Preparation method of hollow micro-channel structure

A micro-channel structure and micro-channel technology, applied in the application field, can solve problems such as high cost, high process requirements, and difficulty in controlling the size of the micro-channel, and achieve the effects of low production cost, large application prospects, and easy and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

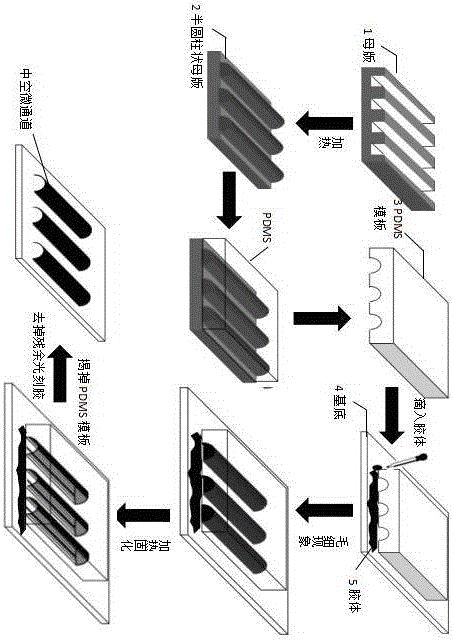

[0014] Specific embodiments: a method for preparing a hollow microchannel structure, which is completed by the following steps:

[0015] Step 1. Preparation of the microchannel master. Clean the used substrate and spin-coat photoresist on it; after standing for ten minutes, place it on a 65°C hot plate and heat it for 10 minutes, then move to 95°C Heating on a hot plate for 30 minutes; then the photoresist mask plate with strip-shaped micron pattern is closely contacted with the photoresist coating, and the photolithography exposure is carried out; the exposed substrate can be developed to obtain the mask. Elongated micro-square structure with the same size as the opaque part of the stencil pattern; place this microstructure on a hot plate, slowly heat up to 140°C, take it off after heating for 30 minutes, and let it cool naturally to room temperature; at 140°C The photoresist is already in a molten state, and it flows under the action of surface tension and gravity, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com