Single side soft absorption type automatic drilling robot

A robot and adsorption technology, applied in the field of automatic hole making technology and robots, can solve the problems of low degree of automation, poor stability of aircraft quality, low precision, etc., and achieve the effect of improving quality and efficiency, reducing processing difficulty and improving work quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings.

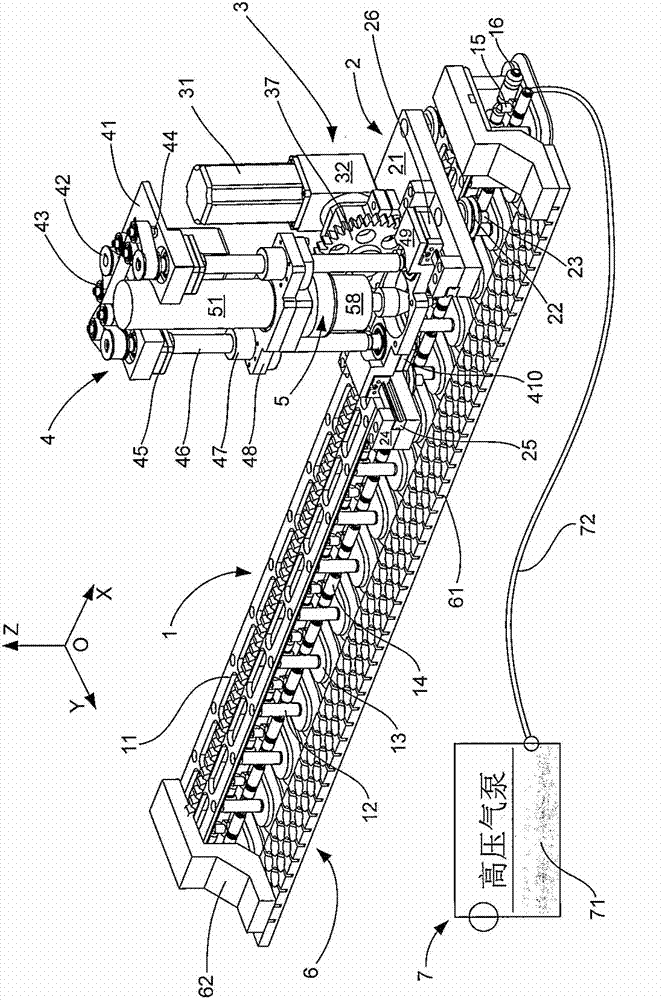

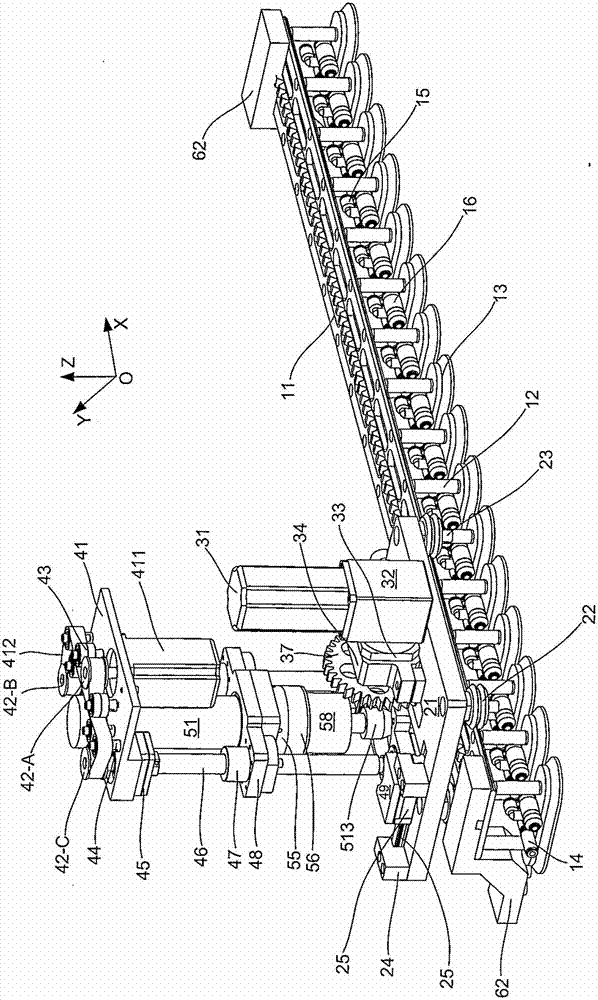

[0053] join figure 1 and figure 2 As shown, the present invention consists of seven parts: a flexible rail assembly 1, an XY-moving carrier assembly 2, an X-motion drive assembly 3, an actuator feed module 4, a spindle assembly 5, a positioning assembly 6 and an air source assembly 7.

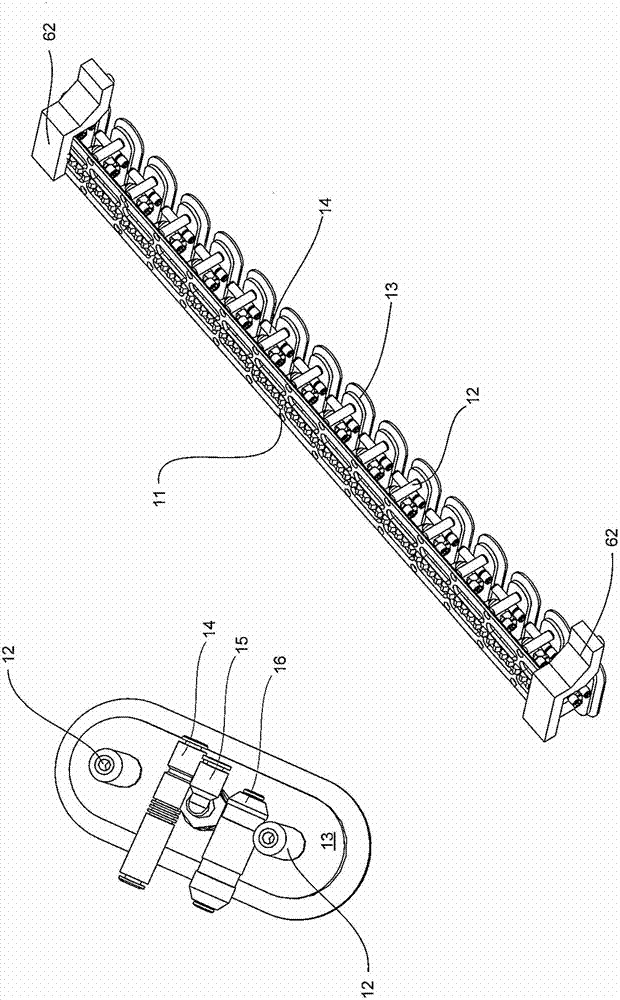

[0054] see figure 1 As shown, the high-pressure air pump 71 provides a high-pressure air source, and the high-pressure air generated by it is delivered to the vacuum chuck 13 in the flexible track assembly 1 through the air guide tube 72, wherein the two ends of the air guide tube 72 are connected to the high-pressure air pump 71 and the air guide reversing tube 14, The control of the flow rate of the air flow through the air guide reversing tube 14 enables the vacuum chuck to be adsorbed on the surface of the workpiece. The high-pressure gas enters the vacuum suction cup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com