Method for preparing multilayer graphene-carbon material

A multi-layer graphene and carbon material technology, applied in graphene, nano-carbon and other directions, can solve the problems of no research results, patent application results, etc., and achieve the effects of simplifying the preparation process, improving electrical properties, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The reactant resorcinol, mass concentration is 37~40% formaldehyde solution, hexadecyltrimethylammonium bromide, deionized water according to resorcinol: formaldehyde solution: hexadecyltrimethylbromide The mass ratio of ammonium chloride: deionized water=1: 1.38: 0.0165: 1.46 is measured, and the reactant manganese acetate (C 4 h 6 MnO 4 4H 2 (0) is carried out with manganese acetate quality accounting for above-mentioned resorcinol, aqueous formaldehyde solution, hexadecyltrimethylammonium bromide and deionized water four kinds of raw material gross mass ratios are carried out, they are mixed homogeneously, obtain free Liquid precursors for shaped carbon materials;

[0032] Move the liquid precursor into a reaction bottle and seal it, heat it at 85°C for 5d, and then follow the following steps: dry at room temperature for 2d, dry at 60°C for 5h, and dry at 110°C for 5h to obtain an amorphous carbon material. solid precursor;

[0033] Put the solid precursor in a ...

Embodiment 2

[0037] In addition to manganese acetate (C 4 h 6 MnO 4 4H 2 O) quality accounted for resorcinol, aqueous formaldehyde solution, cetyltrimethylammonium bromide and deionized water four kinds of raw material total mass ratio is outside 9%, the preparation technology of the liquid precursor of amorphous carbon material and Example 1 is the same.

[0038] The solid precursor of the amorphous carbon material and the preparation process of the amorphous carbon material are also the same as in Example 1.

[0039] The preparation process of the multilayer graphene carbon material is also the same as in Example 1.

