A kind of vanadium microalloying 600mpa grade low temperature steel bar and its production method

A low-temperature steel bar and alloying technology, which is applied in the field of vanadium microalloying 600MPa grade low-temperature steel bar, can solve the problems of unstable yield, unfavorable product quality, fluctuation of mechanical properties, etc., and achieves broad application prospects and product added value. High, good economic and social benefits

Active Publication Date: 2021-07-13

MAANSHAN IRON & STEEL CO LTD

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are deficiencies: (1) Ni content is too high, which greatly increases production cost, which is not conducive to market promotion and application; (2) Ti has strong oxidizing property and unstable yield, which is easy to cause large fluctuations in mechanical properties, which is not conducive to the improvement of product quality. Stablize

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1- Embodiment 8

[0021] A vanadium microalloyed steel for 600MPa grade low-temperature reinforcement, the steel includes the following weight percentage content: see Table 1 below, and the balance is Fe and unavoidable impurities.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

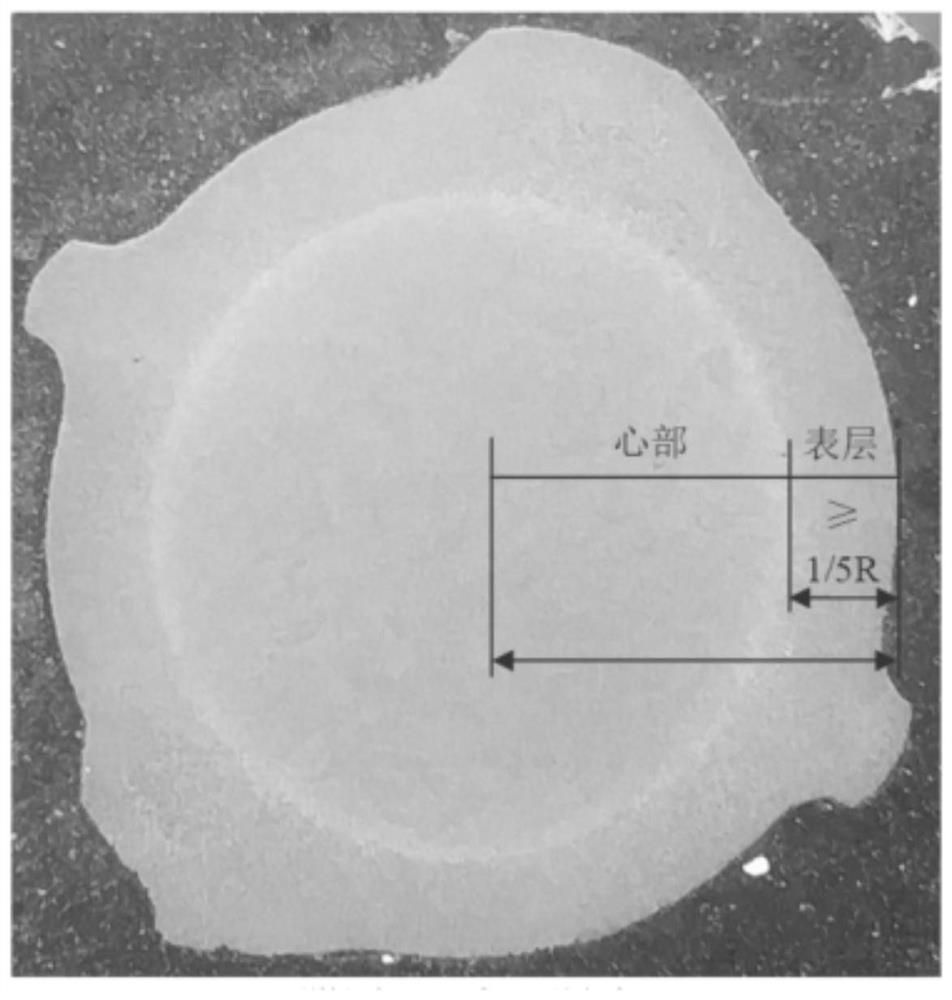

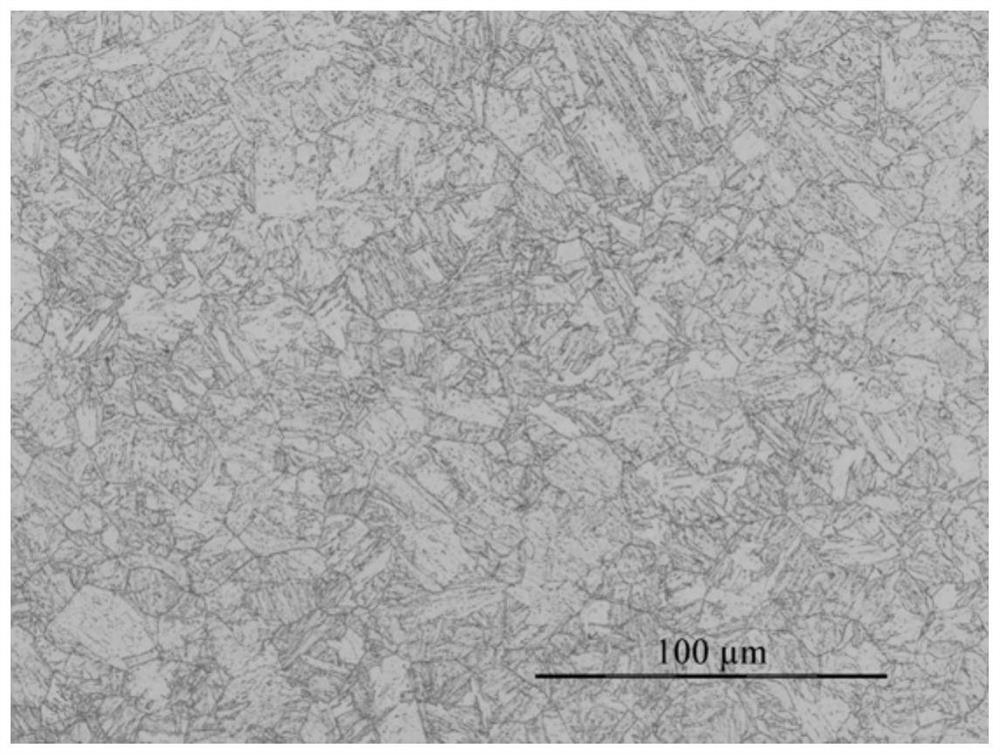

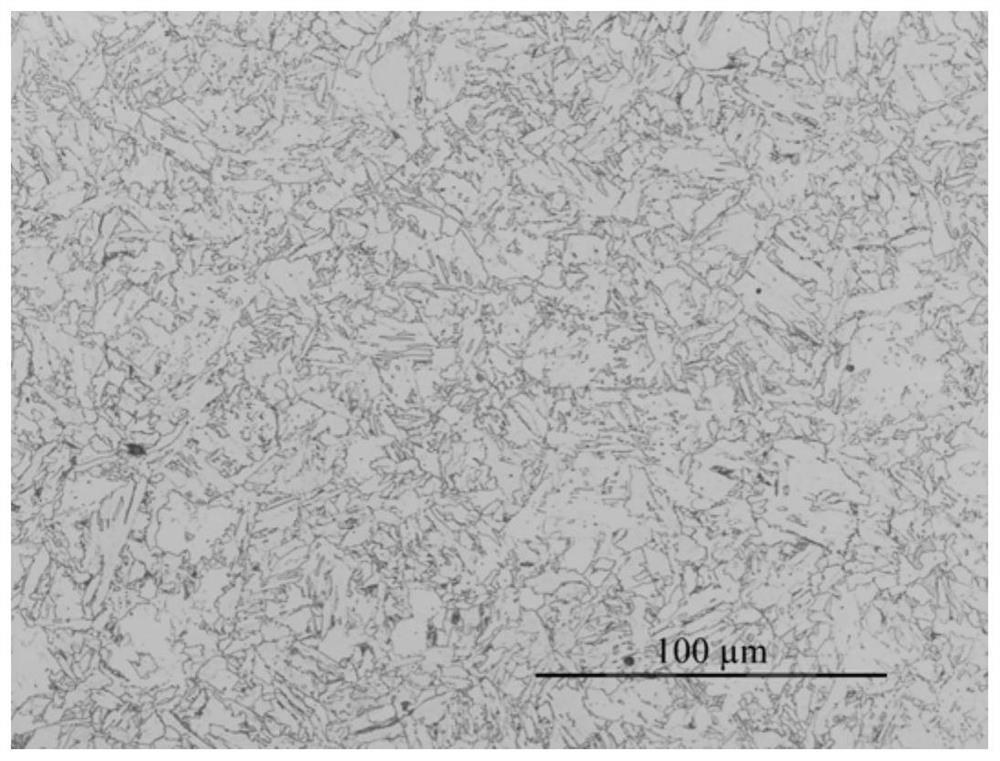

The invention provides a vanadium microalloyed steel for 600MPa grade low-temperature reinforcement and a production method thereof, the components C: 0.04-0.10%, Si: 0.20-0.40%, Mn: 1.30-1.80%, P≤0.008%, S ≤0.008%, Ni: 1.00~2.50%, V: 0.15~0.25%, Als: 0.020~0.040%, [H]≤0.00015%, T.O≤0.0020%, and the rest are Fe and unavoidable impurity elements. Compared with the prior art, the present invention adopts vanadium