A method for removing pigment and impurities in crude lactide

A technology for lactide and impurities, applied in the fields of organic chemistry, products, reagents, etc., can solve the problem of a large number of theoretical plates, achieve good removal effect, reduce operating temperature and operating difficulty, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

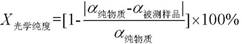

Method used

Image

Examples

Embodiment 1

[0033] Preparation of crude L-lactide: using zinc oxide and stannous octoate as catalyst, 88% L-lactic acid as raw material, after dehydration, polycondensation and depolymerization of lactic acid, the crude L-lactide with a purity of 85.7% was obtained, wherein, meso-lactide ( m -Lactide) content is 5.7%, lactic acid content is 6.3%, lactic acid dimer, trimer content is 1.8%, also includes a small amount of water and other impurities.

[0034] Take 5000 g of the above-mentioned crude L-lactide, grind it to 35-100 mesh with a pulverizer, and put it into a crude lactide storage tank. Before feeding materials, the temperature and pressure of the rectification tower need to be increased. The temperature of the rectification tower is set in three sections. When the pressure in the rectification tower reaches 10MPa, the temperature of the three-stage packing reaches 36°C from bottom to top. At 60°C and 80°C, the supercritical CO 2 Sent into the rectification tower, the supercriti...

Embodiment 2

[0037] Preparation of crude L-lactide: Zinc oxide and stannous octoate are used as catalysts, lactate is used as raw material (self-made, mass fraction 92%), lactate is dehydrated and dealcoholized first, and then oligomers are formed by polycondensation Lactic acid ester is depolymerized at high temperature to obtain crude L-lactide with a purity of 83.1%. in, m -The content of lactide is 6.2%, the content of lactic acid is 4.7%, the content of dimer and trimer lactate is 2.9%, and it also includes a small amount of water and other impurities.

[0038] Take 5000 g of the above-mentioned crude L-lactide, heat and melt at 98°C. Before feeding materials, the temperature and pressure of the rectification tower need to be increased. The temperature of the rectification tower is set in three sections. When the pressure in the rectification tower reaches 10MPa, the temperature of the three-stage packing reaches 36°C from bottom to top. At 60°C and 80°C, the supercritical CO 2 Sen...

Embodiment 3

[0041] Preparation of crude L-lactide: using zinc oxide and stannous octoate as catalyst, 88% L-lactic acid as raw material, after dehydration, polycondensation and depolymerization of lactic acid, the crude L-lactide with a purity of 85.7% was obtained, wherein, meso-lactide ( m -Lactide) content is 5.7%, lactic acid content is 6.3%, lactic acid dimer, trimer content is 1.8%, also includes a small amount of water and other impurities.

[0042] Take 5000 g of the above-mentioned crude L-lactide, grind it to 35-100 mesh with a pulverizer, and put it into a crude lactide storage tank. The temperature and pressure of the rectification tower need to be raised before feeding the material. The pressure in the rectification tower is 9MPa, and the temperature of the rectification tower is gradually raised from the bottom to the top of the tower, that is, from 40°C to 60°C. Supercritical CO 2 Sent into the rectification tower, the supercritical CO entering the rectification tower 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com