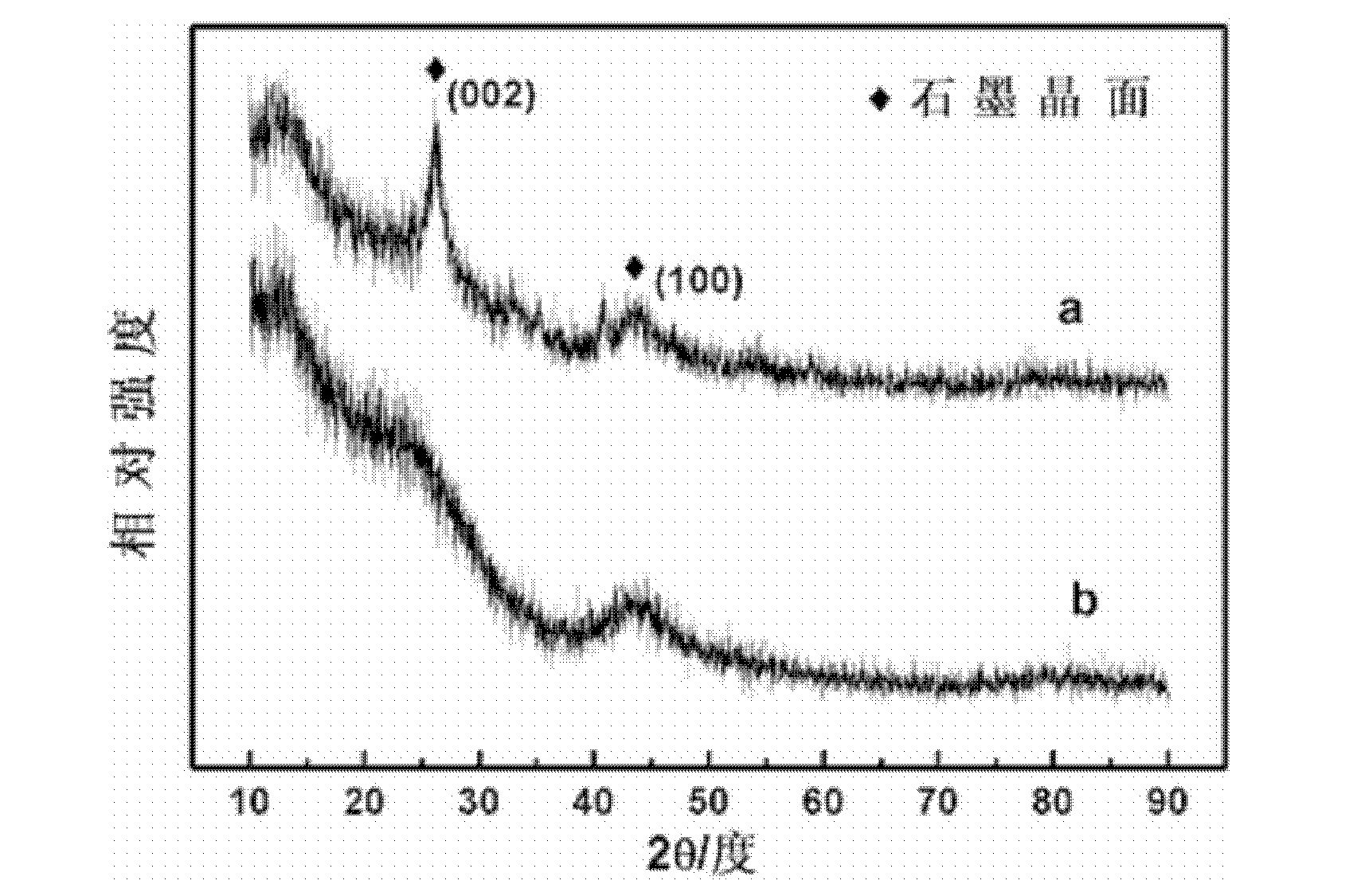

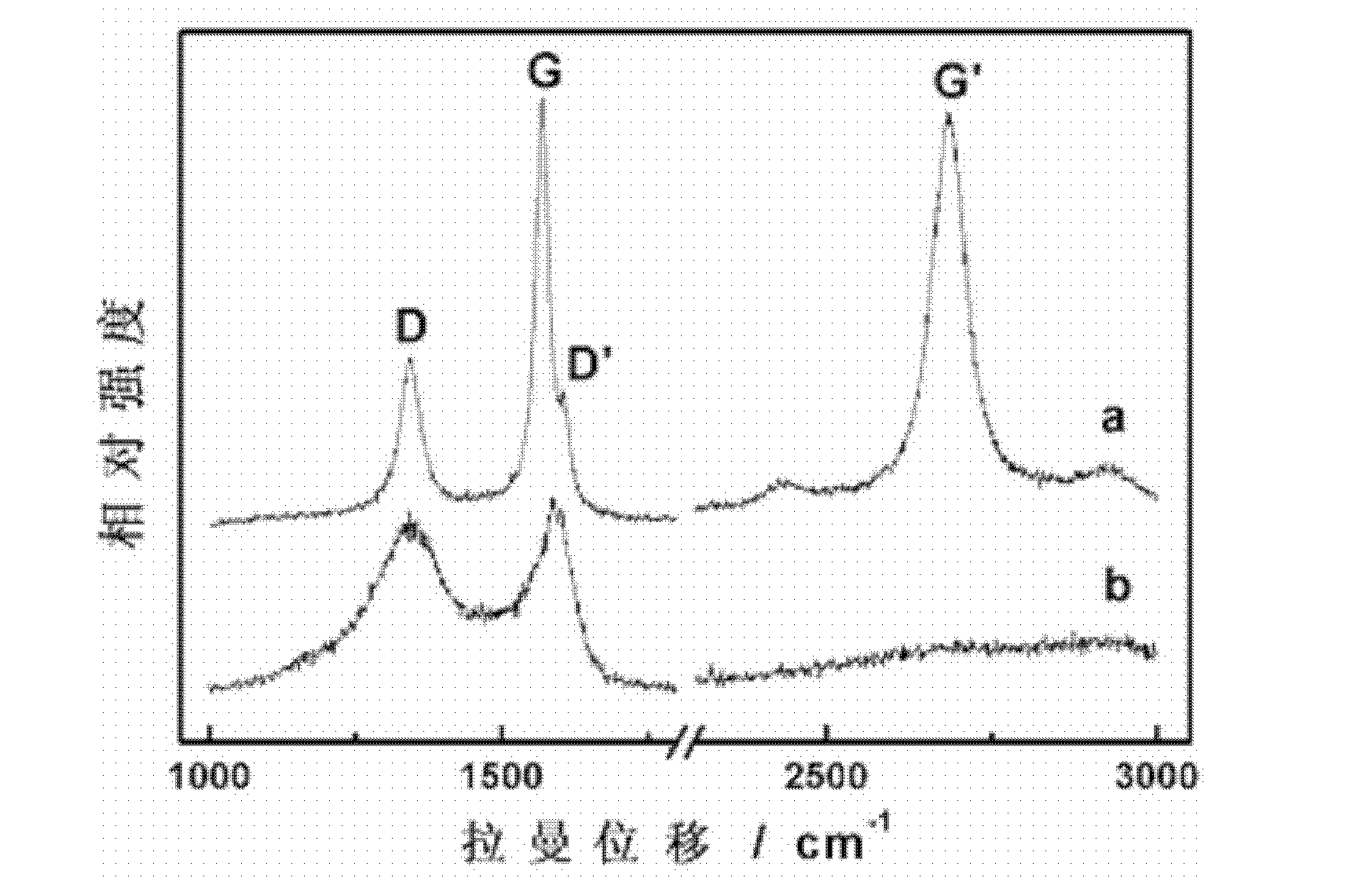

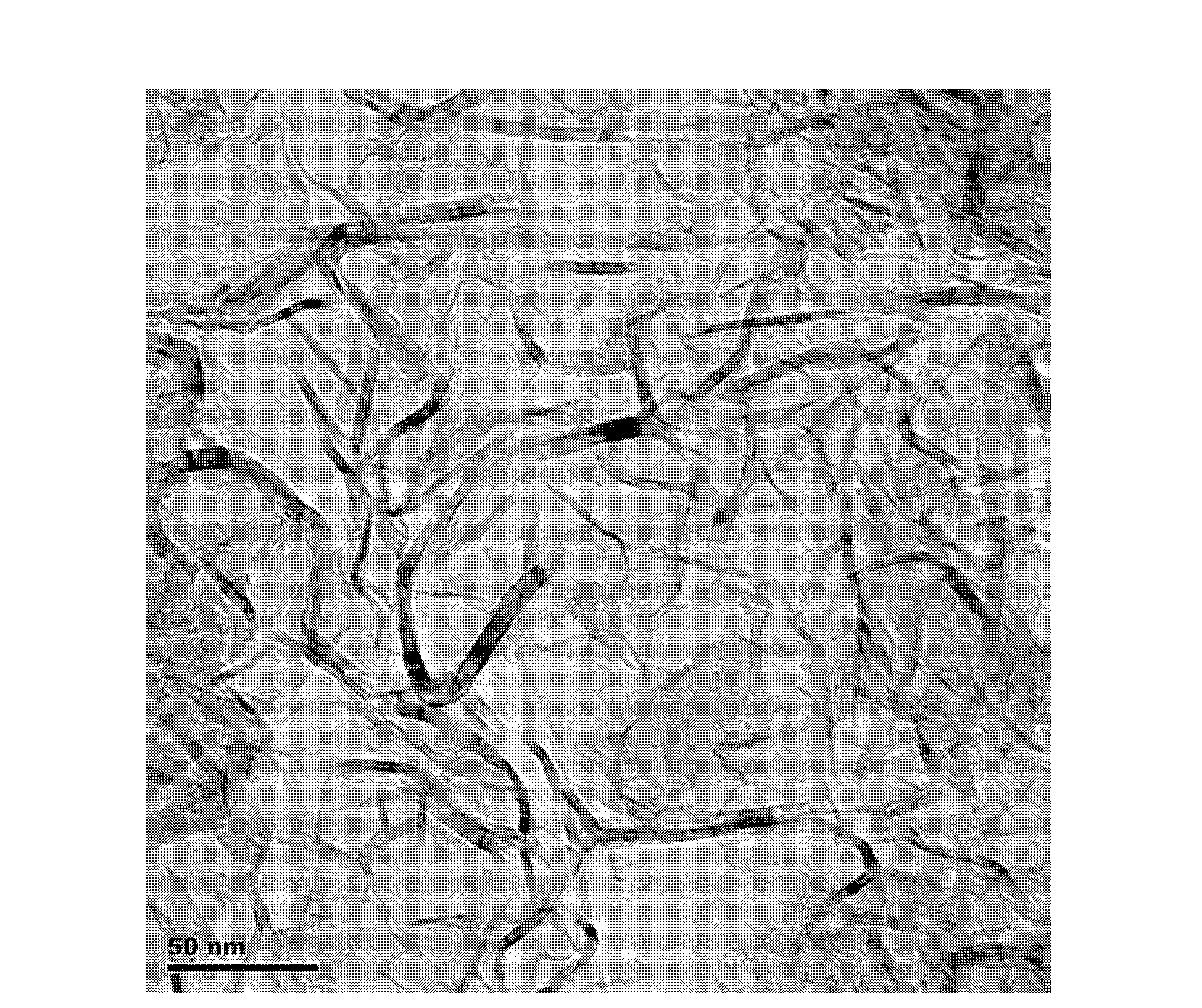

[0040] X-ray powder diffraction, laser Raman spectroscopy and transmission electron microscope analysis were performed on the multilayer graphene carbon material sample, and the obtained characteristics were also the same as in Example 1.

Embodiment 3

[0042] In addition to manganese acetate (C 4 h 6 MnO 4 4H 2 O) quality accounted for resorcinol, aqueous formaldehyde solution, cetyltrimethylammonium bromide and deionized water four kinds of raw material total mass ratio is outside 15%, the preparation technology of the liquid precursor of amorphous carbon material and Example 1 is the same.

[0043] Move the liquid precursor into a reaction bottle and seal it, heat it at 85°C for 4d, and then follow the following steps: dry at room temperature for 2d, dry at 60°C for 6h, and dry at 110°C for 6h to obtain an amorphous carbon material. solid precursor;

[0044] The solid precursor is placed in a crucible of inert material, and then the crucible is placed in a tube furnace. Under the protection of nitrogen, the temperature is raised to 900 ° C and kept for 3 hours, and then cooled to room temperature to obtain an amorphous carbon material;

[0045] The self-made amorphous carbon material and elemental metal sodium (mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com