Recombinant escherichia coli for high yield of cytidine monophosphate and application of recombinant escherichia coli

A technology for recombinant Escherichia coli and Escherichia coli, which is applied in the field of cytidylic acid preparation, can solve the problems of complicated separation operation, corrosion equipment, low yield, etc., and achieve the effects of simplified process, cost saving and mild reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Construction of BL21(DE3)-PET28a-UCK expression strain

[0022] Using the whole genome of Escherichia coli MG1655 as a template, the nucleotide coding sequence of cytidine kinase protein was amplified by conventional PCR.

[0023] The upstream primers used had Nco I restriction site, the sequence is: CATGCCATGGCAatgactgatcagtctcatcagt.

[0024] downstream primers with EcoR I Restriction site, the sequence is CCGGAATTCttaGTGGTGGTGGTGGTGGTGttcaaagaactgacttattttcgct.

[0025] The reaction conditions are: 95°C for 2min, 95°C for 20s, 50°C for 20s, 72°C for 10s, a total of 30 cycles; 72°C for 5min. The obtained sequence was subjected to 1% agarose gel electrophoresis and the corresponding fragments were recovered. The sequence and the expression vector pET28a were used by Takara company Nco I and EcoR I enzyme digestion, enzyme digestion reaction system: 10 × buffer 1 μL, Nco I 1 μL, EcoR I 1 μL, gene fragment or pET28a vector 7 μL. The enzyme digestio...

Embodiment 2

[0027] Example 2 Induced expression of BL21(DE3)-PET28a-UCK and cell disruption

[0028] 1. Induced expression of BL21(DE3)-PET28a-UCK

[0029] The positive strain BL21(DE3)-PET28a-UCK was inoculated into 100 mL LB / KanR liquid medium, and cultured with shaking at 37 °C and 200 rpm until OD 600 ≈1. Inoculate in 500 mL of fresh LB / KanR liquid medium at a ratio of 10:100, culture with shaking at 37°C and 200 rpm until OD600≈0.5~0.7, add IPTG to a final concentration of 0.5‰~1‰, at 20~30 ℃ (eg image 3 As shown, the soluble expression is more between 25~30℃, and 30℃ is the best), shake culture at 200rpm for 13~15h. Centrifuge at 6000rpm for 10min to collect the cells.

[0030] 2. Bacteria fragmentation

[0031] The bacterial cells were resuspended with 100 mM TrisHcl8.0 buffer, and broken up with a high-pressure homogenizer under the conditions of 12000 psi, 4°C, and four cycles. Centrifuge at 6000 rpm for 10 min to collect the supernatant, namely the crude enzyme solution, ...

