Method for controlling roll gap of roller in segment soft reduction control technology

A control technology and roll gap technology, applied in metal rolling and other directions, can solve problems affecting the accuracy of roll gap control, and achieve the effect of ensuring accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

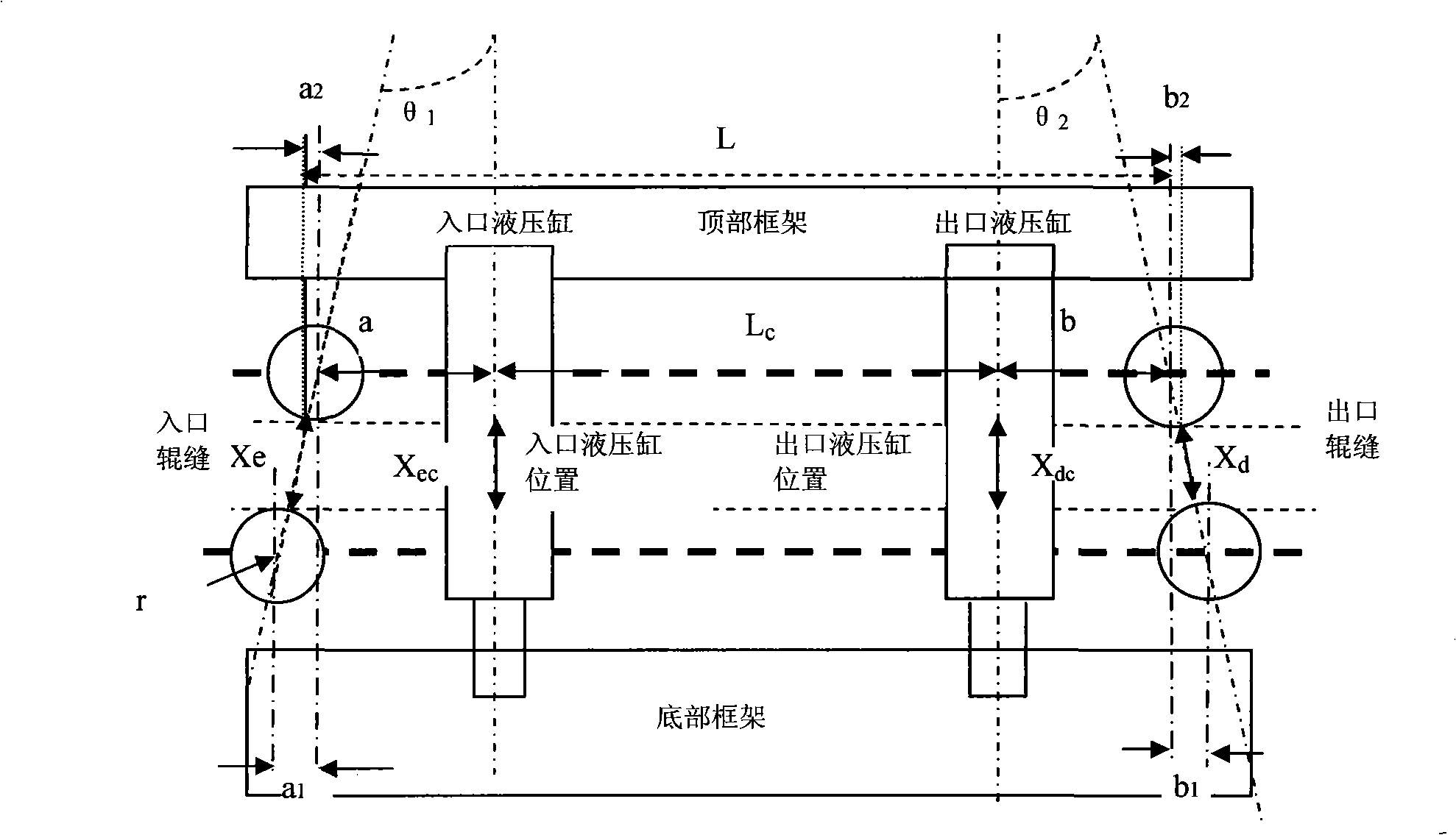

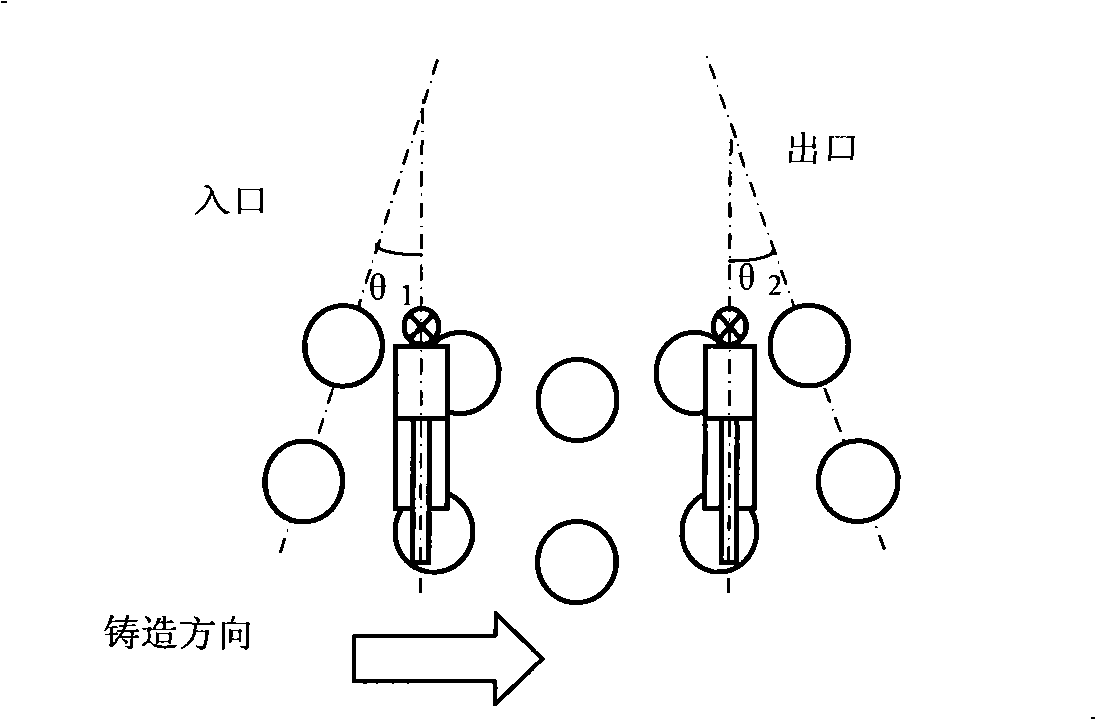

[0086] Such as Figure 8 As shown, first set the target roll gap value of the entrance and exit side rollers of the fan section according to the needs. Then convert the target roll gap value into the target hydraulic cylinder position value, and transmit it to the hydraulic system. After receiving the target hydraulic cylinder