A method for manufacturing a metal silenced honeycomb structure

A technology of a honeycomb structure and a manufacturing method, which is applied to the manufacturing field of metal sound-absorbing honeycomb structures, can solve problems such as low processing efficiency, and achieve the effects of improving production efficiency and hole-making efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

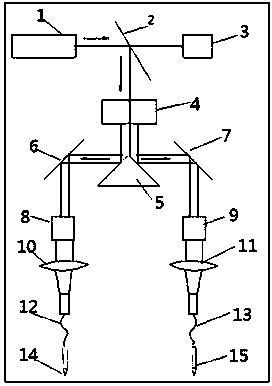

[0021] The manufacturing method of the titanium alloy sound-absorbing honeycomb structure: after the titanium alloy panel is cleaned and cleaned, the solder is arranged on the surface, and the titanium alloy honeycomb core is prepared by welding, and then the titanium alloy panel and the titanium alloy honeycomb core are brazed and assembled , into the vacuum furnace for vacuum brazing. After the brazing is qualified, the obtained titanium alloy sound-absorbing honeycomb structure is clamped and positioned on the multi-beam laser processing platform, and the multi-beam laser beams are used to make holes synchronously. The multi-beam laser beams used are double-beam laser beams, and the double-beam laser beams are generated by splitting a single laser light source, such as figure 1 As shown, the single laser beam emitted by the laser 1 is reflected by the shutter 2 to the beam expander 3, and after being split by the laser beam splitter 5 of the beam expander 4, it is divided in...

Embodiment 2

[0023] Manufacturing method of titanium alloy / stainless steel dissimilar material sound-absorbing honeycomb structure: After cleaning and cleaning the titanium alloy panel, arrange solder on its surface, clean the stainless steel honeycomb core, and then braze and assemble the titanium alloy panel and stainless steel honeycomb core , enter the vacuum furnace for vacuum brazing, vacuum brazing uses foil-like Ag-based solder with a thickness of 0.1-0.2mm, the brazing temperature is 810-835°C, and the holding time is 5-15min. After the brazing is qualified, the titanium alloy sound-absorbing honeycomb structure is clamped and positioned on the multi-beam laser processing platform, and the multi-beam laser beam is used to make holes. The multi-beam laser beam used is more than two laser beams. The multi-beam laser beam is generated by splitting a single laser light source. A single-stage or multi-stage beam splitter system is used to split a single laser beam into two n beam, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com