Embodiment 3

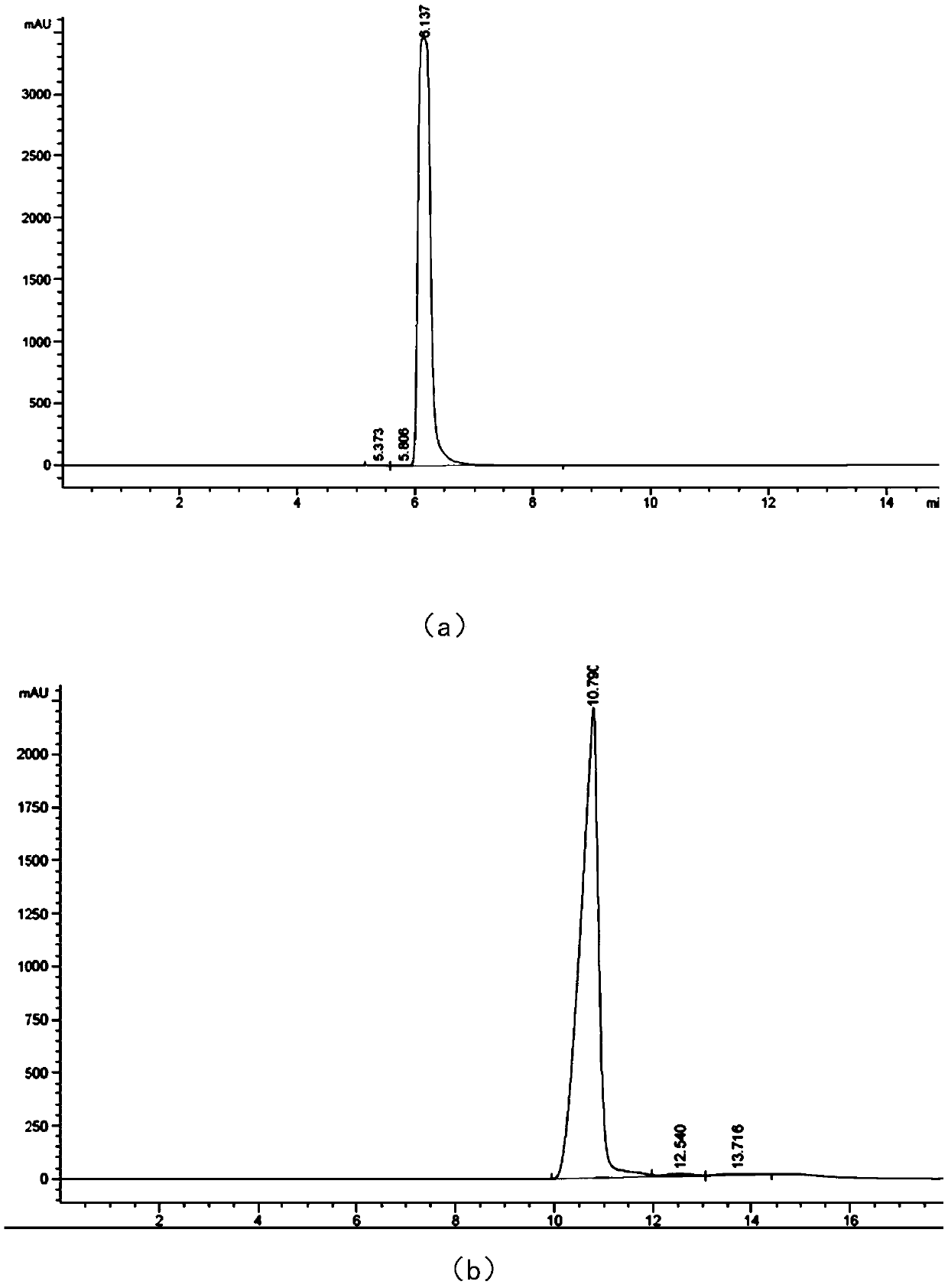

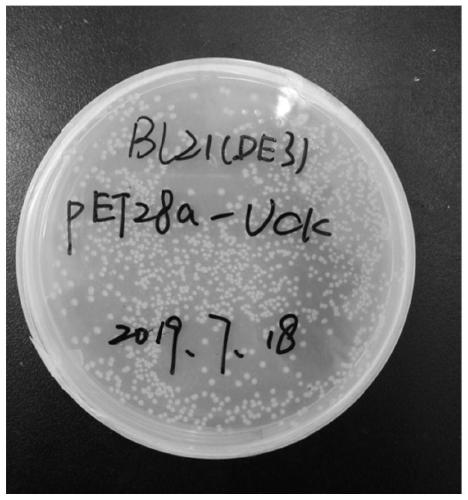

[0032] Example 3 Catalytic synthesis of CAMP

[0033] Mix the following reaction system in a test tube: Add 30-35 mM cytidine, 30-35 mM adenosine triphosphate, 8-10 mM MgCl to the cytidine kinase crude enzyme solution with a protein concentration of 6-8 g / L 2 , Potassium phosphate buffer solution, stirred evenly, reacted at pH 7.5~8.0, 35~37°C for 7~9h, and completed the enzymatic reaction to synthesize cytidylic acid (cytidylic acid is detected by liquid phase as shown in Figure 1(d) It shows that the conversion rate of the substrate cytidine and ATP reaches more than 85%). Use Agilent HC-C18 chromatographic column (150 mm×4.6 mm, 5 μm), mobile phase is 0.05 mol / L potassium dihydrogen phosphate; flow rate 0.8 ml min -1 ; The detection wavelength is 260 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com