constant voltage regulator

A technology of constant pressure regulator and throttle valve, which is applied to safety valves, engine components, balance valves, etc., can solve the problems of high cost, large volume and difficult modification, and achieve the effect of preventing blocking phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

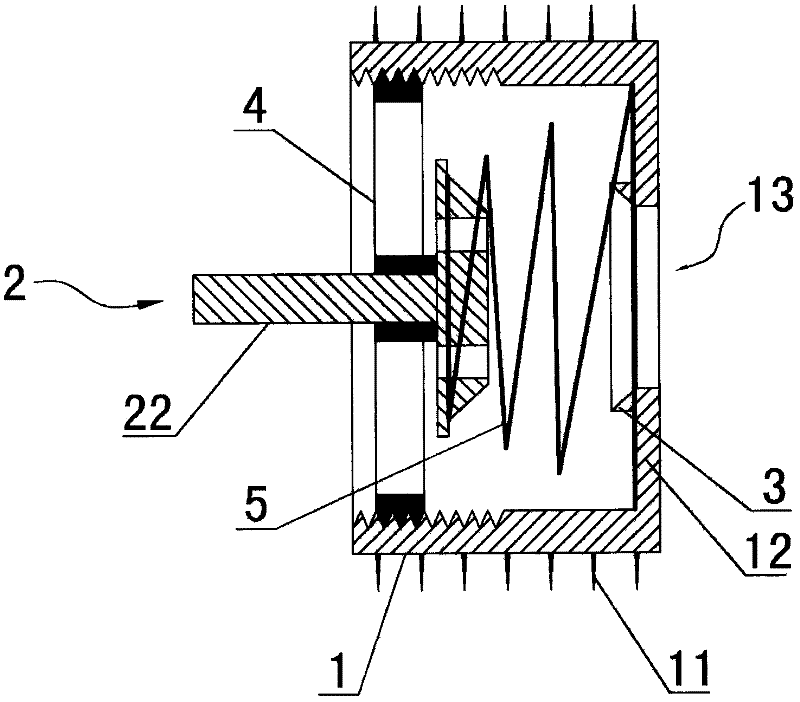

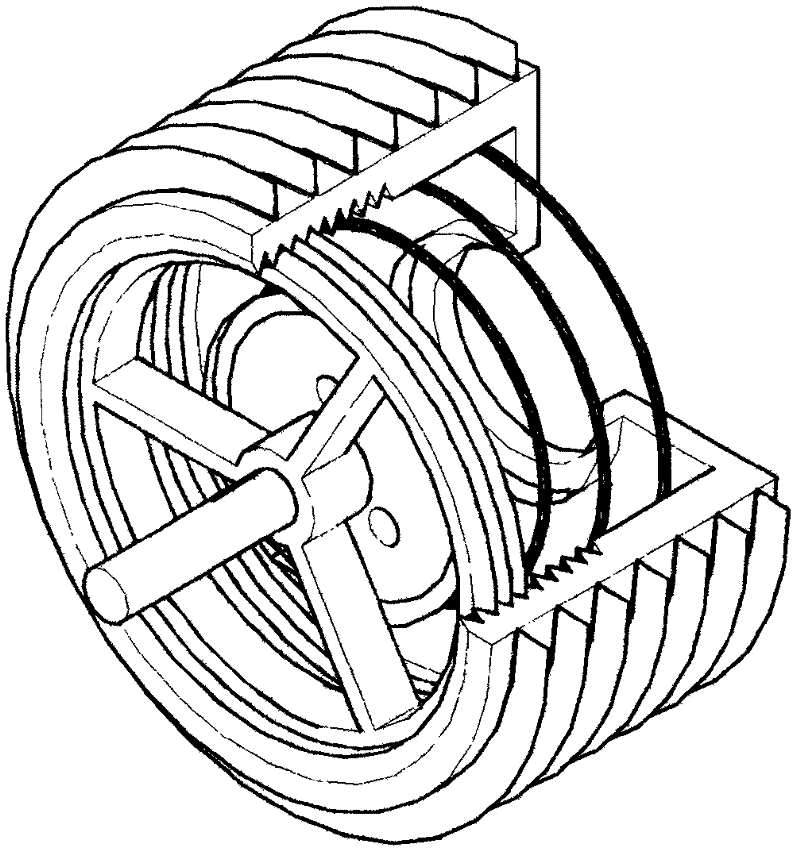

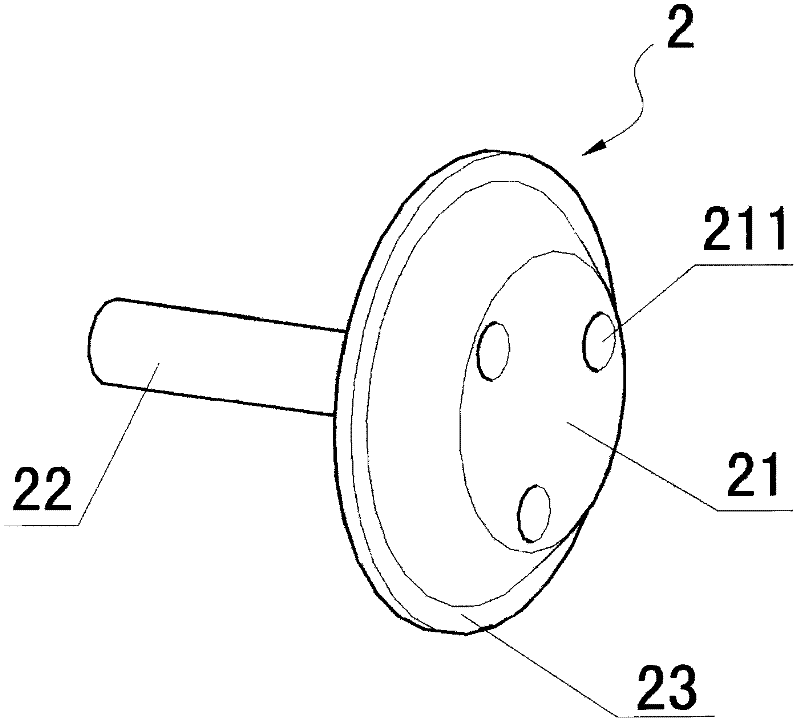

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the constant pressure stabilizer is mainly composed of a base 1, a throttle valve 2, a conical table 3, a positioning seat 4, and a spring 5. The throttle valve 2 includes a conical body 21, a valve stem 22 and a protrusion Edge 23, the base 1 is made of plastic, the outer wall is provided with a sealing pleat 11, the outlet end of the base 1 is provided with a platform 12, and a hole 13 is provided in the center of the platform 12; the spring 5 adopts a tower structure, the large-diameter end is placed on the platform 12 in the base 1; the center hole of the positioning seat 4 is sleeved on the valve stem 22, and the positioning seat 4 enters from the inlet end of the base 1, and is screwed on the base 1 of the inner wall.

[0024] The outer wall of the positioning seat 4 is provided with threads that match the inner wall of the base 1.

[0025] The flange 23 is provided on the bottom edge of the cone 21; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com