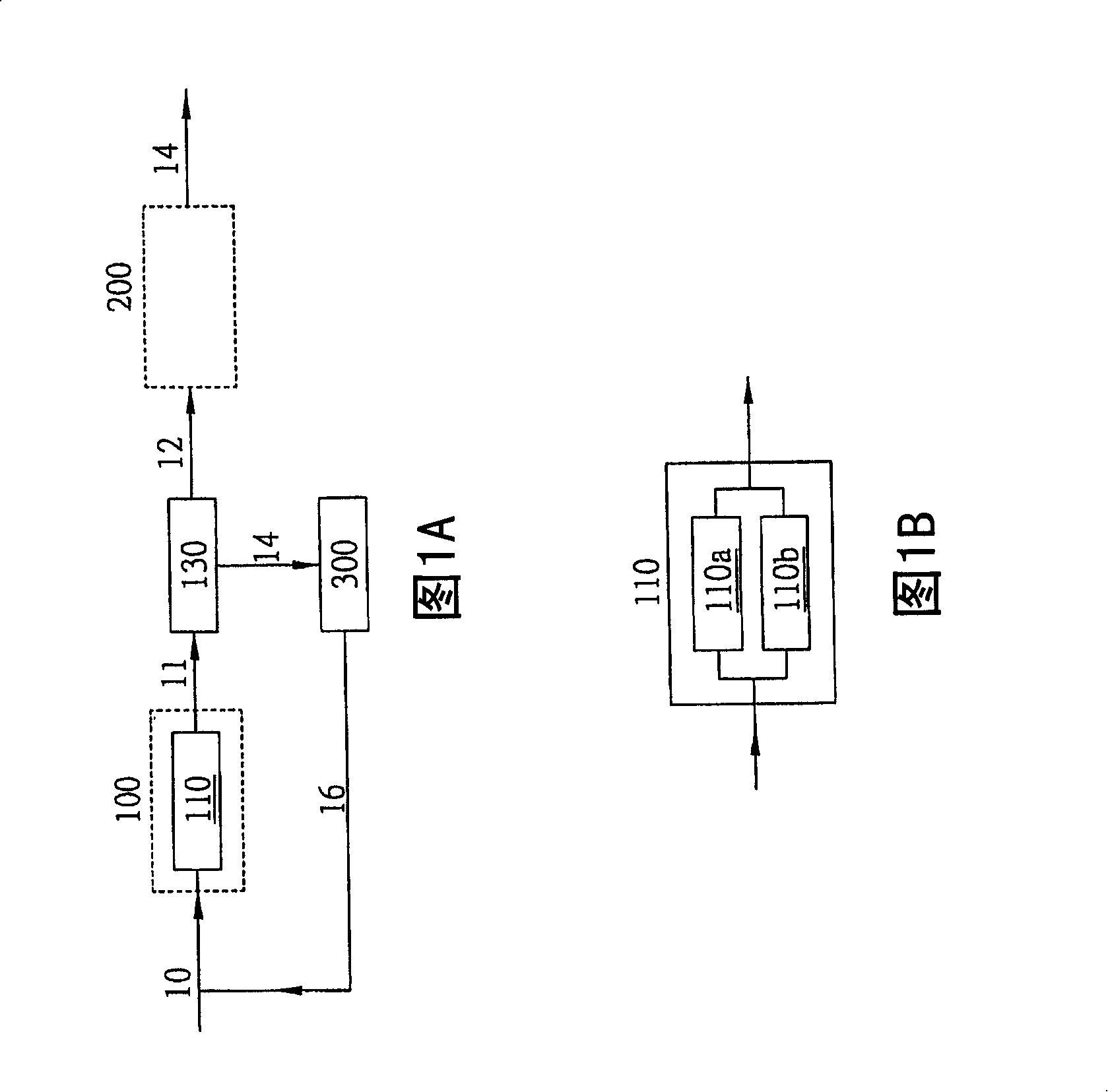

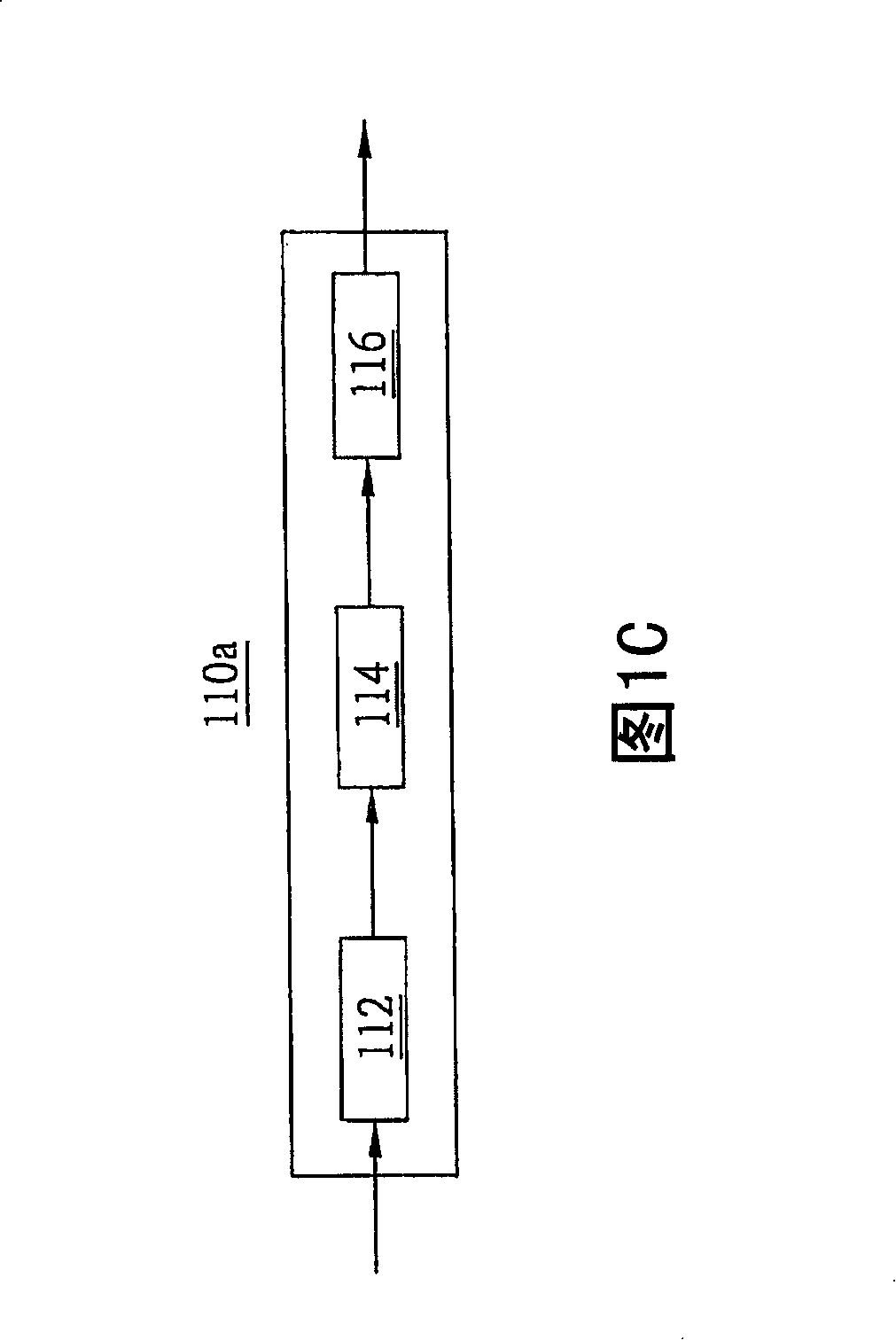

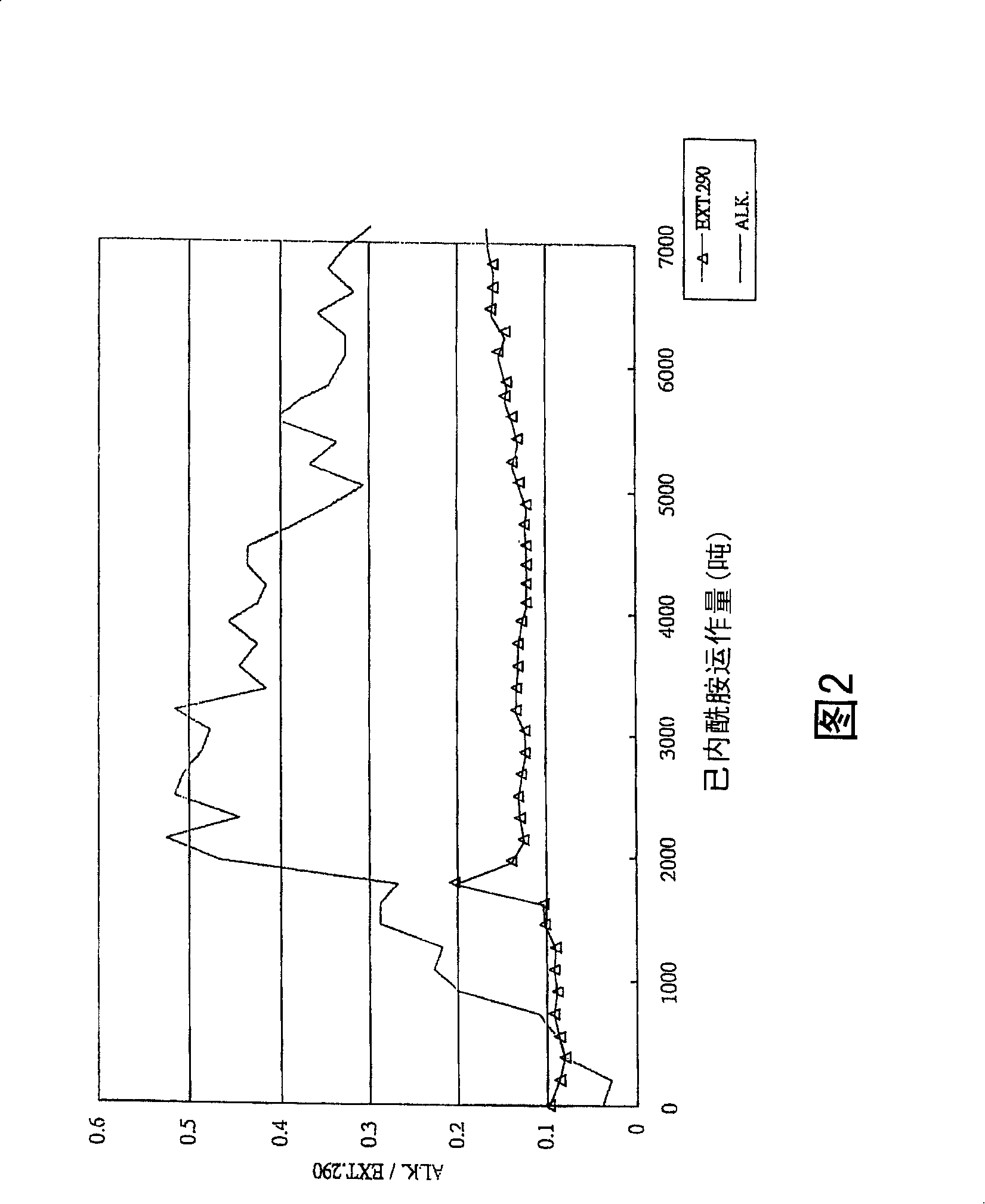

System and method for purifying crude caprolactam water solution

ActiveCN101190893AExtend effective operating timeReduce generationOther chemical processesLactams separation/purificationIonChemistry

