Method for extracting brown pigment from plant

A brown pigment and plant technology, applied in the field of edible brown pigment extraction, can solve the problems of difficult separation and purification, large differences in organic solvents, complicated preparation steps, etc., and achieve the effects of cheap and easy-to-obtain raw materials, increased adsorption effect, and improved extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

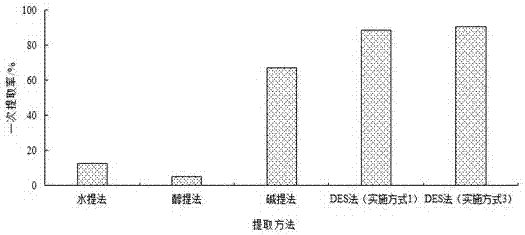

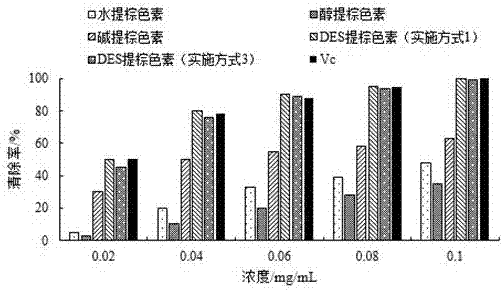

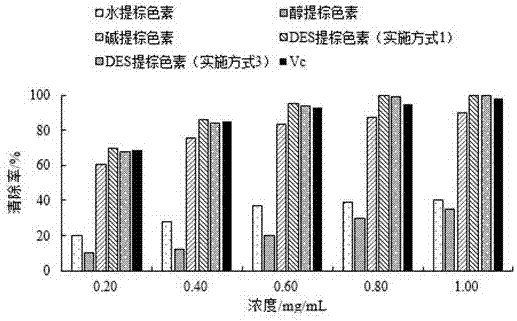

Embodiment approach 1

[0028] This embodiment provides a method for extracting brown pigment in apple seed shells. Take 10 g of apple seed shells that have been dried in the shade and crushed through a 40-mesh sieve, and use the deep eutectic solvent choline chloride-glycerol (molar ratio 1:2, Water content 0%wt) is the extraction solvent, and the solid-liquid ratio is 1g: 30mL, the ultrasonic power is 100W, the electrostatic field strength is 4kV, and the extraction temperature is 50°C, and the brown pigment extraction solution is obtained; petroleum ether and ethyl acetate are respectively used Wash the extract solution with the mixed solution for 3 times to obtain the degreasing pigment extract solution; add 5 g of attapulgite-loaded chitosan cross-linked cyclodextrin complex to the above degreasing extract solution, shake on a shaking table at 30°C and 100 r / min for 4 hours , take the precipitate after centrifugation, ultrasonically wash 3 times with deionized water, and centrifuge to obtain the ...

Embodiment approach 2

[0040] This embodiment provides a method for extracting brown pigment from apple seed shells. Take 10 g of apple seed shell powder that has been dried in the shade and crushed through a 40-mesh sieve, and use a deep eutectic solvent to extract choline nitrate-acetic acid (molar ratio 2: 3, water content 15%wt) as the extraction solvent, under the conditions of solid-to-liquid ratio 1g: 10mL, ultrasonic power 300W, electrostatic field strength 5kV, extraction temperature 50°C, extract for 20min to obtain brown pigment extract; use petroleum ether and acetic acid respectively Wash the extract with ethyl ester mixture for 3 times to obtain the degreasing pigment extract; add 3 g of attapulgite-loaded chitosan cross-linked cyclodextrin complex to the above degreased extract, and shake at 30°C and 100r / min. The bed was shaken for 5 hours, and the precipitate was collected by centrifugation, ultrasonically washed 3 times with deionized water, and centrifuged to obtain the brown pigme...

Embodiment approach 3

[0043] This embodiment provides a method for extracting brown pigment in apple seed shells. Take 10 g of apple seed shells that have been dried in the shade and crushed through a 40-mesh sieve, and use the deep eutectic solvent choline chloride-lactic acid-acetic acid (molar ratio 1:2: 1, water content 30%wt) as the extraction solvent, under the conditions of solid-liquid ratio 1g: 20mL, ultrasonic power 400W, electrostatic field strength 9kV, extraction temperature 60°C, extract for 30min to obtain brown pigment extract; use petroleum ether and acetic acid respectively Wash the extract with ethyl ester mixture for 3 times to obtain the degreasing pigment extract; add 2 g of attapulgite-loaded chitosan cross-linked cyclodextrin complex to the above-mentioned degreased brown pigment extract, at 30°C, 100r / min Vibrate on a shaking table for 5 hours, centrifuge to take the precipitate, wash it with deionized water ultrasonically for 3 times, and centrifuge to obtain the brown pigm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com