Communication circuit layer structure and circuit printing method thereof

A communication circuit and circuit printing technology, applied in the direction of conductive pattern formation, containing printed electrical components, etc., can solve problems such as manufacturing difficulties, achieve the effects of increased control range, accurate control, and convenient programming design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

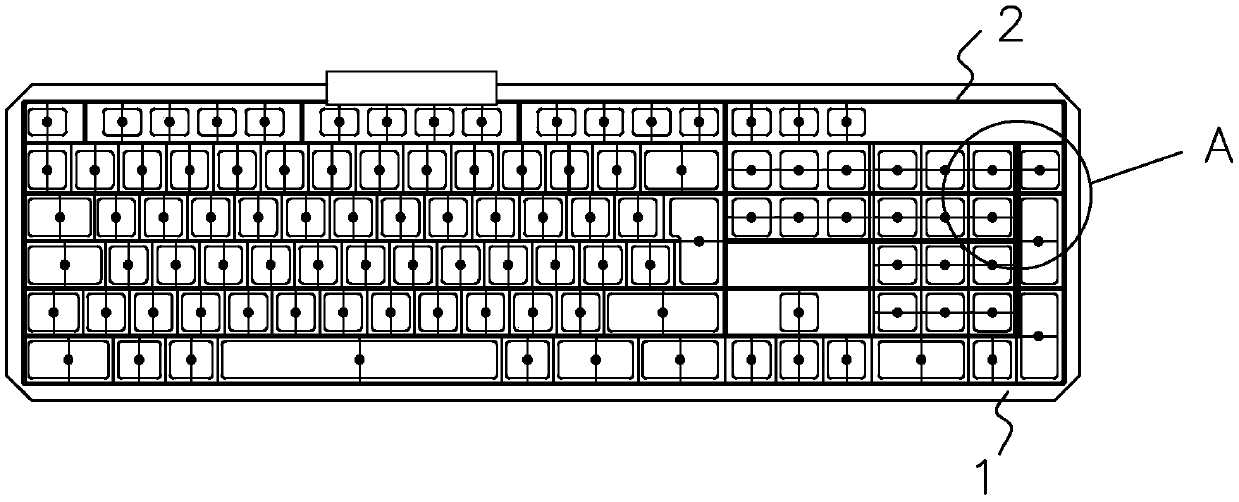

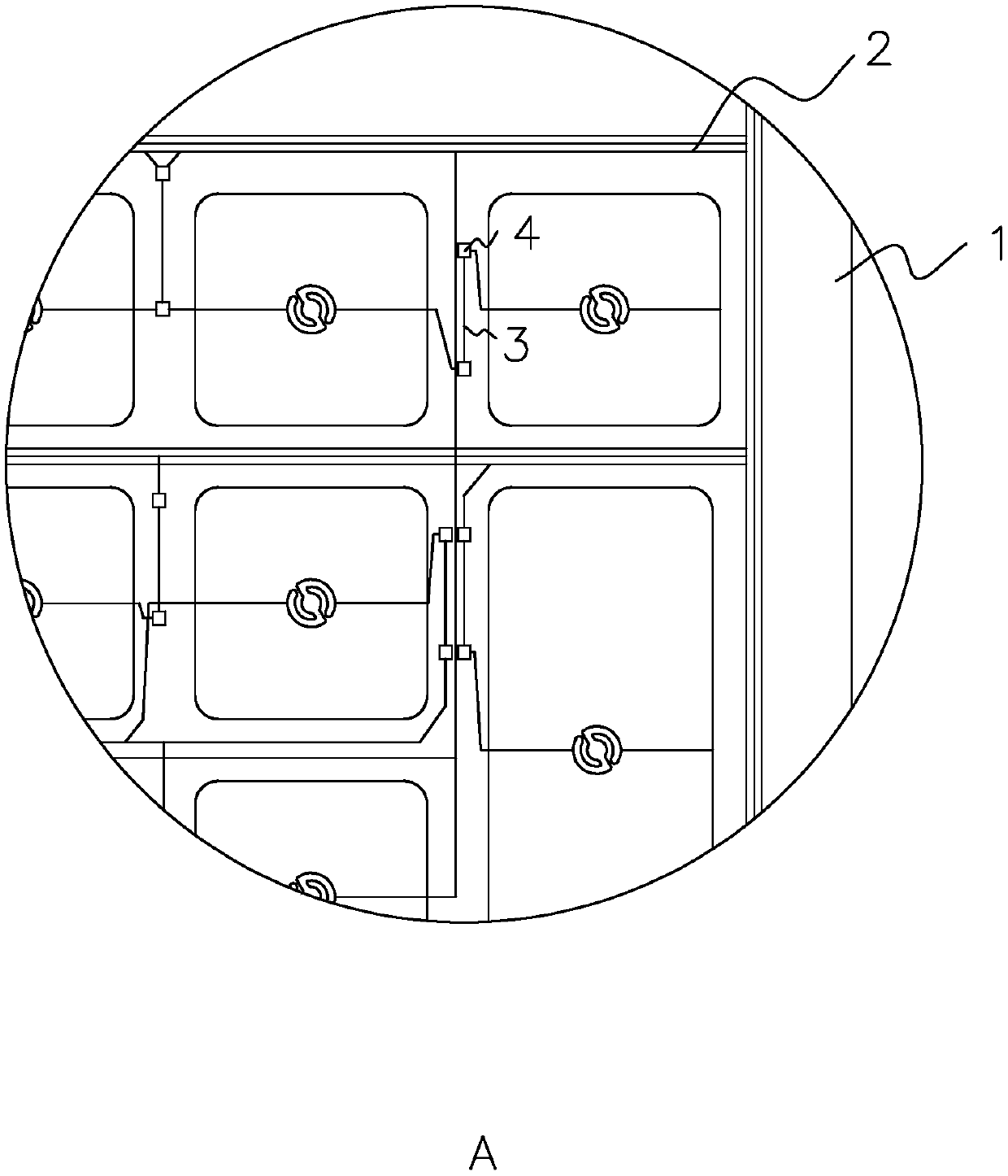

[0034] Embodiment 1: a kind of keyboard communication circuit layer structure, refer to figure 1 and figure 2 , including a flexible circuit board 1 and an insulating cover plate, the thin film circuit board is printed with a signal line 2 printed with a mixed paste, and the mixed paste is made by mixing flake-shaped particle conductive silver paste and round particle conductive silver paste. The intersection of signal lines 2 forms a multi-layer structure, and the insulation layer is formed by printing insulating ink (UV insulating ink produced by Shenzhen Zhihuadian Technology Co., Ltd., Elect-3810) between each layer to insulate and layer the intersection of signal lines 2 . Each signal line 2 is printed with an adjustment section 3 printed with electronic paste, and the adjustment section 3 selects electronic paste with different resistances according to needs.

[0035] In the case that the printing structure of the adjustment section 3 is inconvenient, when the electro...

Embodiment 2

[0037] Embodiment 2: a circuit printing method of the communication circuit layer structure in Embodiment 1, comprising the following steps:

[0038] Step 1. Prepare two plastic films, respectively the first plastic film and the second plastic film, which are respectively used to make the flexible circuit board 1 and the cover plate;

[0039] Step 2, using the electronic paste to print the signal line 2 on the first plastic film with the mixed paste, using the bridging process for multi-layer printing, and reserving the printing space for the adjustment section 3;

[0040] Step 3. According to the current design, use electronic pastes with different resistances, and print the adjustment section 3 in batches, and print the electronic pastes of each component in the same batch;

[0041] Step 4, using ultrasonic welding to connect the flexible circuit board 1 and the cover plate.

[0042] Among them, the mixed paste used in step 2 is made by mixing flake particle conductive silv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com