The invention relates to a system and a method of purifying crude caprolactam solution. The system comprises (A) a filtering area, in which resin is utilized to filter out ionic impurities, (B) a detecting unit used for judging whether the solution filtered by the resin conforms to preset detecting standard, (C) a purifying area used for concentrating the solution that is filtered and conforms to preset detecting standard and (D) a first temporary storage device used for receiving and storing the solution that is filtered and is unqualified for preset detecting standard and also used for mixing solution therein with unfiltered crude caprolactam solution and leading the mixture to the filtering area once again. Continuous filtering is available to the system, thereby reducing operation changing frequency of the resin, having no final unqualified caprolactam and prolonging effective operation period of the resin device for filtering out ionic impurity; the system has the advantage of saving material and reducing waste.

Owner:CHINA PETROCHEM DEVMENT

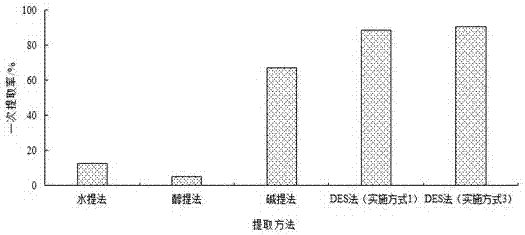

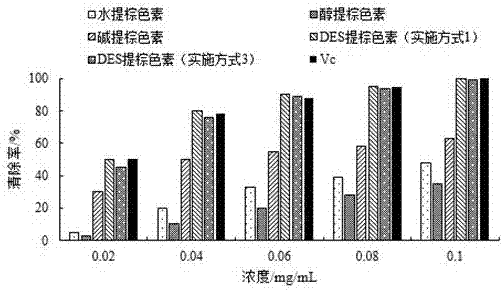

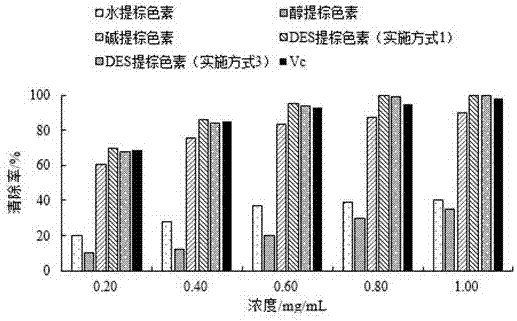

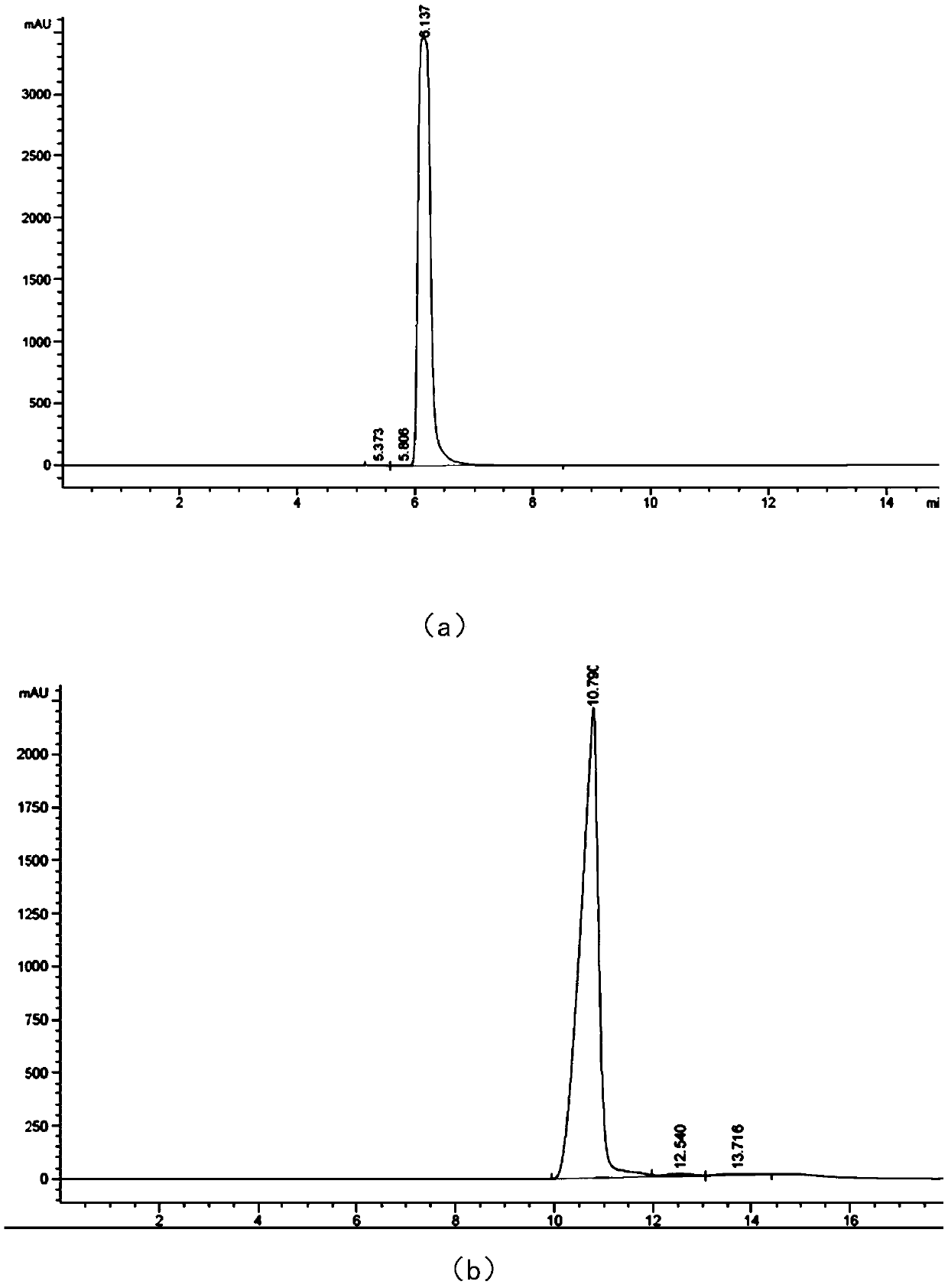

Method for extracting brown pigment from plant

ActiveCN107383930ARaw materials are cheap and easy to getReduce extraction timeNatural dyesFiltration membraneDesorption

The invention relates to the field of edible pigment and discloses a method for extracting brown pigment from a plant. The method comprises the following steps: pulverizing the plant containing the brown pigment and extracting brown pigment extracting liquid by using deep-eutectic solvent extracting liquid; adding mixed liquid of petroleum ether and ethyl acetate into the extracting liquid to remove fat, and adding an attapulgite loaded chitosan crosslinked cyclodextrin compound into the defatted extracting liquid to obtain a brown pigment compound precipitate adsorbed on the attapulgite loaded chitosan crosslinked cyclodextrin compound; dissolving the precipitate in an organic solvent to perform desorption and centrifugation to obtain brown pigment supernatant containing the organic solvent; enabling the supernatant to pass through a microporous filtration membrane to obtain a purified brown pigment solution containing the organic solvent; and removing the organic solvent from the brown pigment solution to obtain a target product brown pigment. The deep-eutectic solvent serves as an extracting solvent, so the method is green and environment-friendly, and the extraction rate is high; and the brown pigment is purified and separated by the attapulgite loaded chitosan crosslinked cyclodextrin compound, so the process is simple and the purification and separation efficiency is high.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Preparation method and application of coix seed extract

InactiveCN109170532AInhibit blood sugar riseImprove starch removal rate and degreasing rateOther chemical processesCombustible gas purificationIonic strengthEmulsion

The invention relates to a preparation method of a coix seed extract. The method comprises the steps as follows: S1, drying and crushing coix seeds to obtain coix seed flour; S2, removing starch and fat in the coix seed flour through acid treatment and addition of a degreasing agent; S3, performing dynamic superhigh-pressure microfluidization treatment on coix seed pulp to promote dissolution extraction of polysaccharide and protein in the coix seed pulp; S4, adjusting the mass concentration of the coix seed pulp, adding an ionic strength regulator to regulate the ionic strength of the coix seed pulp, and adjusting the pH of the coix seed pulp; S5, adding an organic polymer adsorbent to the coix seed pulp to adsorb protein and polysaccharide agglomerates; S6, performing standing and filtration, collecting a filtered-out organic polymer adsorbent, and sequentially eluting polysaccharide and protein; and S7, removing starch and grease again through low-temperature settlement and centrifugal degreasing to finally prepare a coix seed emulsion containing polysaccharide and protein. The prepared coix seed emulsion is compounded into instant compound coix seed flour.

