3D (three-dimensional) printer

A 3D printer and frame technology, applied in the field of 3D printers, can solve the problems of being unsuitable for home or office use, difficult processing, and long processing cycle, and achieve the effects of improving space utilization, large printing range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

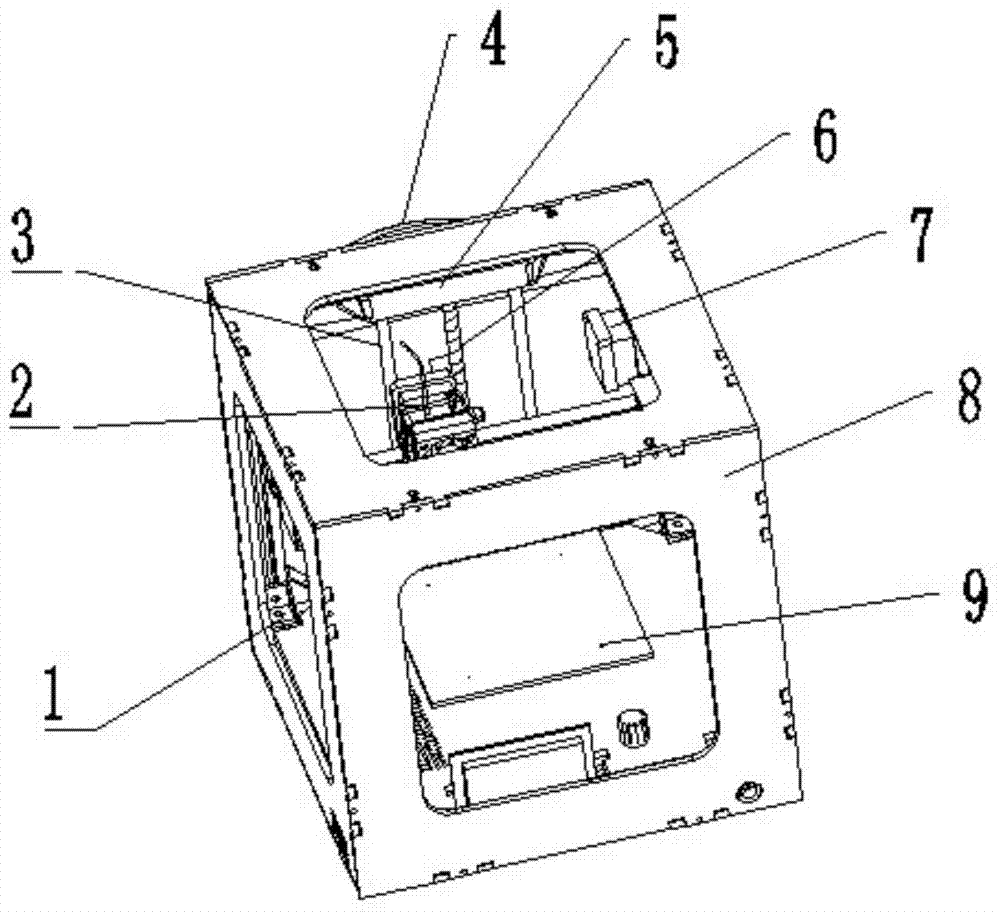

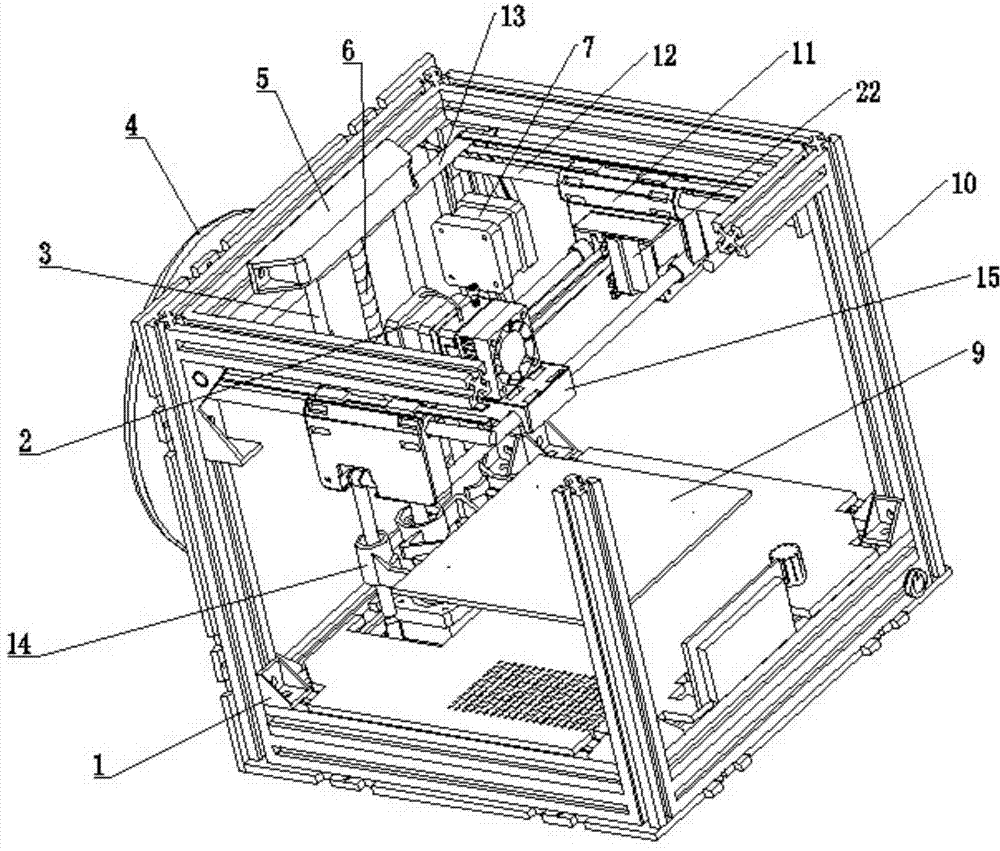

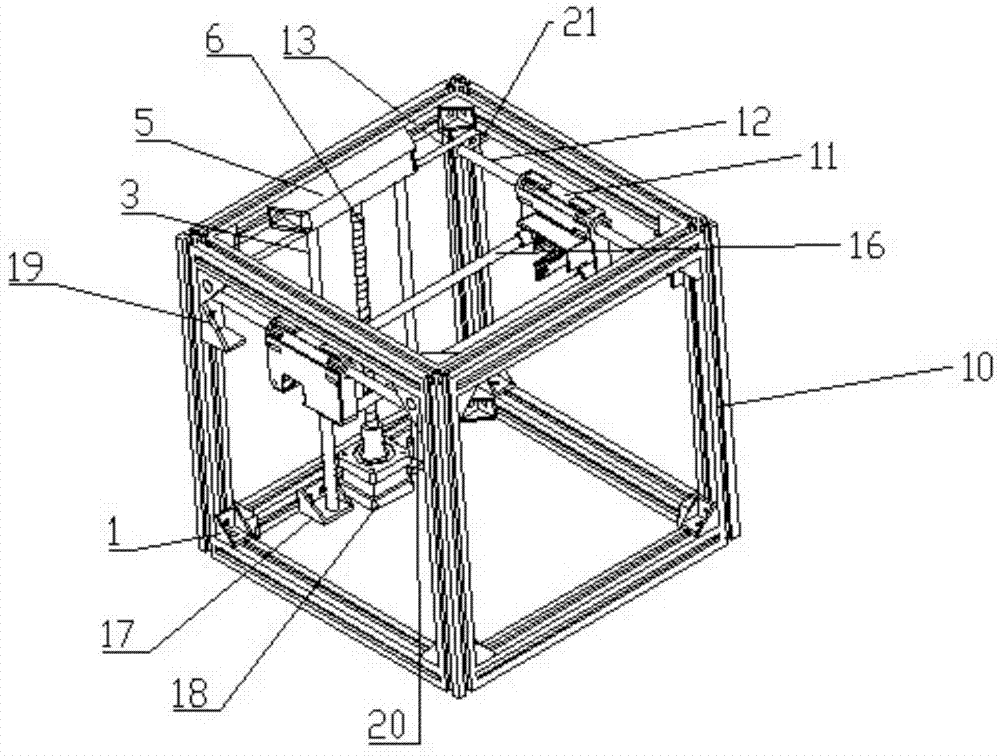

[0020] The three-dimensional printer of this embodiment includes a casing, a frame, a printing unit, a driving device, and a consumables installation box. The driving device includes an X-axis driving motor, a Y-axis driving motor, and a Z-axis driving motor. The printing unit includes a consumables extruding device, The motor bracket, the printing platform, the platform bracket, and the consumable material extruding device are fixedly installed on the motor bracket; the consumable material installation box is fixedly installed on the casing.

[0021] The frame includes an X-axis slide bar 16, a Y-axis slide bar 12, a Z-axis slide bar 3, a Z-axis threaded rod 6, a locking piece, a connecting rod 10, a Y-axis conveyor belt support shaft 13, and the locking piece includes a bottom bracket 17, a top Bracket 5 and fixing piece; Connecting rod 10 forms three-dimensional frame as edge, and the connecting rod 10 that constitutes three-dimensional frame is connected by fixing piece in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com