Method for preparing silver-containing calcium phosphate

A technology of silver calcium phosphate and serum, applied in chemical instruments and methods, phosphorus compounds, nanotechnology for materials and surface science, etc., can solve the problem of poor stability of antibacterial ions, difficulty in industrialized continuous production, and low loading ratio and other issues, to achieve the effect of easy industrial stable mass production, stable industrial mass production, and reduction of energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

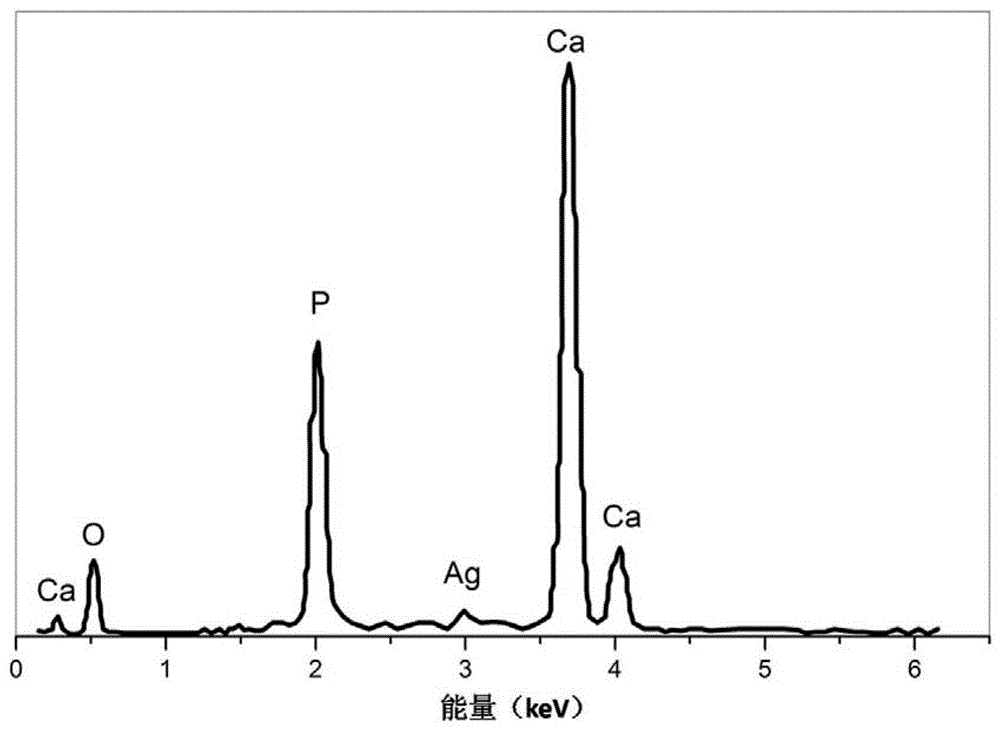

[0065] 1. Preparation of phase A raw material solution, containing 0.09M calcium nitrate, 0.002M silver nitrate and 0.3M polyethylene glycol (PEG-20000) solution;

[0066] 2. Preparation of phase B raw material solution, containing 0.06M phosphoric acid and 0.18M sodium hydroxide solution;

[0067] 3. Set the flow rate F of the phase A raw material liquid delivery pump A =100mL / min, the flow rate F of the phase B raw material liquid delivery pump B =100mL / min, at room temperature of 25°C, the two-phase raw material liquid is simultaneously transported to a microchannel continuous mixing reactor with a channel size of 105 μm. After the two-phase materials are uniformly differentially mixed, the continuous integral reaction forms silver-containing calcium phosphate Aggregates;