Owner:福建拓天生物科技有限公司

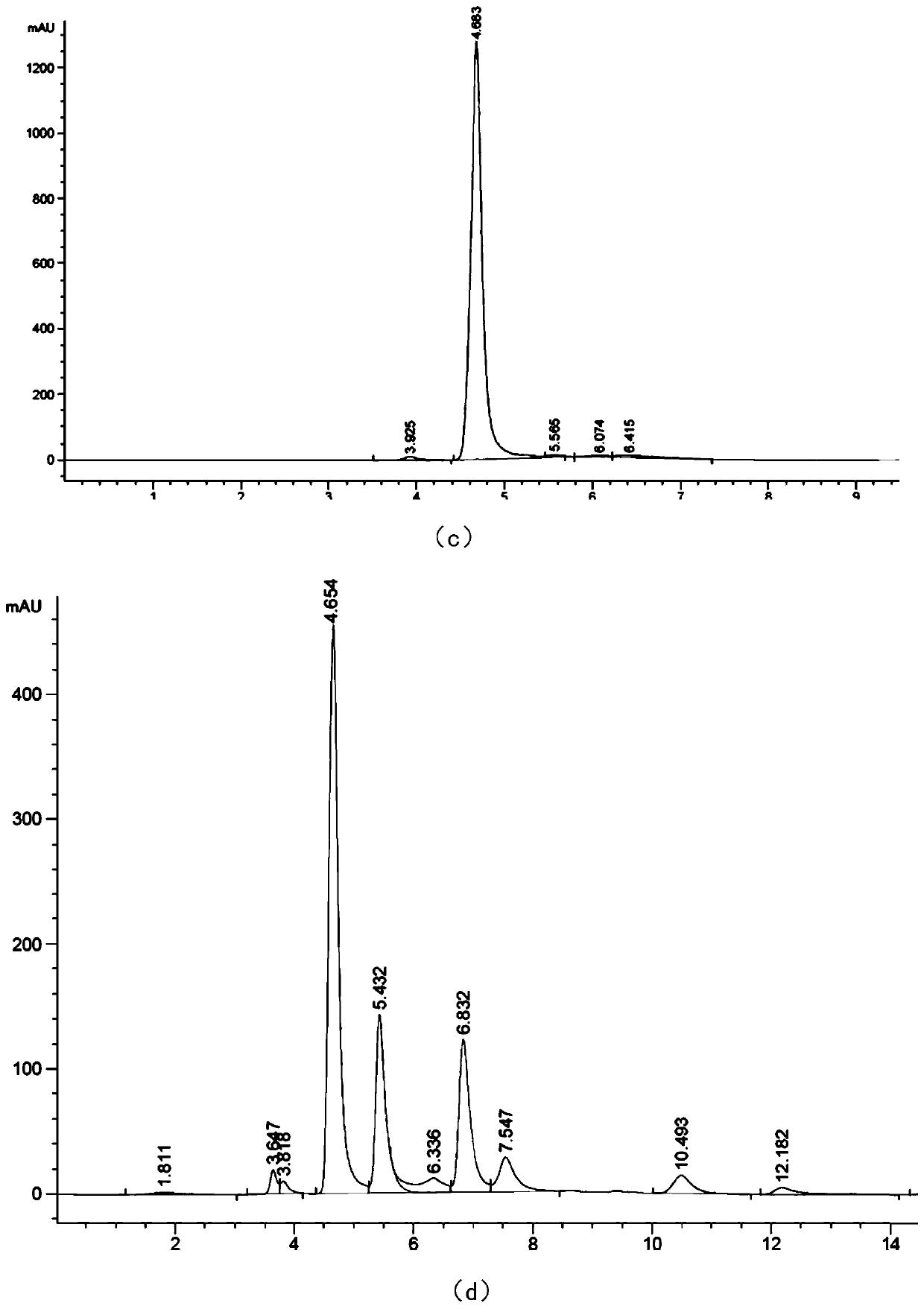

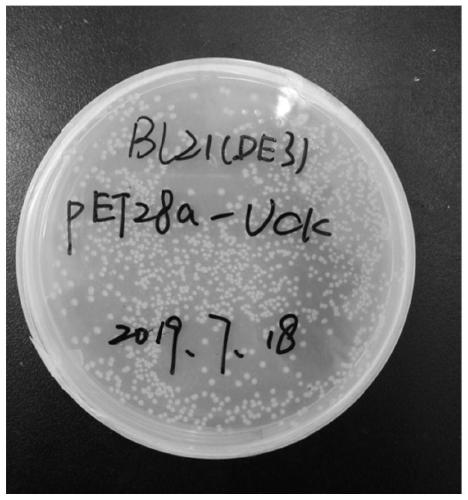

Recombinant escherichia coli for high yield of cytidine monophosphate and application of recombinant escherichia coli

PendingCN111269870AMeet the requirements of large-scale industrial productionReduce purificationBacteriaTransferasesEscherichia coliEnzyme Gene

The invention discloses recombinant escherichia coli for high yield of cytidine monophosphate and application of the recombinant escherichia coli. According to the invention, cytidine kinase gene is obtained by cloning from a cytidine monophosphate production strain; crude enzyme liquid obtained by crushing recombinant bacteria has good catalytic activity and stability; cytidine, adenosine triphosphate (ATP) and Mg < 2 + > are added, the reaction system is simple, the conditions are mild, the period is short, byproducts are fewew, the method is clean and free of pollution, the application is asimple, rapid and efficient production way, and the conversion rate of substrate cytidine and ATP reaches 85% or above.

Owner:NANJING UNIV OF TECH

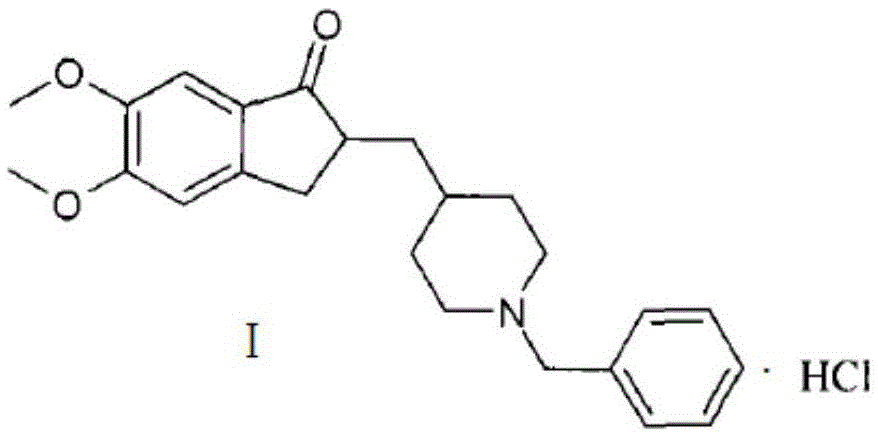

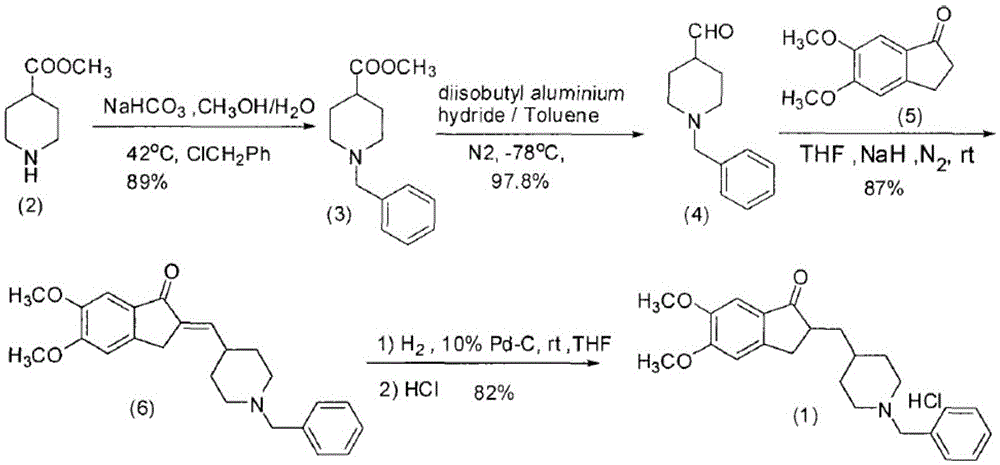

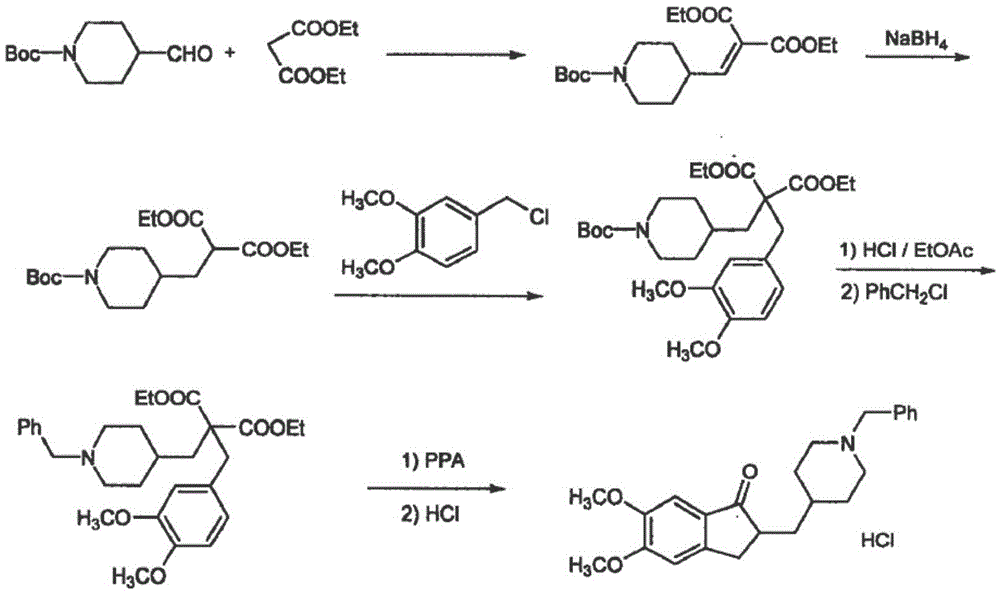

Preparation method of donepezil hydrochloride

ActiveCN105418488AReduce purificationStarting materials are readily availableOrganic chemistryKetoneIonic liquid

The invention discloses a preparation method of donepezil hydrochloride. The preparation method comprises the steps that 3-chlorine-1-(3, 4-dimethoxy phenyl) propane-1-ketone (II) is made to react with N-benzyl-4-formyl-piperidine (III) under the condition of a lewis acid ionic liquid catalyst, and 1-benzyl-4-(5, 6dimethoxy-1-indanone-2-methylene)-piperidine (IV) is obtained through a one-pot method, and then the donepezil hydrochloride (I) is obtained through reduction and salt formation. The preparation method of the donepezil hydrochloride has the advantages of being simple in process, low in production cost, environmentally friendly and suitable for industrialized production.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD

