Microfluid spinning device used for preparing orderly orienting fiber

A spinning device and microfluidic technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as difficult to collect grids, need to be improved, and difficult to overcome surface tension, achieving good repeatability, Satisfy the effect of large-scale industrial production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

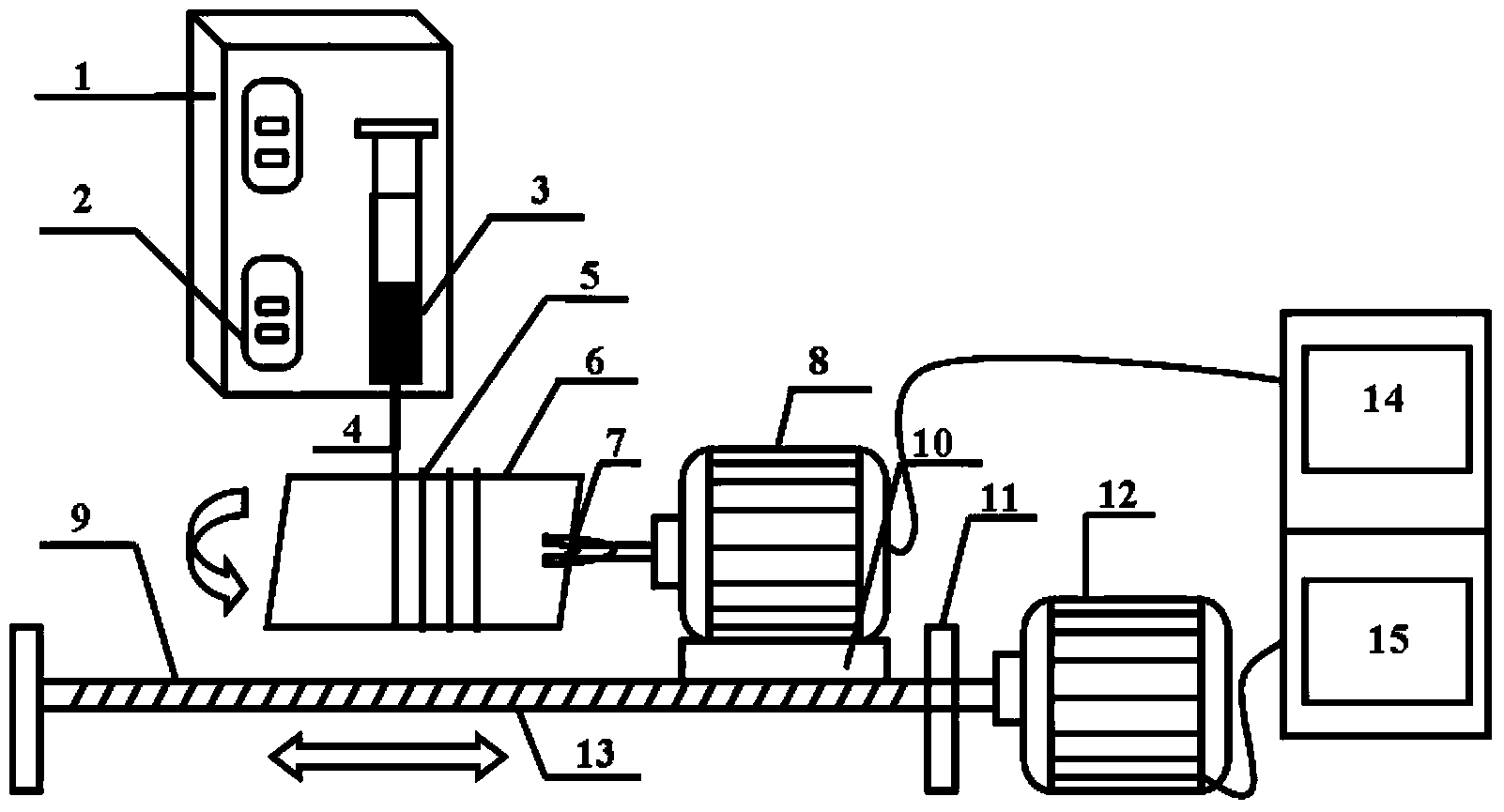

[0023] The microfluid spinning device for preparing ordered and oriented microfibers of the present invention includes a dual-channel microflow pump 1, a control panel 12, an injection spinner 3, an open flat plate receiver 5, a rotating motor 8, and a stepping motor Translation platform 9, control panel II14 and control panel III15, wherein the dual-channel micro-flow pump 1 is installed on the open flat plate receiver 5, and the injection spinner 3 is installed on the dual-channel micro-flow pump 1 and communicates with the open plate through its needle 4. The receiving plate 6 on the open flat receiver 5 is connected, the open flat receiver 5 is installed on the rotating motor 8, and the rotating motor 8 provides the mechanical force of wire drawing, and the receiving plate 6 and the reel 16 on the open flat receiver 5 pass through The iron clamp fixer 7 is fixed on the directional winding wire of the rotary motor 8, and the rotary motor 8 is installed on the base 10 of the ...

Embodiment 2

[0028] Device is as described in embodiment 1, gets 3g polyvinylpyrrolidone (M w =1300000) was dissolved in 10g ethanol (99.5%), and magnetically stirred to dissolve into a homogeneous polymer solution. Under normal temperature and pressure, put the polymer solution into the syringe and install it tightly on the microflow pump, and set the advancing rate to 0.1mL / h. The speed of the rotating motor is set to 800rad / min. First, a fiber is picked out and connected to the glass sheet receiver, and the continuous and uniform filament is rotated and wound by the glass sheet. The step translation speed is set to 10mm / min, so that the position of the unwound filaments is shifted accordingly, and the theoretically equidistant collection makes it possible for them not to overlap, and an equidistant parallel microfilament alignment is obtained.

Embodiment 3

[0030] Device is as described in embodiment 1, gets 3g polycaprolactone (M w =80000) was dissolved in 10g of chloroform, and magnetically stirred to dissolve into a homogeneous polymer solution. Under normal temperature and pressure, put the polymer solution into the syringe and install it tightly on the microflow pump, and set the advancing rate to 0.1mL / h. The speed of the rotating motor is set to 800rad / min, and the step translation rate is set to 12mm / min to obtain equidistant parallel microfilament arrays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com