A cassava degradable plastic and its production process and production equipment

A technology for degrading plastics and cassava, applied in the field of cassava degradable plastics and its production process and production equipment, can solve the problems of easy breakage, short life, and greater impact of photodegradable plastics

Active Publication Date: 2018-04-13

DONGGUAN FANGZHONG SPORT PROD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Existing degradable plastics include starch-added type, photodegradable type, and plant fiber type. Starch-added plastics have poor strength, stretchability, and light transmission, and the degradation time is difficult to control and has a short life; photodegradable plastics It is greatly affected by the weather, and it is not easy to degrade in dark or cloudy days; plant fiber plastics have problems such as low strength, poor wind and rain resistance, and easy breakage. Therefore, existing degradable plastic products generally have defects and are difficult to promote and apply on a large scale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

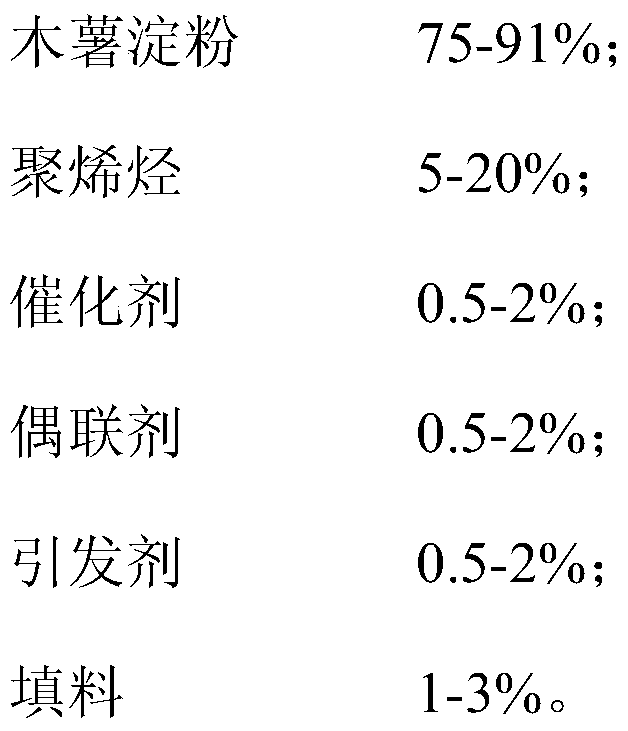

[0030] A kind of cassava degradable plastics, comprising each component of following percentage by weight:

[0031]

Embodiment 2

[0033] A kind of cassava degradable plastics, comprising each component of following percentage by weight:

[0034]

[0035]

Embodiment 3

[0037] A kind of cassava degradable plastics, comprising each component of following percentage by weight:

