Method for purifying lithium difluoroborate and lithium tetrafluoroborate mixed lithium salt and application thereof

A technology of lithium difluorooxalate borate and lithium tetrafluoroborate, applied in chemical instruments and methods, compounds containing elements of group 3/13 of the periodic table, organic chemistry, etc., can solve the problem of high equipment and technical requirements and separation problems such as high difficulty and low purity of mixed salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

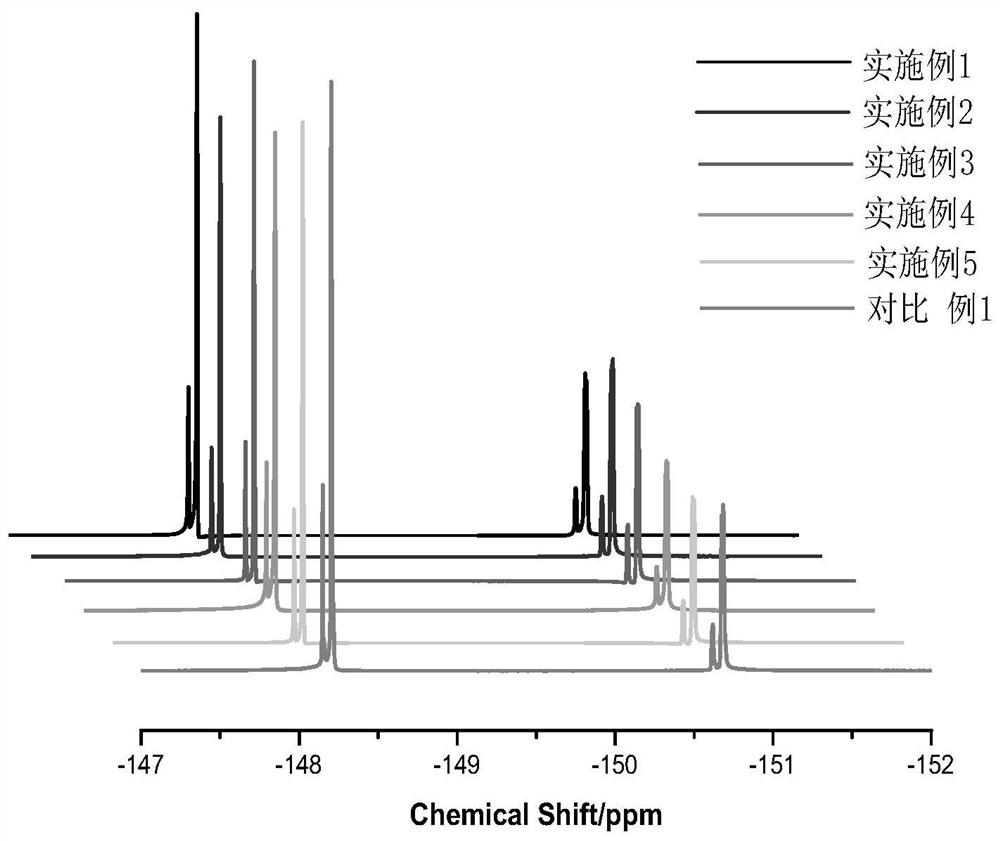

Embodiment 1

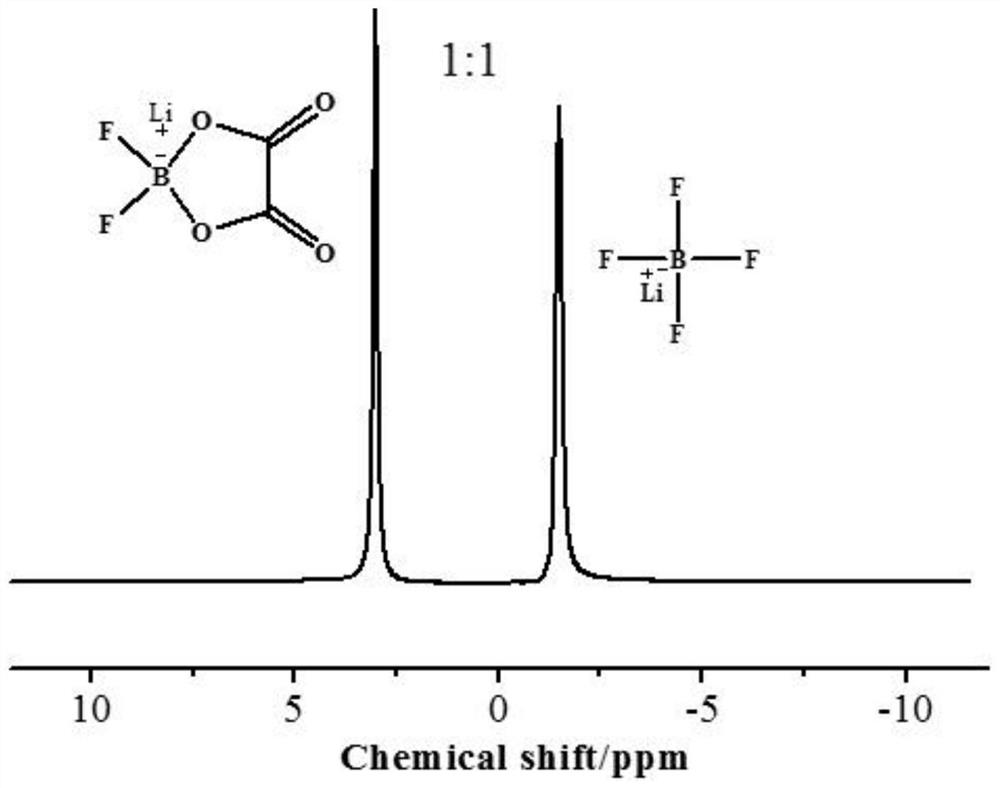

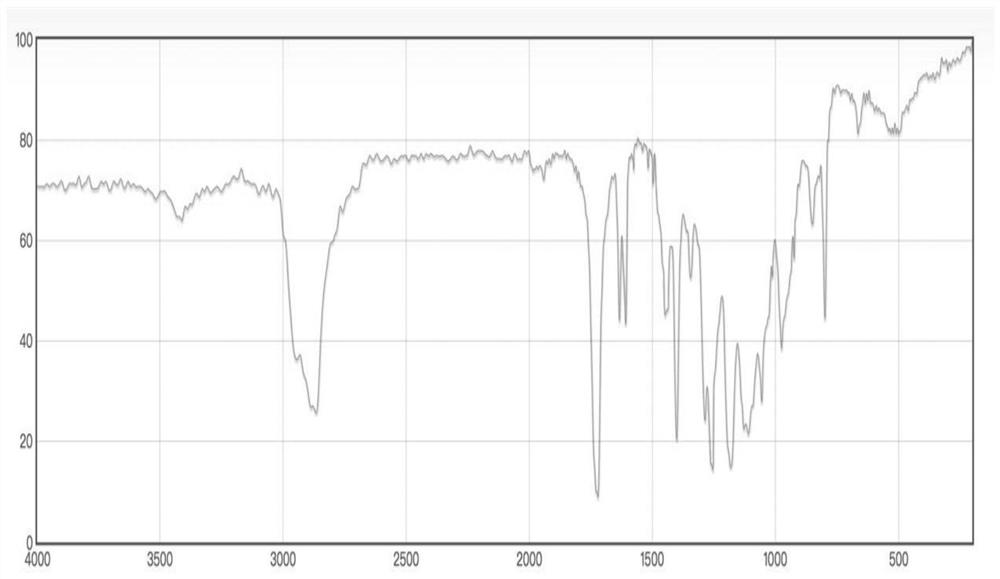

[0038] A kind of preparation method of high-purity fixed ratio mixed lithium salt, comprises the steps:

[0039] (1) Synthesis reaction:

[0040] Add 500mL dimethyl carbonate (DMC) to the three-necked reaction flask, and add 102g lithium oxalate under stirring at 250r / min; raise the temperature to 90°C, stir for 0.5h, and prepare lithium oxalate suspension; weigh trifluoro 252g of boron chloride ether was gradually added dropwise to the lithium oxalate suspension under stirring, and the dropwise addition time was 1h; The mixed reaction solution of lithium oxalate borate and lithium tetrafluoroborate is then purified through a purification aid filter membrane;

[0041] (2) Concentration and crystallization of the reaction solution:

[0042] The purified mixed reaction solution of lithium difluorooxalate borate and lithium tetrafluoroborate was subjected to vacuum distillation at a vacuum degree of -0.11MPa, a rotation speed of 250r / min, and a temperature of 110°C, and the org...

Embodiment 2