microalloying, electric furnace steelmaking, LF furnace refining, RH vacuum degassing, full protection casting, bar mill on-line quenching self-tempering process, and the surface layer of the produced steel bar is tempered wire The core is granular bainite, and the depth of tempered sorbite on the surface is ≥ 1 / 5 of the radius. This multiphase structure makes the steel bar have good strength and toughness.

Description

technical field [0001] The invention belongs to the technical field of low-temperature steel bars for concrete structures of various low-temperature storage tanks such as LNG, and in particular relates to a vanadium microalloyed 600MPa grade steel for low-temperature steel bars and a production method thereof. Background technique [0002] In recent years, with the promulgation and implementation of the national "Energy Development Strategic Action Plan (2014-2020)", the proportion of my country's liquefied natural gas (LNG) consumption has increased significantly, and LNG low-temperature storage tank construction projects in coastal port cities have been launched continuously. demand has greatly increased. The low-temperature steel bar is mainly used for the construction of the concrete structure inside the outer tank of the LNG storage tank. It plays a role of support and reinforcement for the outer tank, and when the internal filling -165 ℃ low-temperature liquid leaks, it...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C21D1/18C21D6/00C21D8/08C21D9/52C22C33/04C22C38/02C22C38/04C22C38/06C22C38/08C22C38/12

CPCC21D1/18C21D6/001C21D6/005C21D6/008C21D8/08C21D9/525C21D2211/002C21D2211/009C22C33/04C22C38/002C22C38/02C22C38/04C22C38/06C22C38/08C22C38/12

Inventor 余良其汪开忠郭湛胡芳忠于同仁龚志翔杨应东尹德福龚梦强姜婷张晓瑞丁雷

Owner MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com