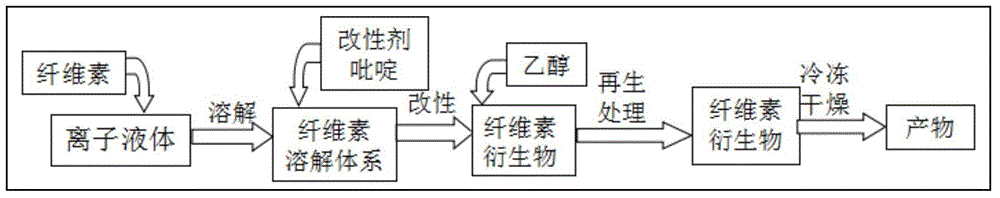

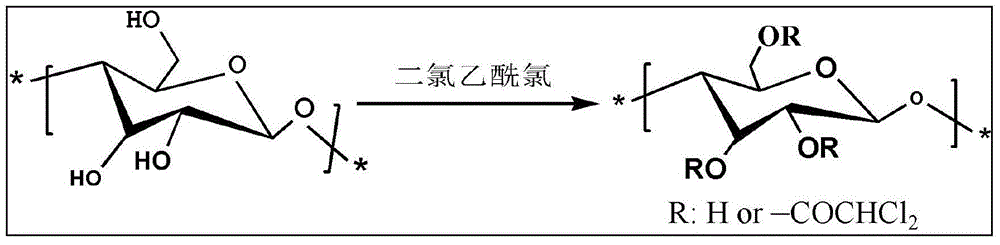

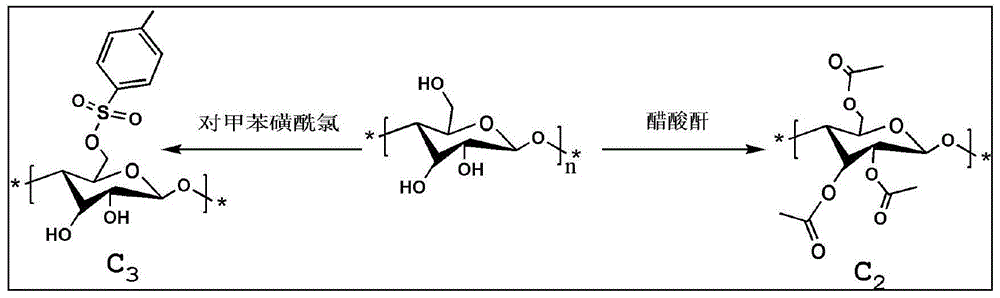

Method for preparing water-soluble cellulose and water-soluble cellulose prepared by the same

The present invention provides a method for preparing water-soluble cellulose. The method uses linter pulp board as a raw material, which is dissolved by an ionic liquid, and then supplemented with a modifier and a catalyst for chemical modification, so as to prepare a water-soluble cellulose derivative. The water-soluble cellulose derivative prepared by the method has the advantages of good solubility and high degree of polymerization, and has broad application prospects in medical engineering, food industry and cellulosic functional materials. The preparation method is simple and convenient for operation, has easily controlled process conditions, greatly simplifies the production process and reduces costs; and the method for the first time reports water-soluble cellulose preparation based on the ionic liquid dissolving system.

Owner:BEIJING FORESTRY UNIVERSITY

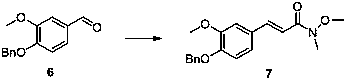

Paradol synthesis method

ActiveCN110937985AHigh purityRaw materials are easy to getPreparation by organometalhalide reactionOrganic compound preparationParadolNatural product

The invention discloses a complete synthesis method of a natural product paradol, the route being represented as the specification. The method employs feasible raw materials and simple operation, is high in yield and low in cost, is high in final product purity, is controllable in quality, and is suitable for industrial production.

Owner:许昌远志生物科技有限公司

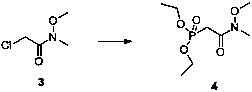

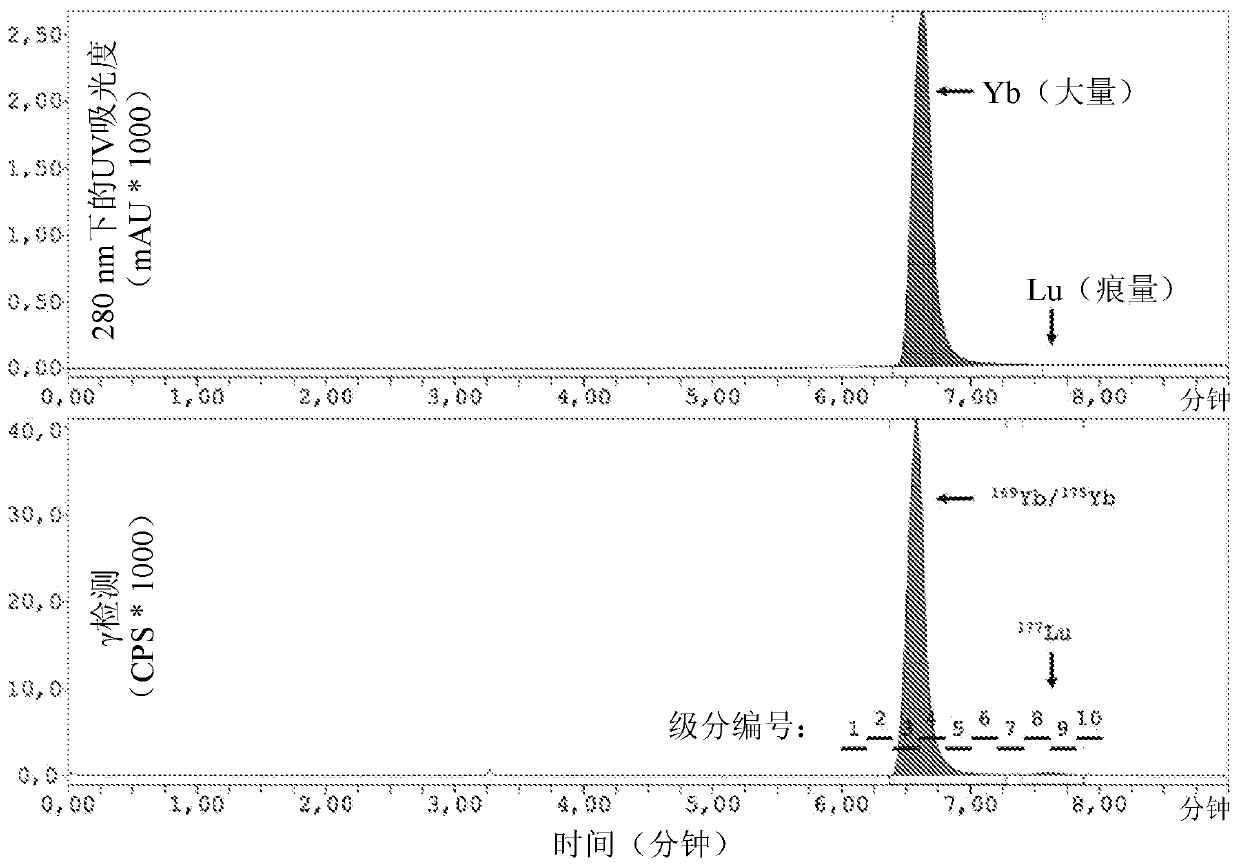

Compounds for separation of rare earth elements and s-, p-, d- metals, method of separation, and use thereof

ActiveCN111511728AEasy transferAvoid pollutionIon-exchange process apparatusOrganic chemistryRare-earth elementChromatographic separation

