UV coating with special convex point structure and preparation method thereof

A bump structure and coating technology, applied in the field of UV coating and its preparation, can solve the problems of excellent scratch resistance, UV coating cannot produce special texture, and there is no mature solution to stabilize mass production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The third aspect of the present invention provides a method for preparing a UV coating, which includes: using a roll coating device equipped with a laser engraved anilox roll, coating the coating on the substrate by means of roll coating, and curing the UV coating After that, you get it.

[0041] The UV curing conditions described in the present invention can be routinely selected by those skilled in the art.

[0042] In one embodiment, the material of the substrate is not particularly limited, and examples thereof include wood, glass, ceramics, polyvinyl chloride, polypropylene, and slate.

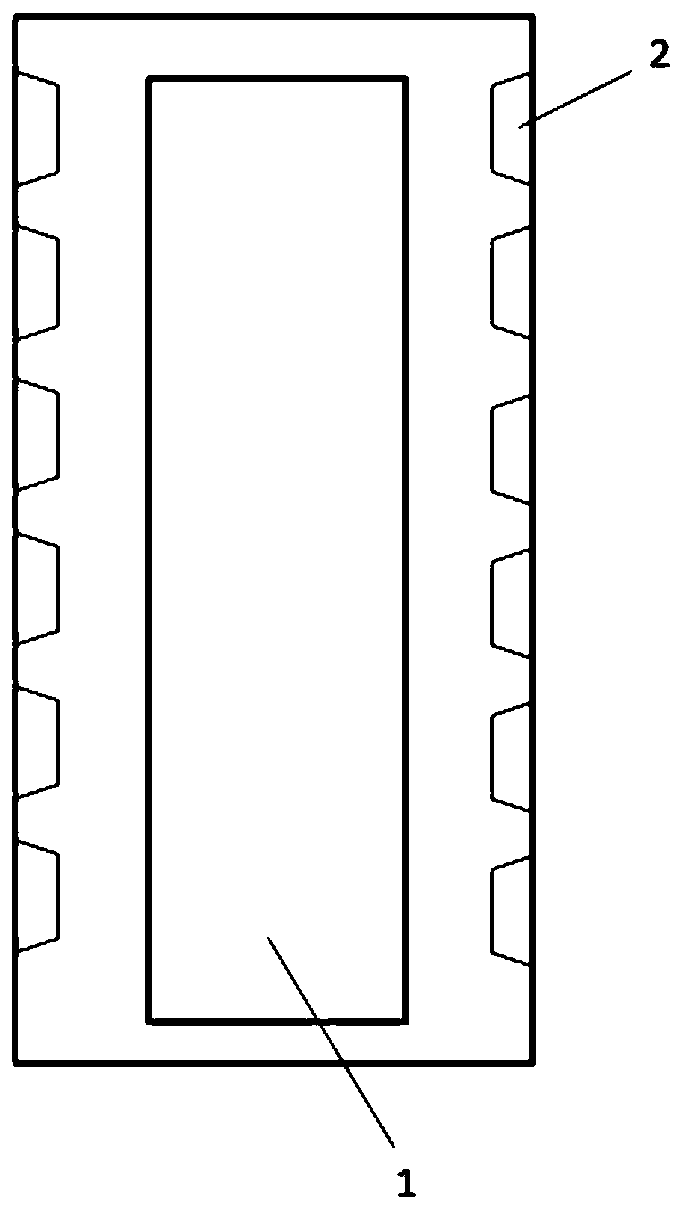

[0043] Such as figure 1 As shown, the laser engraved anilox roll includes a roll body 1 and a cell 2 .

