Purifying method of 1, 1, 1, 2-tetrafluoroethane

A technology of tetrafluoroethane and purification method, which is applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry, etc., can solve the problem that adsorption separation technology does not have industrial application value, HCFC-1122 has low adsorption capacity and poor affinity difference. Significant problems such as achieving good industrial application prospects, meeting large-scale industrial production, and improving the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

[0023] 10g of adsorbent is filled with an inner diameter of 15mm and a length of 150mm in a stainless steel tube, and the crude product of HFC-134a with a total weight of 50g and containing about 950ppm of HCFC-1122 and a purity of about 99.87% is in the gas phase at a temperature of 250℃, the pressure is normal pressure, take 1.0h -1 The space velocity enters the adsorption fixed bed from the top of the adsorption bed. The gas after adsorption was analyzed by gas chromatograph for the content of each component, and the results are shown in Table 1.

[0024] Table 1

[0025] Example

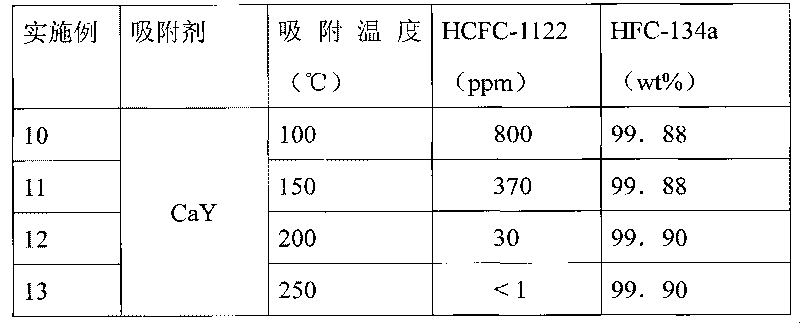

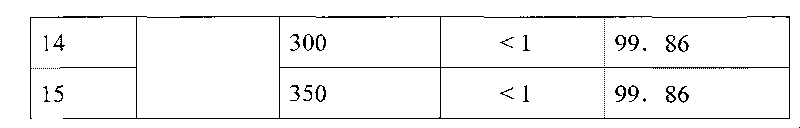

Embodiment 10-15

[0027] Other conditions are the same as those in Examples 1-9, except that the adsorbent is changed to CaY molecular sieve, and the adsorption temperature is changed to 100°C, 150°C, 200°C, 250°C, 300°C, and 350°C. The results are shown in Table 2.

[0028] Table 2

[0029]

[0030]

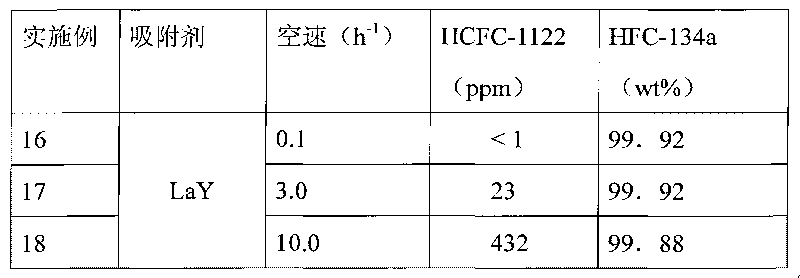

Embodiment 16-18

[0032] Other conditions are the same as in Examples 1-9, only the adsorbent is changed to LaY molecular sieve, and the feed space velocity of HFC-134a crude product is 0.1, 3.0, 10.0h -1 , and the results are shown in Table 3.

[0033] table 3

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com