Patents

Literature

95results about How to "Meet the requirements of large-scale industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dyeing and finishing process of polylactic acid fiber shuttle looms fabric

InactiveCN101446034APrevent loss of strengthEnergy savingBiochemical fibre treatmentDry-cleaning apparatus for textilesRise rateThermal insulation

The invention discloses a dyeing and finishing process of polylactic acid fiber shuttle looms fabric, belonging to the pre-processing, dying and after-finishing process technical field of textiles. The process is carried out according to the following process steps: A. pre-processing procedure: shuttle looms grey fabric is added in an overflow dyeing machine, and then 2-8g / L sodium carbonate or 4-15g / L sodium bicarbonate, 1-2g / L penetrating agent JFC, 1-5.5g / L hydrogen peroxide and 1-2g / L hydrogen peroxide stabilizer are successively added, the temperature is risen to 90 DEG C and the processing is carried out for 30min; B. dyeing procedure: prepared disperse dye and additives are successively added, the temperature is risen to 95-105 DEG C or 110-120 DEG C at the rising rate of 1-2 DEG C / min, and the cooling is carried out after the thermal insulation; C. after-finishing procedure: 7-15g / L hydrophilic amino silicone fabric finishing agent and antistatic agent are added for the low temperature setting, and the setting temperature is 100-130 DEG C. The dyeing and finishing process of the polylactic acid fiber shuttle looms fabric has the advantages of reasonable process design and convenient operation and can reduce the using amount of the additives and the environmental pollution effectively.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

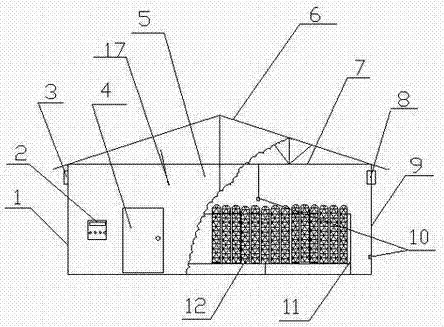

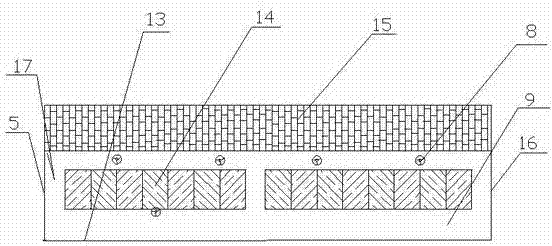

Microfluid spinning device used for preparing orderly orienting fiber

ActiveCN103757717AMeet large-scale industrial productionSimple structureFilament/thread formingFiberHigh voltage

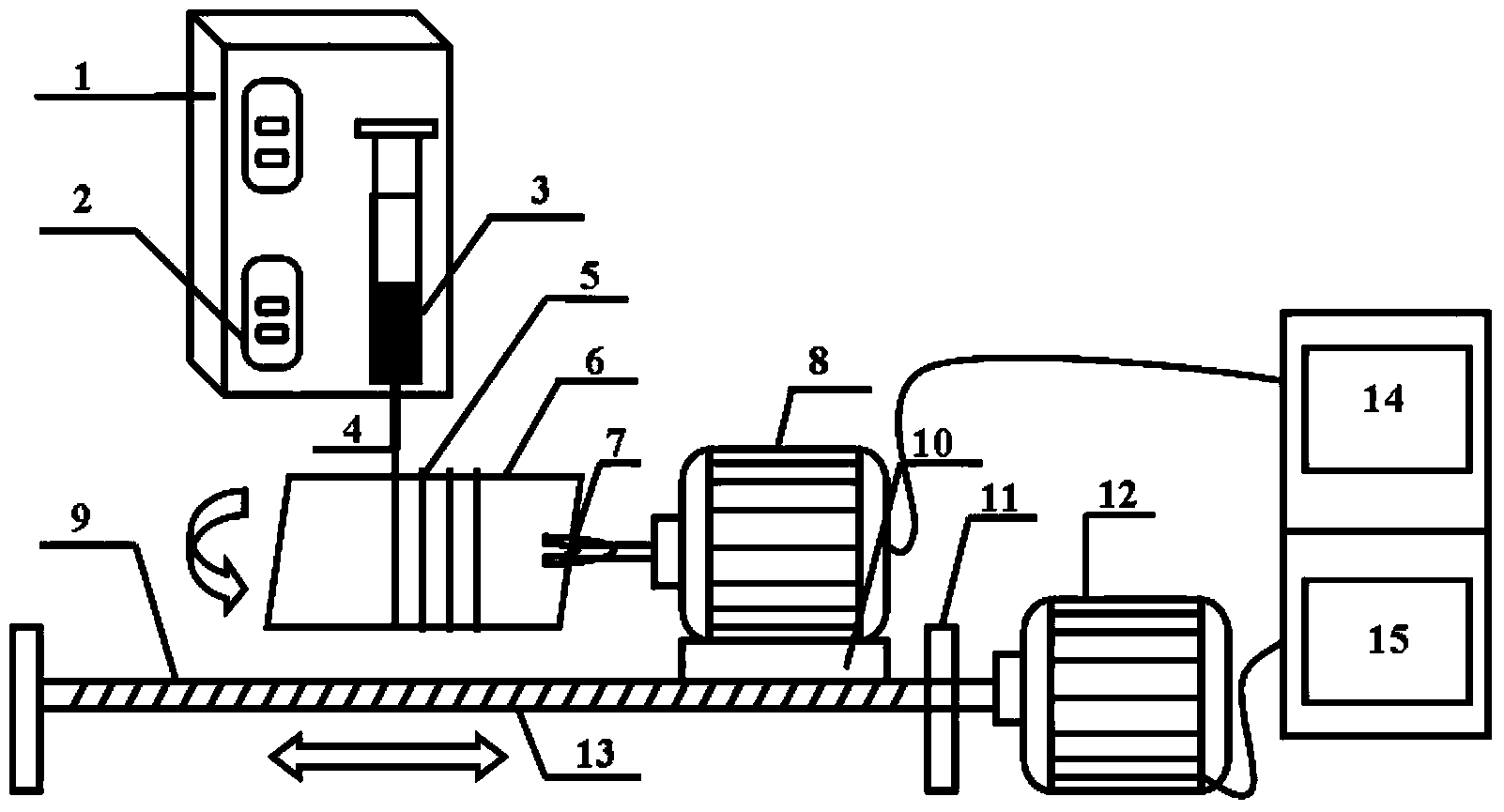

The invention discloses a microfluid spinning device used for preparing orderly orienting fiber to realize a high-voltage-free, safe, energy-saving and rapid spinning process. The microfluid spinning device comprises a microflow pump 1, a control panel I2, an injection silk projector 3, a plate acceptor 5, an electric rotating machinery 8, a stepping motor translation platform 9, a control panel II14 and a control panel III15. The microflow pump 1 is arranged on the plate acceptor 5, the injection silk projector 3 is arranged on the microflow pump 1 and connected with a dash receiver 6 on the plate acceptor 5 via a needle point 4, the plate acceptor 5 is arranged on the electric rotating machinery 8 arranged on a base 10 of the stepping motor translation platform 9, the stepping motor translation platform 9 is provided with a translation stepping motor 12, the translation stepping motor 12 can control movement in the horizontal direction to control the gap of silk to realize quantitative control of thin silk distance, the electric rotating machinery 8 and the stepping motor translation platform 9 are connected with the control panel II14 and the control panel III15.

Owner:NANUS NEW MATERIAL

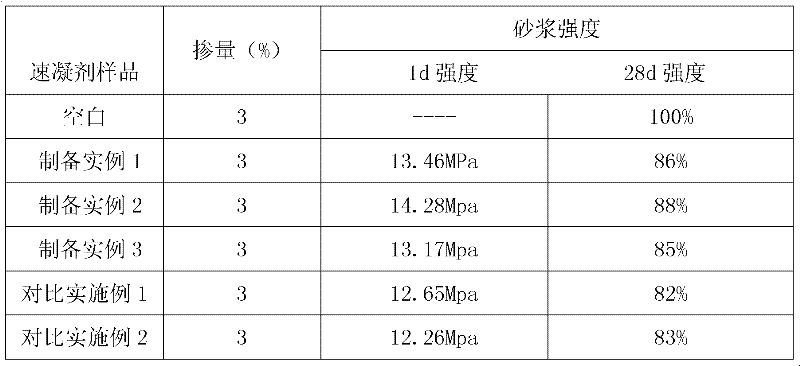

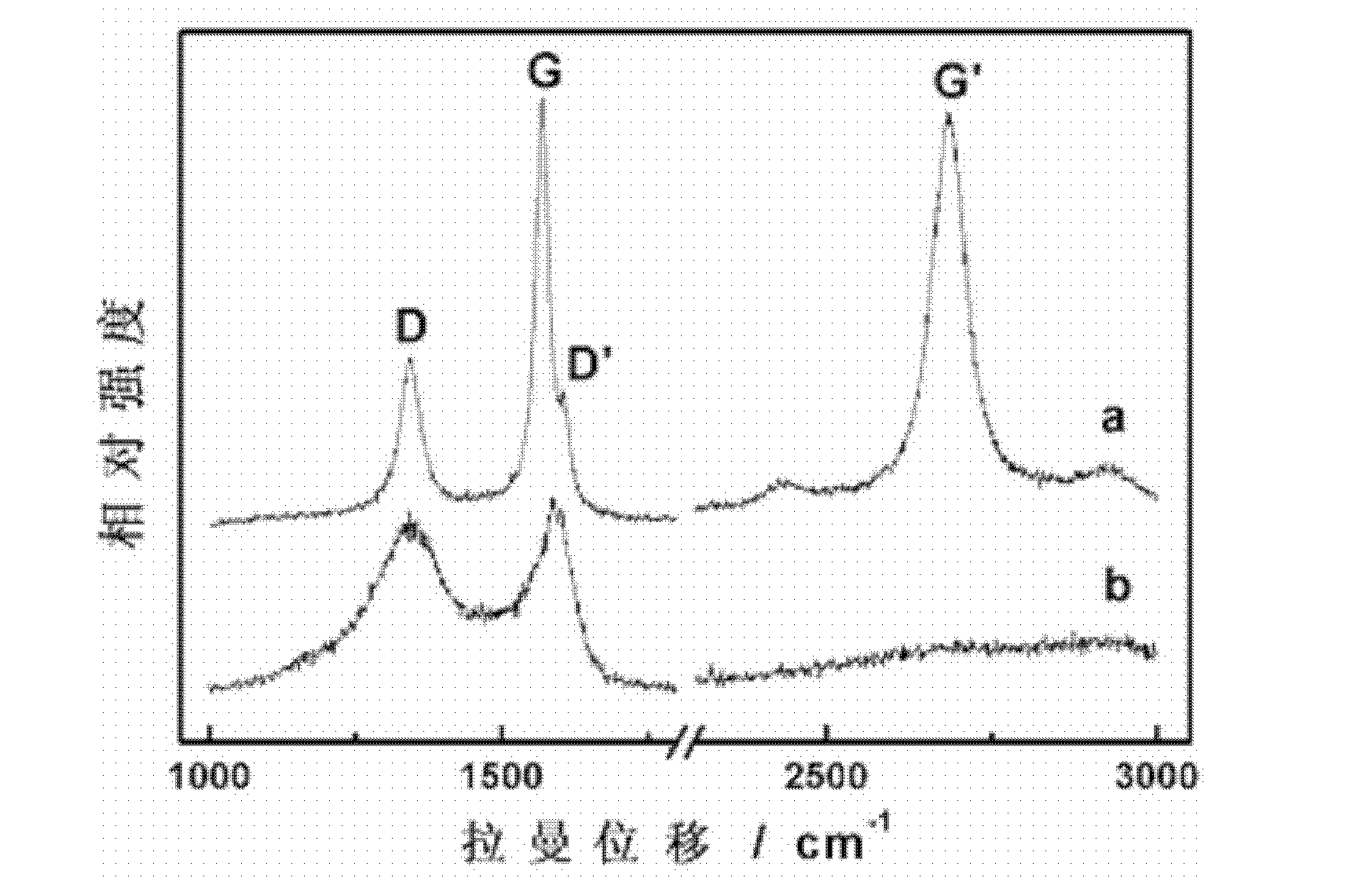

Method for preparing novel low-alkaline liquid setting accelerator

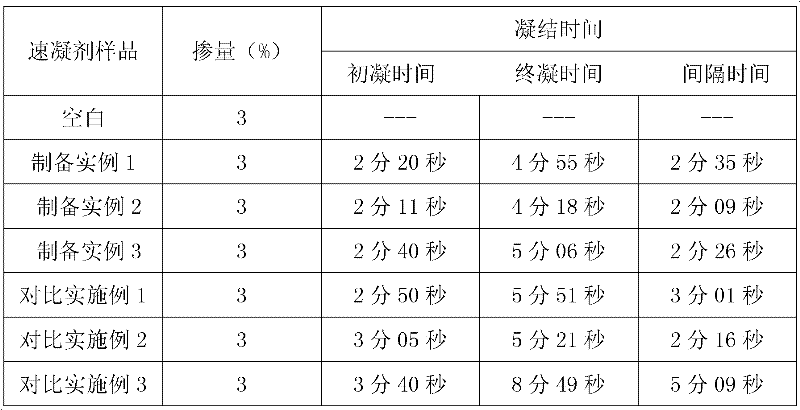

The invention relates to the field of building materials, in particular to a method for preparing a novel low-alkaline liquid setting accelerator. The novel low-alkaline liquid setting accelerator is prepared by the following steps: adding sodium hydroxide, potassium hydroxide and aluminum hydroxide into water according to proportion, and reacting for 2-3h under the temperature being 95-120 DEG C, thereby obtaining aluminate mother liquor; dissolving sodium fluoride in water, and adding silicate into the water solution under a certain temperature, thereby obtaining a modifier; and finally, dropping the modifier into the aluminate composite mother liquor, and reacting fully, thereby obtaining the novel low-alkaline liquid setting accelerator. The setting accelerator has the properties of short setting time, low alkali content and good cement adaptability.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

