Method for treating antimony sulfide concentrate through sulfide phase reductive transformation-ore dressing

An antimony sulfide and sulfide technology, applied in the field of non-ferrous metal metallurgy, can solve the problems of flue gas pollution to the environment and high energy consumption, achieve the effects of low reaction temperature, low energy consumption, and meet the requirements of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

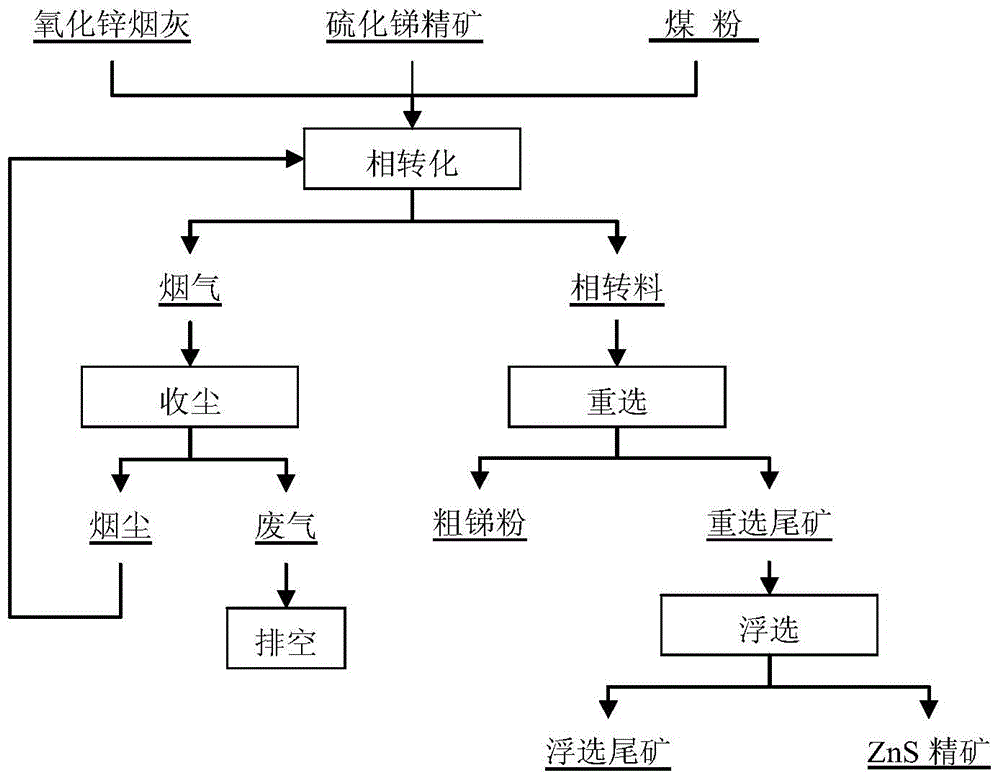

Method used

Image

Examples

Embodiment 1

[0029] The composition (wt.%) of the gold-containing antimony sulfide concentrate as the test raw material is: Sb37.21, Fe13.27, S30.60, Cu0.085, Pb0.18, Bi 0.026, As0.034, SiO 2 7.14、Al 2 o 3 2.26, CaO0.079, Au 56.6g / t; the composition (wt.%) of sulfur-fixing zinc oxide is: Zn74.06, Fe0.076, As0.84, Cu0.011, Pb0.81, F0.44 , Cl0.38, SiO 2 0.5, CaO0.016; the chemical composition (wt.%) of reduced coal powder is: C82.33, S3.01, SiO 2 6.66, CaO0.83, Al 2 o 3 4.81, MgO0.23. Weigh 100g of antimony sulfide concentrate, 65g of zinc oxide soot, and 6g of coal powder with the above ingredients, mix them evenly, put them into a graphite crucible, put them in an electric furnace at 850°C for 2.0h, and obtain a phase inversion product after cooling 154g, its main chemical composition (wt.%) is: Sb24.16, Fe8.62, S19.87, Zn31.26, Pb0.35, F0.013, Cl0.029. The removal rates of fluorine and chlorine are 93% and 80%, respectively. XRD and phase analysis show that the antimony phase is m...

Embodiment 2

[0031] The composition (wt.%) of antimony ore as test raw material is: Sb55.55, S22.51, Fe0.55, SiO 2 21.31, Pb0.01, As0.02, CaO1.52, Al 2 o 3 0.40, Au0.40g / t.

[0032] Weigh 100g of antimony sulfide concentrate of the above composition, 65g of secondary zinc oxide soot and 8g of coal powder in Example 1, mix them evenly, put them into a graphite crucible, put them into an electric furnace and react at 875°C for 1.0h, and obtain a phase after cooling. The conversion product was 153g, and its main chemical components (wt.%) were: Sb36.31, S14.71, Zn31.46, Pb0.34, F0.0093, Cl0.019. The removal rates of fluorine and chlorine are 95% and 88%, respectively. XRD and phase analysis show that the antimony phase is mainly metallic antimony, accounting for 96.35% of the total antimony, and the main phase of zinc is ZnS, accounting for 95.45% of the total zinc.

Embodiment 3

[0034]The composition (wt.%) of antimony ore as test raw material is: Sb48.15, S21.82, Fe2.46, SiO 2 16.94, Pb0.085, Zn0.018, As0.02, CaO0.69, Al 2 o 3 2.16, Au0.31g / t.

[0035] Weigh 100g of antimony sulfide concentrate of the above composition, 60g of secondary zinc oxide soot and 10g of coal powder in Example 1, mix them uniformly, put them into a graphite crucible, put them into an electric furnace and react at 900°C for 45min, and obtain phase inversion after cooling Product 148g, its main chemical composition (wt.%) is: Sb32.53, S14.74, Zn30.00, Fe1.66, Pb0.38, F0.0054, Cl0.012. The removal rates of fluorine and chlorine are 97% and 92%, respectively. XRD and phase analysis show that the antimony phase is mainly metallic antimony, accounting for 97.25% of the total antimony, and the main phase of zinc is ZnS, accounting for 95.32% of the total zinc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com