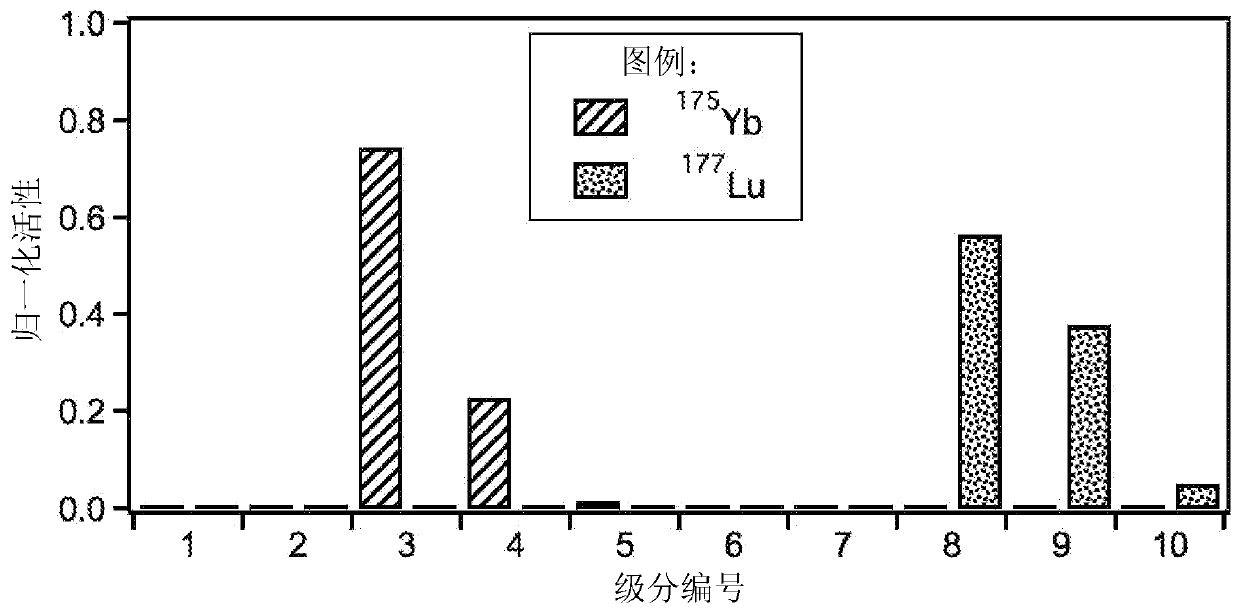

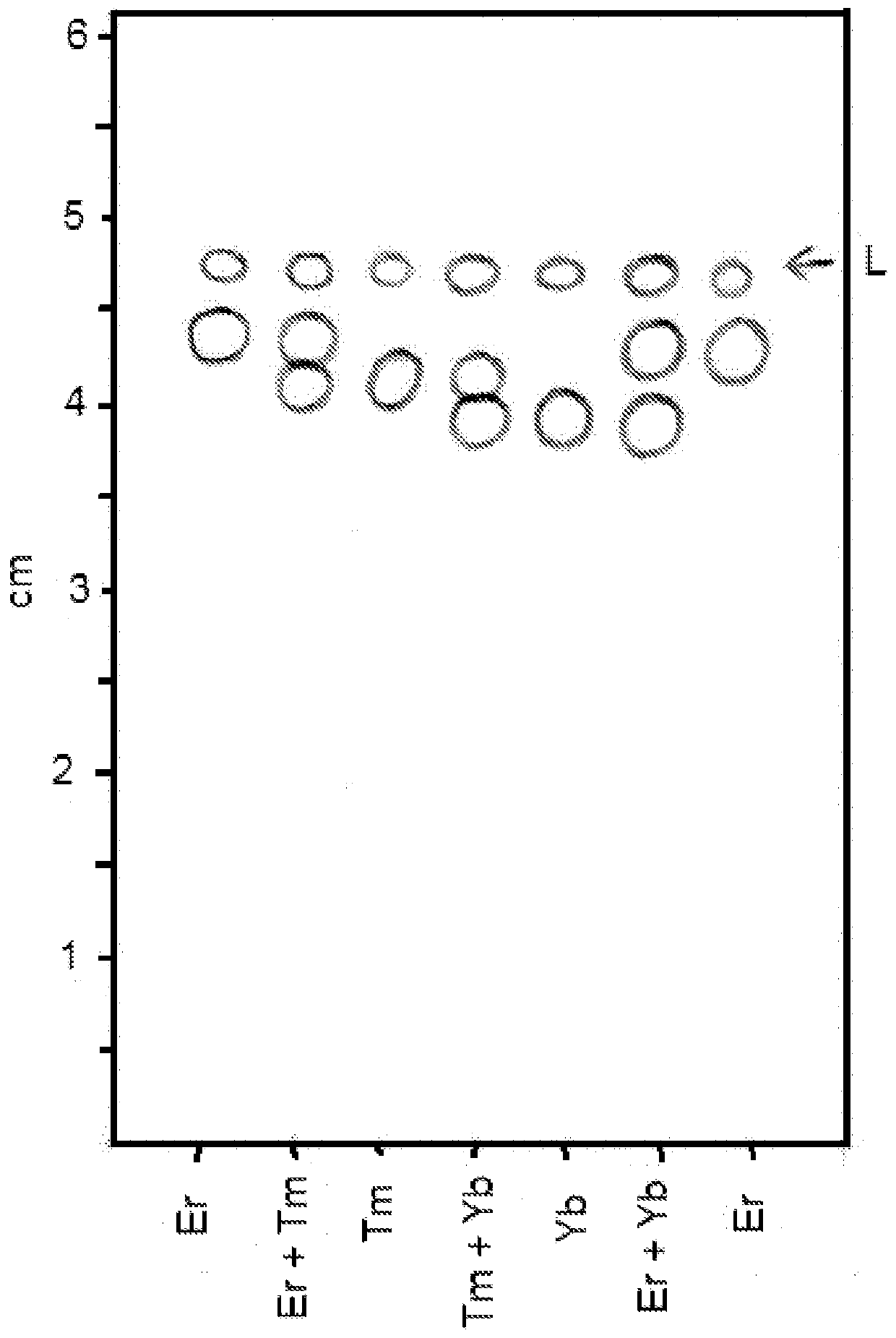

The present invention relates to compounds of general formula (I) for chromatographic separation of rare earth elements and / or s-, p-, d- metals, as well as to the method of the separation of rare earth elements.

Owner:有机生物化学公司

Synthetic method of PHBA

The invention discloses a synthetic method of PHBA, and belongs to the technical field of pharmaceutical synthesis. According to the method, L-glutamic acid is taken as the raw material, and is subjected to diazotization, hydrolysis, aminolysis and Hoffman degradation to obtain (S)-4-amino-2-hydroxybutyrate which is not purified and used directly for synthesizing (S)-alpha-hydroxyl-gamma-N-phthaloylaminobutyric acid. The synthetic method solves the problems that the conventional method is cumbersome in operation, high in energy consumption and serious in environmental pollution due to the fact that ion exchange resin is required to be used repeatedly for separation and purification of a product, steps of reactions are organically combined, the whole process is considered, and numerous distillation and purification processes are omitted, so that the whole process is greatly simplified, the total yield of the product is larger than 60%, the content of the product is larger than 99.0%, the optical purity is higher than 99.0%, the quality is stable, reaction conditions are mild, pollution of the three wastes is little, the preparation cost is low, and the method is suitable for industrial preparation of (S)-alpha-hydroxyl-gamma-N-phthaloylaminobutyric acid.

Owner:CHENGDU LIKAI CHIRAL TECH +1

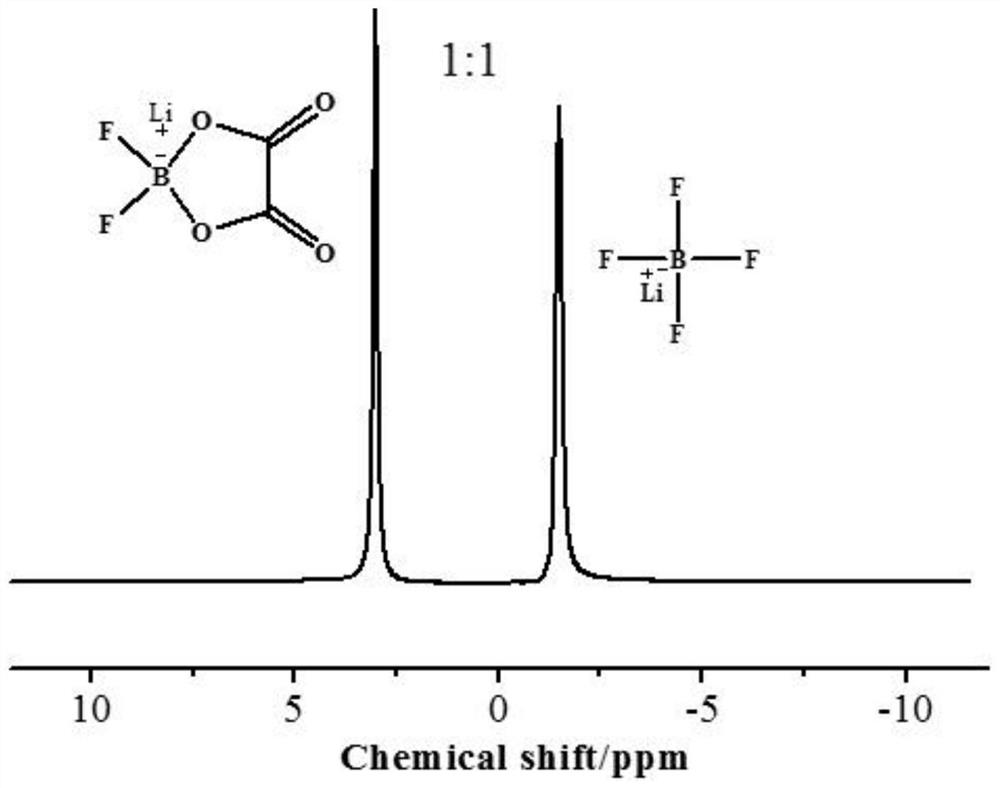

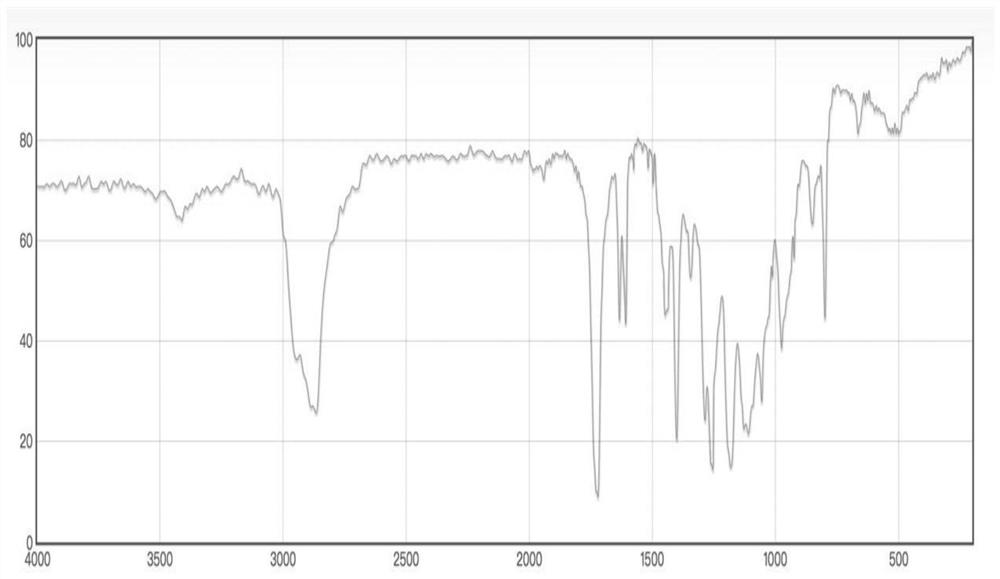

Method for purifying lithium difluoroborate and lithium tetrafluoroborate mixed lithium salt and application thereof

PendingCN112625055AEasy to separateReduce purificationSecondary cellsGroup 3/13 element organic compoundsElectrolytic agentOxalate

The invention belongs to the technical field of lithium ion battery manufacturing, and discloses a method for purifying lithium difluoroborate and lithium tetrafluoroborate mixed lithium salt and application thereof. According to the preparation method of the high-purity mixed lithium salt with different proportions, industrial-grade lithium oxalate is used as a raw material, the mixed lithium salt with different molar proportions of lithium difluoroborate and lithium tetrafluoroborate is prepared through the processes of synthesis, concentration, auxiliary purification filter membrane purification and the like, and the mixed lithium salt can adapt to various electrolyte formulas, is used for manufacturing lithium ion batteries, and the production cost is reduced; meanwhile, the method provided by the invention avoids the tedious process of recrystallization and the solid-liquid separation operation after crystallization in the prior art, can improve the yield and purity of the product, and simplifies the technological process.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Space length adjustable crystal gel and method for preparing same

The interval adjustable crystal colloid and its preparing method relate to an interval adjustable crystal colloid and its preparing method, whose spectrum spectrum can be 20-900nm. Concretely, the preparing method is: place the spheroidal particle whose diameter is 80-250nm into the water with high pressure for dialysis, and renew the water at least for ten minutes in each dialysis until the electric conductivity is 0.1-10ª–s / cm through the supersonic wave, the colloid (dispersed) being colloid (dispersed) is diluted by monomer solution of neutral hydrogel polymer (including ultraviolet light (acrylamide monomer and as the cross linker) ), in which the initiator of ultraviolet light (acrylamide monomer and as the cross linker) is added into the deprivate O2 and CO2, the crystal colloid is generated by ultraviolet light (acrylamide monomer and as the cross linker) raying.

