Preparation and application of attapulgite-supported chitosan crosslinked cyclodextrin composite

A technology of loading chitosan and cross-linked cyclodextrin, which is applied in chemical instruments and methods, natural dyes, organic dyes, etc., can solve the complex process, high requirements and great influence of macroporous adsorption resin refining process and separation technology Pore adsorption resin separation effect and other issues, to achieve the effect of simple purification process steps, excellent purification effect, and shorten the purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

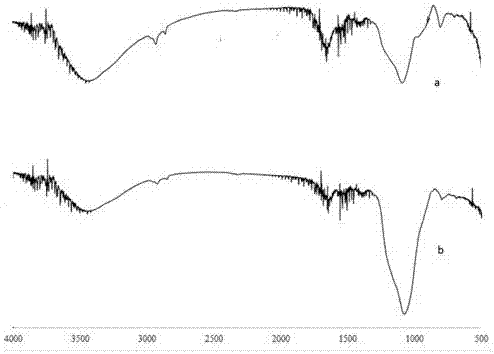

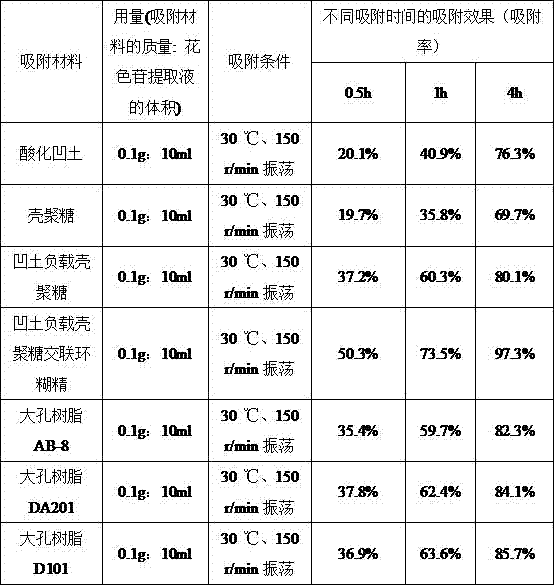

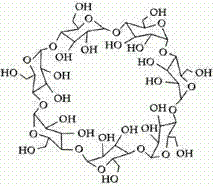

[0019] This embodiment provides an attapulgite-loaded chitosan cross-linked cyclodextrin complex, which is prepared by the following method:

[0020] 1) Preparation of acid-activated attapulgite:

[0021] Attapulgite was calcined at 700°C for 4 h, and after cooling down, it was added to 1 mol / L hydrochloric acid aqueous solution, the concentration of attapulgite in hydrochloric acid aqueous solution was 0.5 g / mL, stirred at 90°C for 4 h, and then centrifuged to collect The solid was washed with water until neutral, then added to 10% oxalic acid aqueous solution, the addition amount was 0.5 g / mL, stirred at room temperature for 2 h, left standing for 5 h, centrifuged, collected solid, washed with water until neutral, 120 °C Dry to obtain acid-activated attapulgite.

[0022] 2) Preparation of chitosan oxalate acetate sol:

[0023] Mix 10wt% oxalic acid aqueous solution and 1wt% acetic acid aqueous solution at a volume ratio of 4:1, then add chitosan with a solution mass of 3%,...

Embodiment approach 2

[0033] This embodiment provides an attapulgite-loaded chitosan cross-linked cyclodextrin complex, which is prepared by the following method:

[0034] 1) Preparation of acid-activated attapulgite:

[0035] The method is the same as that in Embodiment 1.

[0036] 2) Preparation of chitosan oxalate acetate sol:

[0037] The method is the same as that in Embodiment 1.

[0038] 3) Preparation of attapulgite-loaded chitosan:

[0039] a. Take chitosan oxalate acetate sol, dilute it with 2 times the volume of water, heat to 50°C and stir for 1 hour, then cool down to room temperature, and mix acid-activated attapulgite with diluted chitosan oxalate acetate at a solid-to-liquid ratio of 5g:5ml The sols were mixed, stirred for 3 hours, centrifuged, filtered, and vacuum-dried at 55°C to constant weight to obtain attapulgite once loaded with chitosan;

[0040] b. Take the chitosan oxalate acetate sol of the same volume as in a again, dilute it with 2 times the volume of water, mix it ...

Embodiment approach 3

[0046] This embodiment provides a preparation method of attapulgite-loaded chitosan cross-linked cyclodextrin complex, comprising the following steps:

[0047] 1) Preparation of acid-activated attapulgite:

[0048] The method is the same as that in Embodiment 1.

[0049] 2) Preparation of chitosan oxalate acetate sol:

[0050] The method is the same as that in Embodiment 1.

[0051] 3) Preparation of attapulgite-loaded chitosan:

[0052] a. Take chitosan oxalate acetate sol, dilute it with 3 times the volume of water, heat to 50°C and stir for 3 hours, then cool down to room temperature, and mix acid-activated attapulgite with diluted chitosan oxalate acetate at a solid-to-liquid ratio of 5g: 3.5ml The sugar sol was mixed, stirred for 4 hours, centrifuged, filtered, and vacuum-dried at 55°C to constant weight to obtain attapulgite once loaded with chitosan;

[0053] b. Take the chitosan oxalate acetate sol of the same volume as in a again, dilute it with 3 times the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com