Manufacturing method of function module used for absorbing fog drops and VOC (volatile organic compounds) in airflows

A functional module and droplet technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of large pressure drop, pressure drop, and large pressure drop of the gas distribution plate, and achieve the effect of improving the absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

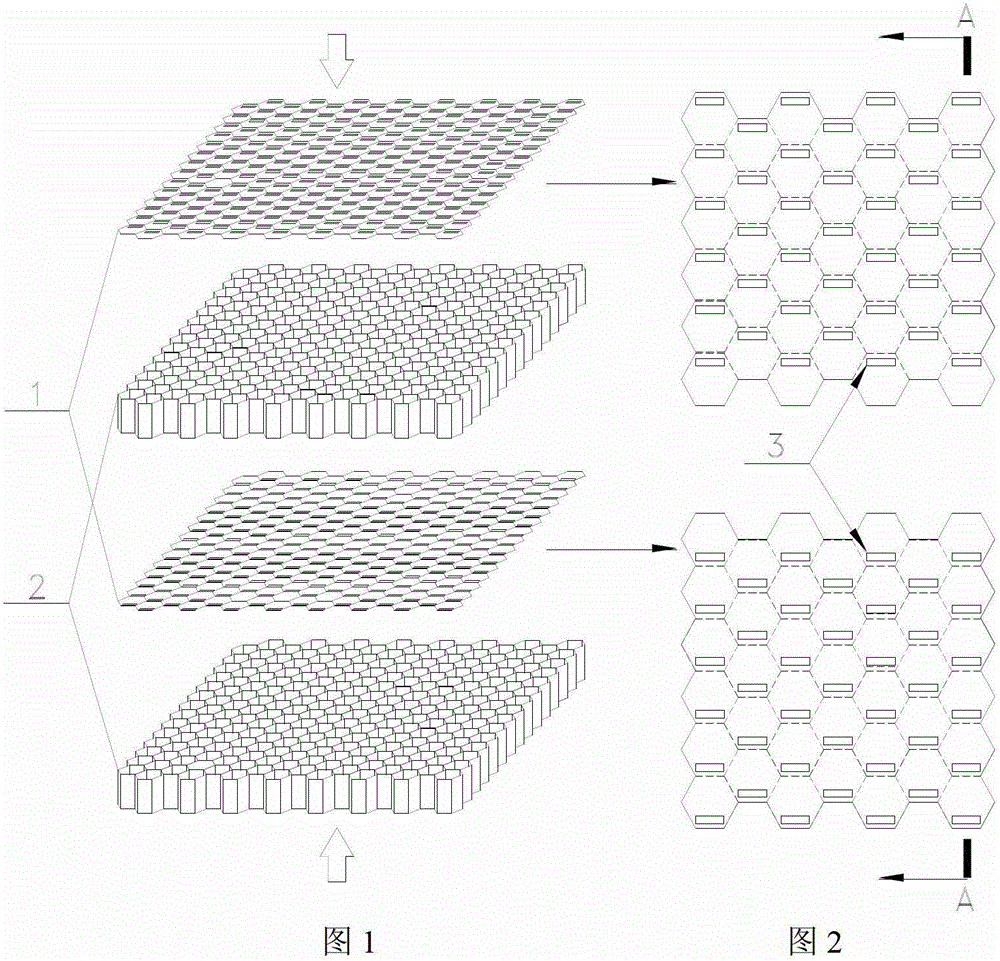

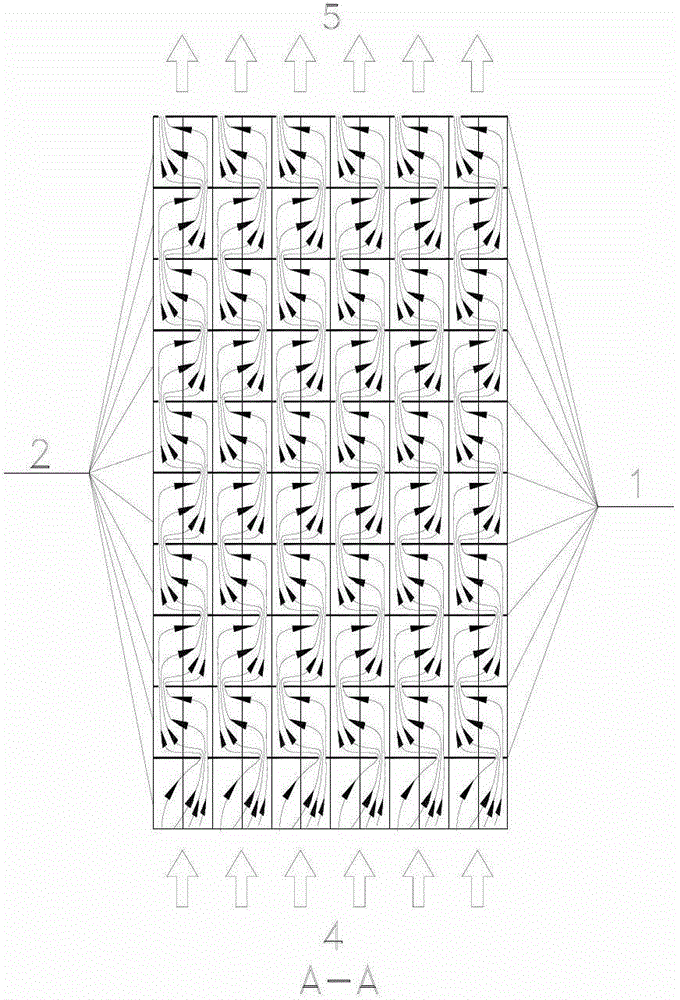

Embodiment 1

[0014] Take 10 circular paper honeycomb panels with a diameter of 200mm (containing 10 layers of honeycomb layers and 10 layers of separator layers respectively), the thickness of each layer of paper honeycomb panels is 100mm, and the side length of the regular hexagon of the honeycomb layer section is 4mm. Open holes in different positions of adjacent separator layers, and dip 8 layers of paper honeycomb panels in a slurry containing 30% diatomaceous earth and 0.1% polyvinyl alcohol (MW300,000), take them out and dry them, while the other 2 The paper honeycomb layer is immersed in a slurry containing 10% activated carbon powder and 0.5% gelatinized starch, taken out and dried, the paper honeycomb layer loaded with diatomaceous earth is placed in front, and the paper honeycomb layer loaded with activated carbon is placed behind , a functional module that can effectively remove mist and VOC in exhaust gas is obtained.

Embodiment 2

[0016] Take 20 square paper honeycomb panels with a size of 300mm×300mm (containing 20 layers of honeycomb layers and 20 layers of separator layers respectively), the thickness of each layer of paper honeycomb panels is 150mm, and the side length of the regular