Continuous production method of aramid fiber enhanced cable core

An optical cable strengthening core and aramid fiber technology, which is applied in the field of ring optical cables, can solve the problems of mold blocking, resource waste, cost increase, etc., and achieve the effects of reducing production costs, improving production efficiency, and preventing mold blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention provides a method for continuous production of aramid fiber-reinforced composite fiber optic cable reinforcement cores. The glue solution is in parts by weight: 2 parts of medium-temperature curing agent, 1.5 parts of high-temperature curing agent, and 1.5 parts of release agent are added for every 100 parts of unsaturated resin. Parts, 0.6 parts of silane coupling agent, 4 parts of filler.

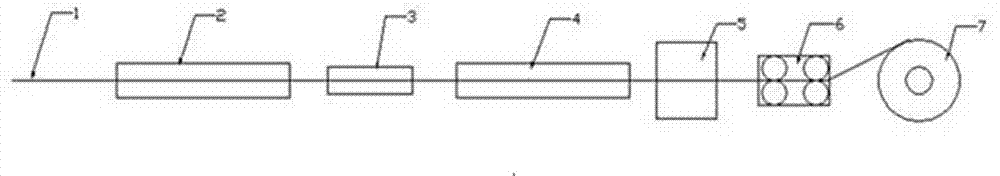

[0022] The continuous production method of the aramid fiber reinforced composite fiber optic cable reinforcing core comprises the following steps:

[0023] The aramid fiber yarn 1 is preheated through the oven 2 heated to 80°C to soften the fiber and increase the degree of impregnation.

[0024] Pass the preheated aramid fiber yarn through the trough filled with the above-mentioned glue solution, and go through the glue wiping process in the trough to completely infiltrate the aramid fiber yarn.

[0025] The fully impregnated aramid fiber yarn is passed through the m...

Embodiment 2

[0030] The glue solution is in parts by weight: for every 100 parts of unsaturated resin, 1.5 parts of medium-temperature curing agent, 1.0 part of high-temperature curing agent, 1.0 part of release agent, 0.3 part of silane coupling agent and 3.0 parts of filler are added. The rest of the production steps or process conditions are the same.

Embodiment 3

[0032] The glue solution in parts by weight is: for every 100 parts of unsaturated resin, add 2.5 parts of medium temperature curing agent, 2.0 parts of high temperature curing agent, 2.0 parts of release agent, 0.8 parts of silane coupling agent, and 5.0 parts of filler. The rest of the production steps or process conditions are the same.

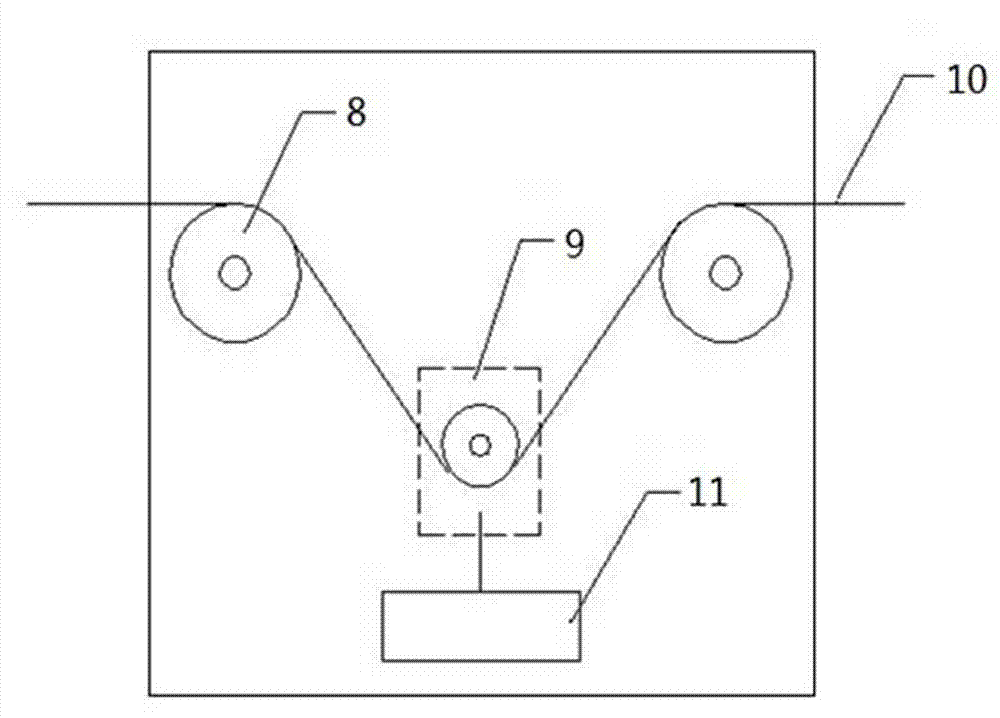

[0033] When the data read by the tension sensor system shows that the tension increases, it means that the mold will be blocked and the fiber optic cable reinforcement core will be broken. At this time, the inner wall of the mold needs to be cleaned by solvent method or abrasive method, that is, the solvent or abrasive liquid is evenly coated on the mold. Clean the inner wall of the mold to keep it smooth on the aramid fiber yarn that has been glued before, so as to reduce the tensile tension and prevent the fracture of the aramid fiber optic cable reinforcement core, so as to achieve continuous production of the aramid fiber optic cable re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com