Owner:SOUTHEAST UNIV

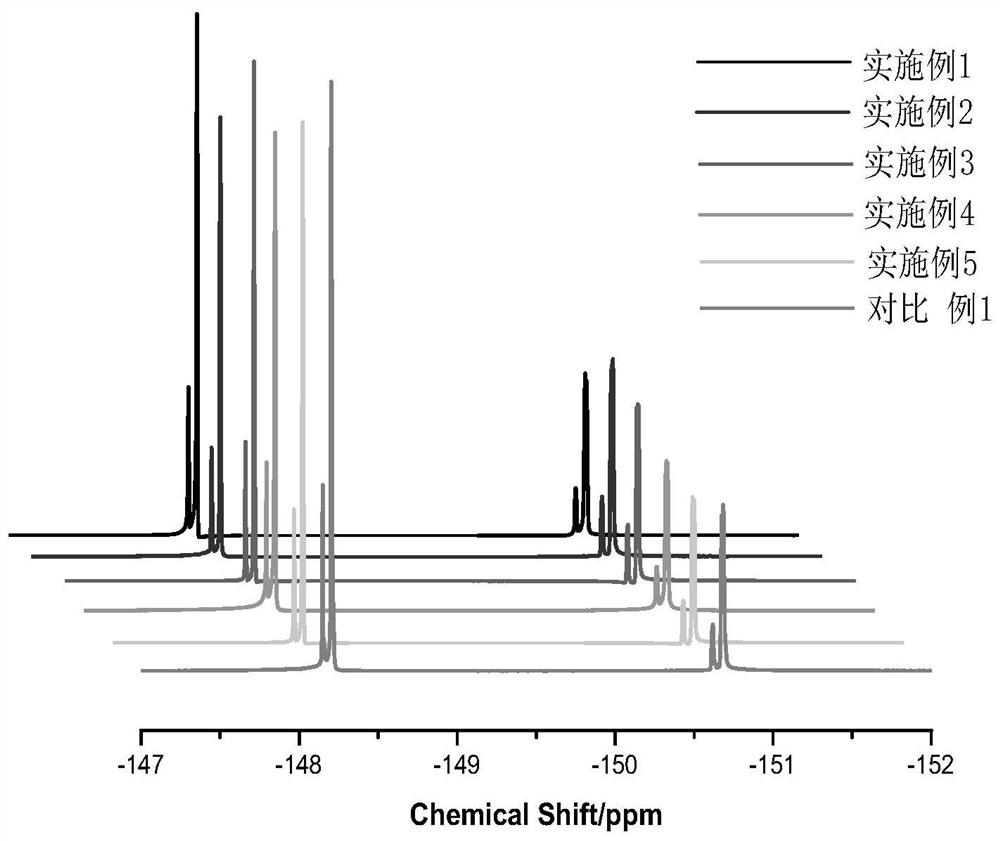

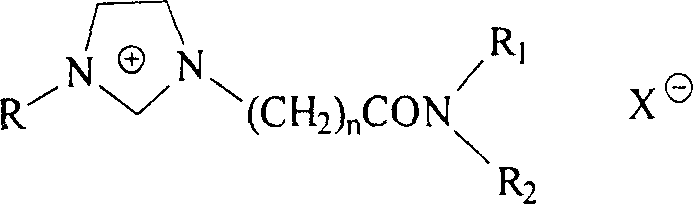

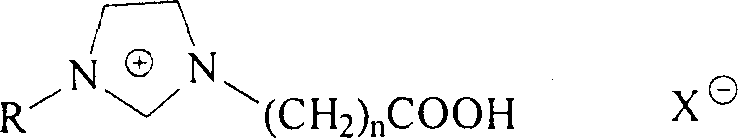

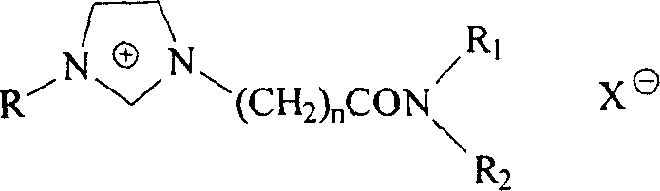

Imidazole type functional ion liquid having N-substituted amide structure fragment, and its prepn. method

This invention provides functional ion liquid of a imidazole type with N-amido- structural segment, the structure is shown as the formula: it is characterized by : when nú¢2 or 3ú¼Rú¢alkyl with straight or branched chain of C1-C12ú”R1R2ú¢Híóstraight alkyl of C1-C12íóbranched alkyl of C1-C12íó -(CH2)m- or -(CH2CH2)2-Oú¼mú¢4-5ú” Xú¢ClíóBF4íóPF6íóCF3SO3(TfO)íóCF3COO(TA),N(CF3SO2)2(NTf2) or NO3íúThe characteristics and innovation of this invent are: 1. preparing functional ion liquid of an Imidazole type with N-amido- structural segment, enriching variety of ion liquid. 2. Providing a preparation method of one familiar functional ion liquid from another one familiar functional ion liquid through ion phase reaction. 3. This invention has the characteristics of broad source of raw material for reaction, low cost, simple equipment , convenient operation, mild reaction condition, easy controlled condition, good quality of the products, high purity, high yield etc., it is suitable for commercial production and application.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

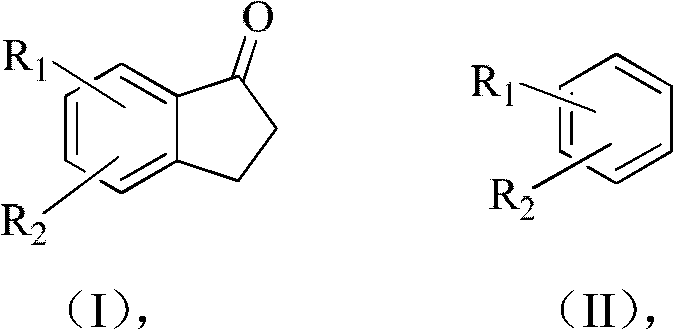

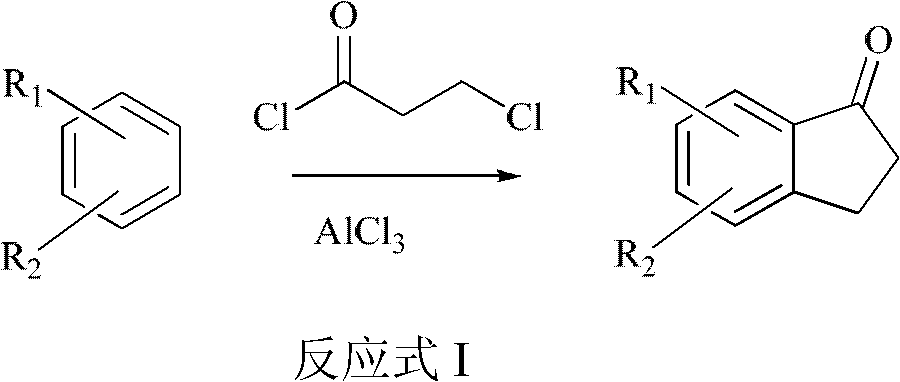

A method for preparing 2,3-dihydro-1-indanone and derivatives thereof

ActiveCN103012086BLow costReduce investmentCarbonyl group formation/introductionCarbonyl compound preparation by condensationHalogenHydrogen

Owner:JIANGXI ALPHA HI TECH PHARMA

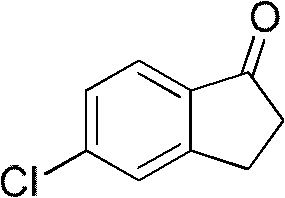

Process for producing ammonium sulfate and hydrogen chloride by employing ammonium chloride and sulfuric acid

InactiveCN103130247ALess equipmentHigh energy consumptionAmmonium sulfatesPreparation from chloridesMother liquorHydrogen chloride

The invention relates to a process for producing ammonium sulfate and hydrogen chloride. The process specifically comprises the following steps: 1, premixing ammonium chloride and sulfuric acid at normal pressure; 2, pumping the obtained sulfuric acid solution of ammonium chloride in step 1 into a tubular reactor, and obtaining ammonium bisulfate and hydrogen chloride gas; and 3, preparing the ammonium bisulfate obtained in step 2 into an aqueous solution, and carrying out an ammonolysis reaction to obtain ammonium sulfate through an ammoniation tower. The ammonium sulfate is prepared by utilizing ammonium chloride, the tubular reactor and the ammoniation tower reactor are mainly selected, a positive pressure reaction is adopted, the reaction conversion rate is improved, the production steps are simplified, the target product yield is improved, and the large-scale continuous production requirements are met; meanwhile, the reaction links are organically combined, the reaction is finished, the generated concentrated sulfuric acid, crystallization mother liquor and the like in the production process are utilized, and the effluent discharge amount is small in the whole production process; and moreover, the ammonium chloride deep-processing problem is effectively solved, and a novel method for producing ammonium sulfate by utilizing high-additional value ammonium chloride is developed.

