Electrode wire for electro-discharge machining and method for manufacturing the same

A technology of electrical discharge machining and electrode wire, which is applied in the direction of electrode manufacturing, electric processing equipment, manufacturing tools, etc., can solve the problems of large particles and alloy coatings that are easily broken, and achieve increased surface area, optimal surface roughness, and improved The effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

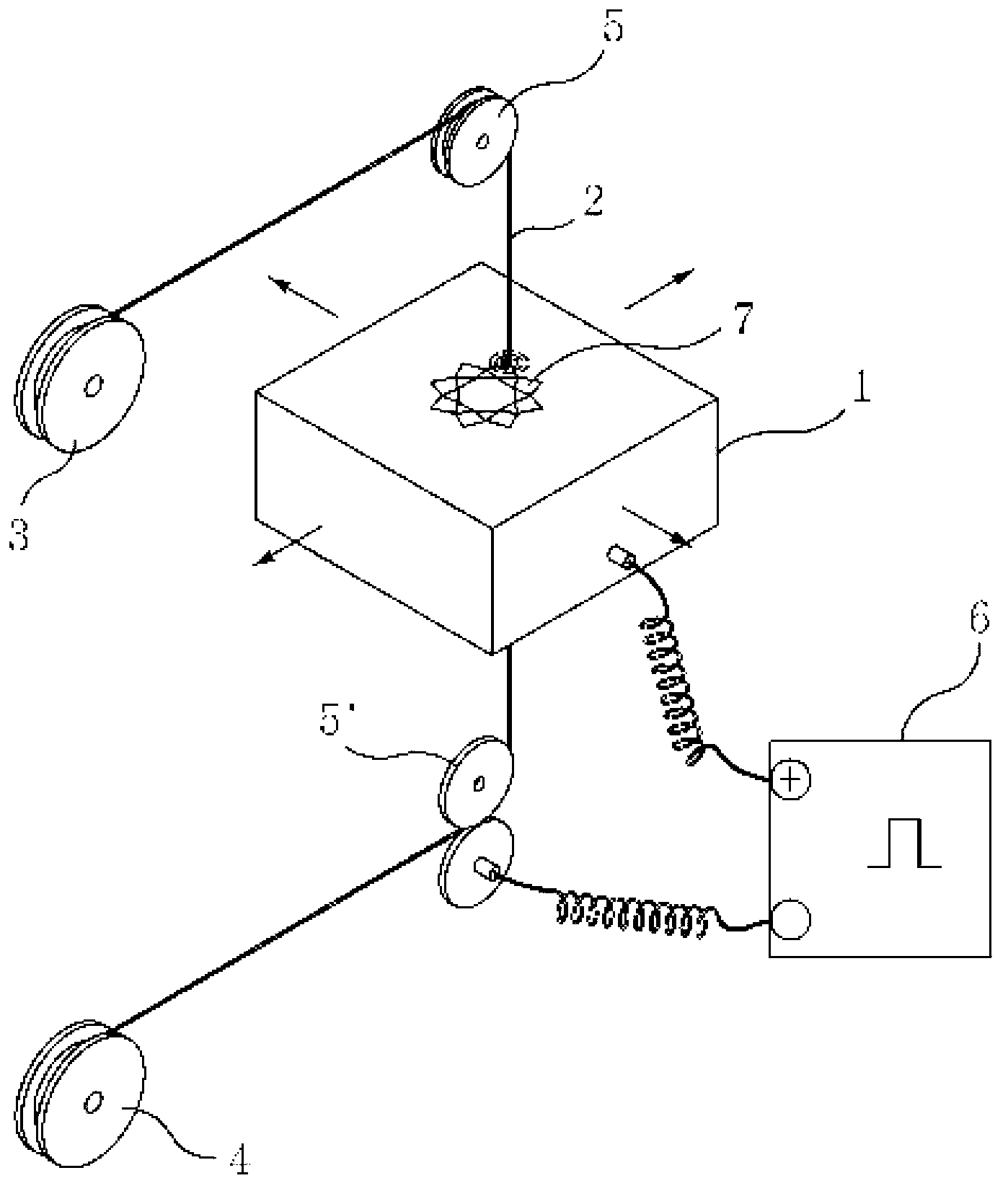

Method used

Image

Examples

Embodiment approach 1

[0077] Prepare a core wire (containing the first metal) as an intermediate wire material, the diameter of the core wire is about 0.9mm, the core wire is a brass wire, and it has about 65% by weight of copper and about 35% by weight of zinc component ratio.

