Organic silicon resin modified heat-resistant back coating material as well as preparation method and use method thereof

A technology of back coating and silicone, which is applied in the direction of coating, printing, ink ribbon, etc., can solve the problems such as the adhesion performance needs to be improved, and achieve the effect of low raw material cost, no irritating smell, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

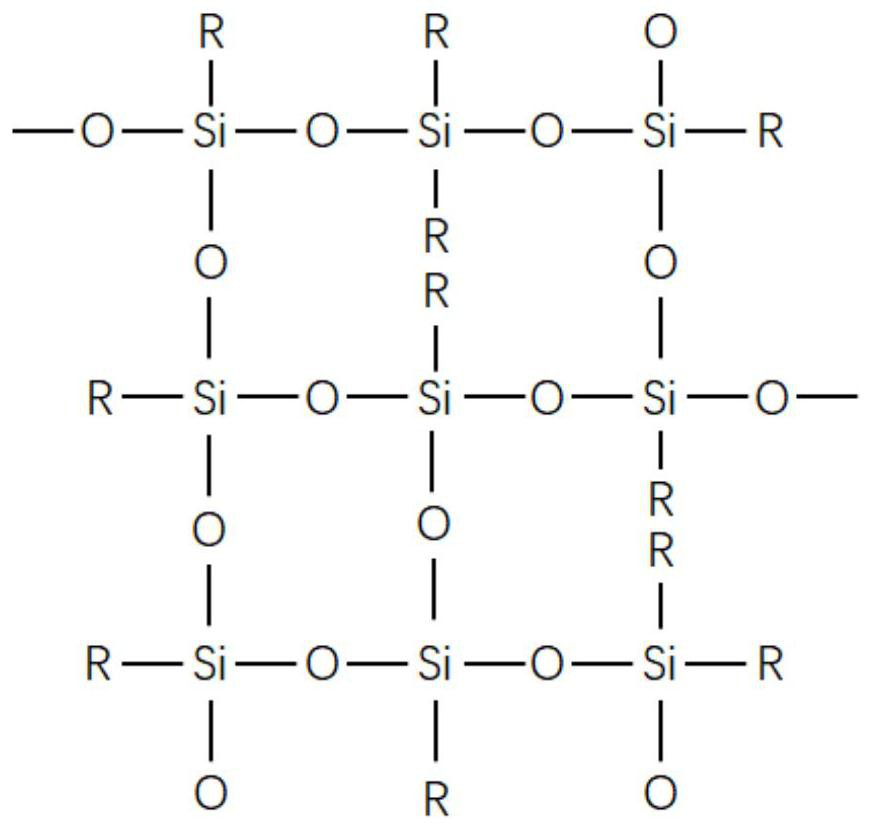

[0047] A silicone resin modified heat-resistant back coating material (organic solvent is xylene)

[0048] (1) Weigh 2g of methyl MQ silicone resin, 180g of dimethyl silicone oil, 18g of methacryloxypropyltrimethoxysilane, and 900g of xylene, mix well, heat and stir at 80°C for 1 hour, and then Stir for 20 hours to obtain an organic solution of methyl MQ silicone resin;

[0049] (2) Add 5000 g of xylene to the solution obtained in step (1) and stir for 3 hours;

[0050] (3) Put the solution obtained in step (2) into an ultrasonic instrument for ultrasonication for 1 hour;

[0051] (4) Weigh 6 g of dibutyltin dilaurate and add it to the solution obtained in step (3), and stir for 10 minutes to obtain a silicone resin-modified heat-resistant back coating material for preparing thermal transfer ribbons.