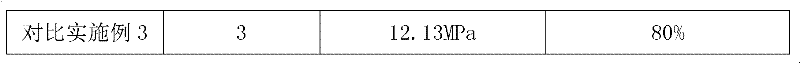

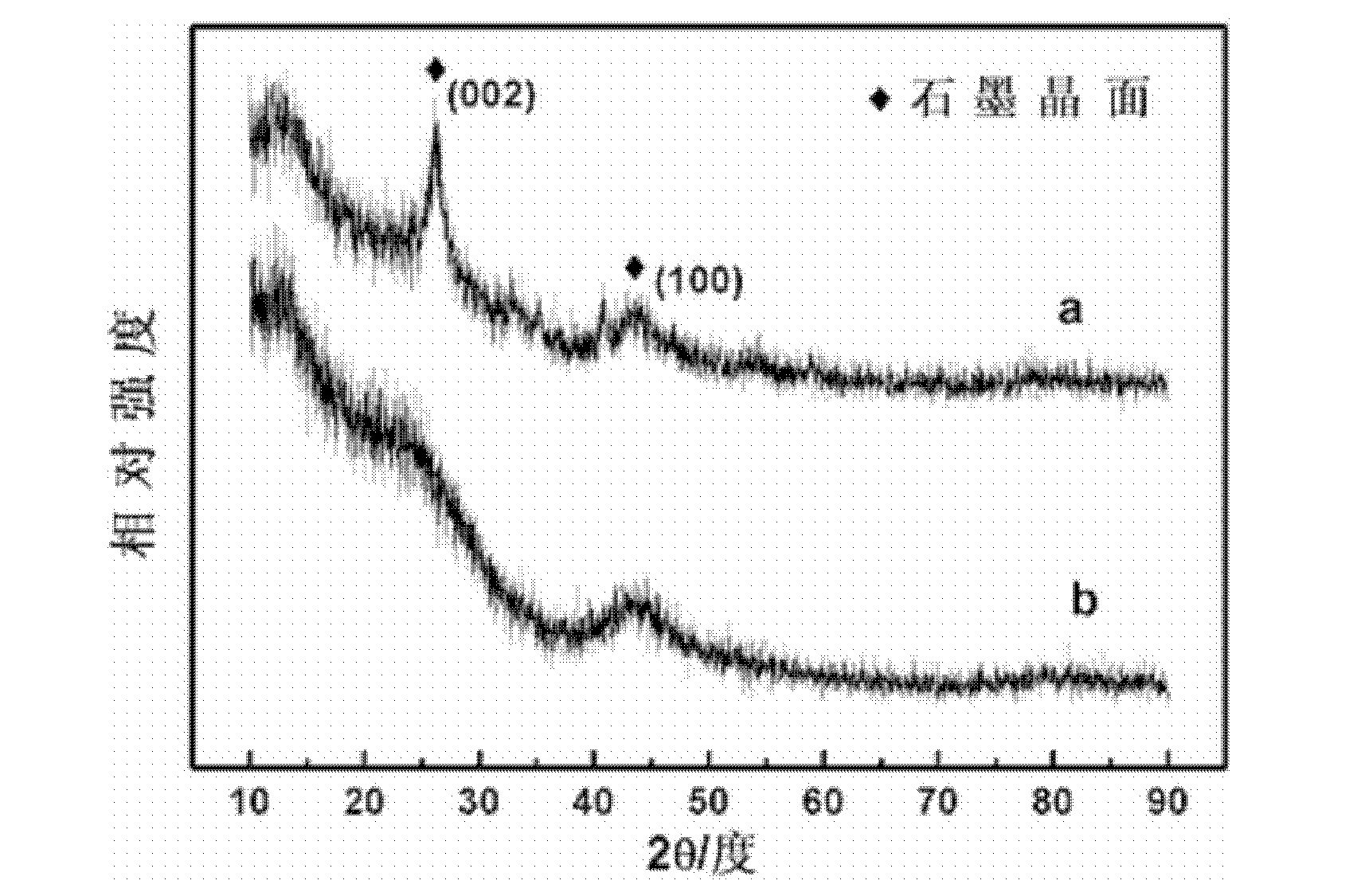

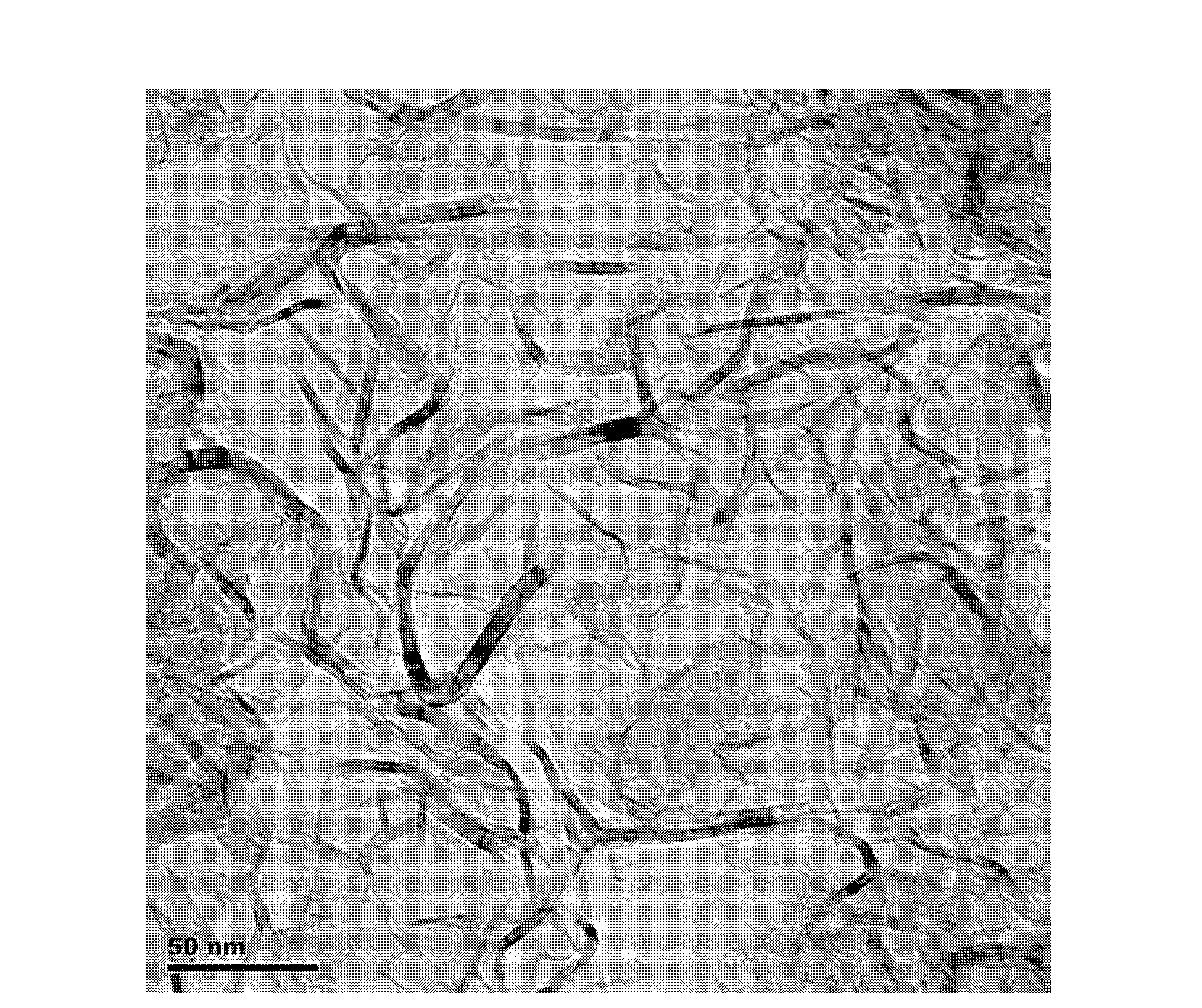

Method for preparing multilayer graphene-carbon material

InactiveCN102515150AAchieve reorganizationSimple manufacturing processGrapheneCarbon layerArgon atmosphere

The invention relates to a method for preparing a multilayer graphene-carbon material. The method provided by the invention is characterized in that a home-made amorphous carbon material is transformed into the multilayer graphene-carbon material at a low temperature under normal pressure; and concretely, the method provided by the invention comprises the following steps that metal elements are doped into the home-made amorphous carbon material; and the home-made amorphous carbon material is transformed into the multilayer graphene-carbon material at a temperature of 500 to 1000 DEG C in the presence of an elemental metal sodium as a catalyst and a medium in the nitrogen or argon atmosphere. The method provided by the invention realizes that amorphous turbostratic carbon is transformed into multilayer graphene at a low temperature under normal pressure, inhibits the increasing of the number of piled carbon layers in carbon atom rearrangement, and prevents that a large amount of the multilayer graphene obtained in structure rearrangement is transformed into graphite crystals. The multilayer graphene-carbon material obtained by the method has wide application prospects in the fields of sensors, capacitors, catalysis and energy storage.

Owner:TONGJI UNIV

Method for preparing fructooligosaccharide from hydrolyzing jerusalem artichoke by column type ion exchanging process

InactiveCN101037454AReduce manufacturing costShort processSugar derivativesOligosaccharidesIonIon exchange

The invention relates to a preparation method for fructooligosaccharid, specifically of hydrolyzing American artichoke to prepare fructooligosaccharid by means of column ion-exchange treatment, including: 1) preparing the American artichoke liquid; 2) treating the prepared extract with calcium hydroxide, airing the CO2 gas, precipitation centrifugal filtering to get transparent American artichoke liquid; 3) treating the American artichoke extract with cation exchange resin controlling the velocity of flow at 800-1200cm3 / h, discharge liquid pH value between 1.0-2.2; 4) dispositing the discharge liquid in room temperature for acidolysis 2-6 hours, passing through strong anion resin, concentrating the liquid, spray drying or drying in vacuum. The invention removes the impurity in the chicory by ion exchange resin, simultaneously reduces its pH value, controls the acid leaching time. Compared to the enzyme method, the present method can get a comparative product in purity, but a lower production cost. The method paves a foundation in the large-scaled for fructooligosaccharid with a simple craft, timesaving and powersaving.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

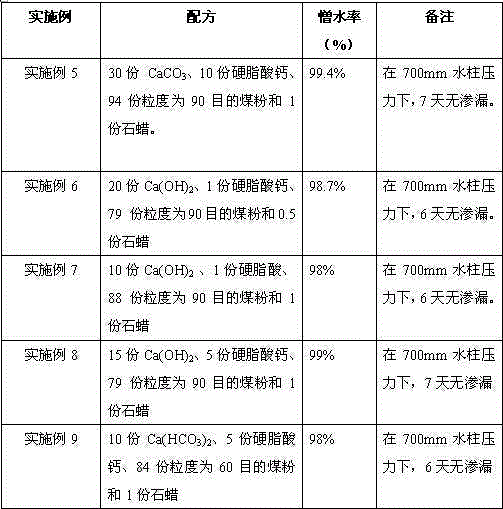

Waterproof pulverized coal and preparation method thereof

The invention discloses a waterproof pulverized coal and a preparation method thereof, wherein the waterproof pulverized coal comprises components with parts by weight: calcium salt or calcium hydroxide (Ca(OH)2) 5-30 parts, stearic acid or stearate 1-10 parts or pulverized coal 60-94 parts. The method for preparing the waterproof pulverized coal comprises steps: firstly, the components with parts by weight are weighted, are added into a roller type reaction kettle to be kept to heat for 20-60 min after being heated to 110-140 DEG C, thereby obtaining the waterproof pulverized coal. The method for preparing the waterproof pulverized coal can convert pulverized coal to be a hydrophobic substance from a hydrotropic substance, greatly reduces hydrophilic performance of the pulverized coal, and can prevent volatile components in the pulverized coal from volatilizing, thereby preventing the autoignition problem of the pulverized coal during storing, prolonging service life, improving safety during storage and transportation, and having excellent application prospect.

Owner:重庆四季金标科技有限公司

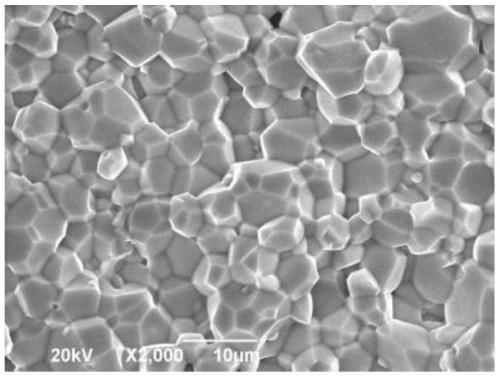

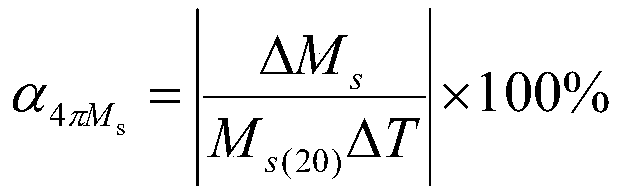

Garnet ferrite with high temperature stability and preparation method thereof

ActiveCN109867518AImprove temperature stabilityGuaranteed low ferromagnetic resonance linewidthInorganic material magnetismInductances/transformers/magnets manufactureMicrowaveMetallurgy

The invention discloses garnet ferrite with high temperature stability and a preparation method thereof, and belongs to the technical field of preparation of microwave magnetic materials. The structural formula of the garnet ferrite is Y<2.7-x>Ca<0.3-z>Gd<x>Al<y>Fe<4.68-y-z>Zr<0.3>Mn<0.02>V<z>O<12>, wherein x is greater than or equal to 0.2 and less than or equal to 0.8, y is greater than or equalto 0.6 and less than or equal to 1.4, and z is greater than or equal to 0.05 and less than or equal to 0.20. According to the garnet ferrite with high temperature stability, Gd<3+>, Al<3+> and V<5+>are simultaneously introduced for substitution, and a Bi2O3 additive is doped, so that alpha<4[phi]Ms> of the obtained garnet ferrite material in a temperature range from -55 DEG C to +85 DEG C is ina range of 0.360-0.475% / DEG C, the temperature of 4[pi]Ms at normal temperature is in a range of 300-500 Gs, and the Curie temperature T<c> is in a range of 110-165 DEG C. in addition, a low ferromagnetic resonance linewidth of the material can be ensured while temperature stability of the material is greatly improved

Owner:江西尚朋电子科技有限公司

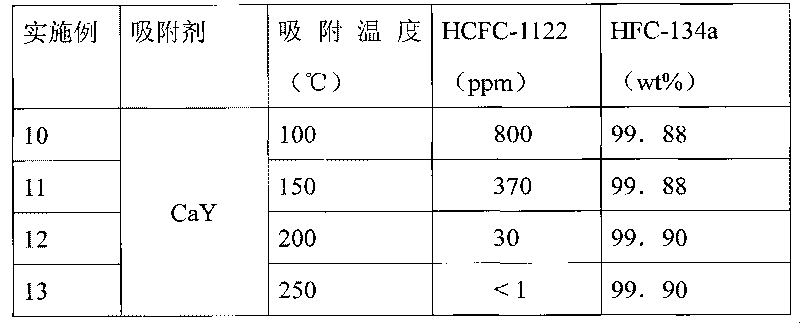

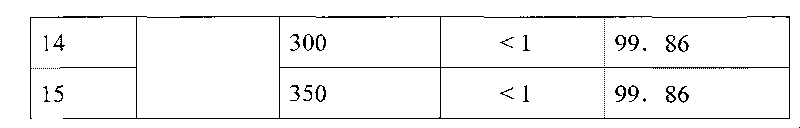

Purifying method of 1, 1, 1, 2-tetrafluoroethane

ActiveCN101747140AImprove adsorption capacityFast adsorption rateHalogenated hydrocarbon preparationMolecular sieveAlkaline earth metal

The invention discloses a purifying method of 1, 1, 1, 2-tetrafluoroethane, which comprises the steps of: contacting a 1-chlorine-2, 2-difluoroethylene-containing 1, 1, 1, 2-tetrafluoroethane crude product with a cation-modified molecular sieve under the condition of gas phase; absorbing 1-chlorine-2, 2-difluoroethylene in the 1, 1, 1, 2-tetrafluoroethane crude product by taking the cation-modified molecular sieve as adsorbent; and controlling the absorption temperature at 150-350 DEG C to obtain the purified 1, 1, 1, 2-tetrafluoroethane, wherein the cation is selected from one or several combination of the following components: H+, alkaline earth metal ion, rare-earth metal ion or transition metal ion. With chemisorption, the purifying method selectively removes HCFC-1122 in HFC-134a, has higher absorption velocity, obviously improves the adsorption capacity of the HCFC-1122, and is environment-friendly.

