Device and method for separating suspended micro-oil-fume particles on range hood

A technology for particle separation and tiny particles, applied in separation methods, dispersed particle separation, combined devices, etc., can solve problems such as electrostatic and mechanical methods that cannot be caught

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

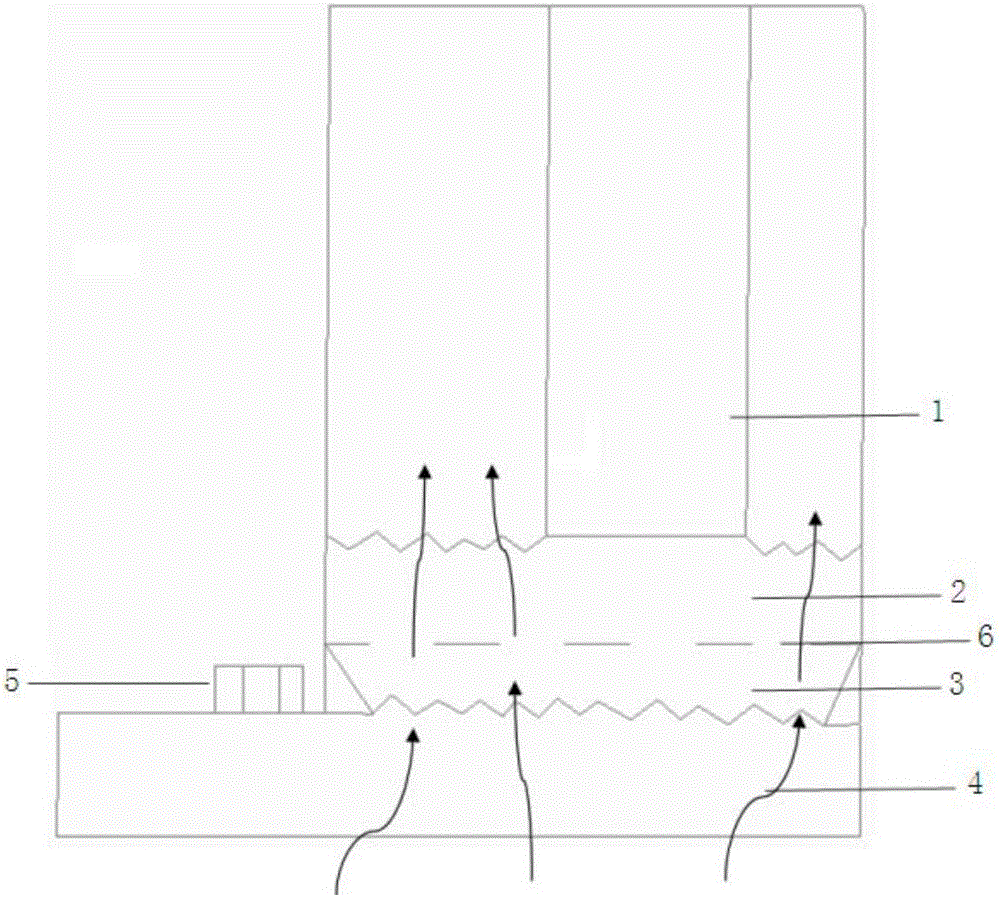

[0030] Embodiment one: as attached figure 1 As shown, the suspended micro fume particle separation device on the range hood includes a range hood body 1 and a range hood collecting device 4. The range hood collecting device 4 is located below the range hood body 1 and further includes Oil fume velocity slowing condenser 3, rectification net 6, oil fume water molecule collision mixing condenser 2 and cold water particle generator 5 located on range hood body 1, said oil fume velocity slowing condenser 3, rectification net 6, oil fume water The molecular collision mixing condenser 2 is located above the oil fume collecting device 4 , and the cold water micro particles generated by the cold water micro particle generator 5 are sprayed in the oil fume velocity slowing condenser 3 and / or the oil fume water molecule collision mixing condenser 2 .