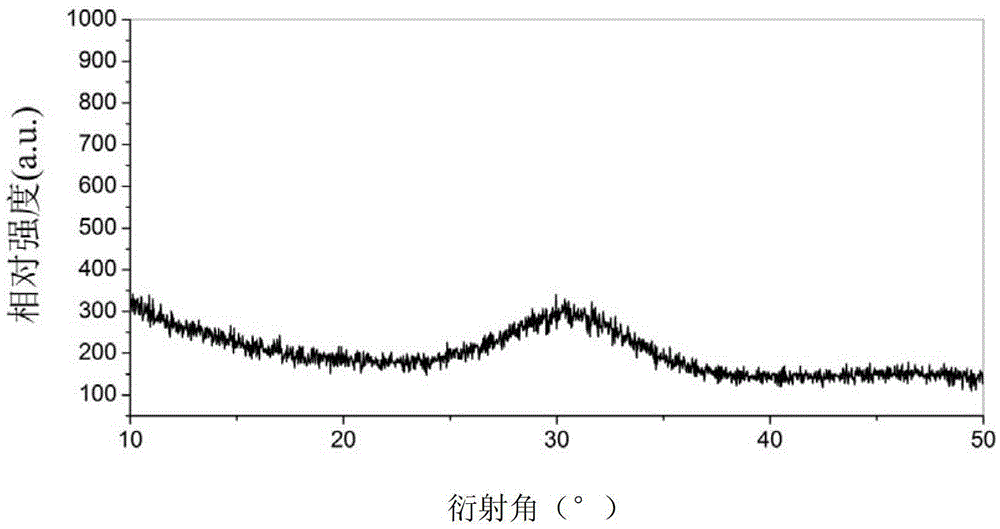

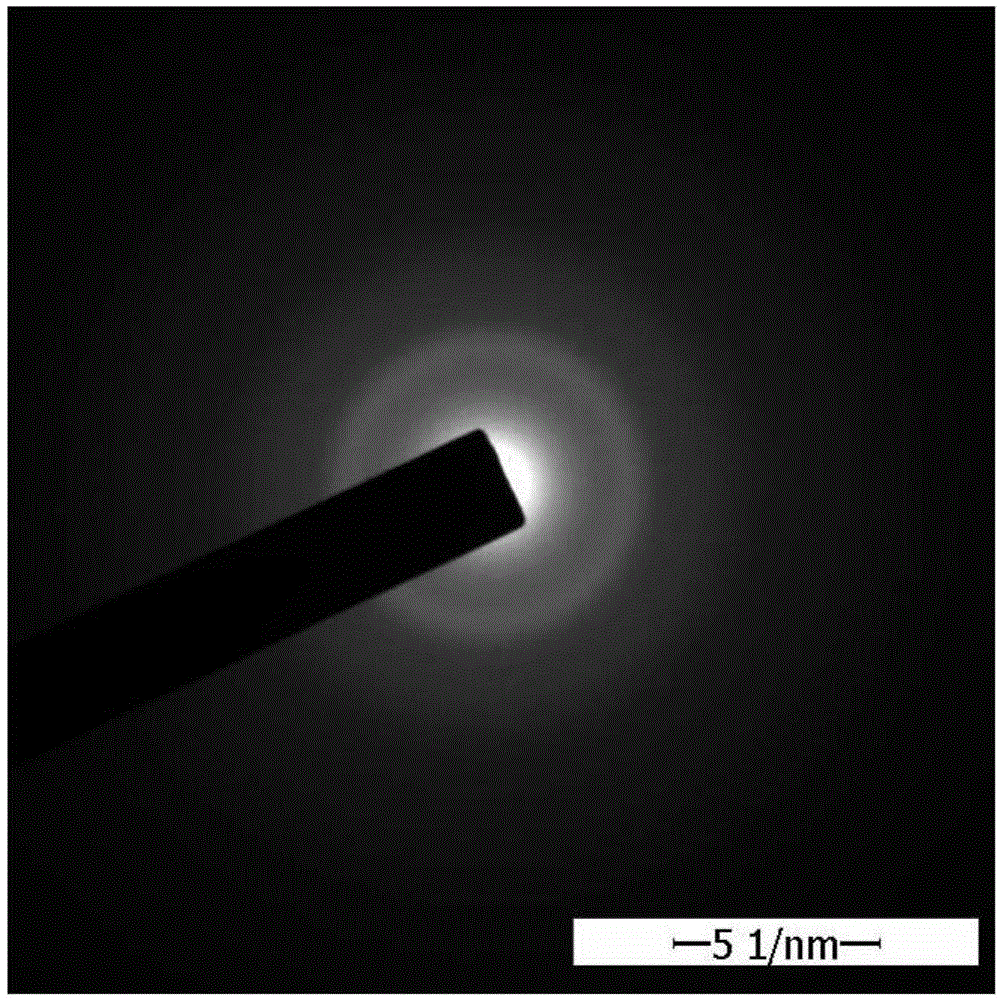

[0068] 4. Transport the mixed reaction product calcium phosphate aggregate sol to a washing and dehydrating device, wash with water three times, and vacuum dry at 60° C. to constant weight to obtain am...

Embodiment 2

[0072] 1. Preparation of phase A raw material solution, containing 0.09M calcium nitrate, 0.005M silver nitrate and 0.3M polyethylene glycol (PEG-1500) solution;

[0073] 2. Preparation of phase B raw material solution, containing 0.06M phosphoric acid and 0.18M sodium hydroxide solution;

[0074] 3. Set the flow rate F of the phase A raw material liquid delivery pump A =1000mL / min, the flow rate F of the phase B raw material liquid delivery pump B =1000mL / min, at 50°C, the two-phase raw material liquid is simultaneously transported to a microchannel continuous mixing reactor with a channel size of 105 μm. After the two-phase materials are uniformly mixed differentially, the continuous integral reaction forms silver-containing calcium phosphate aggregates body;

[0075] 4. Transport the mixed reaction product calcium phosphate aggregate sol to a washing and dehydrating device, wash with water three times, and vacuum dry at 60° C. to constant weight to obtain amorphous silver...

Embodiment 3

[0077] 1. Preparation of phase A raw material solution, containing 0.225M calcium nitrate, 0.0056M silver nitrate and 2.25M polyethylene glycol (PEG-20000) solution;

[0078] 2. Preparation of phase B raw material solution, containing 0.15M phosphoric acid and 0.45M sodium hydroxide solution;

[0079] 3. Set the flow rate F of the phase A raw material liquid delivery pump A =10mL / min, the flow rate F of the phase B raw material liquid delivery pump B =10mL / min, at room temperature of 30°C, the two-phase raw material liquid is simultaneously transported to a microchannel continuous mixing reactor with a channel size of 10 μm. After the two-phase materials are uniformly differentially mixed, the continuous integral reaction forms silver-containing calcium phosphate Aggregates;

[0080] 4. Transport the mixed reaction product calcium phosphate aggregate sol to a washing and dehydrating device, wash with water three times, and vacuum dry at 60° C. to constant weight to obtain am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com