Owner:ZHEJIANG UNIV OF TECH

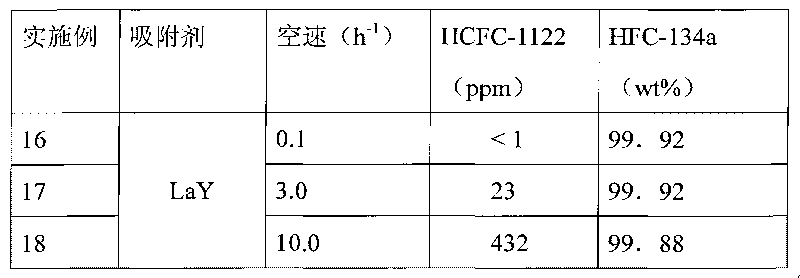

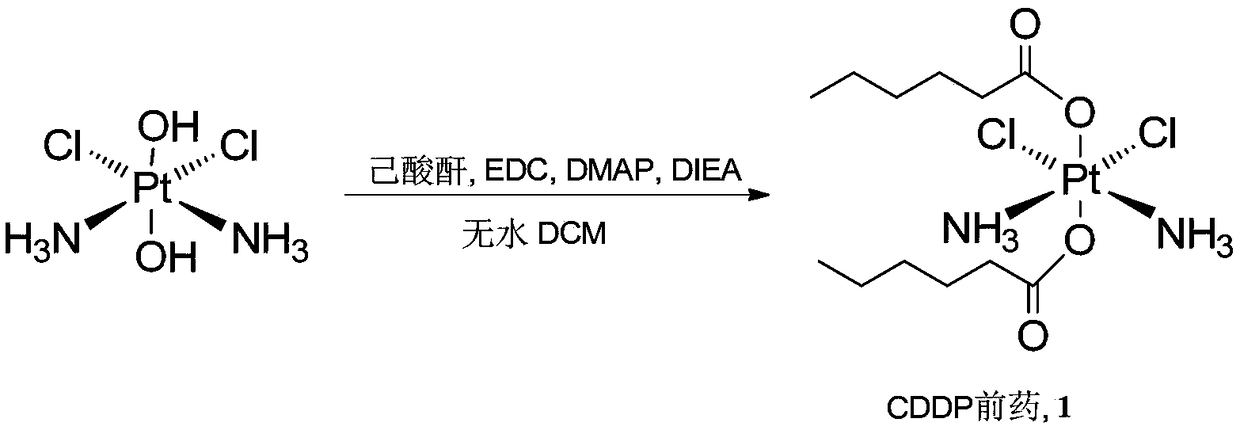

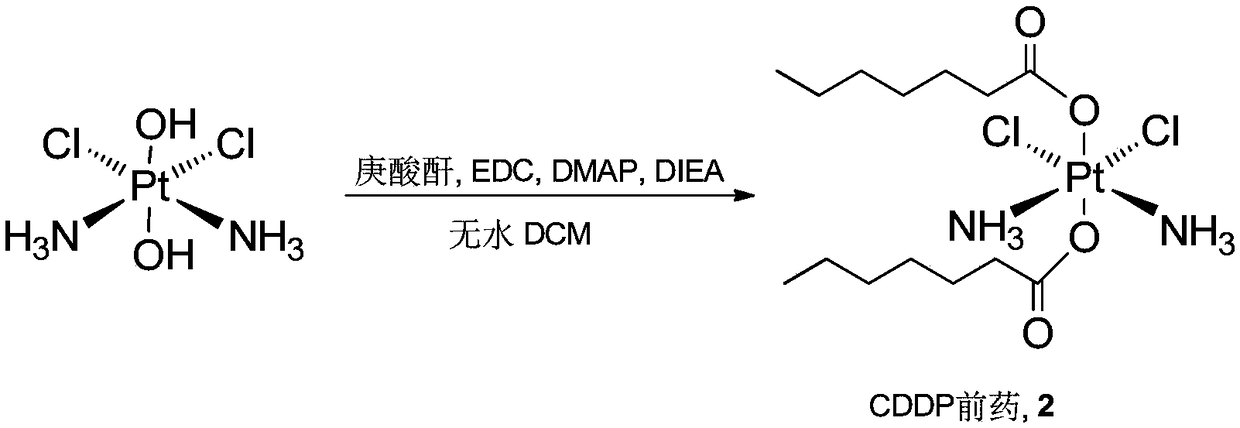

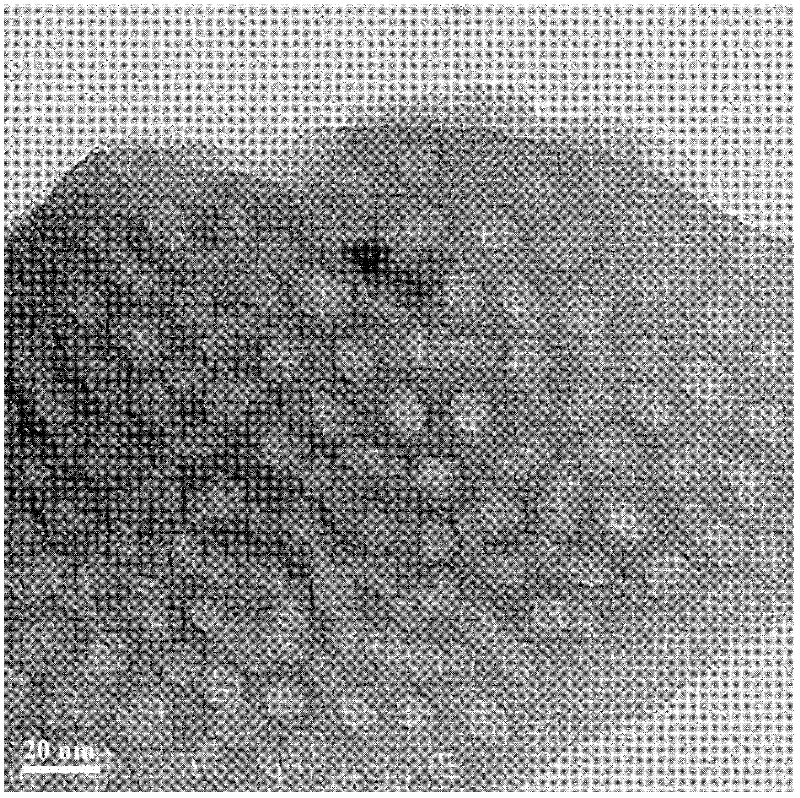

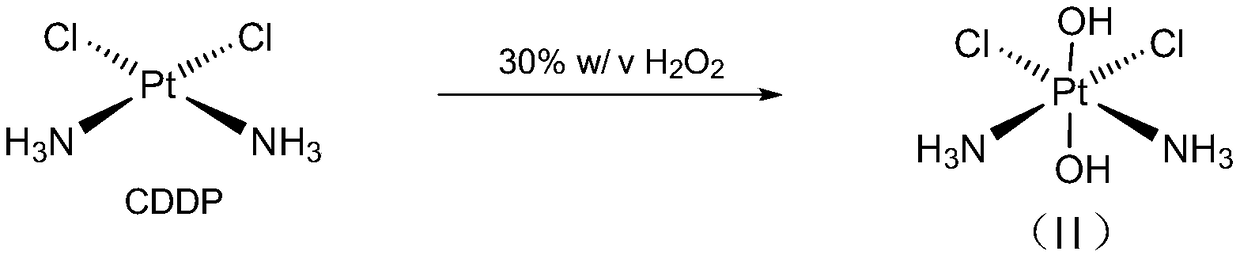

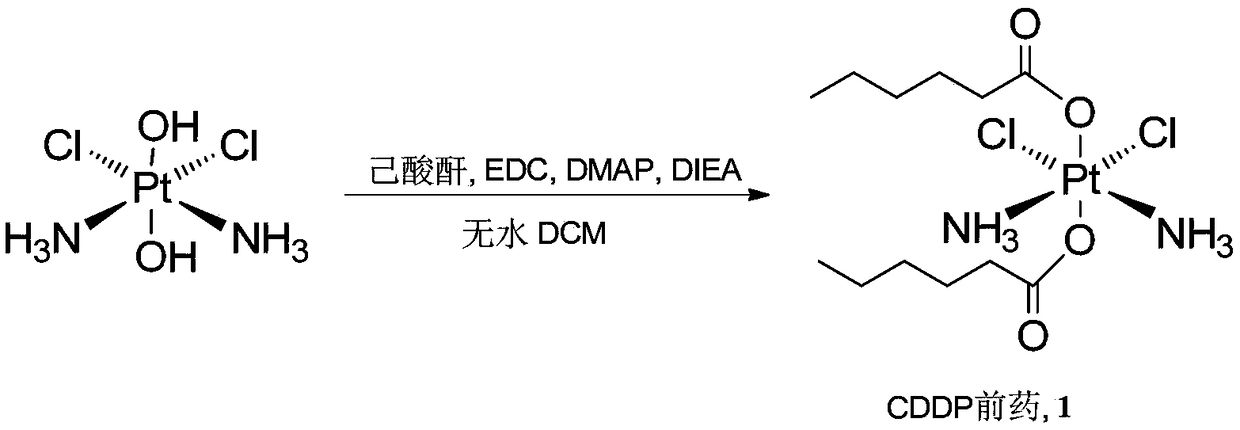

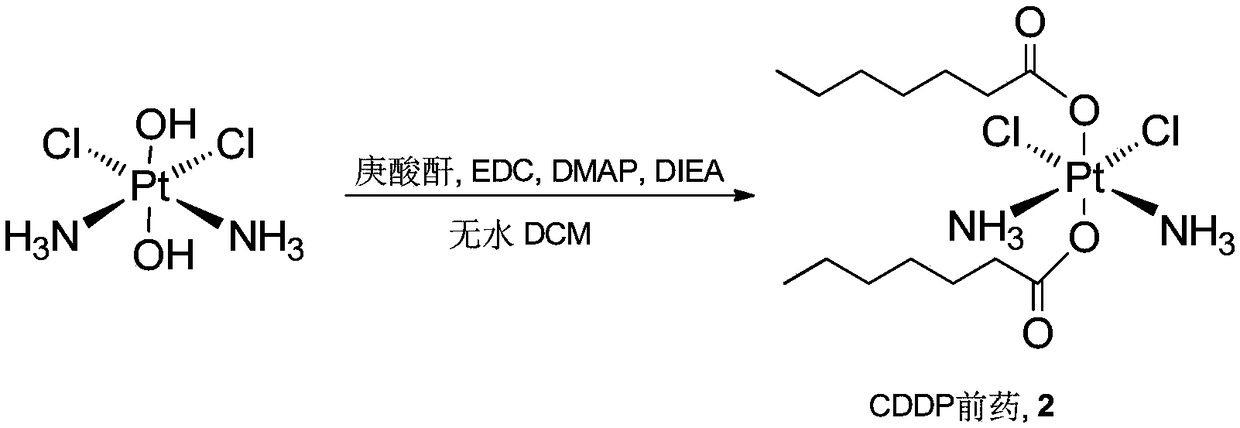

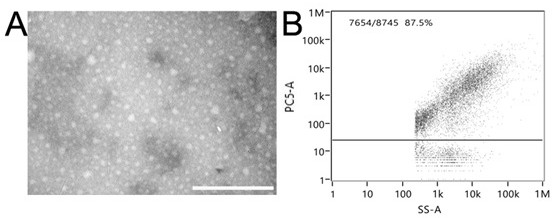

Cis-dammine dichloroplatinum prodrug, preparation method and application

InactiveCN109021026ABiologically activeExcellent ability to kill tumor cellsHeavy metal active ingredientsPlatinum organic compoundsStructural formulaWilms' tumor

The invention discloses a cis-dammine dichloroplatinum (CDDP) prodrug, a preparation method and application. The structural formula of the CDDP prodrug is shown as formula (I), and is generated by theesterification reaction of activated dihydroxy cisplatin with hydrophobic molecules. Characterization of the nano-preparation by dynamic light scattering and transmission electron microscopy indicates that the nanoparticles involved in the invention are uniformly distributed and are at about 30nm. In vitro cytotoxicity experiments show that the nano-drug can significantly inhibit the proliferation of tumor cells (A549 and LoVo). In vivo experiments show that compared with CDDP injections, on the basis of reducing the systemic toxicity, the nano-drug has the effect of inhibiting the non-smallcell lung cancer A549 subcutaneous tumor, and has good market prospects and clinical application value.

Owner:ZHEJIANG UNIV

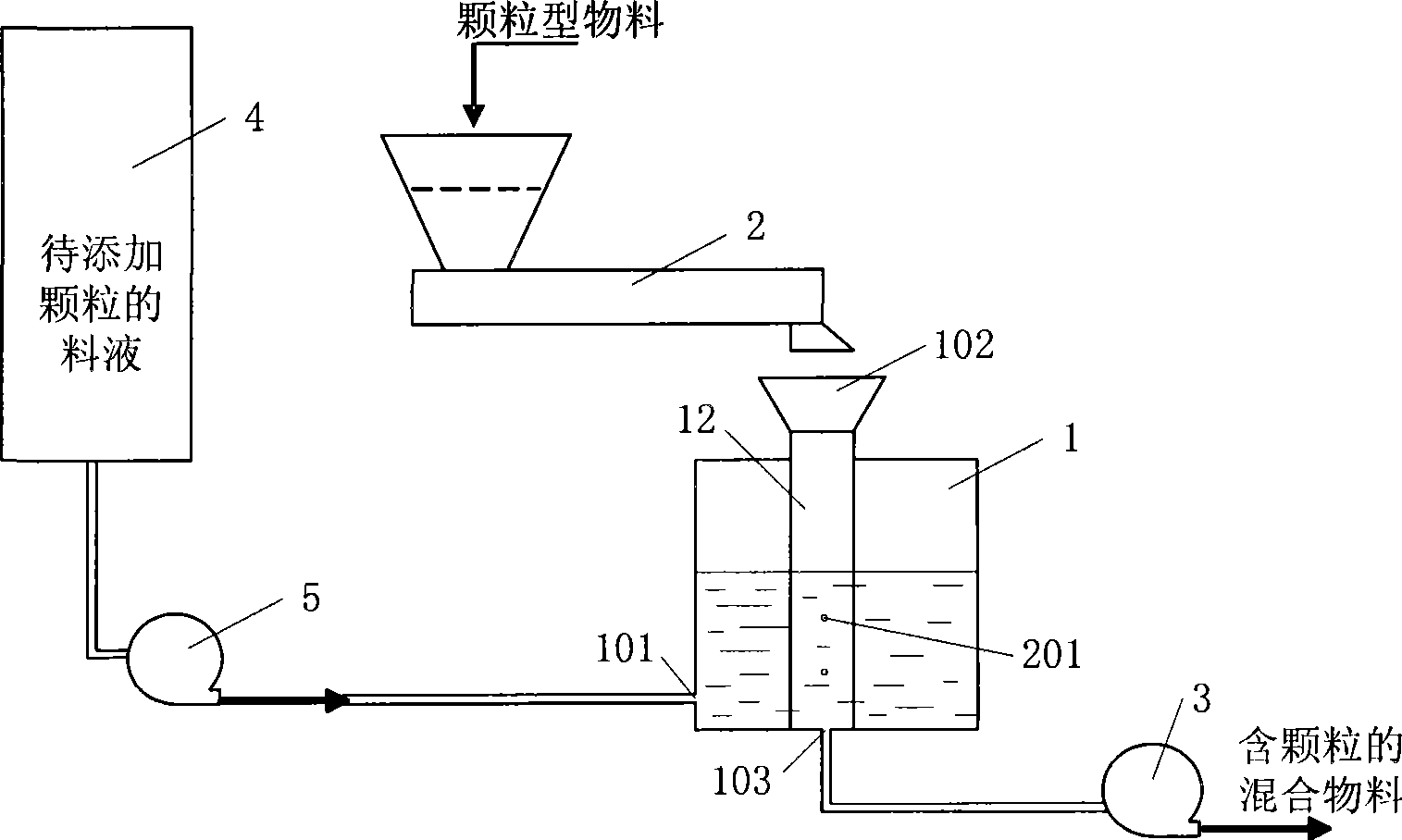

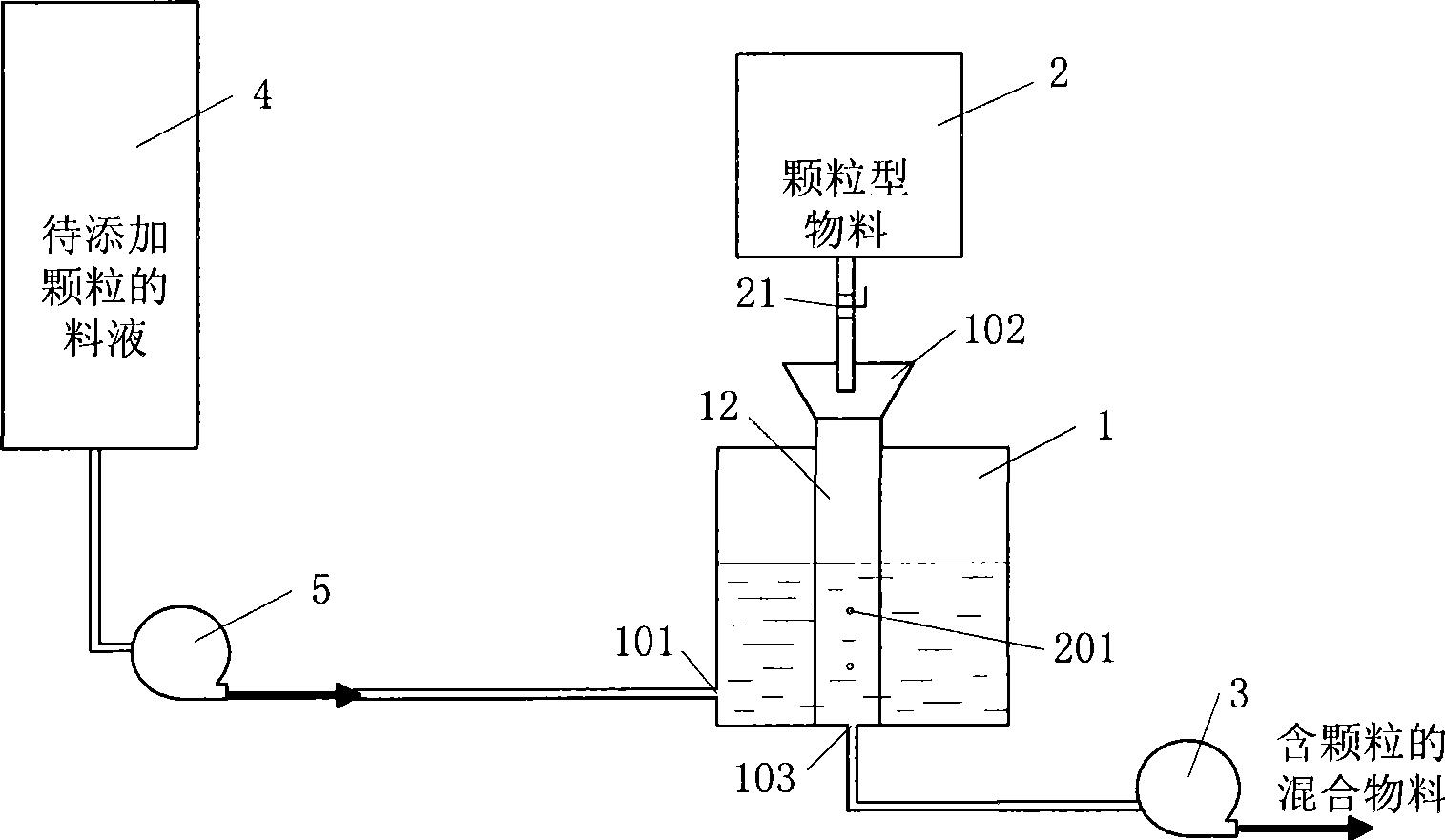

Granule-adding method and device for granule-containing liquid drink processing technique

