Vacuum evaporation heating device

A heating device and vacuum technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems that are not conducive to reducing the frequency of opening cavity and refueling and other machine maintenance items, the horizontal and radial temperature of the crucible Poor, not conducive to production efficiency and other issues, to achieve the effect of simple structure, improve production efficiency, and prevent hole plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

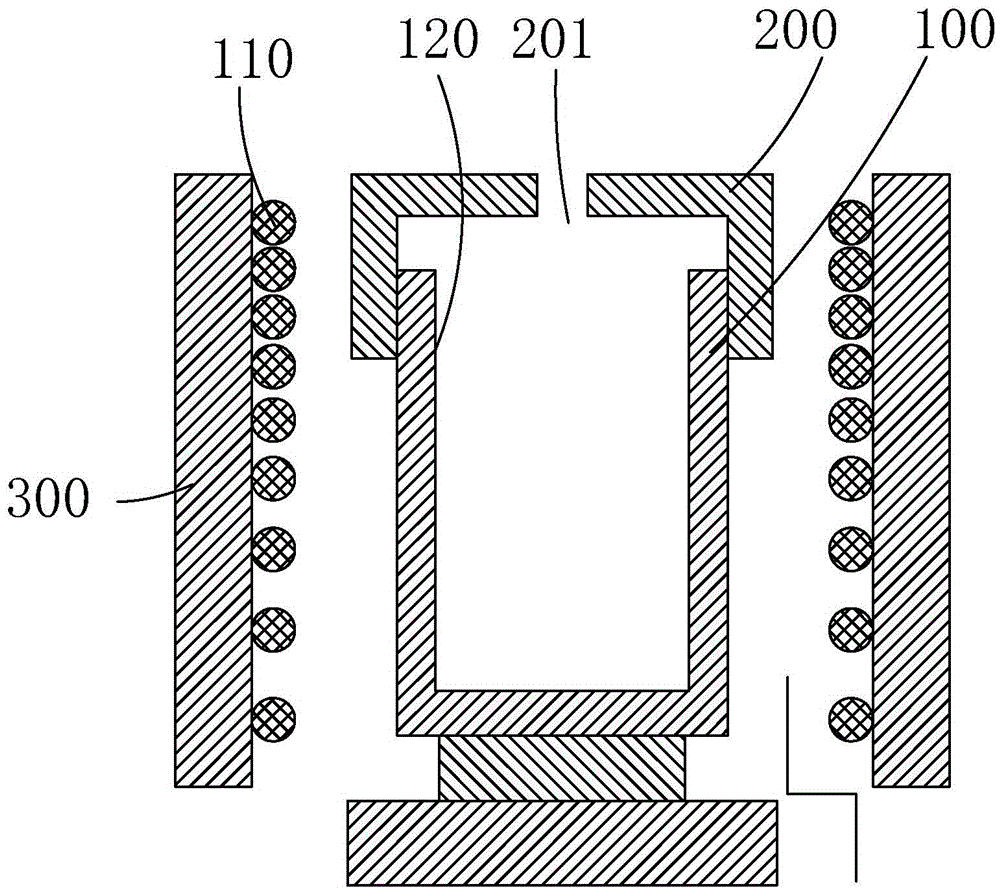

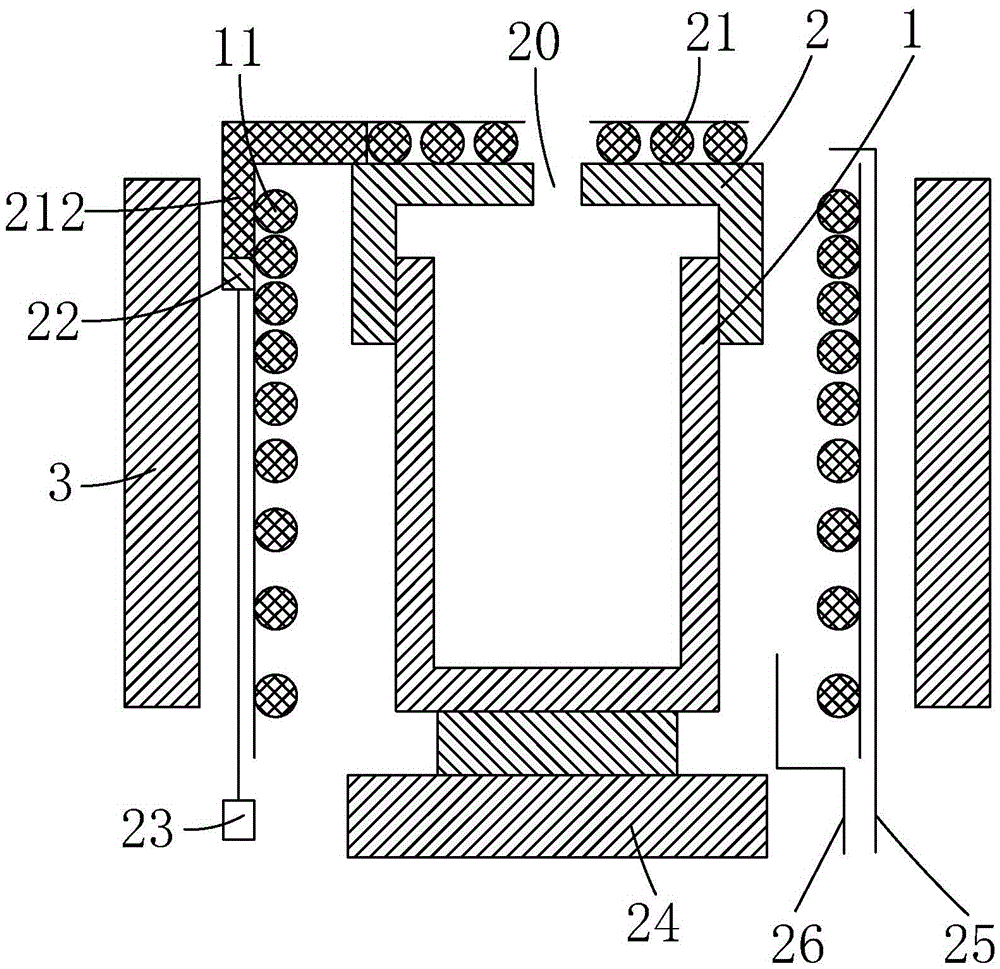

[0027] see Figure 2 to Figure 4 , The present invention provides a heating device for vacuum evaporation, comprising an outer