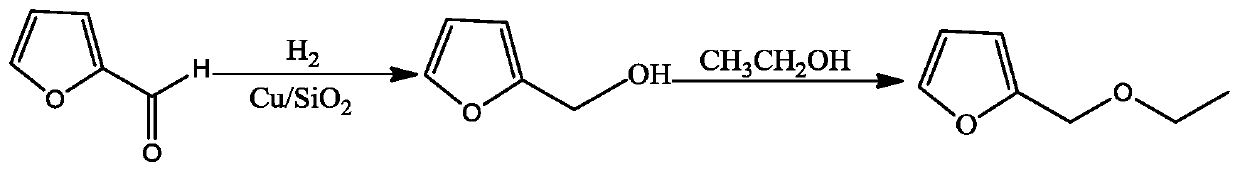

Method and catalyst for preparing ethyl furfuryl ether by liquid-phase hydrogenation of furfural and preparation method of catalyst

A technology of furfuryl ether and catalyst, which is applied in the field of furfural liquid-phase hydrogenation to produce ethyl furfuryl ether, can solve the problems of difficult industrial synthesis production, difficult reaction control, high catalyst cost, etc., achieve high conversion rate, easy scale-up, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

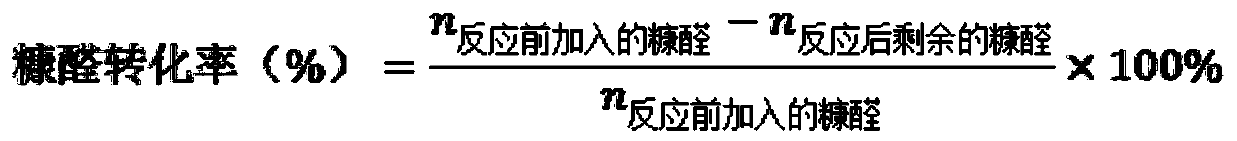

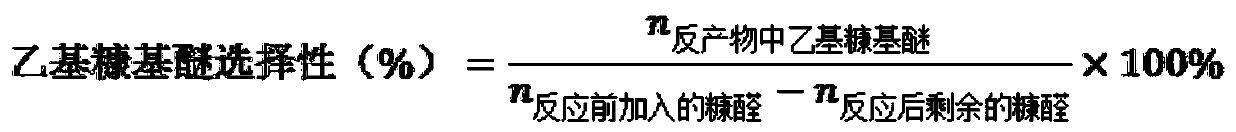

Examples

Embodiment 1

[0036] Preparation of Cu / SiO by Ammonia Distillation 2 . Will accurately weigh 3.09g of Cu(NO 3 ) 2 ·3H 2 O was placed in a three-neck round bottom flask and dissolved in 100ml of deionized water, and ammonia water (14%) was added dropwise at room temperature at 1mL / min until the pH of the solution was >9.0 to form a cuproammonia solution. After the solution was stirred for 10 min, 4.9 g of mesoporous SiO was added 2 , continue to stir for 2 hours, and then move to a 90°C water bath until the pH of the solution is 5. Take out the three-neck round bottom flask, and observe the color change of the solution. The catalyst precursor was obtained by filtration, washed with deionized water for 3 times, dried in an oven at 120°C overnight, and calcined at 250°C in an air atmosphere for 2 hours; after that, the catalyst was ground and sieved to 40-60 mesh particles for future use. in H 2 Reduction at 150°C for 1 h in the atmosphere; after the reduction, cool to room temperature, ...

Embodiment 2

[0038] Preparation of Cu / SiO by Ammonia Distillation 2 . Will accurately weigh 6.17g of Cu(NO 3 ) 2 ·3H 2 O was placed in a three-neck round bottom flask and dissolved in 100ml of deionized water, and ammonia water (14%) was added dropwise at room temperature at 1mL / min until the pH of the solution was >9.0 to form a cuproammonia solution. After the solution was stirred for 20 min, 4.9 g of mesoporous SiO was added 2 , continue to stir for 2 hours, and then move to a 90°C water bath until the pH of the solution is 6. Take out the three-neck round bottom flask, and observe the color change of the solution. The catalyst precursor was obtained by filtration, washed with deionized water for 3 times, dried in an oven at 120°C overnight, and calcined at 450°C in an air atmosphere for 4 hours; after that, the catalyst was ground and sieved to 40-60 mesh particles for future use. in H 2 Restore at 350°C for 2 hours in the atmosphere; after the reduction, cool to room temperature...

Embodiment 3

[0040] Preparation of Cu / SiO by Ammonia Distillation 2 . Will accurately weigh 8.23g of Cu(NO 3 ) 2 ·3H 2 O was placed in a three-neck round bottom flask and dissolved in 100ml of deionized water, and ammonia water (14%) was added dropwise at room temperature at 1mL / min until the pH of the solution was >9.0 to form a cuproammonia solution. After the solution was stirred for 30 min, 4.9 g of mesoporous SiO was added 2, continue to stir for 2 hours, and then move to a 90°C water bath until the pH of the solution is 7. Take out the three-neck round bottom flask, and observe the color change of the solution. The catalyst precursor was obtained by filtration, washed with deionized water for 3 times, dried in an oven at 120°C overnight, and calcined at 650°C in an air atmosphere for 6 hours; after that, the catalyst was ground and sieved to 40-60 mesh particles for future use. in H 2 Reduction at 550°C for 4 hours in the atmosphere; after the reduction, cool to room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com