ActiveCN101480266AReduce complexityIncrease the amount of controlMilk preparationPre-extraction tea treatmentLiquid stateEngineering

The invention provides a method and a device for adding granules in the process of inclusion granule liquid drink. The technical scheme of the device is mainly achieved as follows: a feeding pipe is arranged in a compensating groove, the wall of the feeding pipe is provided with holes, the bottom end of the feeding pipe contacts with the bottom surface of the compensating groove in a sealing way so as to enable feed liquid to be added with granules to enter into the feeding pipe from the holes on the wall of the feeding pipe after entering into the compensating groove, granular materials enter into the feeding pipe from the upper port of the feeding pipe, the feed liquid to be added with granules are mixed with the granular materials in the feeding pipe to form inclusion granule mixed materials which are led out of a mixed material outlet arranged on the bottom surface of the compensating groove corresponding to the bottom end surface of the feeding pipe from the compensating groove so that the granular materials are uniformly added into the feed liquid on line. The invention also provides a method for producing the inclusion granule liquid drink by the method and the device for adding granules.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

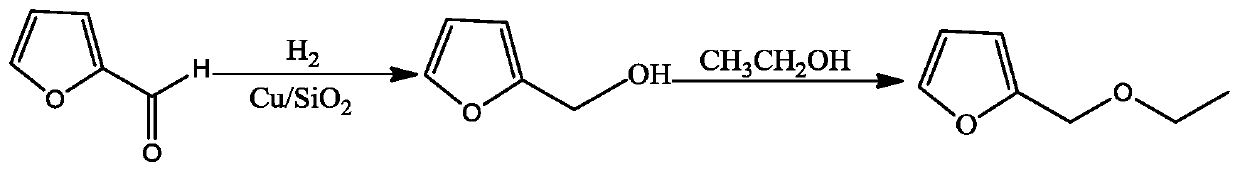

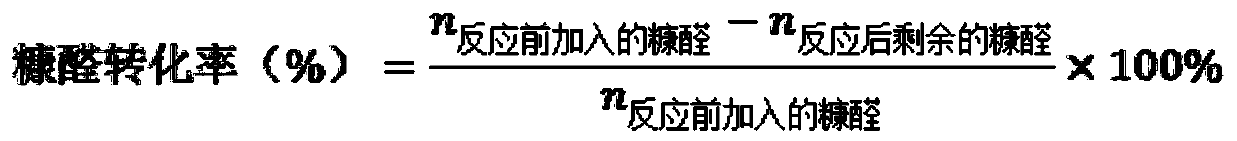

Method and catalyst for preparing ethyl furfuryl ether by liquid-phase hydrogenation of furfural and preparation method of catalyst

ActiveCN109985626AReduce manufacturing costLow priceOrganic chemistryMolecular sieve catalystsHydrogen pressureReaction temperature

The invention relates to a method and catalyst for preparing ethyl furfuryl ether by liquid-phase hydrogenation of furfural and a preparation method of the catalyst. Active metal Cu is supported on asilica-containing carrier by adopting an ammonia distillation method, and the catalyst is the metal Cu supported by the silica-containing carrier, wherein the supporting capacity of the copper is 5-45wt%. The silica-containing carrier is one or more selected from mesoporous SiO2, MCM-41, SBA-15 and silica sol. Absolute ethyl alcohol is taken as a solvent, and furfural and the catalyst are added,wherein the mass ratio of the furfural to the absolute ethyl alcohol is (0.1-1):1, and the mass ratio of the catalyst to the furfural is (0.02-0.1):1; and a reaction is carried out for 0.5-24 hours under the condition that the hydrogen pressure is 0.5-15 MPa and the reaction temperature is 80-250 DEG C to obtain the ethyl furfuryl ether. The catalyst disclosed by the invention has relatively highcatalytic activity. When furfural is used as a raw material to synthesize ethyl furfuryl ether in one step, the reaction conditions are mild, and requirements of large-scale industrial production aremet.

Owner:TIANJIN UNIV

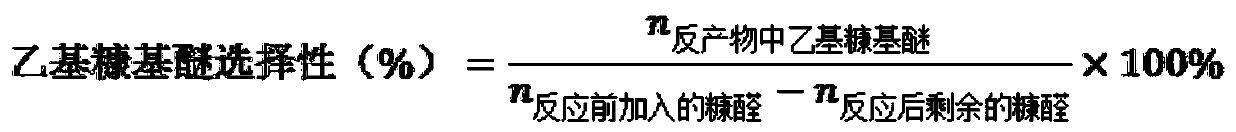

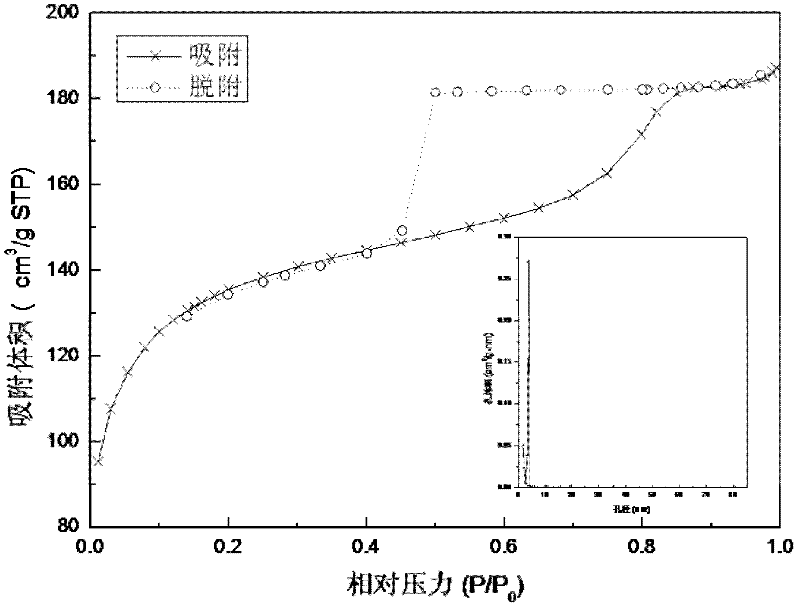

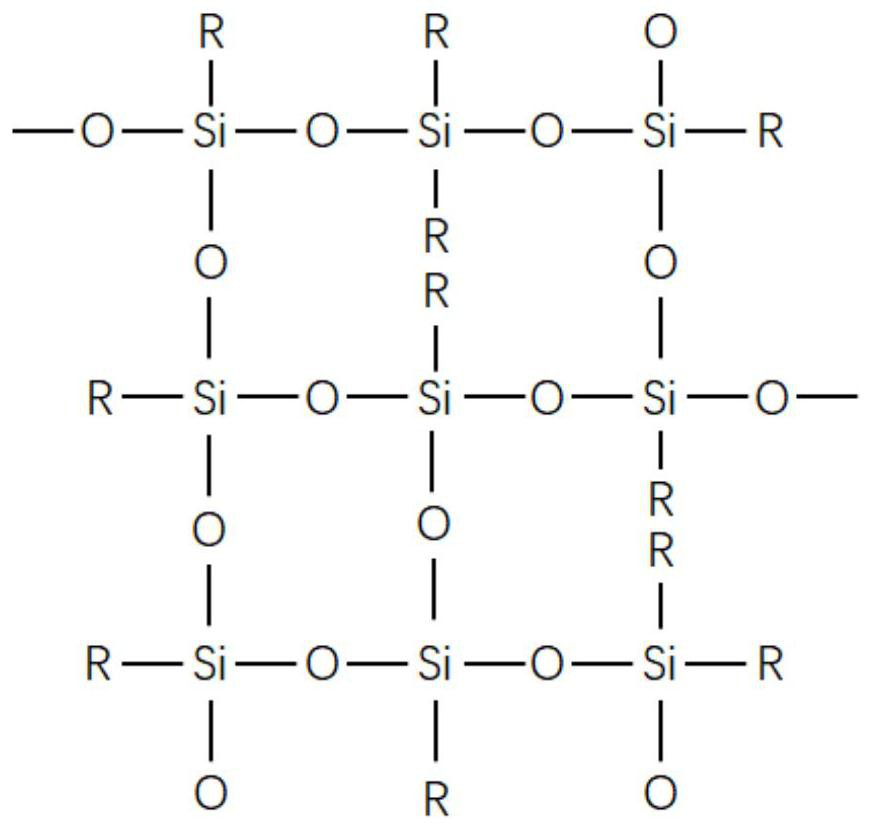

A kind of method for preparing mesoporous silica

InactiveCN102295291ALow reaction temperatureEasy to manufactureSilicaMesoporous silicaSilicon dioxide

The invention relates to a method for preparing mesoporous silicon dioxide, the method is characterized in that mercapto-vinyl can be used for a free radical addition reaction, organo-silicone containing a mercapto group and polybutadiene block of triblock copolymer of styrene-butadiene-styrene are reacted, an organo-siloxane modified styrene-butadiene-styrene triblock copolymer can be obtained, then the organo-siloxane modified styrene-butadiene-styrene triblock copolymer is carried out a sol-gel reaction with a silicon source under the acidic or alkaline condition to form gel, the mesoporous silicon dioxide is obtained after cracking the gel. Compared with the prior art, the mesoporous silicon dioxide material has the average pore diameter of 5-18nm, the pore volume of 0.24-0.30 cm<3> / g, the specific surface area of 418-480 cm<2> / g, and has the advantages of cheap raw material and easy raw material acquisition, mild reaction condition, simple and high efficient preparation process, safety and environmental protection, and is convenient for large scale production.

Owner:SHANGHAI JIAO TONG UNIV

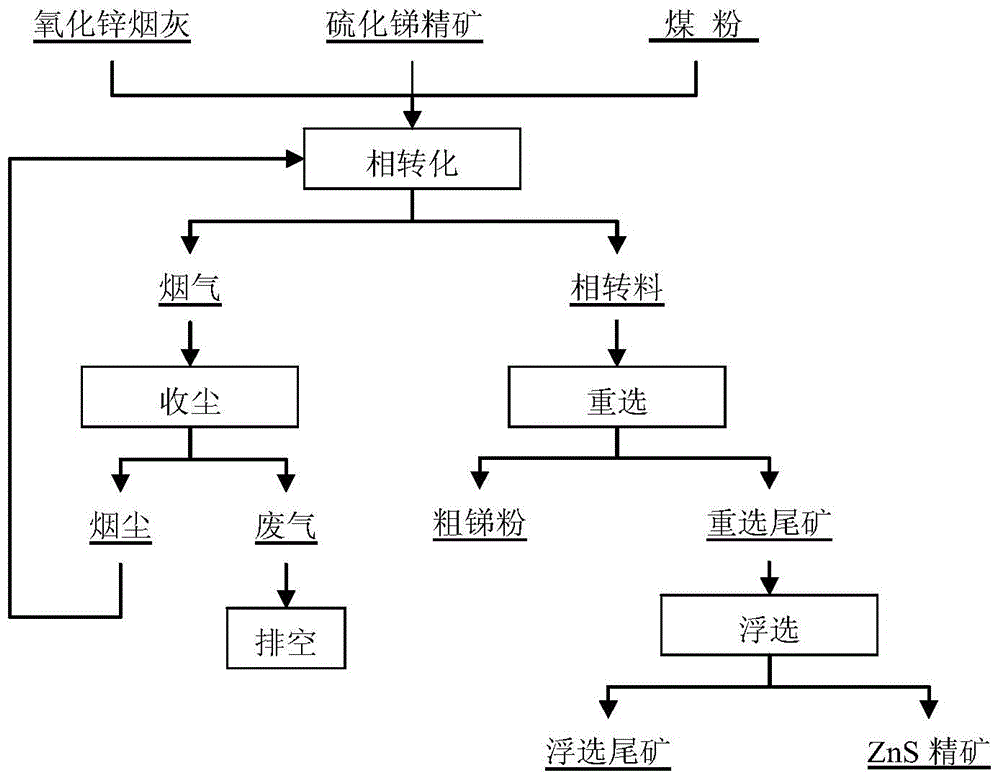

Method for treating antimony sulfide concentrate through sulfide phase reductive transformation-ore dressing

InactiveCN104975166AEasy to operateMeet the requirements of large-scale industrial productionPollutionAntimony

The invention discloses a method for treating antimony sulfide concentrate through sulfide phase reductive transformation-ore dressing. According to the method, antimony sulfide concentrate and secondary zinc oxide undergo reductive transformation at a temperature no more than 950 DEG C so as to produce reductive transformation products--metallic antimony and zinc sulfide; and the reductive transformation products undergo reselection and flotation so as to separate metallic antimony from the antimony sulfide concentrate. The method has the characteristics of cleanness, low temperature and low carbon, eliminates a great amount of low-concentration SO2 flue gas pollution in traditional antimony pyrometallurgical smelting process, shortens antimony smelting flow, and greatly reduces energy consumption and improves economic benefit; the method can realize continuous production by using continuously-operating large-size conventional equipment like a rotary kiln and a multi-hearth furnace, and is capable of passingly treating secondary zinc oxide with high fluorine and chlorine contents so as to allow secondary zinc oxide to become high-quality zinc sulfide concentrate which is two times higher in price.

Owner:CENT SOUTH UNIV

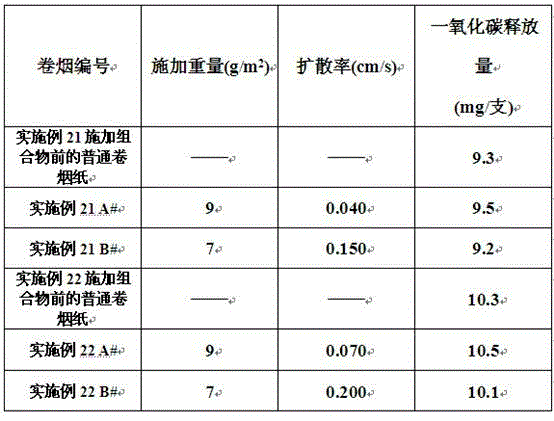

Burning inhibition composition with carbon monoxide reduction function for cigarette paper and applying method and manufacturing method thereof

ActiveCN104805730AEasy to prepareReduce manufacturing costNon-fibrous pulp additionPaper/cardboardProcess engineeringCo carbon monoxide

The invention provides a burning inhibition composition with a carbon monoxide reduction function for a cigarette paper and an applying method and a manufacturing method thereof. The burning inhibition composition comprises the following materials in parts by weight: 10-30 parts of an adhesive, 10-30 parts of a filling agent, 0.2-5 parts of an additive and 20-79.8 parts of a solvent. The burning inhibition composition is used for reducing carbon monoxide of the cigarette paper.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