position value, the hydraulic system controls the piston stroke of the hydraulic cylinder to make the piston of the hydraulic cylinder move to the received target hydraulic cylinder position value. The operation of the piston of the hydraulic cylinder drives the movement of the rollers, making the roller gap reach the set target roller gap value, thereby realizing the control of the roller gap. In the present invention, the conversion of the target roll gap value into the target hydraulic cylinder position value is realized in the following manner.

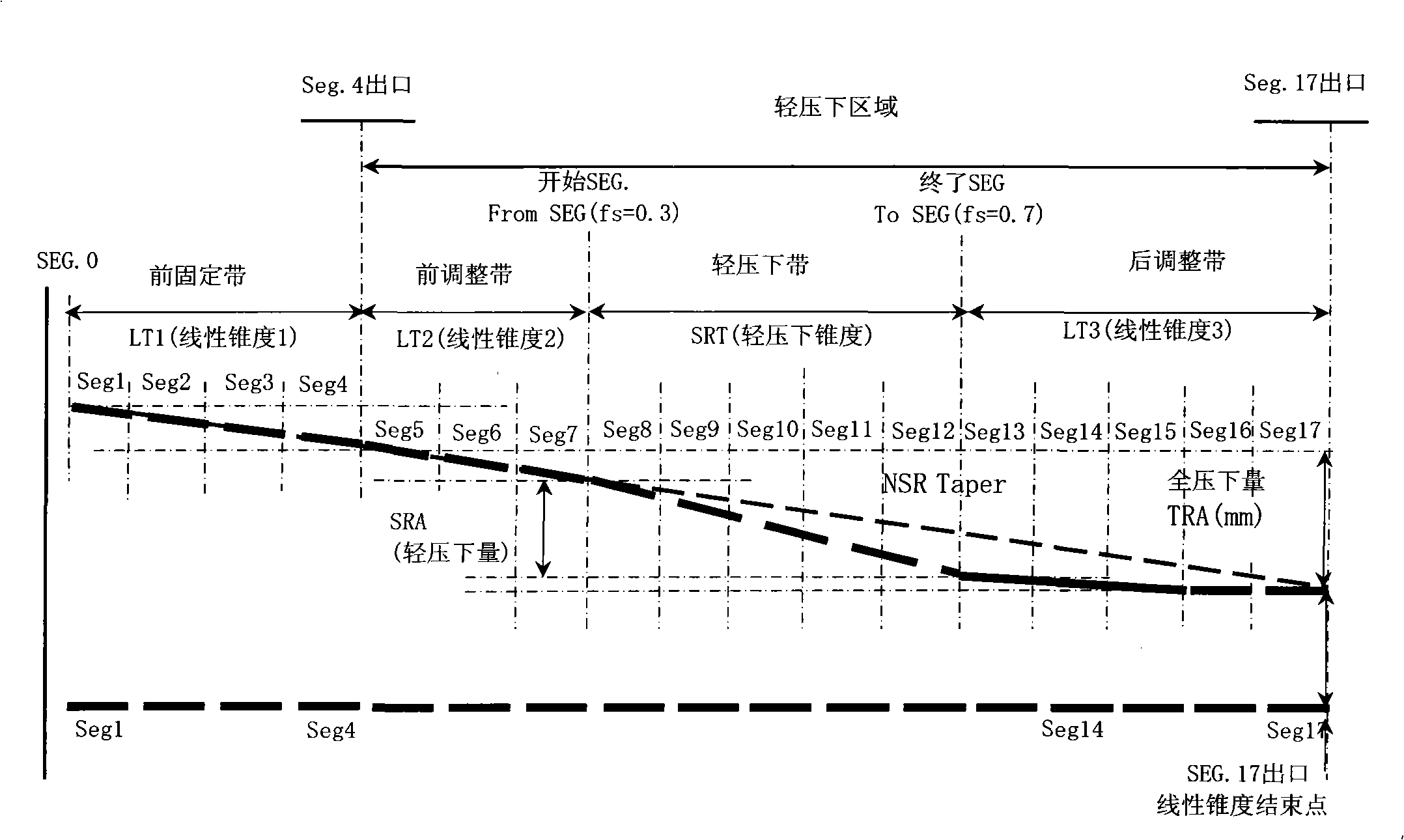

[0087] Such as figure 1 As shown, the continuous casting machine of the present invention has 17 segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com