Auxiliary apparatus for the manual guidance of moving threads

An auxiliary device, manual guidance technology, applied in the direction of starting filament formation, transportation and packaging, conveying filamentous materials, etc., to achieve the effect of short penetration and splicing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

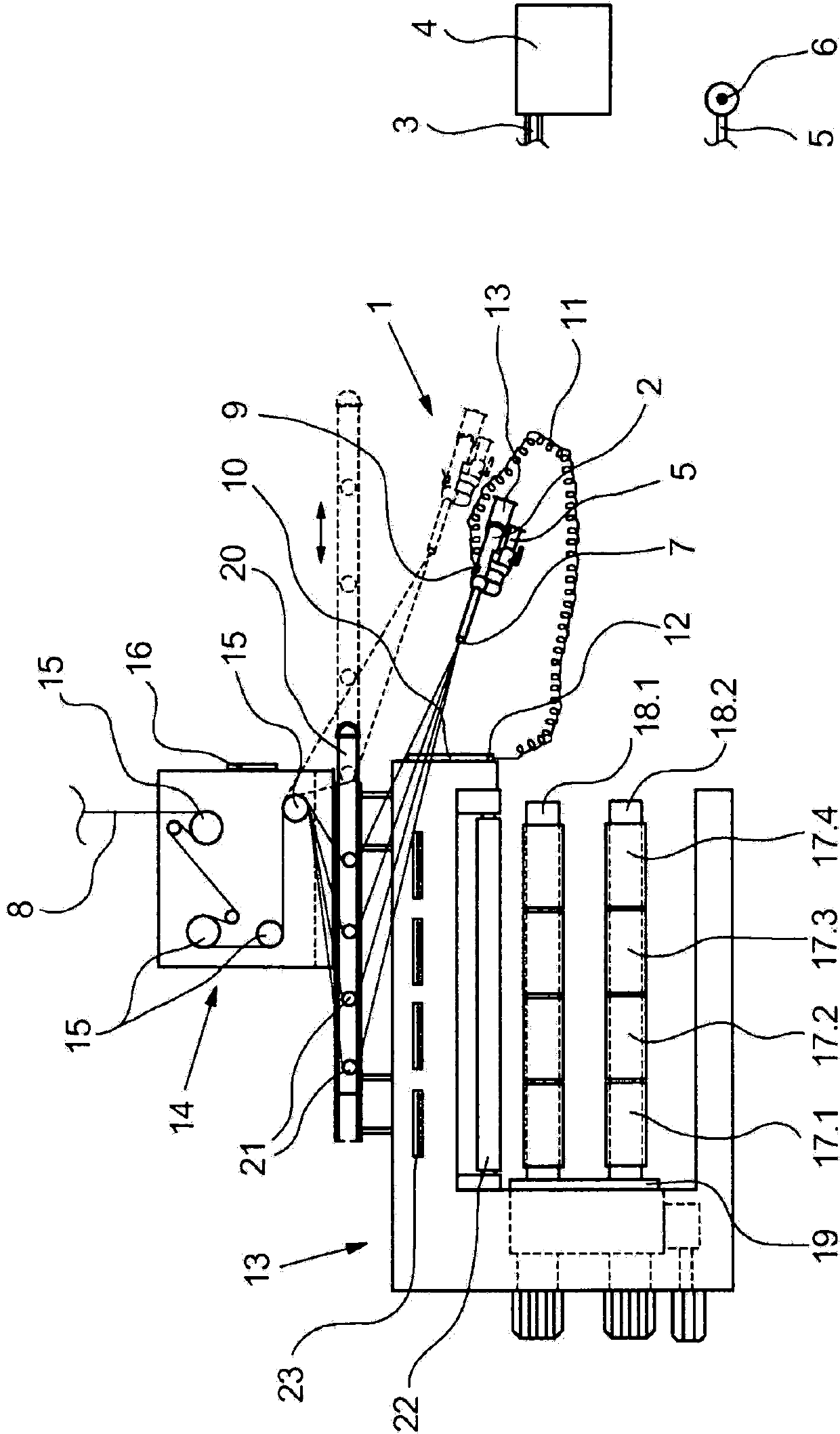

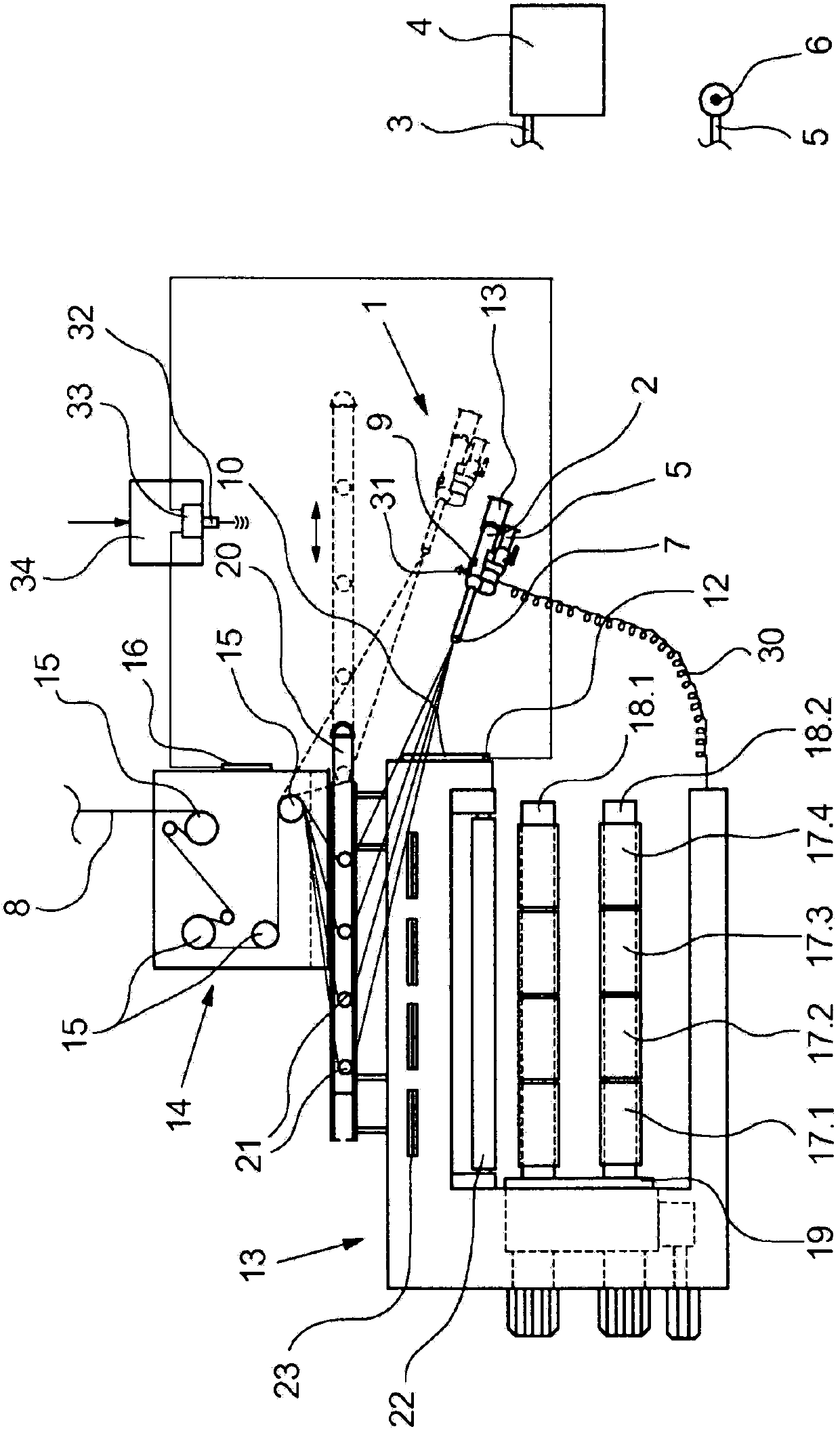

[0025] figure 1 A first embodiment of an auxiliary device for manually guiding the advancing wire during the wire manufacturing process is schematically shown in . The yarn manufacturing process involves a melt spinning apparatus in which multiple yarns are spun in parallel at each spinning position. It is customary in such melt-spinning installations that the freshly spun yarn is drawn off by means of a drawing device and, after drawing, is wound up into bobbins by means of a winder. in this regard figure 1 The diagram shows the thread production process by means of a drawing device 14 and a winding machine 13. The drawing device 14 has a plurality of driven godets 15 , which are drawn off by a spinning device (not shown here) and guided over the circumference of the respective godet 15 . The drive of each godet 15 is controlled via a godet control unit 16 .

[0026] Below the stretching device 14 there is arranged a winder 13 which has a winding position for each thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com