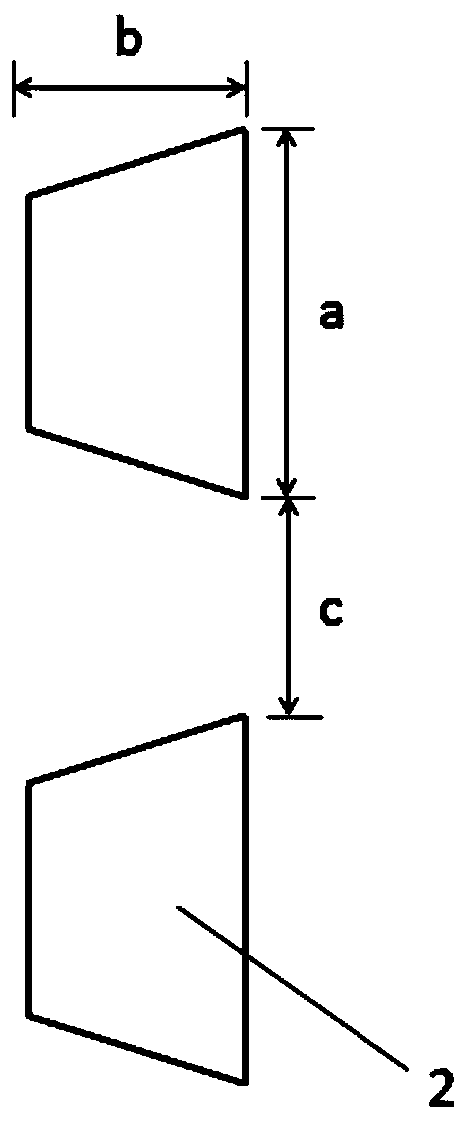

[0044] figure 2 It is a schematic diagram of the cross-section of the cell, where a is the diameter of the cell, b is the depth of the cell, and c is the distance between adjacent cells.

[0045] In one embodiment, the anilox of the laser engraved anilox roll consists of se...

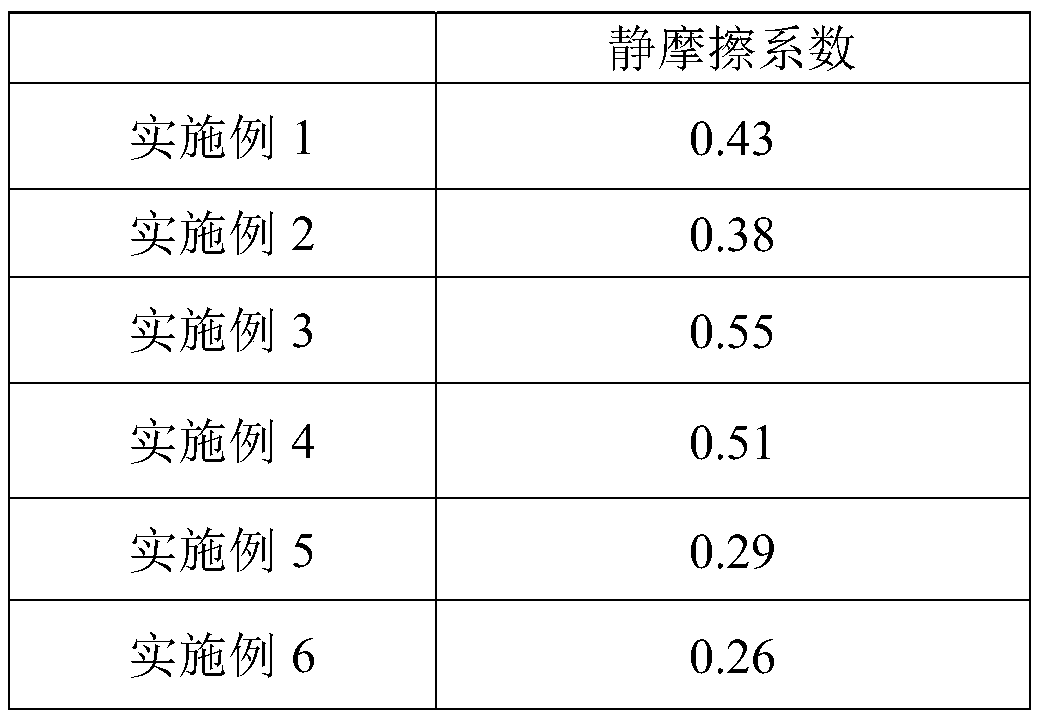

Embodiment 1

[0059] Embodiment 1 of the present invention provides a UV coating, the surface of which has circular bump structures distributed at equal intervals.

[0060] The coating weight of the coating is 3g / m 2 ; The diameter of the bumps is 0.3 mm, the height is 0.3 mm, and the pitch is 0.2 mm.

[0061] The preparation method of the UV coating comprises: using a roller coating device equipped with a laser engraved anilox roller, coating the coating on the base material by means of roller coating, and curing it by UV.

[0062] The material of described substrate is wood; The shape of described mesh hole is circular; The diameter of described mesh hole is 0.3mm, and depth is 0.3mm, and spacing is 0.2mm; Described coating is commercially available common UV coating , the gloss of the coating is 10°.

Embodiment 2

[0064] Embodiment 2 of the present invention provides a UV coating, the surface of which has irregularly distributed circular bump structures.

[0065] The coating weight of the coating is 8g / m 2 ; The diameter of the bumps is 1mm, the height is 0.2mm, and the distance is 0.5-1mm.

[0066] The preparation method of the UV coating comprises: using a roller coating device equipped with a laser engraved anilox roller, coating the coating on the base material by means of roller coating, and curing it by UV.

[0067] The material of the base material is wood; the shape of the mesh hole is circular; the diameter of the mesh hole is 1mm, the depth is 0.2mm, and the spacing is 0.5~1mm; the coating is a commercially available common UV coating , the gloss of the coating is 70°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com