A ball mill control method

A control method and ball mill technology, applied in the direction of computer control, program control, general control system, etc., can solve the problems of long lag time, swelling, non-linear factors and other problems in the ball milling process, so as to ensure the particle size and work efficiency of the mill overflow ore. Efficiency, reducing the impact of model errors, avoiding uncertain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

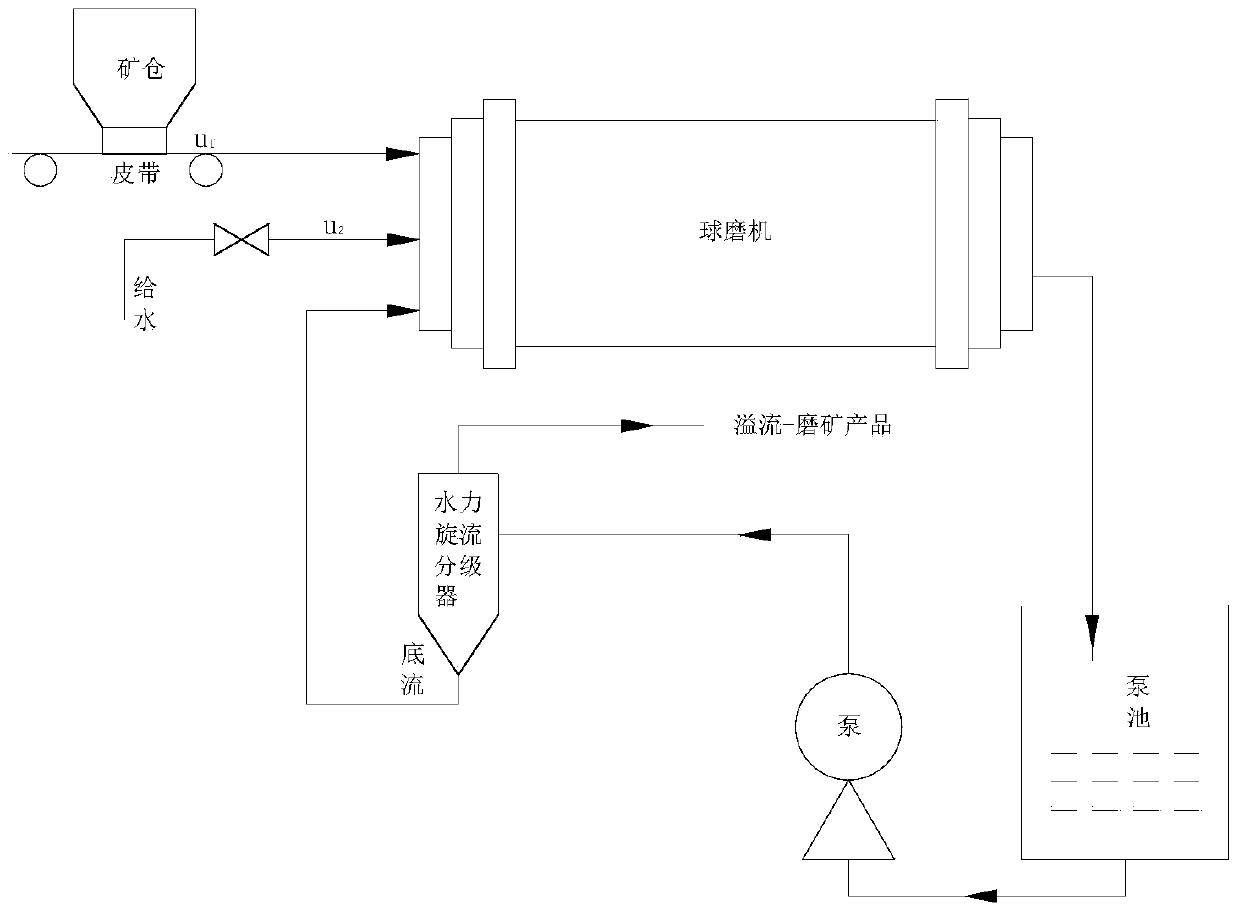

[0018] The process flow chart of ball mill grinding is as follows figure 1 shown. The grinding circuit of the ball mill is mainly composed of an overflow ball mill, a pump pool, a hydrocyclone classifier and other equipment. The ore enters the ball mill through the feeder, and at the same time, the feed water flows into the ball mill inlet. The ore is ground in the ball mill to form a slurry that enters the pump pool, and is lifted by the pump to the hydrocyclone classifier. Classified fine-grained pulp is sent to subsequent processes such as flotation, and the coarse-grained pulp is returned to the ball mill for grinding again.

