Method for preparing electrode materials with hollow carbon fibers coated with manganese dioxide

A manganese dioxide and carbon fiber technology, used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve problems such as poor conductivity and application limitations of MnO2, and achieve high specific capacitance, mild conditions, and process economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

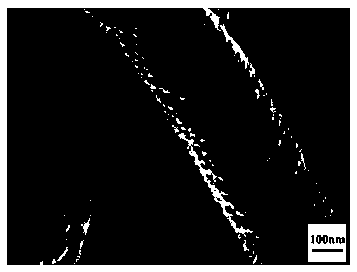

[0034] Example 1: MnO 2 The water heat load temperature is 40°C.

[0035] a. Weigh 0.45gMnSO 4 · h 2 O and 1gKMnO 4 Dissolve in 30mL deionized water respectively, and stir magnetically. When the solid is completely dissolved, the MnSO 4 · h 2 O solution poured into KMnO 4 solution, continue to stir until the mixture gradually turns into a brown-yellow suspension. Then it was transferred to a 100mL stainless steel hydrothermal reaction kettle and reacted at a constant temperature of 160°C for 24h. Then the precipitate in the kettle was filtered under reduced pressure, washed with ethanol and double distilled water for 3 times, and dried to obtain MnO 2 metal oxide nanorods.

[0036] b. Weigh 0.5g of PAN and dissolve it in 4.5gDMF, stir magnetically until it is completely dissolved, then add 0.5gMnO 2 Continue to stir the metal oxide nanorods until they are evenly mixed to obtain a spinning solution.

[0037] c. The ambient temperature of electrospinning is ≤40°C, a...

Embodiment 2

[0042] Example 2: MnO 2 The water heat load temperature is 60°C.

[0043] a. Weigh 0.45gMnSO 4 · h 2 O and 1gKMnO 4 Dissolve in 30mL deionized water respectively, and stir magnetically. When the solid is completely dissolved, the MnSO 4 · h 2 O solution poured into KMnO 4 solution, continue to stir until the mixture gradually turns into a brown-yellow suspension. Then it was transferred to a 100mL stainless steel hydrothermal reaction kettle and reacted at a constant temperature of 160°C for 24h. Then the precipitate in the kettle was filtered under reduced pressure, washed with ethanol and twice distilled water for 3 times, and dried to obtain MnO 2 metal oxide nanorods.

[0044] b. Weigh 0.5g of PAN and dissolve it in 4.5gDMF, stir magnetically until it is completely dissolved, then add 0.5gMnO 2 Continue to stir the metal oxide nanorods until they are evenly mixed to obtain a spinning solution.

[0045] c. The ambient temperature of electrospinning is ≤40°C, an...

Embodiment 3

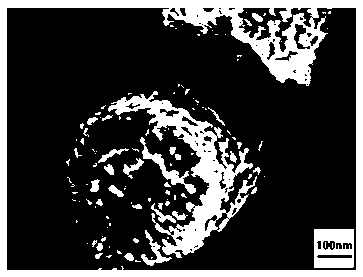

[0050] Example 3: MnO 2 The water heat load temperature is 80°C.

[0051] a. Weigh 0.45gMnSO 4 · h 2 O and 1gKMnO 4 Dissolve in 30mL deionized water respectively, and stir magnetically. When the solid is completely dissolved, the MnSO 4 · h 2 O solution poured into KMnO 4 solution, continue to stir until the mixture gradually turns into a brown-yellow suspension. Then it was transferred to a 100mL stainless steel hydrothermal reaction kettle and reacted at a constant temperature of 160°C for 24h. Then the precipitate in the kettle was filtered under reduced pressure, washed with ethanol and twice distilled water for 3 times, and dried to obtain MnO 2 metal oxide nanorods.

[0052] b. Weigh 0.5g of PAN and dissolve it in 4.5gDMF, stir magnetically until it is completely dissolved, then add 0.5gMnO 2 Continue to stir the metal oxide nanorods until they are evenly mixed to obtain a spinning solution.

[0053] c. The ambient temperature of electrospinning is ≤40°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com