Owner:BEIJING EDGEIN TECH +2

Process for producing lotus seed spirit

ActiveCN101831371BIncrease ethyl caproate contentStrong fragranceAlcoholic beverage preparationBiotechnologyYeast

The invention relates to a process for producing lotus seed spirit. The process comprises the following steps of: selecting and crushing lotus seeds, moistening and stewing the crushed lotus seeds at the high temperature, adding water into the lotus seeds, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into a cylinder to perform large dreg fermentation, discharging fermented grains from the cylinder, distilling the lotus seeds to obtain first dreg spirit and rest secondary dreg yeast, and adding a stirring material into the secondary dreg yeast in a ratio of 1: 0.4-0.6, wherein the stirring material is prepared after the lotus seeds are selected, crushed, moistened at the high temperature and stewed; adding water into the lotus seeds again, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into the cylinder to perform secondary dreg fermentation, discharging the fermented grains from the cylinder, and distilling the lotus seeds to obtain secondary dreg spirit or rest third dreg yeast; adding water into the lotus seeds again, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into the cylinder to perform third dreg fermentation, discharging the fermented grains from the cylinder, and distilling the lotus seeds to obtain third dreg spirit; and blending the first dreg spirit and the second dreg spirit, or blending the first dreg spirit, the second dreg spirit and the third dreg spirit, and putting the blended spirit into storage and ageing the spirit. Therefore, the process can effectively control the acidity during fermentation, reasonably increase the activity of enzyme, reduce purification, effectively inhibit impurity bacteria, improve the content of ethyl acetate and ethyl caproate in the spirit, reduce the methanol in the spirit, enrich the mouthfeel, and keep the fragrance of the sprit thick.

Owner:浙江硒莲液富硒科技有限公司

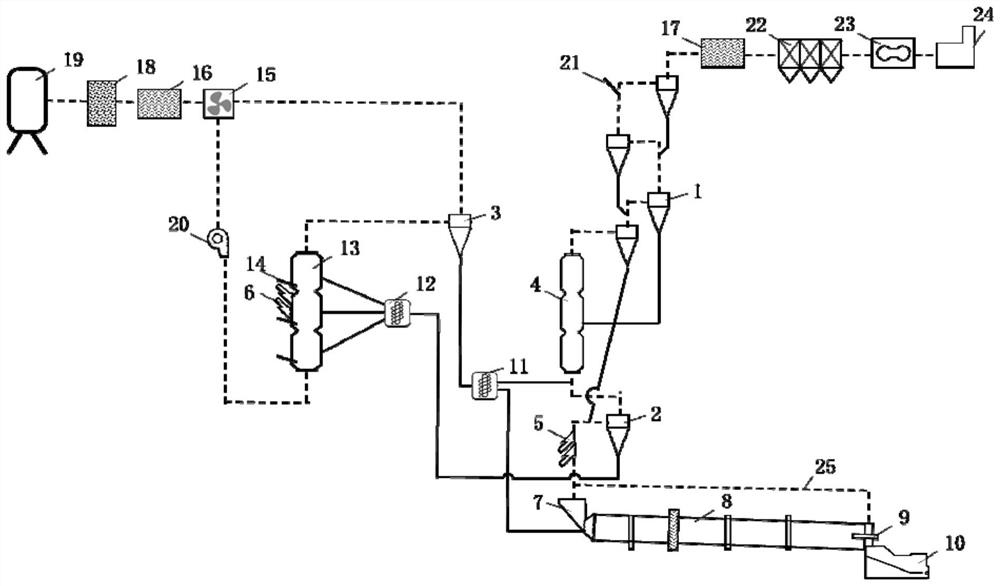

Local calcium circulation and pure oxygen combustion coupling carbon capture device and process for cement production

ActiveCN113509834AReduce captureReduce difficulty of useProductsGas treatmentDust controlCarbonization

The invention discloses a local calcium circulation and pure oxygen combustion coupling carbon capture device and process for cement production, and the device comprises a preheater-carbonization furnace-rotary kiln module, a pure oxygen combustion decomposing furnace module and an auxiliary and purification device. The preheater-carbonization furnace-rotary kiln module comprises a raw material feeding device, a first-series cyclone preheater, a carbonization furnace, a second-series cyclone preheater, a smoke chamber, a rotary kiln, a tertiary air pipe, a rotary kiln combustor and a cooling machine. The pure oxygen combustion decomposing furnace module comprises a decomposing furnace, a decomposing furnace combustor, a third-series cyclone preheater and a booster fan. The auxiliary and purification device comprises a first SNCR (Selective Non Catalytic Reduction) device, a second SNCR device, an air distribution device, a first material distribution device, a second material distribution device, a first heat exchange device, a second heat exchange device, a condensation and water removal device, a CO2 collection and storage device, a dust removal device, an SCR (Selective Catalytic Reduction) device and a flue gas exhaust device. Through modular separation and coupling, the CO2 capture and utilization difficulty is reduced, and good economical efficiency is achieved.

