Burning inhibition composition with carbon monoxide reduction function for cigarette paper and applying method and manufacturing method thereof

A carbon monoxide and combustion suppression technology, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of fire safety doubts, increase the health hazards of smokers, and the extinguishing rate is less than 50%, and achieve the simple preparation method and reduce the harm. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

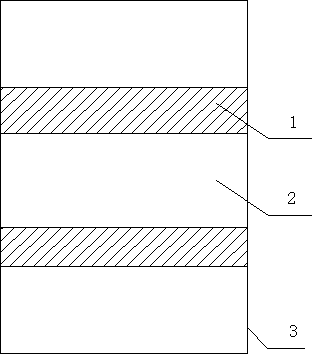

Image

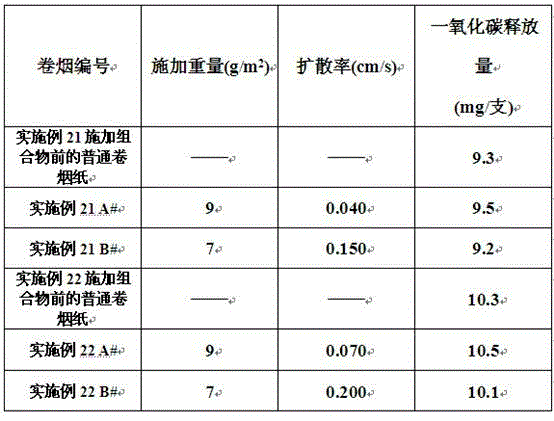

Examples

Embodiment 1

[0028] The combustion-inhibiting composition for reducing carbon monoxide in cigarette paper described in Example 1, the binder is oxidized starch or maltodextrin or gum arabic, or the binder is any several of oxidized starch, maltodextrin, and gum arabic mixture.

Embodiment 2

[0030] The combustion-inhibiting composition for reducing carbon monoxide in cigarette paper described in Example 2, the oxidized starch is corn starch or tapioca starch or sweet potato starch or potato starch; the maltodextrin is corn dextrin or tapioca dextrin or wheat Dextrin or rice dextrin.

Embodiment 3

[0032] The combustion-inhibiting composition for reducing carbon monoxide in cigarette paper described in Example 1, the filler is calcium carbonate or aluminum hydroxide or talcum powder or titanium dioxide, or any combination of calcium carbonate, aluminum hydroxide, talcum powder and titanium dioxide mixture of species.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com