Production method of super-hard and super-flat precision strip steel SMT steel mesh material

A production method and technology for strip steel, which can be used in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of unstable key product quality, poor fit, and poor product warpage, and achieve stable mass production. , the effect of excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1 (301-0.2-SEHTA)

[0055] (1) Finish rolling:

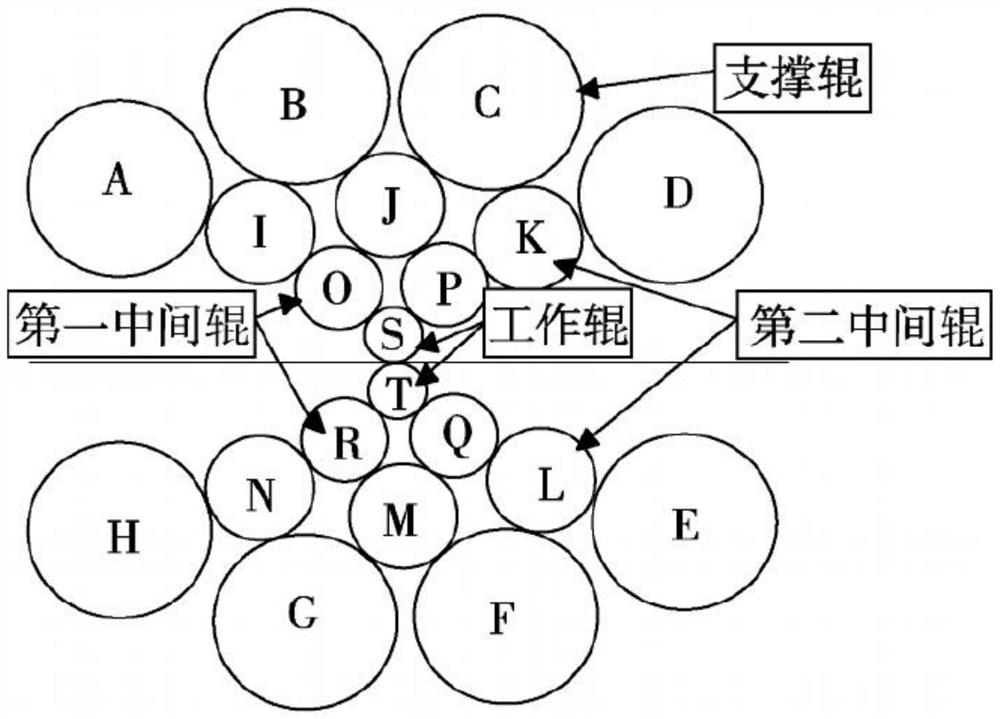

[0056] Use 301 grade steel cold-rolled raw material 1.2mm (thickness) × 640mm (width), and use Sendewei four-column twenty-high rolling mill to carry out two rolling passes, among which, the middle thickness of the first rolling pass is 0.5mm , After intermediate annealing, the thickness of the finished product rolled in the second rolling process is 0.2mm.

[0057] 0.5mm rolling 0.2mm roll configuration:

[0058] roll Convexity / Taper free roll 0.5mm Drive roller flat roll first intermediate roll 140×0.26mm

[0059] In this embodiment, both the first rolling process and the second rolling process adopt 5 passes, the deformation rate of the first pass is designed to be ≤28%, and the deformation rate of the final pass is designed to be ≤10%. details as follows:

[0060] The first rolling pass:

[0061] pass 1 2 3 4 5 Deformation rate 25.00% 18.33% 15.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com