[0051] Add 500mL dimethyl carbonate (DMC) to the three-necked reaction flask, and add 102g lithium oxalate under stirring at 250r / min; raise the temperature to 90°C, stir for 0.5h, and prepare lithium oxalate suspension; weigh trifluoro 252g of boron chloride ether was gradually added dropwise to the lithium oxalate suspension under stirring, and the dropwise addition time was 1h; The mixed reaction solution of lithium oxalate borate and lithium tetrafluoroborate is then purified through a purification aid filter membrane;

[0052] (2) Concentration and crystallization of the reaction solution:

[0053] The purified mixed reaction solution of lithium difluorooxalate borate and lithium tetrafluoroborate was subjected to vacuum distillation at a vacuum degree of -0.1MPa, a rotation speed of 250r / min, and a temperature of 110°C to distill out 80% of the organic solvent as the initial solvent. %, stop vacuum distillation to obtain mixed lithium salt crude product;

[0054] (3) P...

Embodiment 3

[0059] Add 500mL dimethyl carbonate (DMC) to the three-necked reaction flask, and add 102g lithium oxalate under stirring at 250r / min; raise the temperature to 90°C, stir for 0.5h, and prepare lithium oxalate suspension; weigh trifluoro 252g of boron chloride ether was gradually added dropwise to the lithium oxalate suspension under stirring, and the dropwise addition time was 1h; The mixed reaction solution of lithium oxalate borate and lithium tetrafluoroborate is then purified through an auxiliary purification filter;

[0060] (2) Concentration and crystallization of the reaction solution:

[0061] The purified mixed reaction solution of lithium difluorooxalate borate and lithium tetrafluoroborate was subjected to vacuum distillation at a vacuum degree of -0.1MPa, a rotation speed of 250r / min, and a temperature of 110°C to distill out 60% of the organic solvent as the initial solvent. %, stop vacuum distillation to obtain mixed lithium salt crude product;

[0062] (3) Pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com