Papermaking sewage treatment agent and preparation method thereof

A technology of papermaking sewage and treatment agent, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of difficult to meet the wastewater treatment requirements, long sedimentation treatment time and low treatment effect. Inadequate and other problems, to achieve the effect of low requirements for process equipment and parameter conditions, good use effect, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

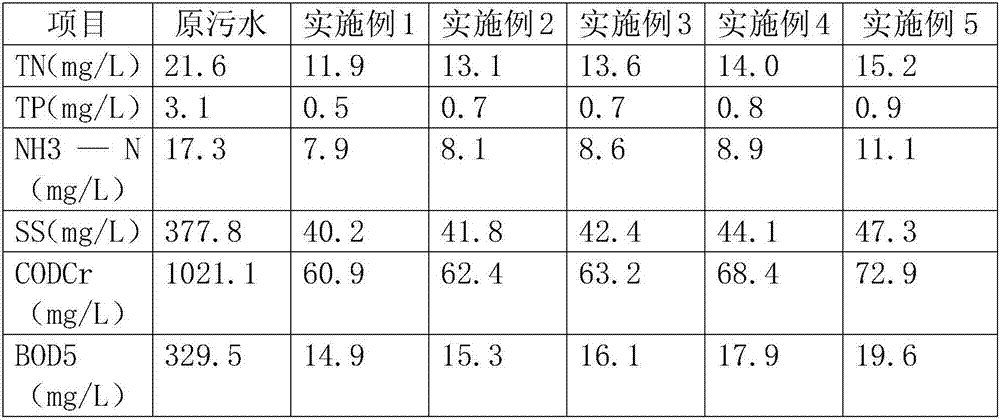

Examples

Embodiment 1

[0021] 1), Weigh the following raw materials in parts by weight: 66 parts of fruit shell powder, 10 parts of zinc chloride, 15 parts of polyaluminum chloride, 15 parts of polyacrylamide, 5 parts of bentonite, 5 parts of zinc white powder, and 8 parts of trioctylamine , 12 parts of cellulase, 6 parts of zinc oleate, 4 parts of silica powder, 7 parts of potassium laureth phosphate, described fruit shell powder is by walnut shell powder, chestnut shell powder, hazelnut shell powder according to 1:1: The mass ratio of 1 is obtained by mixing, and the shell powder is passed through a 100-mesh sieve;

[0022] 2), adding 5 times the mass of hydrochloric acid with a concentration of 10% to the fruit shell powder in step 1) for aging, then washing with water until neutral, and drying at 75°C for 13 hours;

[0023] 3) Add the ripened and dried husk powder in step 2) together with other raw materials except husk powder weighed in step 1) into the reaction kettle, and preheat and mix at 7...

Embodiment 2

[0025] 1), Weigh the following raw materials in parts by weight: 66 parts of fruit shell powder, 8 parts of zinc chloride, 12 parts of polyaluminum chloride, 12 parts of polyacrylamide, 4 parts of bentonite, 6 parts of zinc white powder, 7 parts of trioctylamine , 12 parts of cellulase, 6 parts of zinc oleate, 3 parts of silica powder, 6 parts of potassium lauryl ether phosphate, described nut shell powder is made of walnut shell powder, chestnut shell powder, macadamia nut shell powder according to 1:1 The mass ratio of :1 is obtained by mixing, and the shell powder is passed through a 100-mesh sieve;

[0026] 2), add 4 times the mass of hydrochloric acid with a concentration of 10% to the fruit shell powder in step 1) for aging, then wash with water until neutral, and bake at 80°C for 12 hours;

[0027] 3) Add the ripened and dried husk powder in step 2) together with other raw materials except husk powder weighed in step 1) into the reaction kettle, and preheat and mix at 6...

Embodiment 3

[0029] 1), Weigh the following raw materials in parts by weight: 70 parts of fruit shell powder, 8 parts of zinc chloride, 12 parts of polyaluminum chloride, 15 parts of polyacrylamide, 5 parts of bentonite, 57 parts of zinc white powder, and 8 parts of trioctylamine , 12 parts of cellulase, 8 parts of zinc oleate, 5 parts of silica powder, 7 parts of potassium lauryl ether phosphate, and the described fruit shell powder is obtained by mixing walnut shell powder and chestnut shell powder according to the mass ratio of 1:1 , the husk powder is passed through a 100-mesh sieve;

[0030] 2), adding 5 times the mass of hydrochloric acid with a concentration of 10% to the fruit shell powder in step 1) for aging, then washing with water until neutral, and drying at 70°C for 15 hours;

[0031] 3) Add the ripened and dried husk powder in step 2) together with other raw materials except husk powder weighed in step 1) into the reaction kettle, and preheat and mix at 70°C Stir for 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com