Owner:SOUTH CHINA UNIV OF TECH

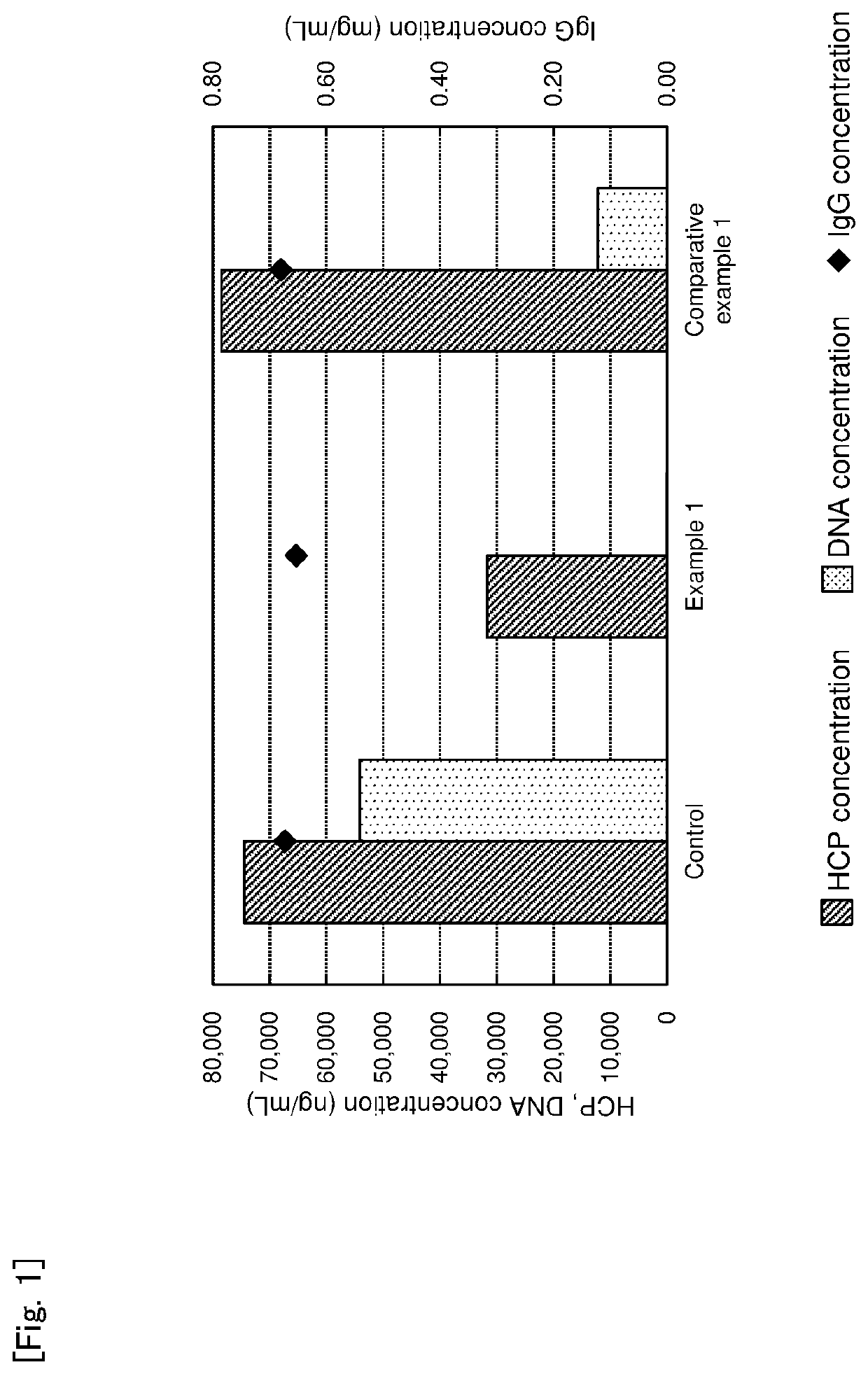

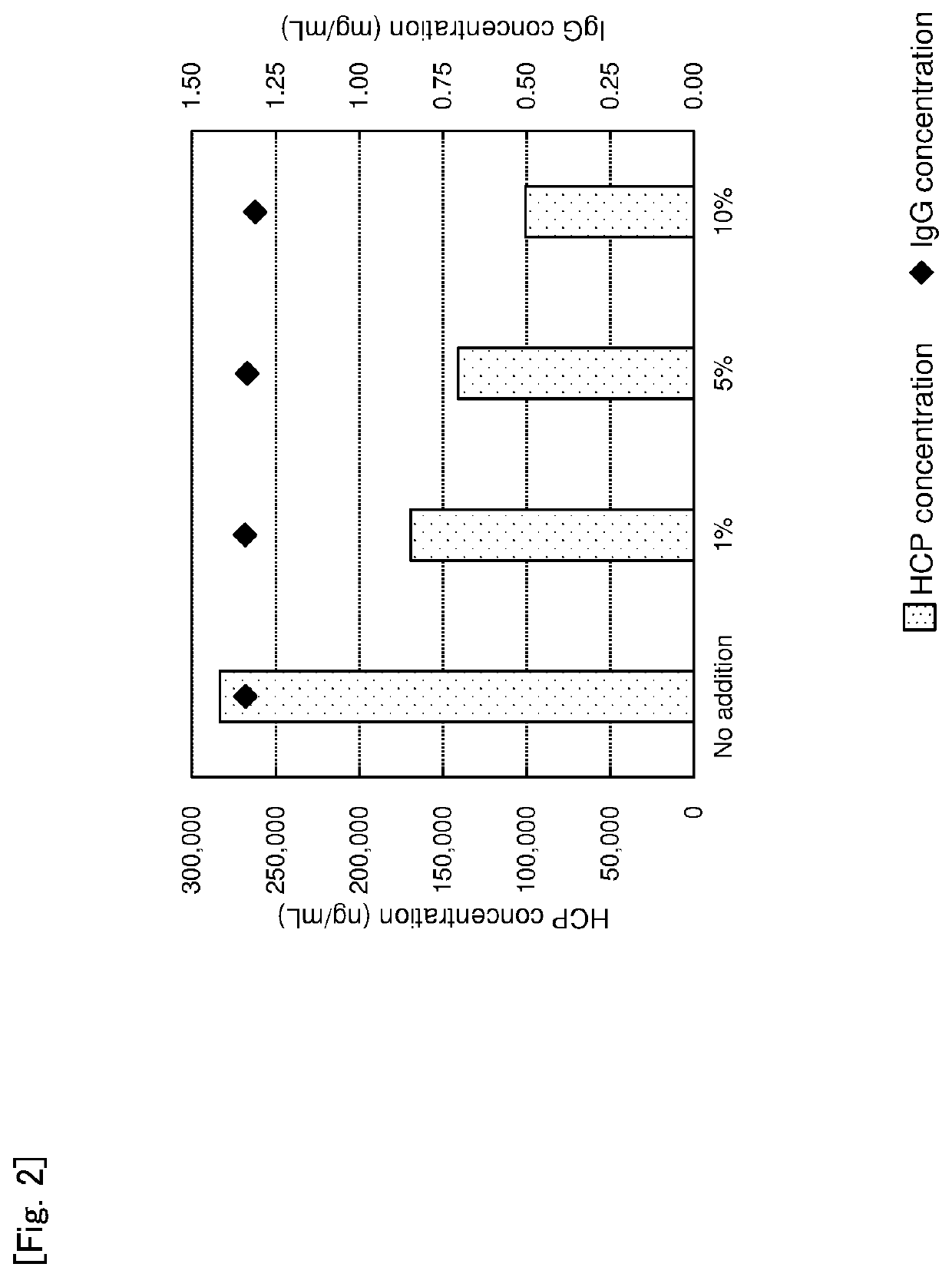

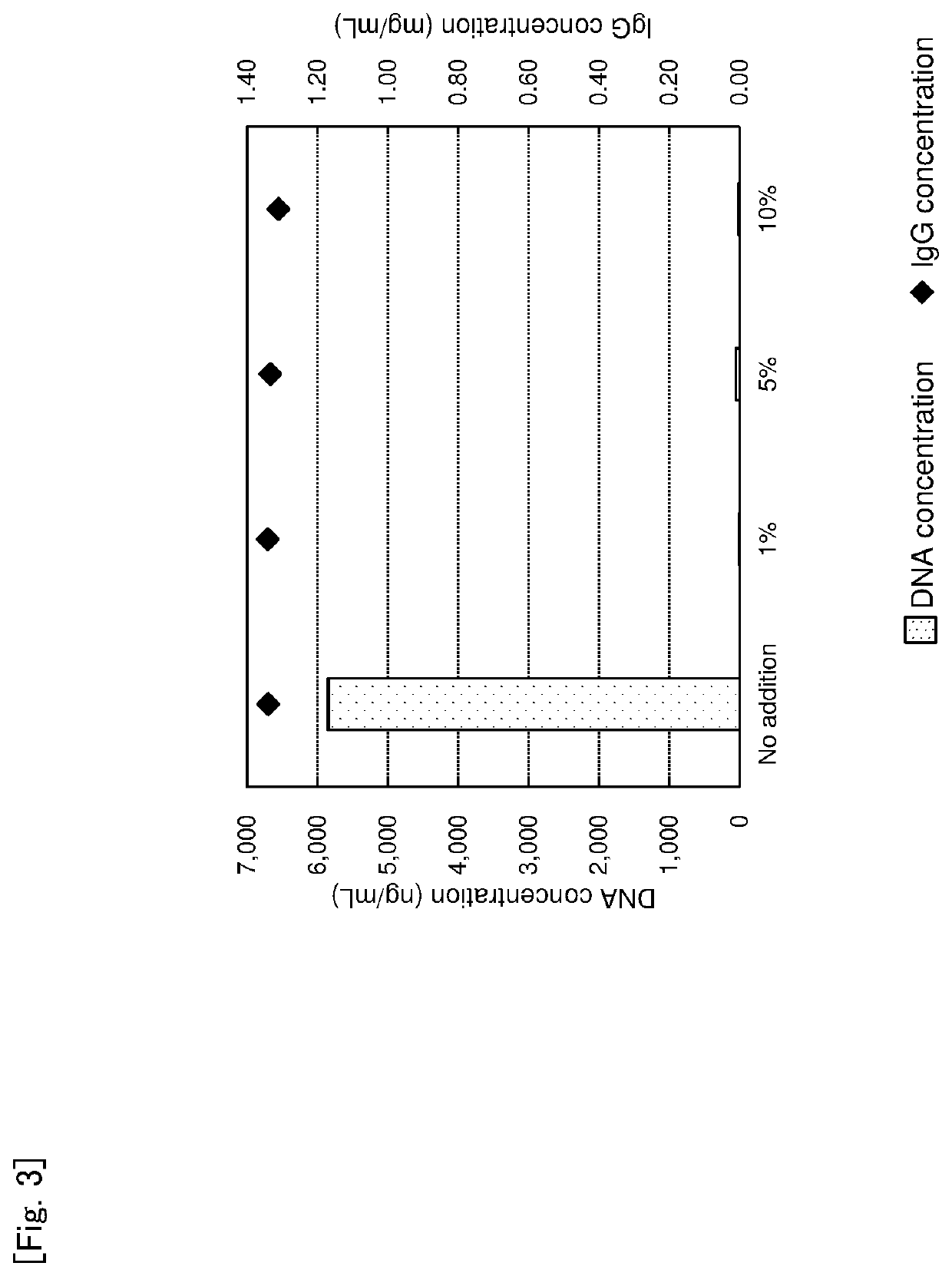

Method for purifying antibody or antibody-like molecule

PendingUS20210198309A1Efficient removalReduce purificationHydrolasesPeptide preparation methodsChemical compoundCombinatorial chemistry

The objective of the present invention is to provide a method capable of efficiently removing an impurity from an aqueous solution or a suspension comprising an antibody or an antibody-like molecule and the impurity. The method for purifying an antibody or an antibody-like molecule according to the present invention is characterized in treating an aqueous solution or a suspension comprising the antibody or the antibody-like molecule and an impurity with a water-insoluble inorganic compound, wherein the water-insoluble inorganic compound comprises one or more elements selected from magnesium, calcium and aluminum.

Owner:KANEKA CORP

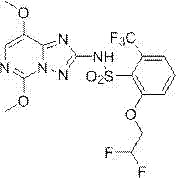

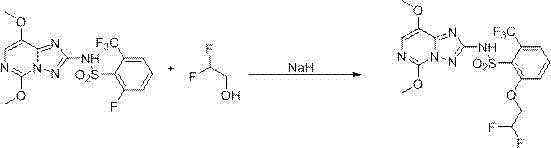

Improved synthetic method of penoxsulam

The invention discloses an improved synthetic method of penoxsulam. The improved synthetic method comprises the following steps: taking a strong-alkalinity substance, difluoroethanol and 2-fluoro-6-trifluoromethyl-N-(5,8-dimethoxy[1,2,4]triazolo[1,5-c]pyridine-2-yl)benzsulfamide (hereinafter to be referred as tetrafluorosulfamide) as raw materials; taking the strong-alkalinity substance and the difluoroethanol to react to prepare a solution A (in the presence of the difluoroethanol) which has relatively weak alkalinity and contains F2CH1CH2O-; adding the tetrafluorosulfamide to prepare the penoxsulam. Therefore, all the raw materials are added in sequence and the temperature of a reaction system is controlled; side reaction can be effectively reduced; the content of impurities is reduced, the purity of a product is improved or a purification step is reduced.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

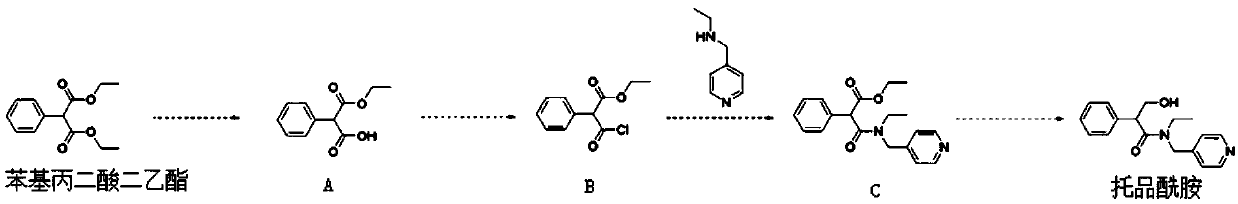

Synthetic method of tropicamide

The invention relates to a production method of chemical medicines and particularly relates to a synthetic method of tropicamide. The synthetic method comprises the steps of carrying out hydrolysis and acylation on the raw material, namely diethyl phenylmalonate, condensing diethyl phenylmalonate with N-ethyl-4-methylpyridine amine, and generating reduction reaction with hydroboron, so as to obtain tropicamide. The synthetic method has the beneficial effects that the raw material cost is low, the properties of an intermediate product are stable, impurities are few, the operation steps such aspurification are reduced, and the process is simplified; reaction conditions are safe and mild, extremely toxic substances are not introduced, and the industrial amplified production is promoted; andby optimizing the raw material ratio, the total yield of the reaction is increased to be 65% and is greatly increased, and the production cost is lowered.

Owner:上海泰坦科技股份有限公司

Meropenem intermediate and preparation method thereof

ActiveCN113929684AShort reaction timeExtended reaction timeOrganic chemistryFormic Acid EstersAzabicyclo Compounds

The invention belongs to the technical field of medicines, and particularly relates to a meropenem intermediate and a preparation method thereof. The meropenem intermediate provided by the invention has a structure as shown in a formula I which is described in the specification. In the formula, R is selected from C1-C6 alkyl groups, optionally substituted phenyl groups or optionally substituted benzyl groups. The preparation method of the meropenem intermediate comprises the following step: mixing an azabicyclo compound, a chloroformate compound, a first organic base and an organic solvent for a reaction to obtain the meropenem intermediate, wherein the azabicyclo compound has a structure as shown in a formula II, the chloroformate compound has a structure as shown in a formula III, and the meropenem intermediate has a structure as shown in the formula I. The meropenem intermediate and the preparation method thereof provided by the invention can effectively overcome the technical defects that in an existing meropenem synthesis process, a phosphorus-containing reagent cannot be recycled, is not friendly to a water body and the ecological environment and pollutes the environment, and solid-liquid waste liquid treatment cost is increased.

Owner:SHENZHEN HAIBIN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com