Embodiment 2

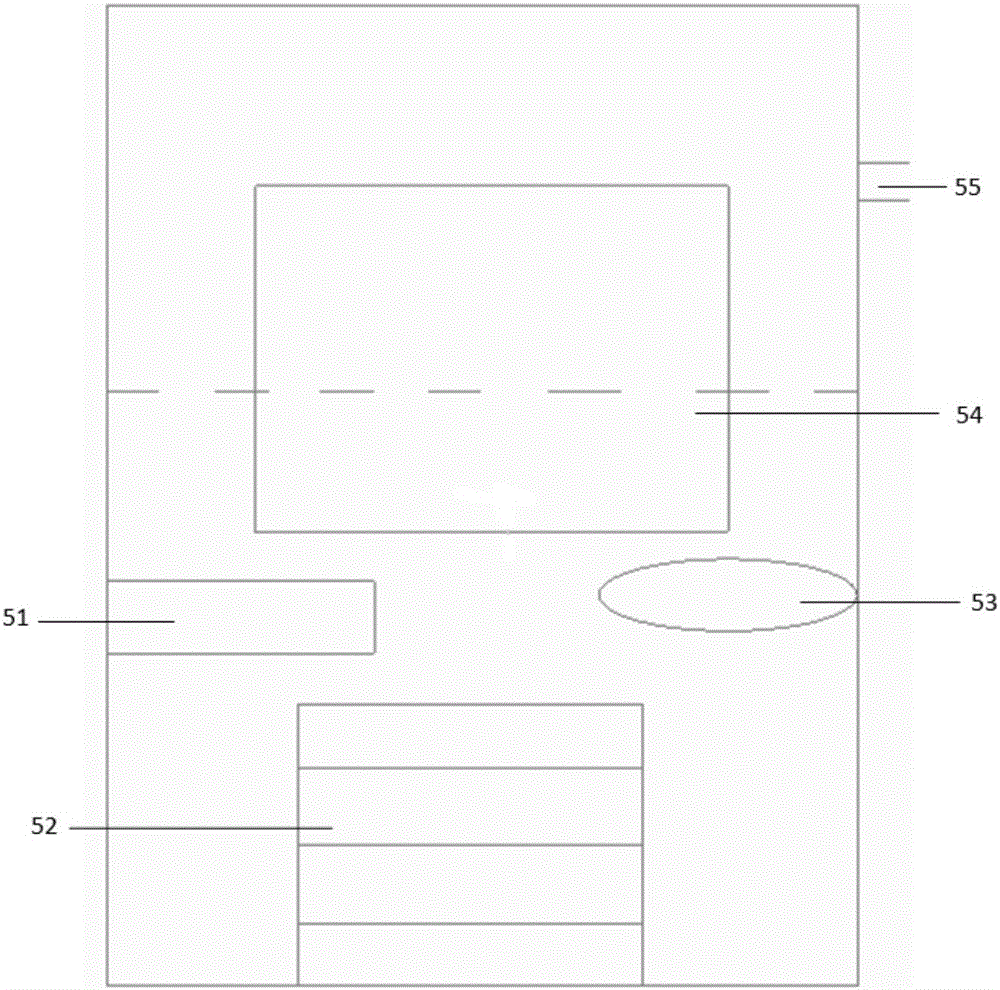

[0031] Embodiment 2: In the foregoing embodiment, as attached Figure 4 As shown, the oil fume water molecule collision mixing condenser 2 is provided with a channel communicating with the cold water particle generator 5, and the side wall of the oil fume water molecule collision mixing condenser 2 is provided with a plurality of The water molecule collision mixing condenser 2 is a water mist spray nozzle for spraying water mist inside; specifically: a left water mist spray nozzle 22 and a right water mist spray nozzle 21 can be respectively provided on both sides; In the device 2, the atomized water mist is sprayed on the area through a reasonable arrangement of water mist nozzles to form a certain concentration. Atomized water molecules collide and mix thoroughly.

Embodiment 3

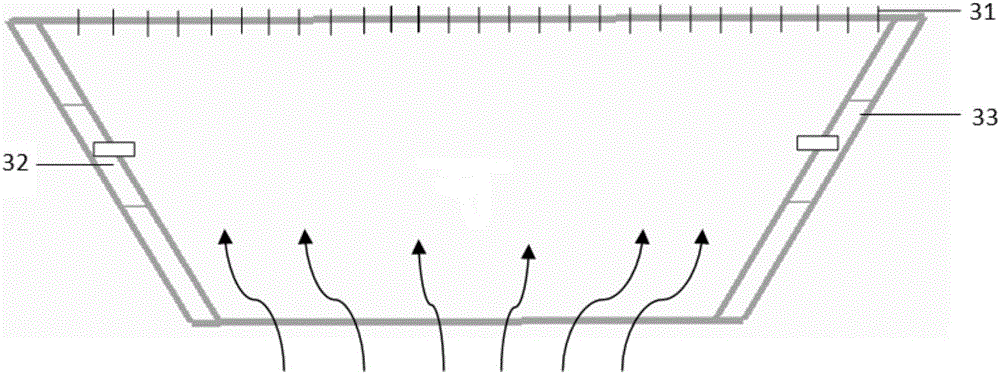

[0032] Embodiment three: In the above embodiment, as attached figure 2 As shown, the oil fume flow velocity slowing condenser 3 is an inverted trapezoidal structure, and the cross-sectional area of the oil smoke flow velocity slowing condenser 3 gradually increases according to the flow direction of the flue gas. According to the Venturi effect, the oil fume flow rate through the oil fume flow rate slowing condenser 3 can be effectively slowed down, reaching a speed that can effectively condense water molecules and oil smoke, and the cold water tiny particles sprayed in the oil smoke flow rate slowing condenser 3 are in and tiny During the condensation process of soot particles, the temperature of tiny soot particles can be cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com