Lithium boron alloy production process, and device thereof

A lithium-boron alloy, production process technology, applied in the field of lithium-boron alloy production process and its equipment, can solve problems such as inclusions, holes, segregation, nitriding, moisture absorption, hydrolysis, and easy oxidation, etc., to avoid surface deterioration, Ensure precise control and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

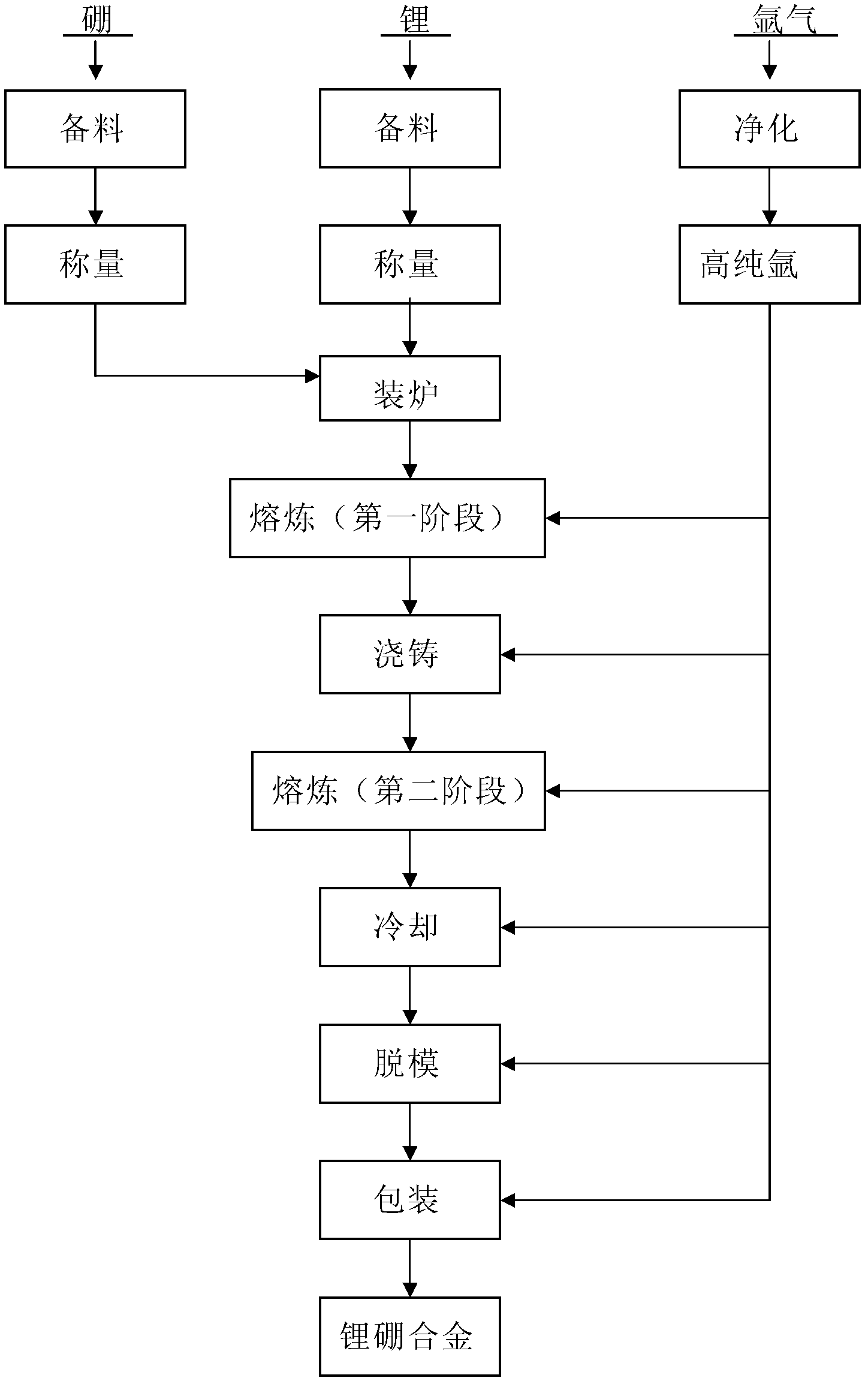

[0020] Such as figure 1 Shown is a flow chart of the lithium-boron alloy production process of the present invention. The process includes the following steps:

