Process for producing ammonium sulfate and hydrogen chloride by employing ammonium chloride and sulfuric acid

A technology for the production of sulfuric acid and ammonium chloride, applied in the field of chemical technology, can solve the problems of reducing the purity of hydrogen chloride gas, and achieve the effects of easy separation, continuous feeding and economic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

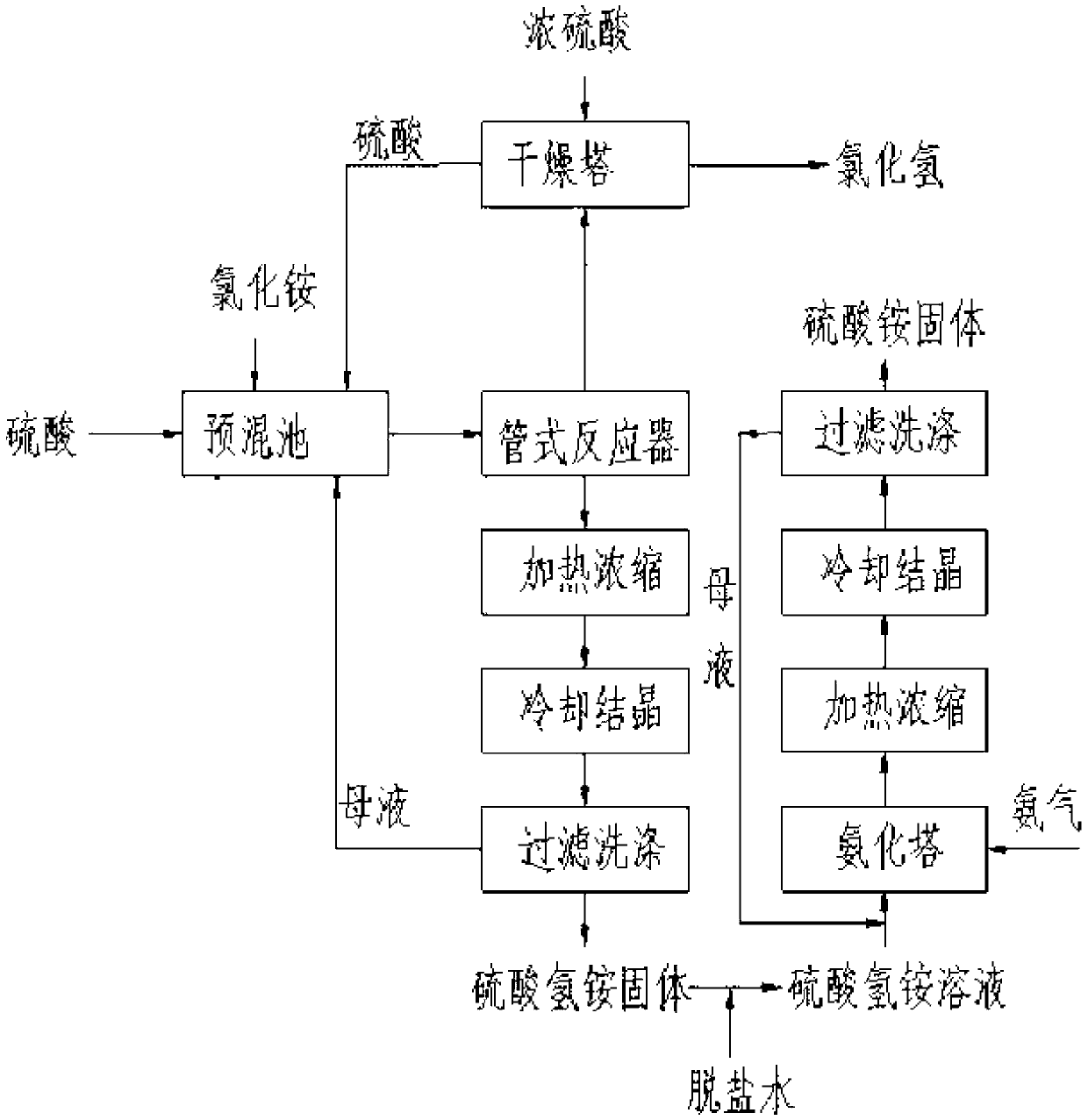

[0029] The present embodiment provides a kind of production method of ammonium sulfate, as attached figure 1 As shown, specifically:

[0030] Step 1, the concentrated sulfuric acid of the 98wt% of 5349 grams of ammonium chloride and 11000 is added in the premixing tank of band stirring and strainer and carry out normal pressure premixing, the ratio of the amount of substance of ammonium chloride and sulfuric acid 1:1.1, premixing The mixing temperature is 15°C.

[0031] Step 2, the premixed ammonium chloride sulfuric acid solution is continuously pumped into a tubular reactor with a steam jacket, and a metathesis reaction occurs to generate ammonium bisulfate and hydrogen chloride. This reaction is an endothermic reaction, and the required heat is obtained by The steam jacket of the tubular reactor is provided, the reaction temperature is 110°C, and the pressure is 0.2MPa. The obtained ammonium bisulfate solution is evaporated and concentrated, cooled and crystallized at 20°C...

Embodiment 2

[0038] The present embodiment provides a kind of production method of ammonium sulfate, with embodiment 1, specifically:

[0039] Step 1, the vitriol oil of 60wt% of 5349 grams of ammonium chloride and 24500 is added in the premixing tank of belt stirring and strainer and carry out normal pressure premixing, the ratio of the amount of substance of ammonium chloride and sulfuric acid 1:1.5, pre The mixing temperature is 30°C.

[0040] Step 2, the premixed ammonium chloride sulfuric acid solution is continuously pumped into a tubular reactor with a steam jacket, and a metathesis reaction occurs to generate ammonium bisulfate and hydrogen chloride. This reaction is an endothermic reaction, and the required heat is obtained by The steam jacket of the tubular reactor is provided, the reaction temperature is 90°C, and the pressure is 0.7MPa. The obtained ammonium bisulfate solution is evaporated and concentrated, cooled and crystallized at 10°C, filtered and washed to obtain solid a...

Embodiment 3

[0046] The present embodiment provides a kind of production method of ammonium sulfate, with embodiment 1, specifically:

[0047] Step 1, the concentrated sulfuric acid of the 90wt% of 5349 grams of ammonium chloride and 13067 is added in the premixing tank of band stirring and strainer and carry out normal pressure premixing, the ratio of the amount of substance of ammonium chloride and sulfuric acid 1:1.2, premix The mixing temperature is 40°C.

[0048] Step 2, the premixed ammonium chloride sulfuric acid solution is continuously pumped into a tubular reactor with a steam jacket, and a metathesis reaction occurs to generate ammonium bisulfate and hydrogen chloride. This reaction is an endothermic reaction, and the required heat is obtained by The steam jacket of the tubular reactor is provided, the reaction temperature is 145°C, and the pressure is 1.3MPa. The obtained ammonium bisulfate solution is evaporated and concentrated, cooled and crystallized at 38°C, filtered and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com