wall 3 of the heating device, a crucible 1 disposed inside the outer wall 3 of the heating device, and a crucible cover 2 disposed on the crucible 1 .

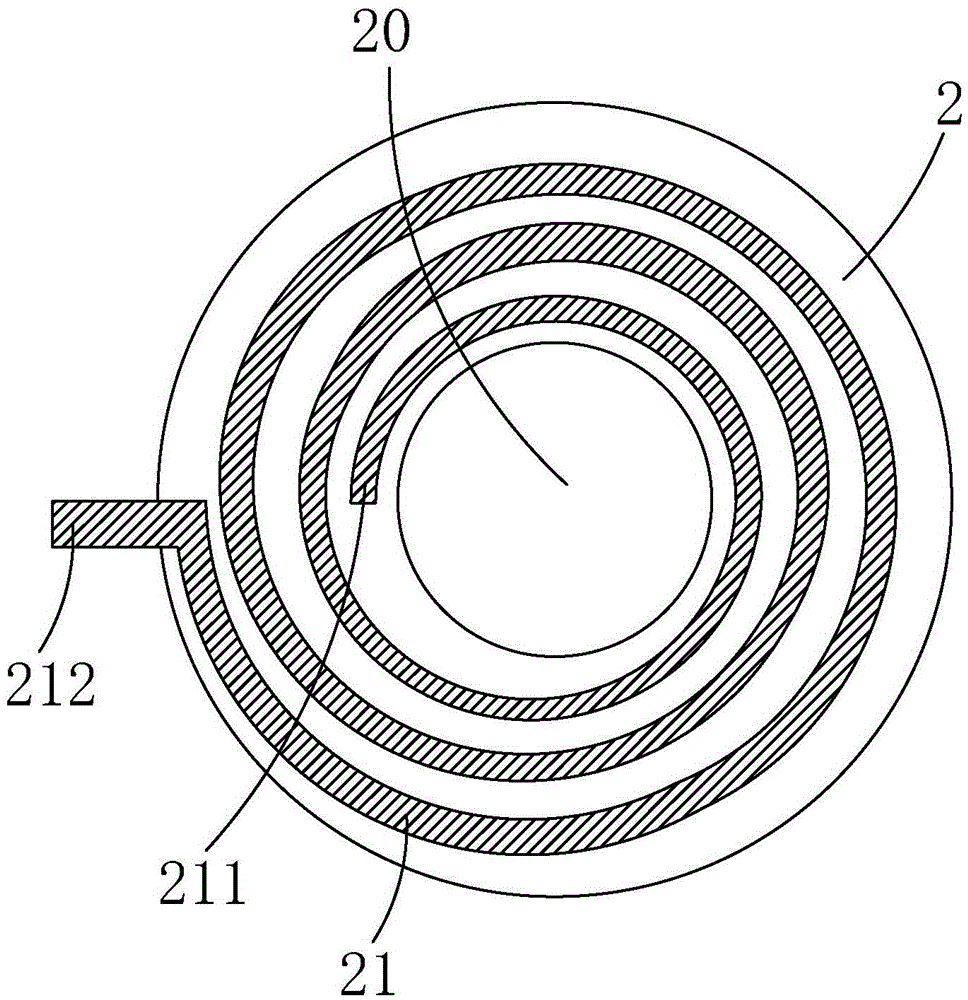

[0028] Specifically, a first heating coil 11 is provided between the crucible 1 and the outer wall 3 of the heating device corresponding to the peripheries of the crucible 1 and the crucible cover 2 . The center of the crucible cover 2 is provided with a nozzle 20 penetrating through the upper and lower surfaces of the crucible cover 2, which is used to fly vaporized evaporation material molecules from the nozzle 20 to deposit on the substrate to form a solid film duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com