Production device and production method of electronic-grade hydrofluoric acid

A technology for electronic grade hydrofluoric acid and production equipment, which is applied in separation methods, chemical instruments and methods, perfluorocarbon/hydrofluorocarbon capture, etc., and can solve the problems of increasing preparation costs, low yield, and waste Environmental pollution and other issues, achieve high economic benefits and environmental protection, avoid waste of resources, and reduce the effect of purification processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

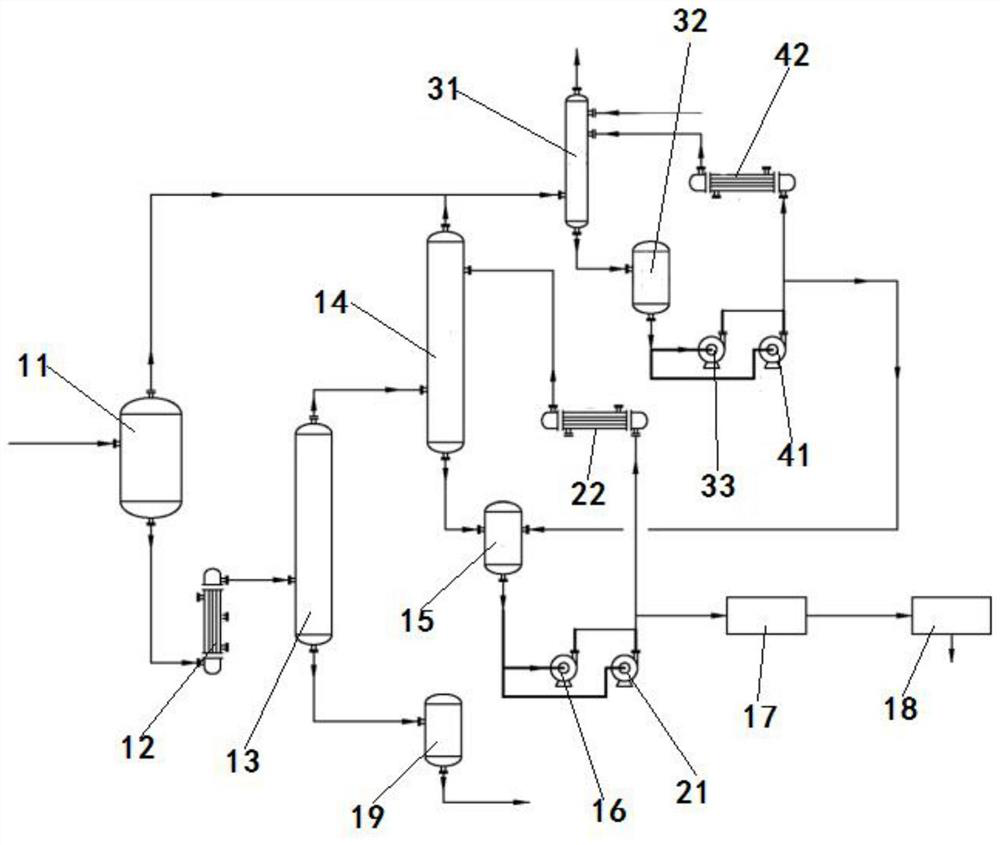

[0032] as attached figure 1 As shown, a kind of production device of electronic grade hydrofluoric acid provided by the present invention includes a purification system, a reabsorption system and a first tail gas absorption system;

[0033] The purification system comprises a raw material tank 11, an evaporator 12 connected to the bottom of the raw material tank 11 at the inlet, a purification tower 13 connected to the outlet of the evaporator 12 at the bottom, an absorption tower 14 connected to the top of the purification tower 13 at the bottom, and connected to the absorption tower 14 Absorption tower still storage tank 15 at the bottom, the bottom of absorption tower still storage tank 15 is connected with the first delivery pump 16, ultrapure filter device 17 and filling device 18 in turn, and the bottom of purification tower 13 is connected with raffinate storage tank 19.

[0034] The operating process of the above-mentioned device is:

[0035] (1) Rectification: transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com