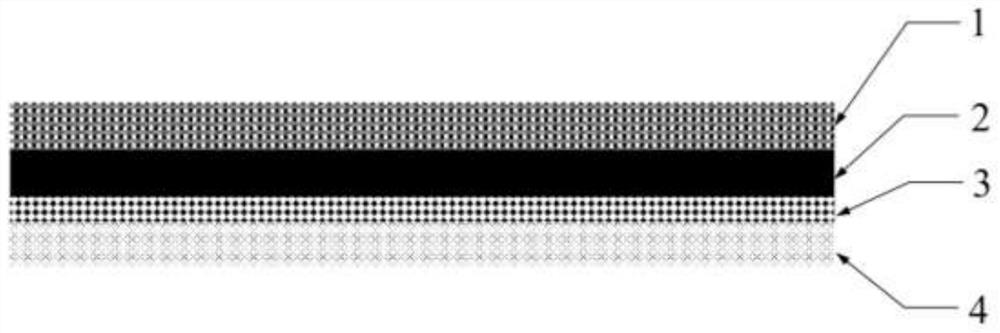

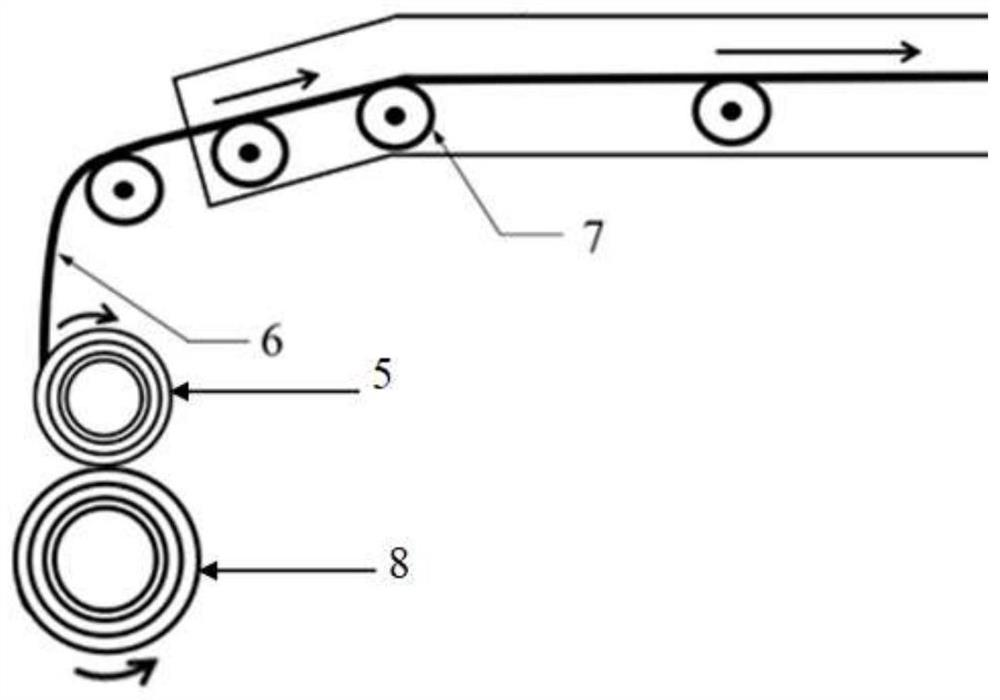

[0052] A kind of silicone resin modified heat-resistant back coating material prepared in Example 1 is applied to the production process of heat-resistant back coating. Norma...

Embodiment 2

[0055] A silicone resin modified heat-resistant back coating material (organic solvent is acetone)

[0056] (1) Weigh 3g of methyl MQ silicone resin, 190g of dimethyl silicone oil, 19g of methacryloxypropyltrimethoxysilane, and 950g of acetone, heat and stir at 80°C for 2 hours, then stir at room temperature for 30 hours, Obtain the organic solution of methyl MQ silicone resin;

[0057] (2) Add acetone 5300g to the solution obtained in step (1) and stir for 4 hours;

[0058] (3) Put the solution obtained in step (2) into an ultrasonic instrument and sonicate for 1.5 hours;

[0059] (4) Weigh 6 g of dibutyltin dilaurate and add it to the solution obtained in step (3), and stir for 10 minutes to obtain a silicone resin-modified heat-resistant back coating material for preparing thermal transfer ribbons.

[0060] A silicone resin modified heat-resistant back coating material prepared in Example 2 is applied to the production process of the heat-resistant back coating, and the o...

Embodiment 3

[0063] A silicone resin modified heat-resistant back coating material (organic solvent is ethyl acetate)

[0064] (1) Weigh 4g of methyl MQ silicone resin, 200g of dimethyl silicone oil, 20g of methacryloxypropyltrimethoxysilane, 1000g of ethyl acetate, heat and stir at 80°C for 1 hour, then stir at room temperature for 40 Hour, obtain the organic solution of methyl MQ silicone resin;

[0065] (2) Add 5500 g of ethyl acetate to the solution obtained in step (1) and stir for 5 hours;

[0066] (3) Put the solution obtained in step (2) into an ultrasonic instrument for ultrasonication for 2 hours;

[0067] (4) Weigh 6 g of dibutyltin dilaurate and add it to the solution obtained in step (3), and stir for 10 minutes to obtain a silicone resin-modified heat-resistant back coating material for preparing thermal transfer ribbons.

[0068] Applying the heat-resistant back coating solution prepared in Example 3 to the production process of heat-resistant back coating, the prepared ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com