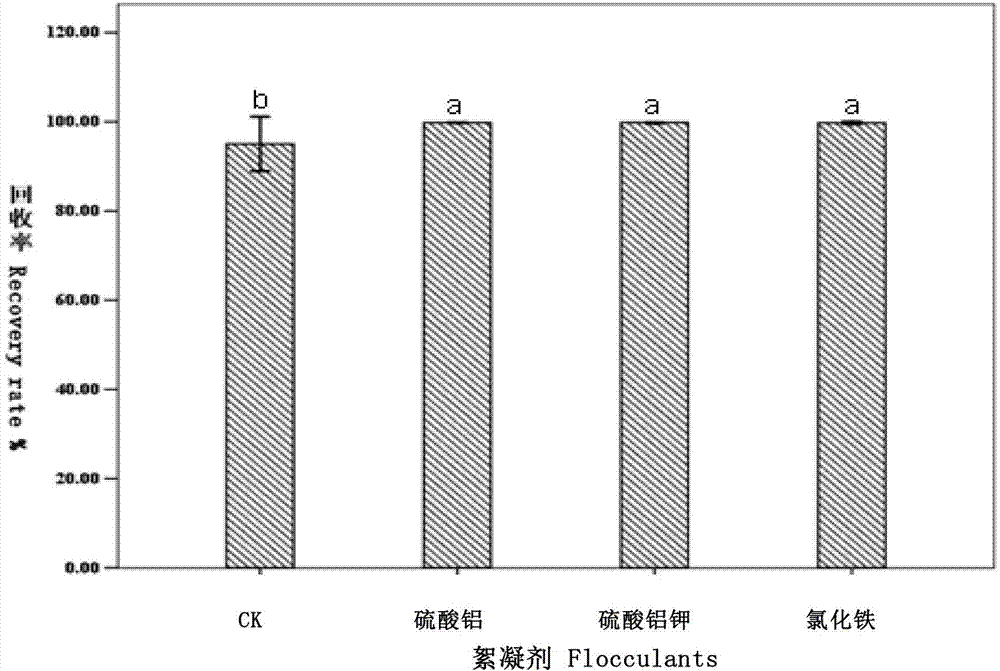

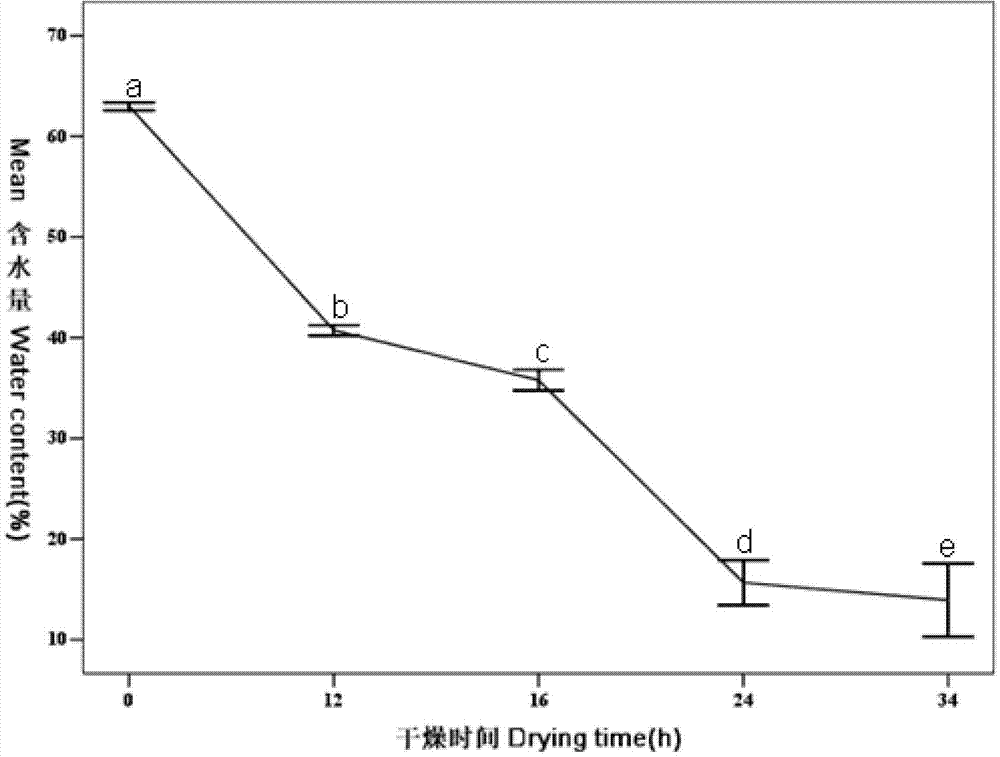

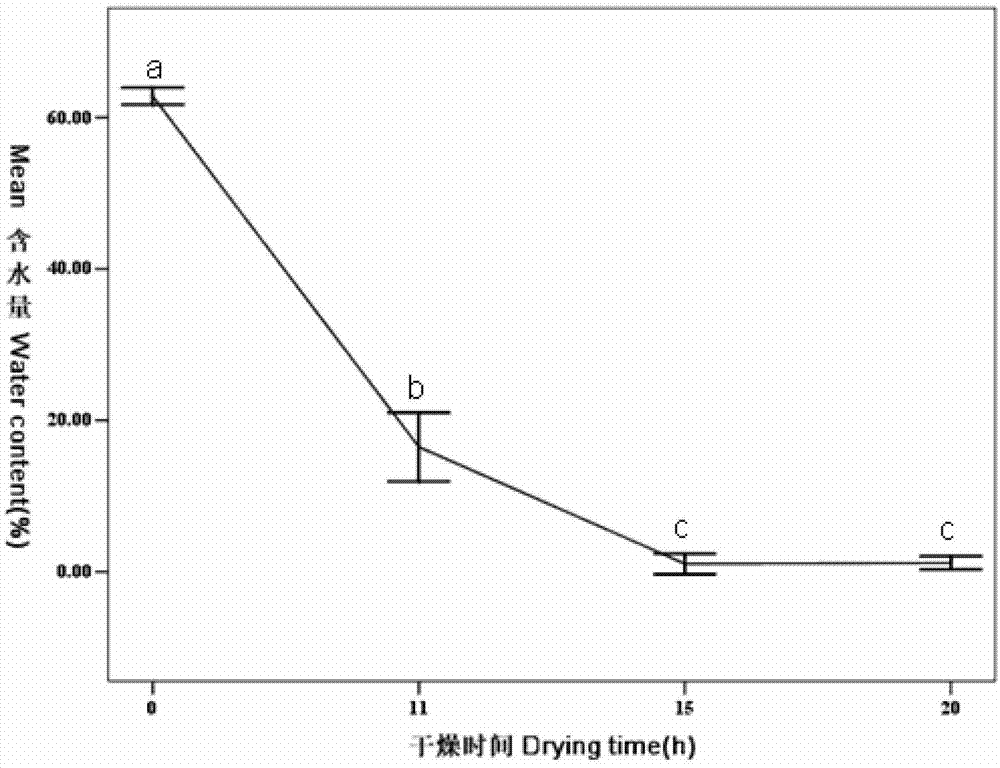

Preparation method of paecilomyces lilacinus spore powder

ActiveCN102925405AHigh recovery rateHigh sporulationMicroorganism based processesSpore processesBiotechnologySpore

The invention discloses a preparation method of paecilomyces lilacinus spore powder. The method comprises the following steps of: (1) preparing a paecilomyces lilacinus liquid fermentation broth; (2) recovering conidia from the paecilomyces lilacinus liquid fermentation broth; and (3) drying the recovered paecilomyces lilacinus conidia to obtain the paecilomyces lilacinus spore powder. According to the invention, the technological parameters for preparing paecilomyces lilacinus spore powder are screened and optimized to obtain optimal technological parameters for preparation, thus the yield and product quality of paecilomyces lilacinus spores are effectively improved. The preparation method of paecilomyces lilacinus spore powder, disclosed by the invention, has the advantages of high recovery rate, high spore content, high live spore rate, low water content and the like, and conforms to the requirements of large-scale industrial production.

Owner:INST OF FOREST ECOLOGY ENVIRONMENT & PROTECTION CHINESE ACAD OF FORESTRY

Method for comprehensively utilizing waste tobacco leaves

ActiveCN108689803AEfficient separationHigh yieldSugar derivativesOrganic compound preparationChlorogenic acidRutin

The invention discloses a method for comprehensively utilizing waste tobacco leaves. The method comprises the steps of after using an organic solvent to extract the waste tobacco leaves, using a stepwise solvent extraction method to obtain condiments, chlorogenic acid, and precipitates of a nicotine extract and rutin; obtaining high-purity nicotine, condiments, solanesol, rutin and chlorogenic acid by using separation and purification means of solvent extraction, column chromatography, crystallization and the like; fermenting tobacco leaf residues of the extracted effective components to prepare a bacterial manure. The method provided by the invention can realize high-value utilization of effective components of multiple waste tobacoo leaves, is simple in process and low in cost, and meetsthe large-scale industrial production requirement; the yield and the purity of the effective components are high, the condiments do not contain the nicotine, and microbial fertilizer is short in production period and high in viable count, so that the method is a tobacco leaf comprehensive utilization technology with high efficiency, good economy and environment friendliness.

Owner:DALIAN UNIV OF TECH

Preparation method of N-alkyloxy oxalyl alanine alkyl ester

ActiveCN102249946AEasy to operateShort preparation cycleOrganic compound preparationCarboxylic acid amides preparationPyruvic acidPhotochemistry

The invention discloses a preparation method of N-alkyloxy oxalyl alanine alkyl ester, comprising the steps of: subjecting pyruvic acid alkyl ester (2) and oxamic acid alkyl ester (3) to a reductive amination reaction so as to obtain a target compound (1) directly in the following reaction route; or, conducting a dehydration reaction to pyruvic acid alkyl ester (2) and oxamic acid alkyl ester (3) first so as to obtain an intermediate Schiff base (4), which then undergoes a reduction reaction, thus obtaining the target compound (1), with a following reaction route; wherein, R1 and R2 respectively represent methyl, ethyl, n-propyl, isopropyl, n-butyl, isobutyl or t butyl. With the advantages of simple operation, short preparation period, low energy consumption, strong industrial feasibility and the like, the preparation method provided in the invention can satisfy the requirements for large-scale industrial production.