[0021] 1. Accurately weigh lithium (purity 99.9%) and boron powder (purity 99.9%, particle size 100μm) and mix them into a crucible, wherein the content of lithium is 70±2%, in high-purity argon Under a protective atmosphere, raise the temperature to 400°C and stir for two hours, then raise the temperature to 450°C to complete the first-stage reaction and form a alloy melt with good fluidity;

[0022] 2. In the same high-purity argon atmosphere, cast the alloy melt into the mold to form a billet, continue to heat up to 650 ° C for 1 hour to harden, and complete the second stage of reaction;

[0023] 3. After the mold is cooled to room temperature, it is demoulded and packaged to obtain a lithium-boron alloy product.

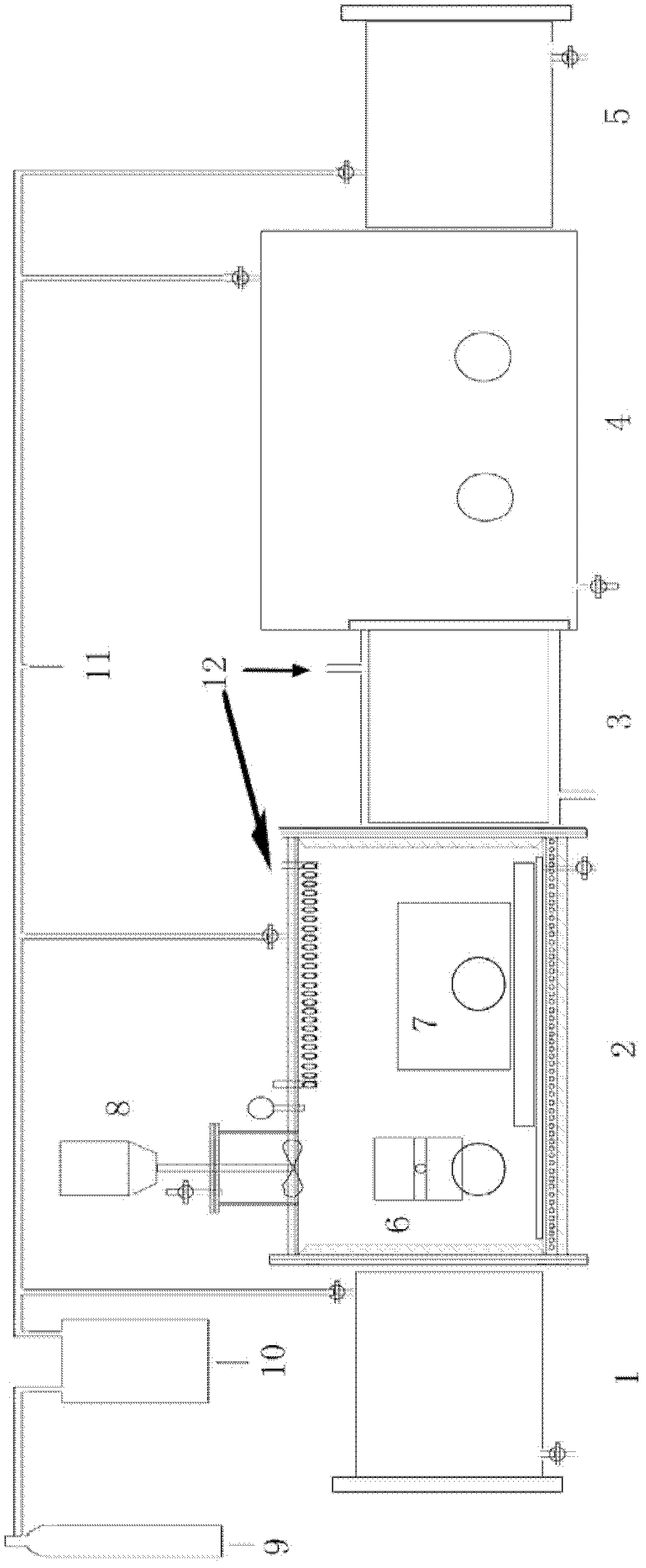

[0024] Such as figure 2 Shown is a schematic structural view of the device of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com