[0078] When passing through the alkaline degreasing solution, the core wire is cleaned. Then, after the core wire is subjected to an acid washing process, the core wire is cleaned again.

[0079] Then, the cleaned core wire was subjected to an electrogalvanizing process at a line speed of 20 m / min by using zinc as the second metal and applying a current of 770 A, thereby plating the core wire with a predetermined thickness.

[0080] Then, the intermediate wire rod subjected to the electrogalvanizing process is thinned and elongated, so that the diameter of the intermediate wire rod is 0.25 mm.

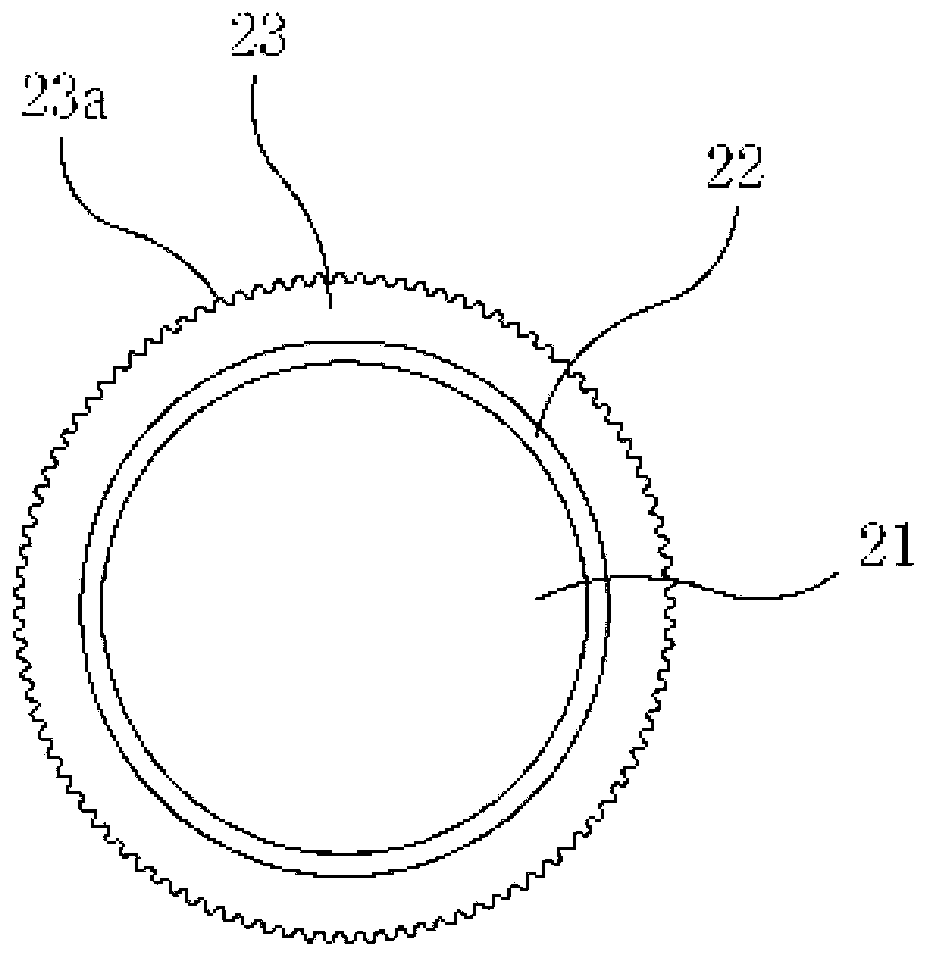

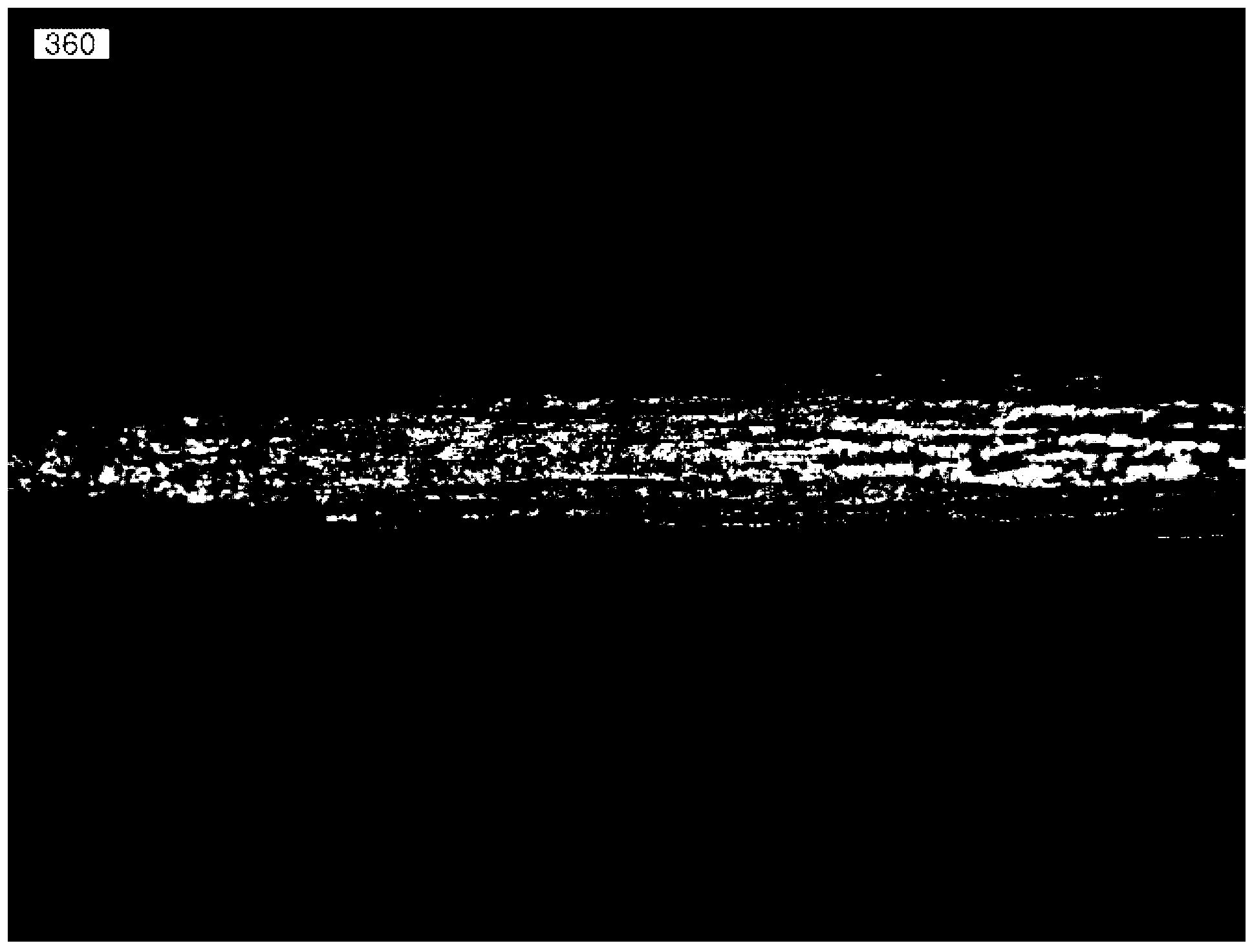

[0081] In the filament elongation process, corrugations having a predetermined pattern are formed on the surface of the interme...

Embodiment approach 2

[0099] Prepare a core wire (containing the first metal) as an intermediate wire material, the diameter of the core wire is about 0.9mm, the core wire is a brass wire, and it has about 65% by weight of copper and about 35% by weight of zinc component ratio.

[0100] When passing through the alkaline degreasing solution, the core wire is cleaned. Then, after the core wire is subjected to an acid washing process, the core wire is cleaned again.

[0101] Then, the cleaned core wire was subjected to an electrogalvanizing process at a line speed of 20 m / min by using zinc as the second metal and applying a current of 770 A, thereby plating the core wire with a predetermined thickness.

[0102] Then, the intermediate wire rod subjected to the electrogalvanizing process is thinned and elongated, so that the diameter of the intermediate wire rod is 0.25 mm.

[0103] Then, the thinned and strengthened intermediate wire is subjected to a heat treatment process in an oxidizing atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com