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

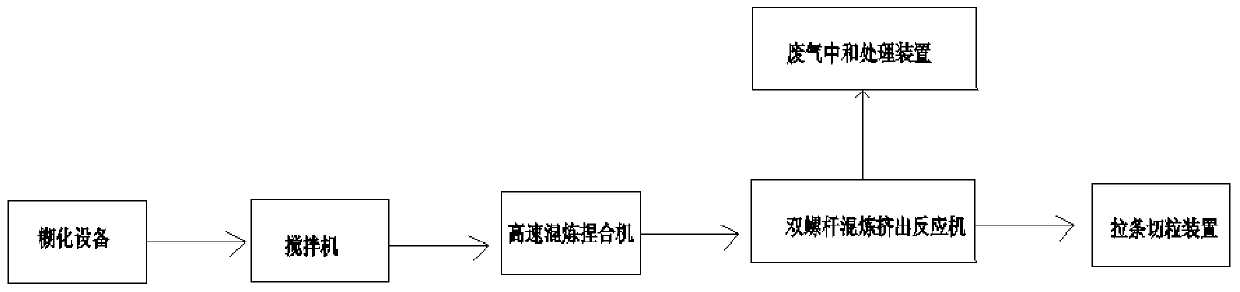

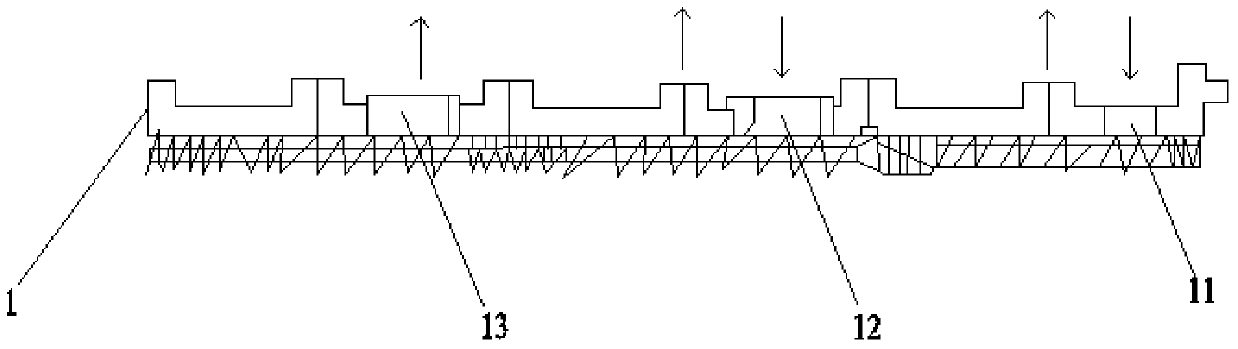

Abstract

The invention relates to the technical field of cassava degradable plastic as well as a process and equipment thereof, and in particular relates to a cassava degradable plastic as well as a production process and production equipment thereof. The cassava degradable plastic consists of the following components in percentage by weight: 75-91% of cassava starch, 5-20% of polyolefin, 0.5-2% of a catalyst, 0.5-2% of a coupling agent, 0.5-2% of an initiator and 1-3% of filler. The production process comprises the following steps: carrying out gelatinizing pretreatment, carrying drying pretreatment, then mixing and kneading powder at a high speed, reacting and extruding in a twin-screw extrusion reacting machine, and finally bracing, dicing, drying and sub-packaging to obtain the cassava degradable plastic. The cassava degradable plastic production equipment comprises a sieving machine for sieving the filler and a stirrer for mixing materials, and further comprises gelatinizing equipment for gelatinizing the cassava starch, a high-speed mixing and kneading machine, a twin-screw melting-extrusion reacting machine and a bracing and dicing device; the stirrer is connected to the high-speed mixing and kneading machine; the high-speed mixing and kneading machine is connected to the twin-screw melting-extrusion reacting machine; and the twin-screw melting-extrusion reacting machine is connected to the bracing and dicing device. The degradation rate can reach more than 85%.

Description

technical field [0001] The invention relates to the technical field of degradable plastics and its technology and equipment, in particular to a cassava degradable plastic and its production process and production equipment. Background technique [0002] Plastics have brought various conveniences to people's daily life, but because organic polymers are difficult to degrade, they have caused serious pollution. The "white pollution" of plastics threatens the ecological environment and is a worldwide problem. The emergence of environmentally friendly degradable plastics has pointed out the development direction for the future plastics industry. [0003] Existing degradable plastics include starch-added type, photodegradable type, and plant fiber type. Starch-added plastics have poor strength, stretchability, and light transmission, and the degradation time is difficult to control and has a short life; photodegradable plastics It is greatly affected by the weather, and it is not...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L3/02C08L23/08C08L23/12C08K13/02C08K3/26C08K5/14C08K5/10C08K3/22C08K3/34C08K13/04C08K7/20C08K3/36C08K5/09B29C47/92B29B9/06B29C47/08B29C48/92

Inventor 赵奎

Owner DONGGUAN FANGZHONG SPORT PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com