Owner:SHANGHAI HEGNO PHARMA HLDG +2

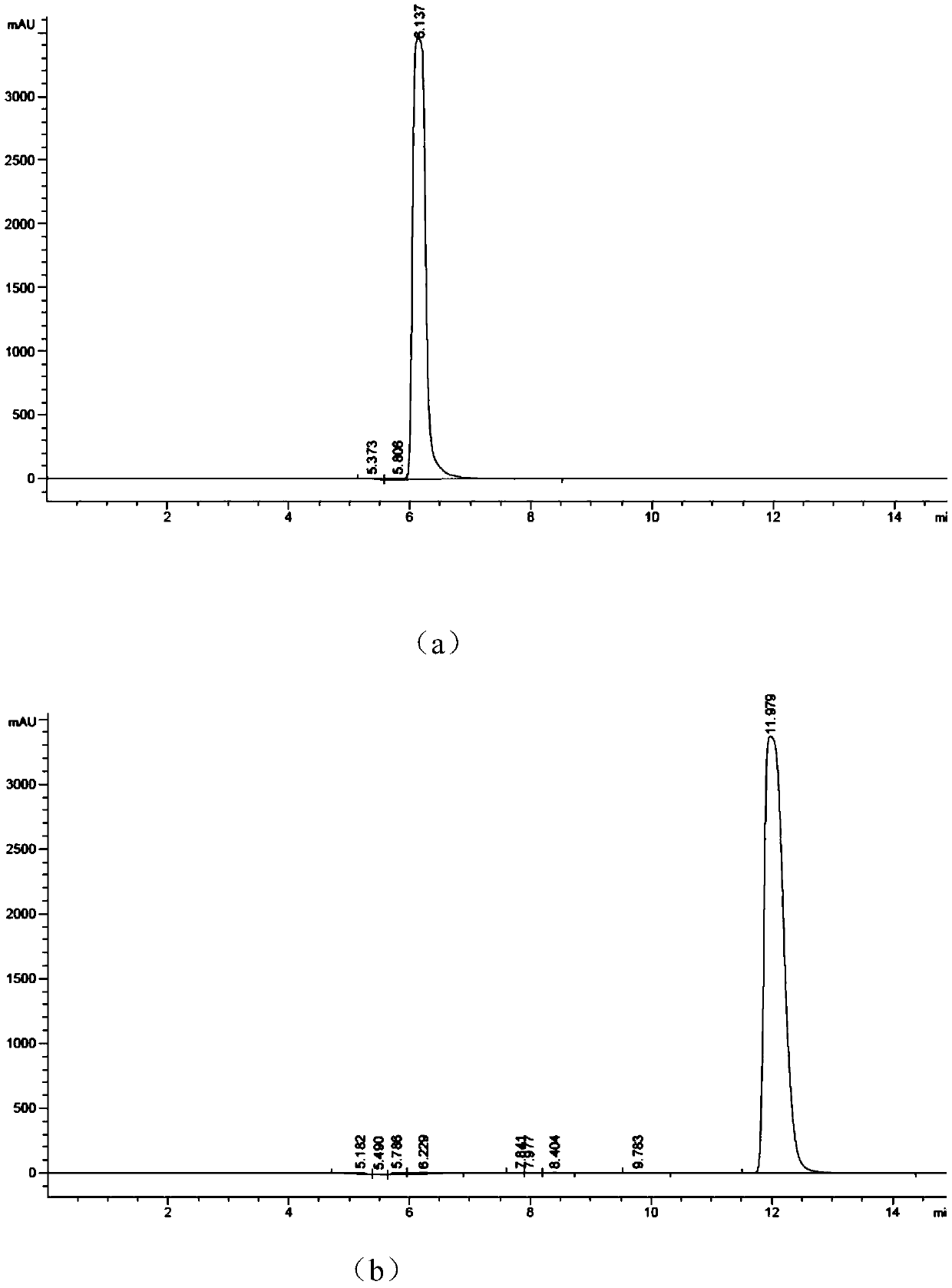

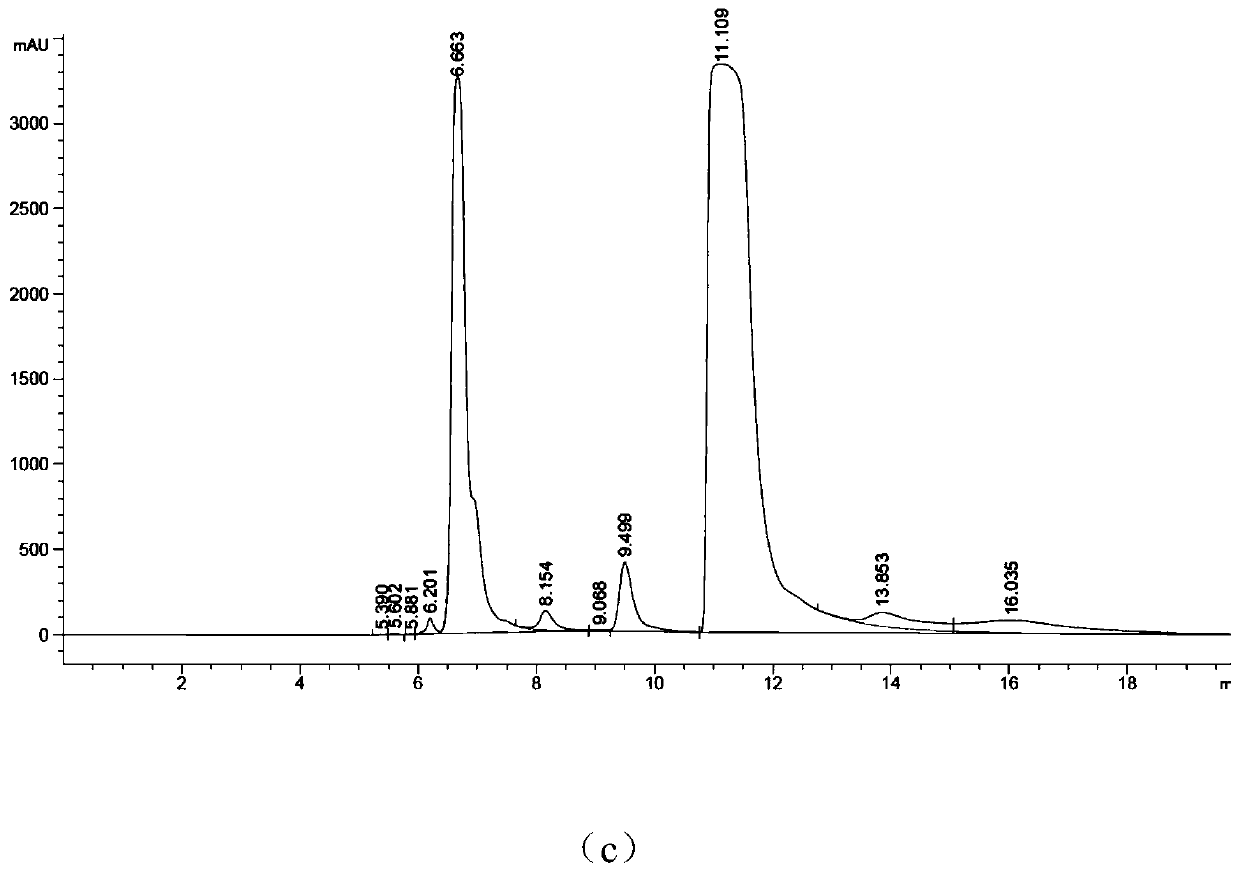

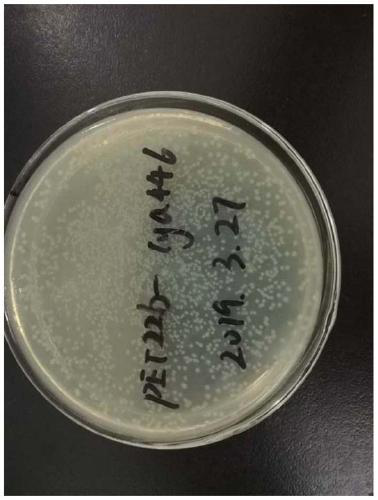

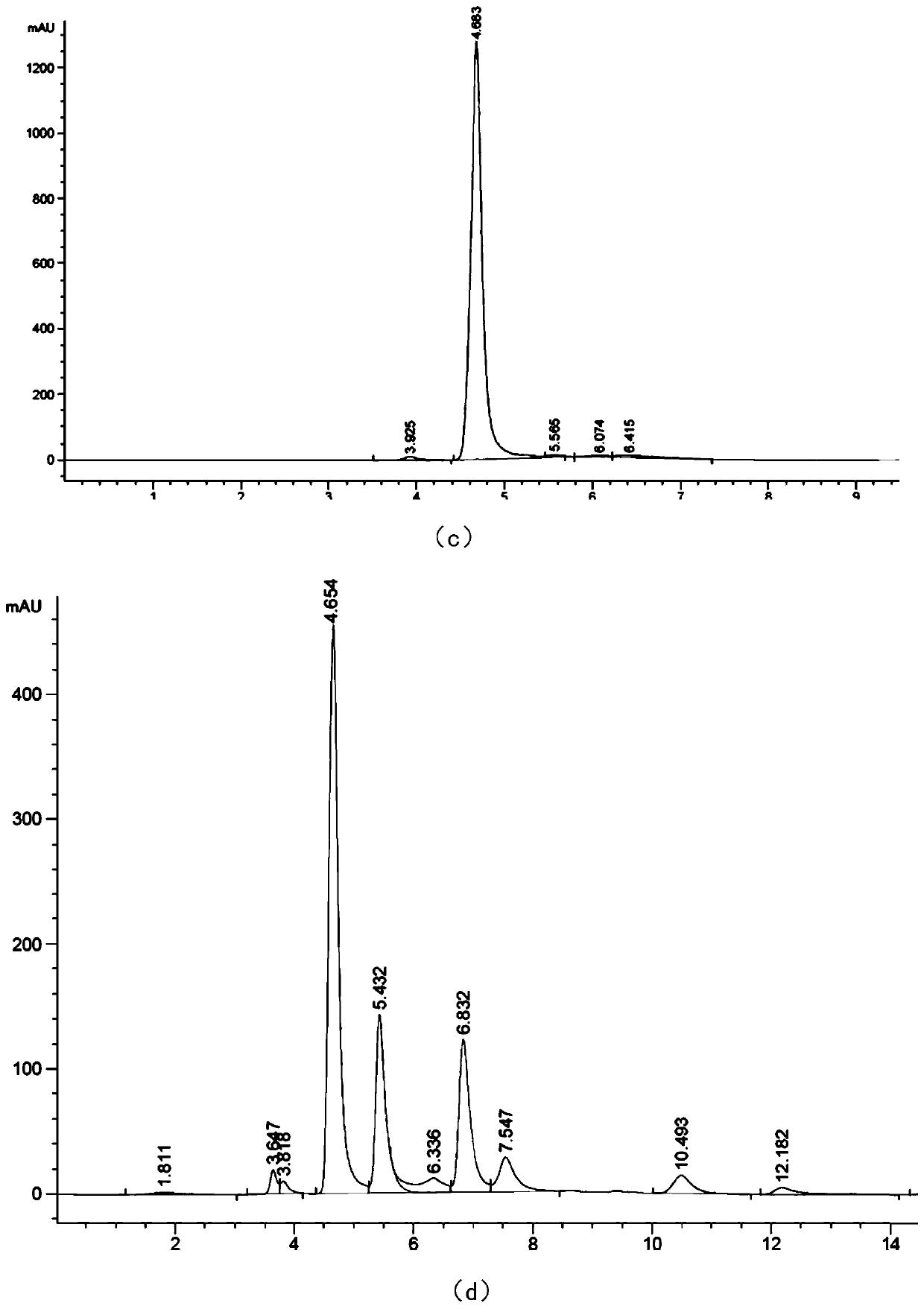

Recombinant escherichia coli for producing cyclic adenosine monophosphate with high yield and application thereof in synthetization of cyclic adenosine monophosphate

PendingCN110157653AMeet the requirements of large-scale industrial productionEasy to separateBacteriaPhosphorus-oxygen lyasesEscherichia coliRecombinant escherichia coli

The invention discloses recombinant escherichia coli for producing cyclic adenosine monophosphate with high yield and application of the recombinant escherichia coli in synthetization of cyclic adenosine monophosphate. An adenylate cyclase gene is cloned from a cAMP production strain, a crude enzyme solution obtained after recombinant bacteria are broken has good catalytic activity and stability,adenosine triphosphate (ATP) and Zn2 + are added, a reaction system is simple, the conditions are mild, a period is short, few byproducts are produced, the method is clean and pollution-free and is asimple, rapid and efficient production way, and the conversion rate of substrate ATP reaches 90% or above.

Owner:NANJING UNIV OF TECH

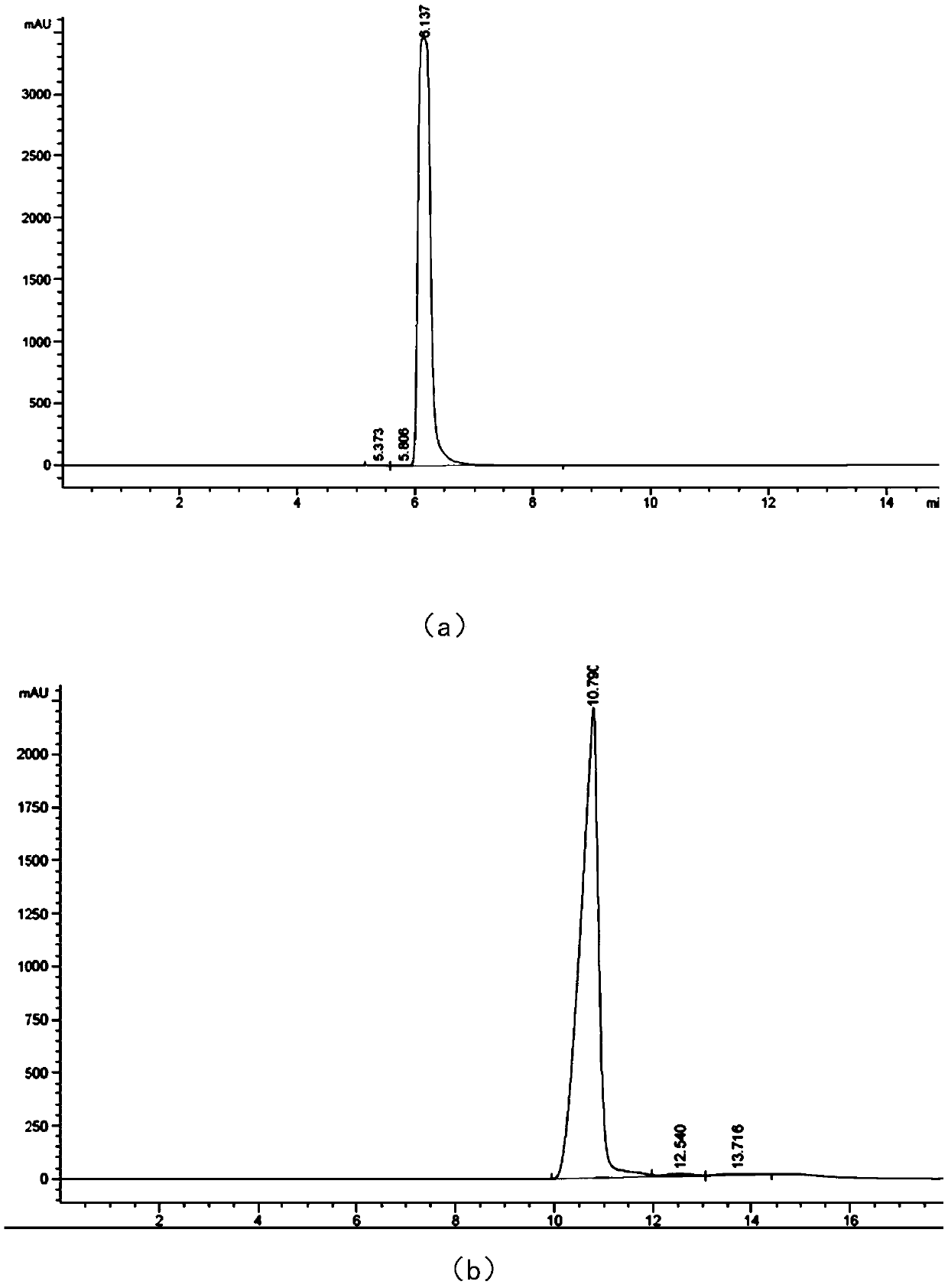

Recombinant escherichia coli for high yield of cytidine monophosphate and application of recombinant escherichia coli

PendingCN111269870AMeet the requirements of large-scale industrial productionReduce purificationBacteriaTransferasesEscherichia coliEnzyme Gene

The invention discloses recombinant escherichia coli for high yield of cytidine monophosphate and application of the recombinant escherichia coli. According to the invention, cytidine kinase gene is obtained by cloning from a cytidine monophosphate production strain; crude enzyme liquid obtained by crushing recombinant bacteria has good catalytic activity and stability; cytidine, adenosine triphosphate (ATP) and Mg < 2 + > are added, the reaction system is simple, the conditions are mild, the period is short, byproducts are fewew, the method is clean and free of pollution, the application is asimple, rapid and efficient production way, and the conversion rate of substrate cytidine and ATP reaches 85% or above.

Owner:NANJING UNIV OF TECH

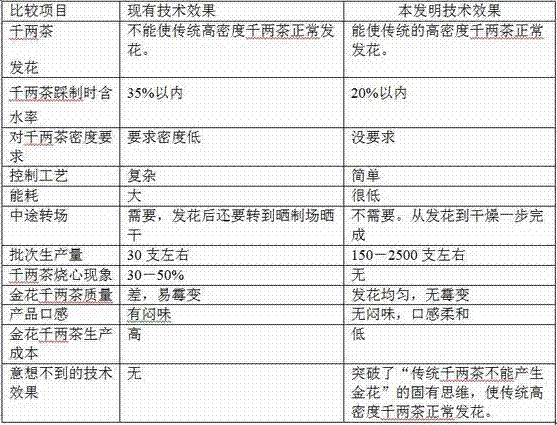

Fungus growing method of Qianliang tea, and Jinhua Qianliang tea

A fungus growing method of Qianliang tea, and Jinhua Qianliang tea relate to a fungus growing method of Qianliang tea, and a product thereof. The fungus growing method is specially characterized by controlling moisture content of Qianliang tea at 16%-22% in stepping; cooling for 0.5-2 days, and then vertically putting in a closed Qianliang tea fungus growing and drying room with top covering iron tiles and a controllable ventilation device at the temperature of being less than or equal to 35DEG C and humidity of being less than or equal to 85%; when performing fungus growing for 1.5 to 2 months, then turning round and performing fungus growing for 0.5-1.5 months, ventilating and drying until the moisture rate reaches 10% or below. The fungus growing method of Qianliang tea has the advantages of being capable of leading the traditional high-density Qianliang tea to grow fungus, conducting fungus growing and drying in the same field, saving transportation cost, simply controlling the fungus growing, and being low in energy consumption, uniform for fungus growing, free from mildew and heartburn phenomena, and high in the rate of finished products. The fungus growing method of Qianliang tea breaks through the inherent concept that eurotium cristatum can be grown normally only under the condition of sufficient oxygen, and the traditional Qianliang tea cannot generate Jinhua fungus, and has unexpected technical effects.

Owner:湖南清山月茶业有限公司

Ceramic pug

InactiveCN104086157AAvoid deformationExtended temperature rangeClaywaresAluminium hydroxideExpanded clay aggregate

The invention discloses ceramic pug. The ceramic pug is prepared from the following raw material components in parts by weight: 30-40 parts of kaolinite powder, 1-2 parts of nanosilicon dioxide, 2-3 parts of aluminium oxide, 2-5 parts of montmorillonite powder, 10-20 parts of mica powder, 15-20 parts of vermiculite powder, 5-10 parts of ceramsite powder, 3-5 parts of turf, 5-10 parts of zeolite powder, 10-15 parts of pyroxene powder, 10-15 parts of hornblende powder, 2-5 parts of magnesium oxide, 2-3 parts of ferric oxide, 3-5 parts of aluminium hydroxide, 5-8 parts of limestone, 2-3 parts of sodium metaaluminate, 3-5 parts of Na[Al(OH)4] and 5-8 parts of polycarboxylate water reducing agent. The ceramic pug has the advantages that the defects of easy deformation and unstable shrinkage ratio in a firing process are overcome, the shrinkage ratio is controlled under the synergistic effect of all the components in a formula, so that a product has small possibility of deformation in the firing process; meanwhile, firing shrinkage ratio is controlled to be 14-15%, the range of firing temperature of the product can be expanded, so that yield of fired products is high, and the requirement of large-scale industrial production is met.