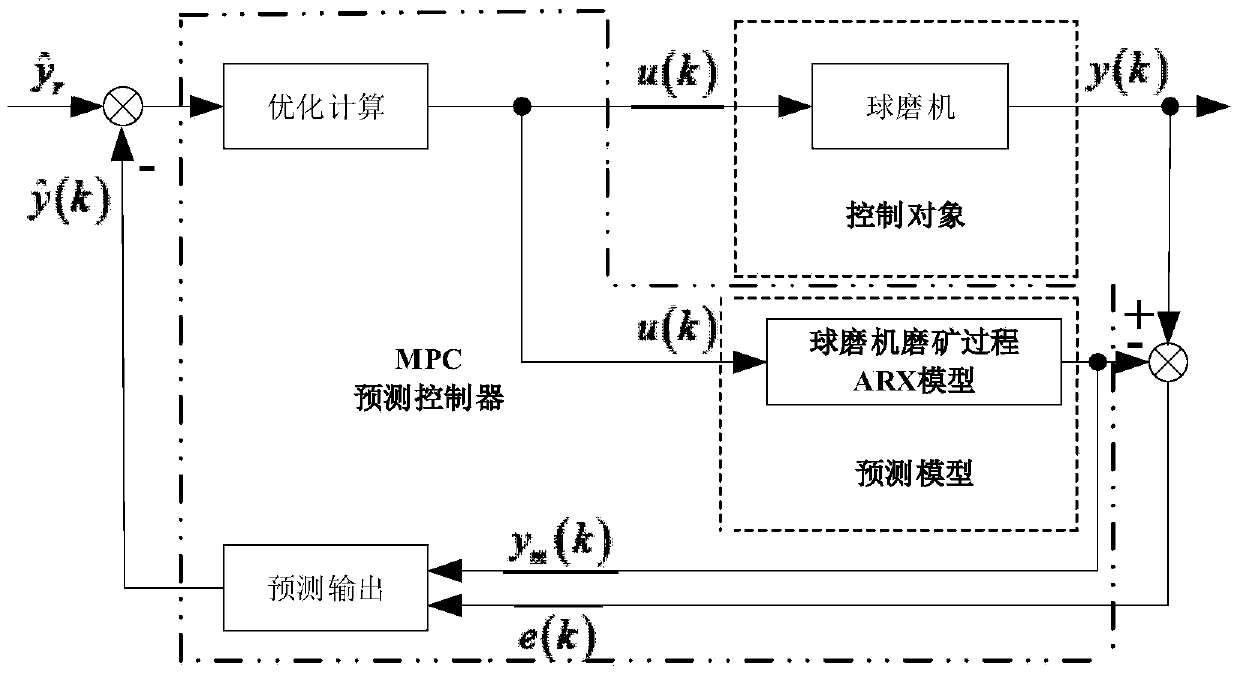

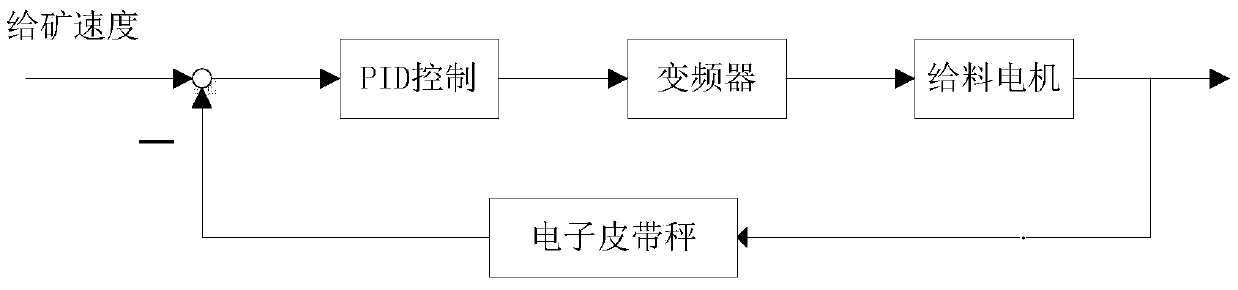

[0019] In the present invention, the actual feeding speed is measured by a belt scale, the actual feeding water flow is measured by a flow meter, the actual feeding speed and the actual feeding water flow are controlled, and the overflow particle size of the grinding is obtained by a particle size analyzer, which is the largest in the ball mill. Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com