hexagon of the honeycomb layer section is 10mm , open holes at different positions of adjacent separator layers, and impregnate 10 layers of paper honeycomb panels in a slurry containing 50% expanded vermiculite powder and 5% polyethylene glycol (MW1000), take them out and dry them, while the other The 10-layer paper honeycomb is immersed in a slurry containing 1% active coke powder and 0.1% methylcellulose, taken out and dried, the paper honeycomb layer loaded with vermiculite powder is placed in front, and the paper honeycomb layer loaded with active coke After being installed, a functional module that can effectively remove mist and VOC in the exhaust gas is obtained.

Embodiment 3

[0018] Take 30 pieces of paper honeycomb panels with a diameter of 1000mm (containing 30 layers of honeycomb layers and 30 layers of separator layers respectively), the thickness of each layer of paper honeycomb panels is 200mm, and the side length of the regular hexagon of the honeycomb layer section is 200mm. Holes were opened at different positions adjacent to the separator layer, and 22 layers of paper honeycomb panels were dipped in a slurry containing 40% activated alumina powder and 2% polyvinyl alcohol (MW 25,000), taken out and dried, while the other The 8-layer paper honeycomb is impregnated in a slurry containing 20% chopped activated carbon fiber and 0.1% cationic etherified starch, taken out and dried, the paper honeycomb layer loaded with activated alumina is placed in front, and the chopped activated carbon After the fibrous paper honeycomb is placed, a functional module that can effectively remove mist and VOC in the exhaust gas is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com