Owner:梁胜光

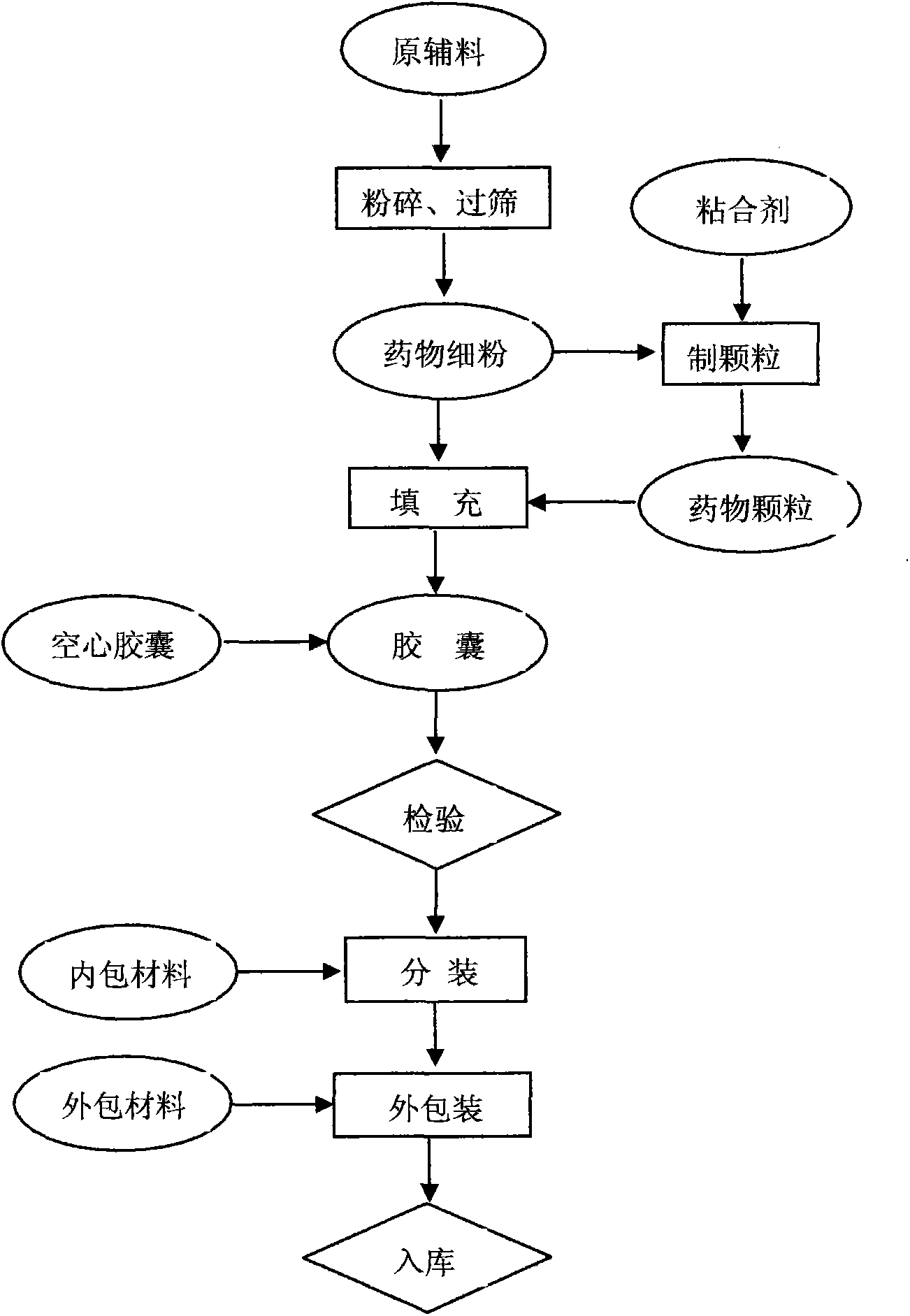

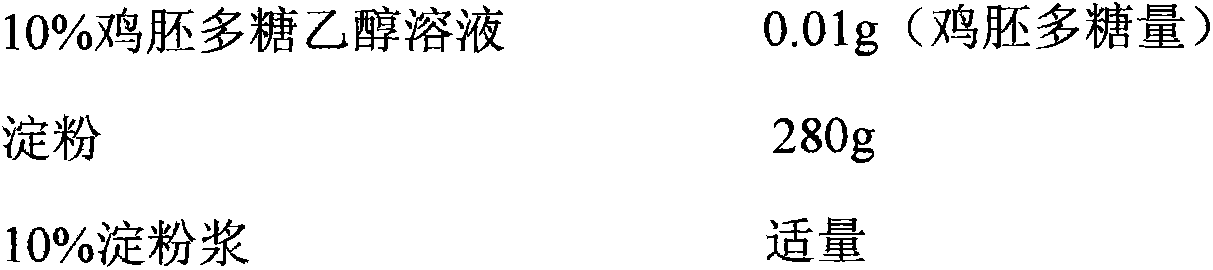

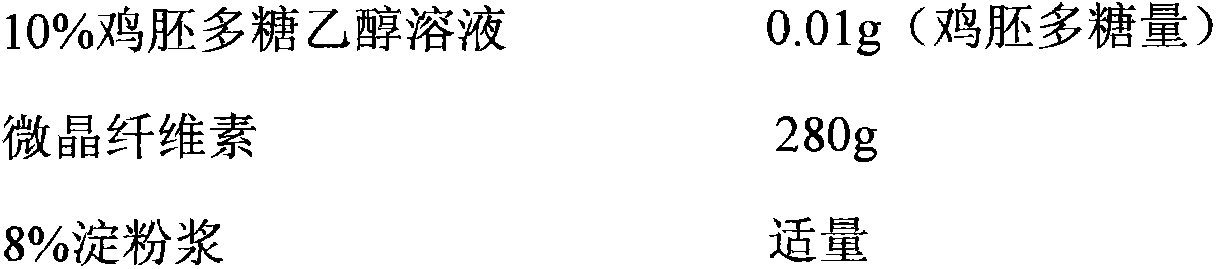

Chick embryo polysaccharide capsule preparation and preparation method thereof

InactiveCN103301088AEasy to takeMeet the requirements of large-scale industrial productionOrganic active ingredientsCapsule deliveryAdhesiveEmbryo

The invention relates to a chick embryo polysaccharide capsule preparation and a preparation method thereof. The chick embryo polysaccharide capsule preparation is a small-dosage medicinal preparation; each capsule contains 10mu g of chick embryo; the preparation contains the following auxiliary materials in percentage by weight: 95-99% of a filler, 0-10% of an adhesive and 0-5% of a lubricant. The preparation method comprises the steps of filling powder into the capsule directly and filling the powder into the capsule after being pelletized. The chick embryo polysaccharide capsule preparation provided by the invention is good in mobility, uniform in content, stable in preparation property, simple in production process and good in reproducibility, and can meet the requirements of large-scale industrialization.

Owner:金莲英 +2

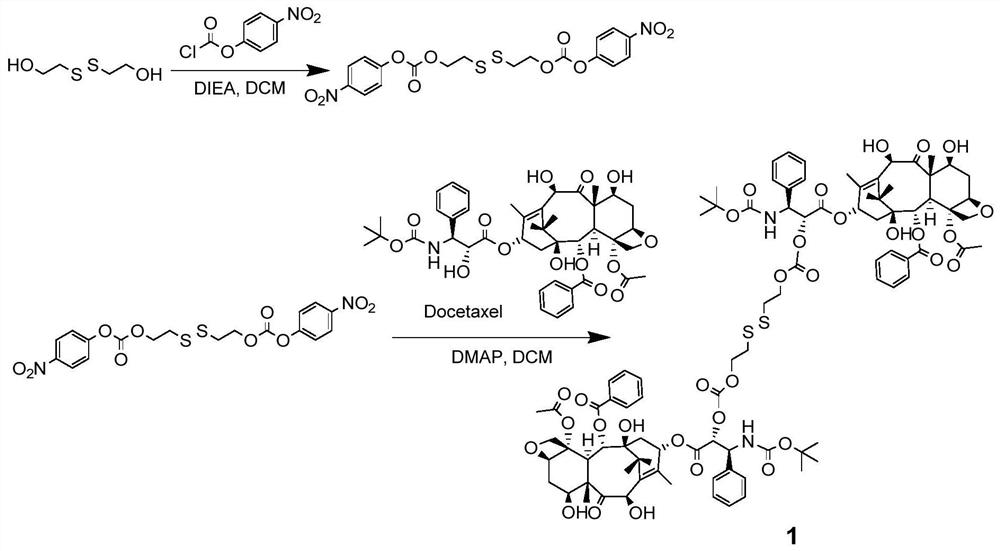

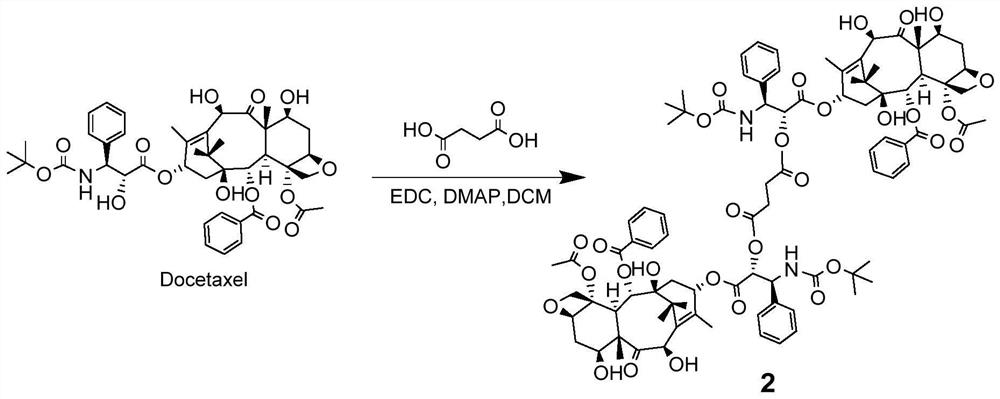

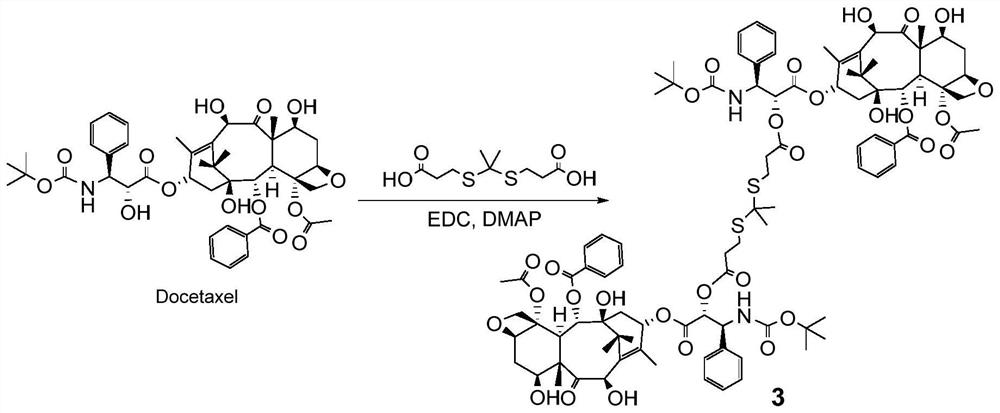

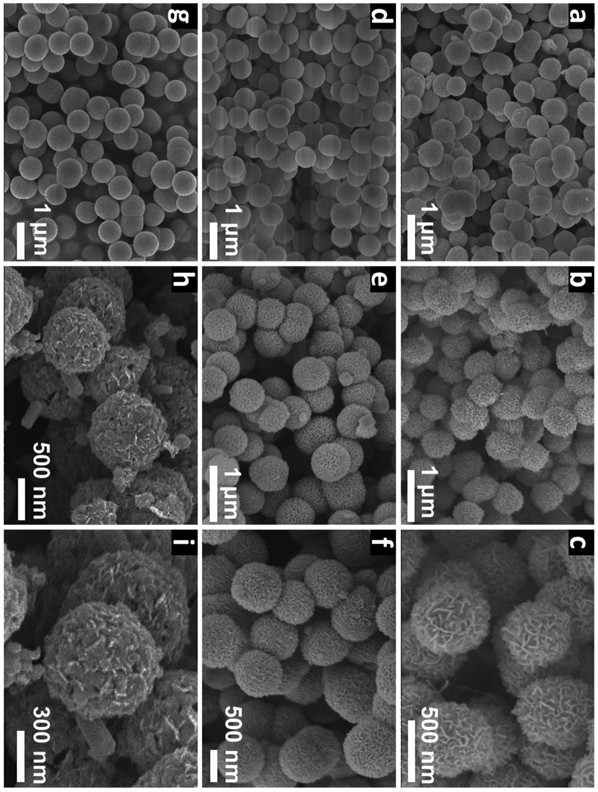

Taxane prodrug, preparation method and application thereof

PendingCN112250647AIncreased Tolerated DoseReduce toxicity in vivoOrganic active ingredientsOrganic chemistryCabazitaxelDocetaxel

The invention discloses a taxane prodrug, which has a structure of Y1-R-Y2, wherein the Y1 and the Y2 are docetaxel or cabazitaxel, R comprises a specific connecting bond for environmental response intumor cells, and the taxane prodrug is generated by carrying out substitution or condensation reaction on a taxane drug and a tumor microenvironment-responsive connecting bond. According to the invention, the prodrug has good anti-tumor activity, can directly release active ingredients in vivo in a hydrolysis or oxidation mode, and can avoid in vivo toxicity caused by direct injection of taxane drugs; the prodrug disclosed by the invention not only has good solubility in water, but also can be self-emulsified in water to form nanoparticles; and the prodrug can be obtained through a single-step reaction method, the yield is high, the preparation cost is low, the stability is high, the safety is good, the requirements of clinical medication are met, the requirements of large-scale industrial production are met, and the prodrug has good market prospects and clinical application value.

Owner:ZHEJIANG UNIV

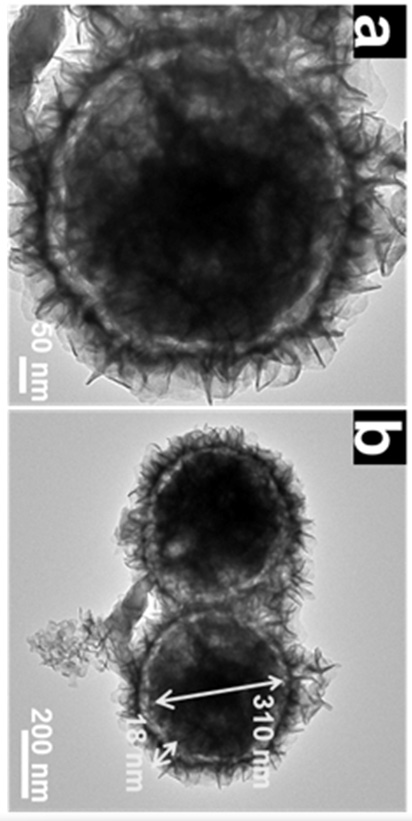

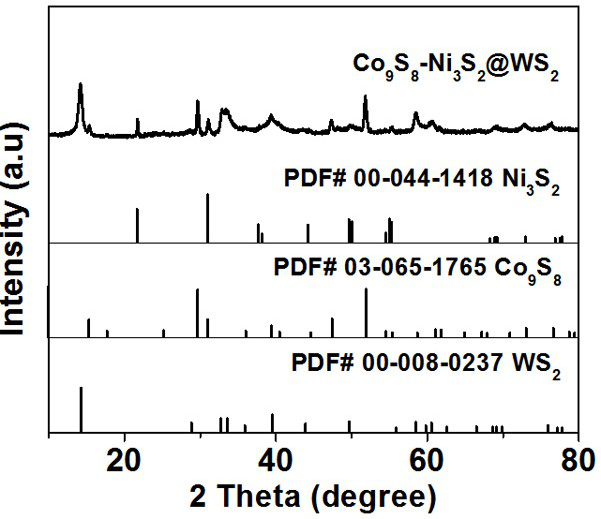

Nickel-cobalt-tungsten polysulfide bifunctional catalyst with core-shell spherical structure as well as preparation method and application of nickel-cobalt-tungsten polysulfide bifunctional catalyst

ActiveCN112473697ALow priceSmall sizePhysical/chemical process catalystsPhotoelectrochemical storage cellsNickel saltPtru catalyst

The invention discloses a preparation method of a nickel-cobalt-tungsten polysulfide bifunctional catalyst with a core-shell spherical structure. The method comprises the following steps: firstly, dissolving a cobalt salt, a nickel salt and glycerol in a specific solvent, then putting a mixed solution into a stainless steel high-pressure reaction kettle taking polytetrafluoroethylene as a lining,carrying out heating reaction for a period of time, and then carrying out centrifugal drying to obtain a nickel-cobalt glycerol precursor; and carrying out tungsten doping and vulcanization treatmenton the precursor, ammonium tungstate and thioacetamide under a solvothermal reaction condition to finally obtain the quaternary tungsten sulfide doped cobalt nickel sulfide Co9S8-Ni3S2@WS2 catalyst. The preparation method has the advantages of easily available raw materials, low cost, simple process, short reaction time, unique catalyst morphology, high specific surface area and excellent electrocatalytic performance, can be applied to dye-sensitized solar cells, has photoelectric efficiency of 9.67%, and has good application prospects in the field of water electrolysis hydrogen production.

Owner:FUZHOU UNIV

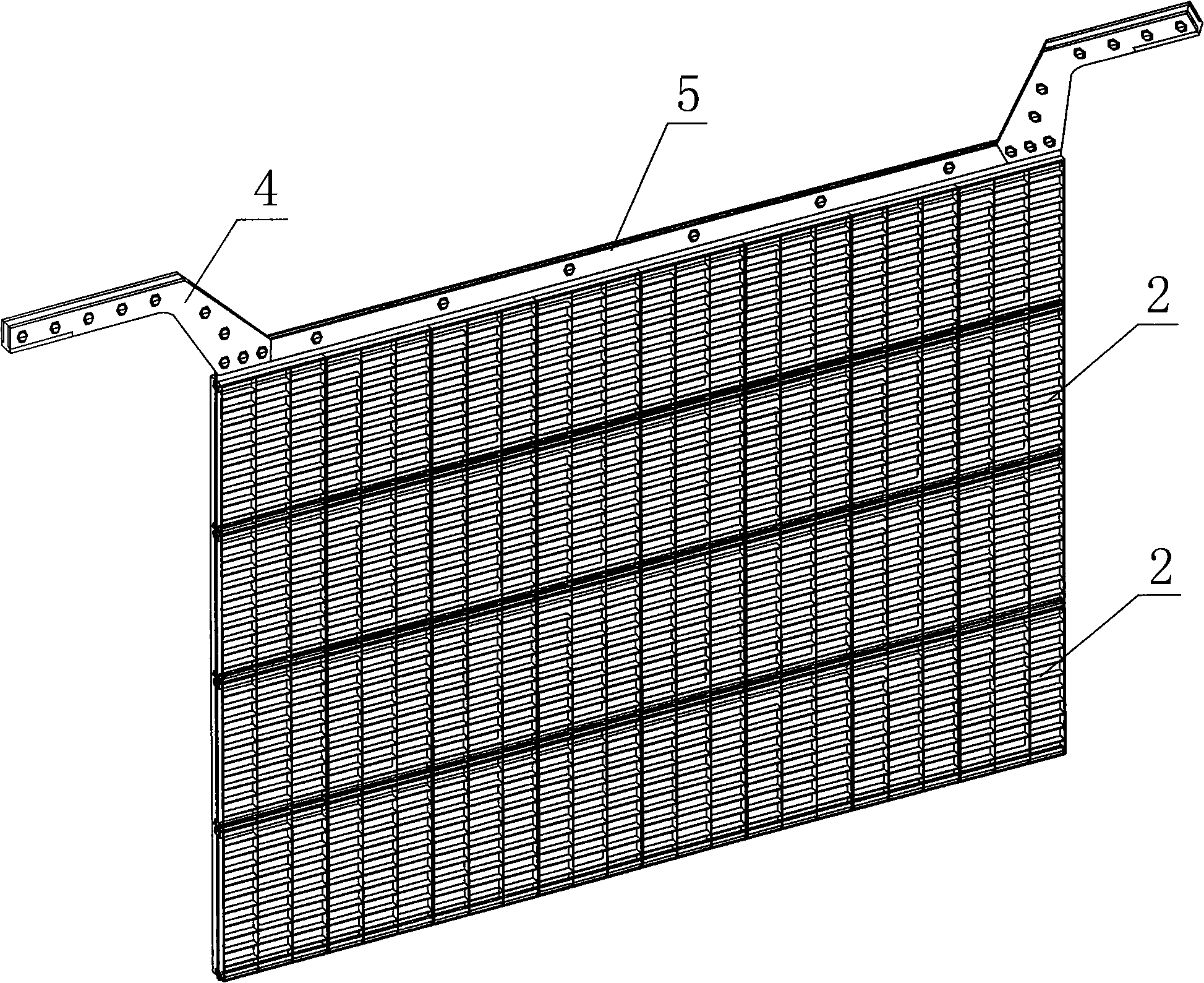

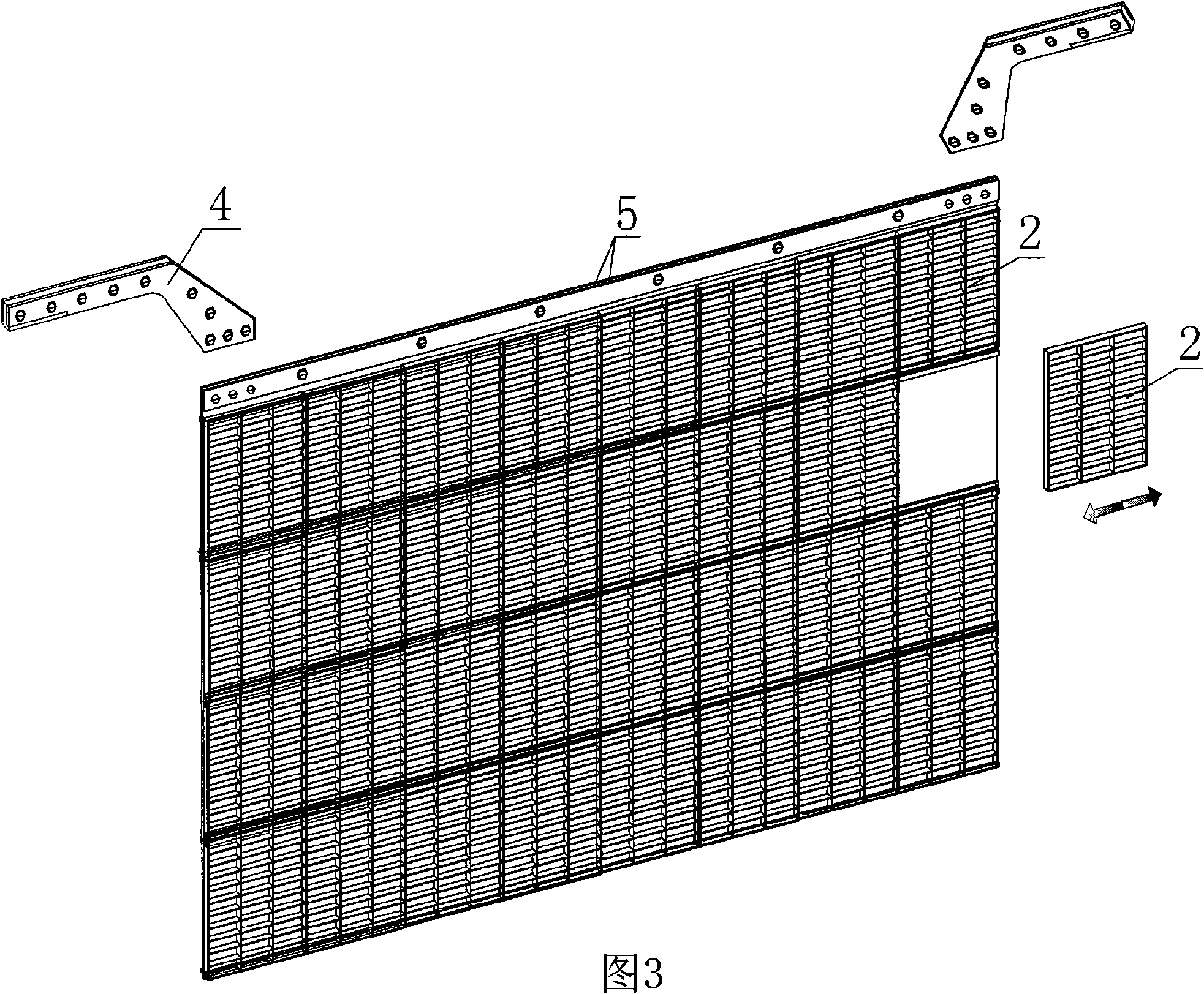

Combined electrolytic cathode plate

InactiveCN101358360AImprove the effective area of electrolysisImprove loading and unloading efficiencyPhotography auxillary processesElectrodesElectrolysisEngineering

The invention discloses a combined electrolysis cathode plate which comprises an electrolysis cathode plate and a conductive connecting piece, and is characterized in that the electrolysis cathode plate comprises an electrolysis mother plate, a plurality of electrolysis unit plates and connecting mechanisms thereof, wherein, the electrolysis mother plate is in a plane structure, and the upper end of the mother plate is connected with a conductive connecting structure; the connecting mechanism is arranged on the surface of the electrolysis mother plate; the electrolysis unit plates are frame plates which are applicable to paste application and removing devices with surface area smaller than that of the electrolysis mother plate; the electrolysis unit plates are movably arranged on the electrolysis mother plate by the connecting mechanisms, to form a large removable combined electrolysis cathode plate. The combined electrolysis cathode plate of the invention can not only meet the requirements for the mechanical operation during paste application and removing processes, but also realize wet electrolysis mass industrialized production, improve production efficiency, improve current efficiency and reduce power consumption.

Owner:DONGGUAN SONGSHAN TECH GROUP

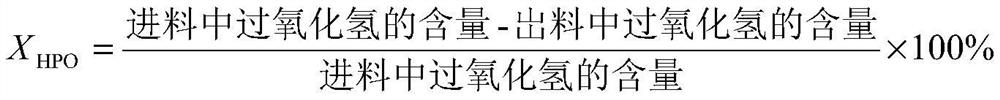

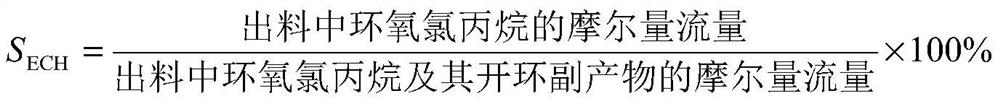

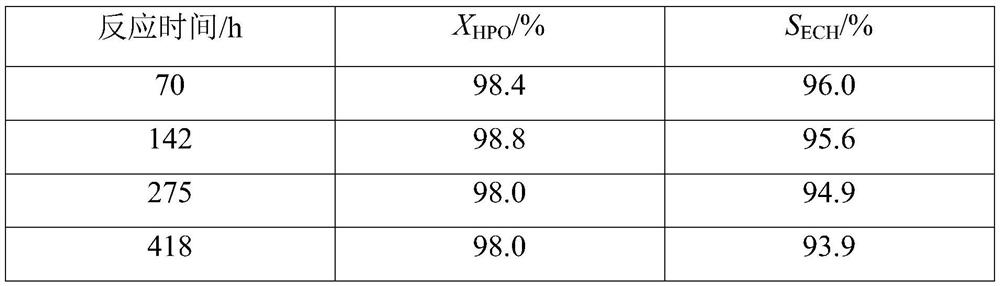

Olefin epoxidation method

ActiveCN112209902AExtended one-way reaction timeHigh selectivityOrganic chemistryMolecular sievePtru catalyst

The invention relates to the field of olefin oxidation, and discloses an olefin epoxidation method, which comprises the following steps: contacting a liquid mixture containing olefin, hydrogen peroxide, a solvent and an alkaline additive with a titanium silicalite molecular sieve catalyst in a reactor with a height-diameter ratio of 100-1000, and carrying out an epoxidation reaction on the olefinto generate epoxidized olefin, wherein a liquid heat-conducting medium with the average flow rate of 0.01-2 m / s is introduced into a jacket of the reactor, the temperature of the liquid heat-conducting medium is increased from 20-50 DEG C to 55-85 DEG C, and the temperature rise rate of the liquid heat-conducting medium is 0.001- 0.2 DEG C / h. By adopting the method, the one-way reaction time of the catalyst can be greatly prolonged, and high hydrogen peroxide conversion rate and product selectivity can be maintained.

Owner:CHINA PETROLEUM & CHEM CORP +2

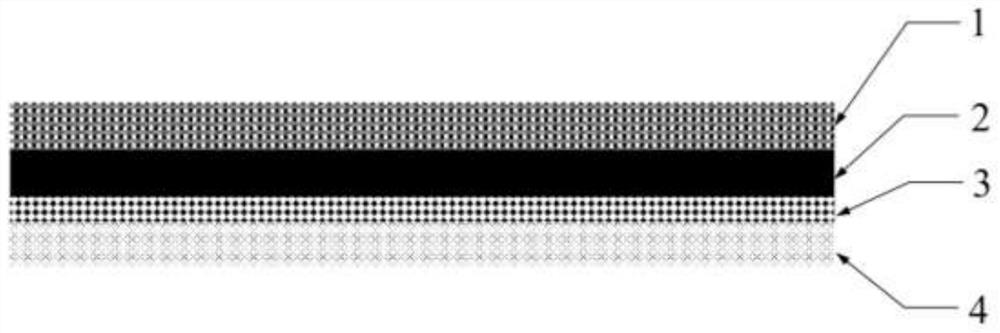

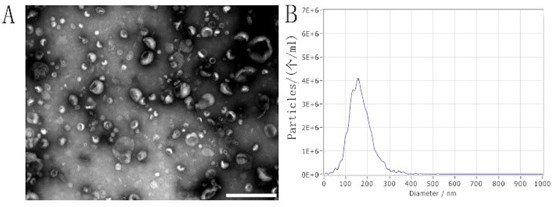

Cis-platinum nano pharmaceutical preparation, preparation method and application

ActiveCN108836937AIncreased Tolerated DoseReduce systemic toxicityPlatinum organic compoundsPharmaceutical non-active ingredientsStructural formulaPt element

The invention discloses a tetravalent platinum pharmaceutical preparation, and a preparation method and application thereof. The tetravalent platinum pharmaceutical preparation comprises a prodrug andan amphipathic high molecular material. The prodrug has a structural formula (I). Dynamic light scattering and a transmission electron microscopy show that nanoparticles are uniformly distributed andare about 40-60 nm; an in vitro cytotoxicity test shows that the nanoparticles coated with platinum prodrug can inhibit proliferation of tumor cells (MDA-MB-468 and HT-29) obviously. An in vivo experiment shows that compared with a cis-platinum injection liquid, the cis-platinum nano pharmaceutical preparation has an effect of inhibiting subcutaneous tumor MDA-MB-468 on the basis of reducing thesystemic toxicity and has good market prospect and clinical application value.

Owner:ZHEJIANG UNIV

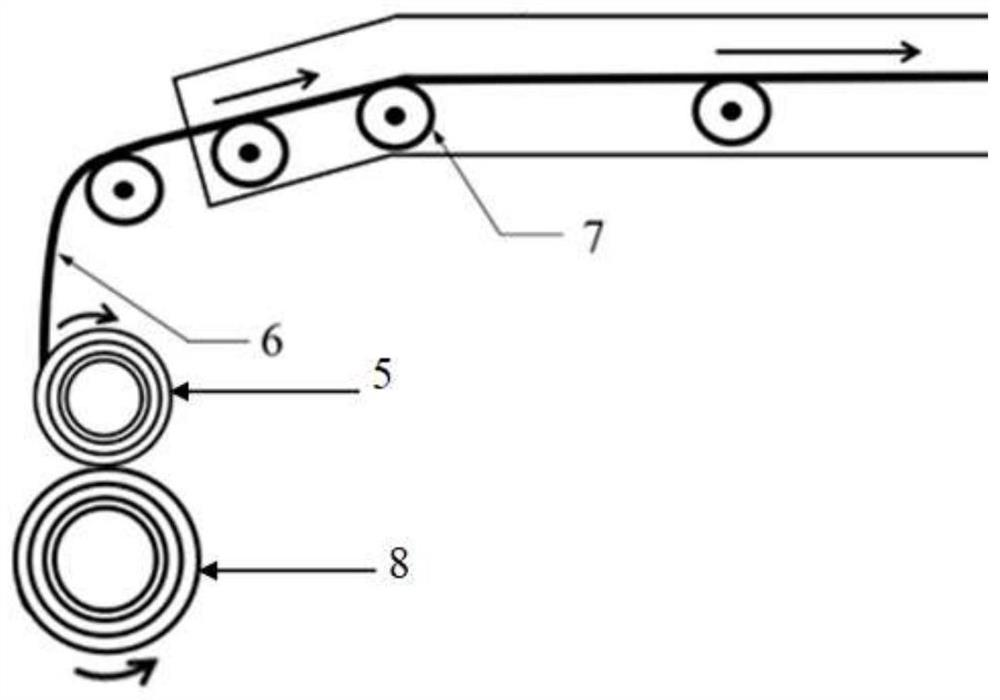

Organic silicon resin modified heat-resistant back coating material as well as preparation method and use method thereof

PendingCN112724826ABreak the helixImprove heat resistanceInk ribbonsCoatingsMeth-Dibutyl tin dilaurate

The invention discloses an organic silicon resin modified heat-resistant back coating material, which is prepared from the following components in parts by mass: 2 to 4 parts of methyl MQ silicon resin, 180 to 200 parts of simethicone, 18 to 20 parts of methacryloyloxypropyltrimethoxysilane, 6 parts of dibutyltin dilaurate and 5800 to 6800 parts of organic solvent. According to the using method of the organic silicon resin modified heat-resistant back coating material, a transmission roller drives a PET base film to keep uniform motion, and the surface of the PET base film is uniformly coated with the organic silicon resin modified heat-resistant back coating material; and the redundant organic silicon resin modified heat-resistant back coating material on the surface of the PET base film is scraped off, the release layer and the ink layer are coated, and drying is carried out to finally obtain the finished product of the thermal transfer ribbon. The production process is simple, the raw material cost is low, the cost is considered while the heat resistance of the thermal transfer ribbon is improved, and the large-scale industrial production requirement of a factory is met.

Owner:福建鸣友新材料科技有限公司

A kind of exosome drug delivery system and its preparation method and application

ActiveCN113292608BProtect completenessHigh drug loadingInorganic active ingredientsOrganic chemistry methodsPhospholipidDrug loading dose

The invention discloses an exosome drug delivery system and its preparation method and application, and provides an active drug loading system that uses phospholipid compounds to load cisplatin prodrugs on exosomes, so as to solve the problem of membrane rupture caused by exosome drug loading strategy and low drug loading; the present invention prepares cisplatin prodrugs in advance, prepares them into liposomes, and then mixes them in exosomes to realize active drug loading, utilizing the fusion of phospholipid compounds and exosome membranes It protects the integrity of the exosome membrane and increases the drug loading capacity of the exosome anticancer drugs.

Owner:天津外泌体科技有限公司

Preparation method of alkalescent liquid accelerator

The invention relates to the field of building materials, in particular to a method for preparing a weak base liquid quick-setting agent. When preparing, first add sodium hydroxide, potassium hydroxide, and aluminum hydroxide into water in proportion, and react at a temperature of 95-120°C for 2-3 hours to obtain the aluminate mother liquor; first dissolve sodium fluoride in water, At a certain temperature, silicate is added to the aqueous solution to obtain a modifier; finally, the modifier is added dropwise to the aluminate composite mother liquor, and after fully reacting, the novel low-alkali liquid quick-setting liquid of the present invention is obtained agent. The quick-setting agent of the invention has the characteristics of short setting time, low alkali content and good cement adaptability.

Owner:如皋市玉辉助剂厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com