Large caliber aspheric surface measuring apparatus and method based on ultra-precise revolving scanning

A measuring device, ultra-precise technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low measurement speed, high motion accuracy requirements, and reduce the detection accuracy of the measured aspheric surface contour, so as to improve the contrast, The effect of increasing the measurement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

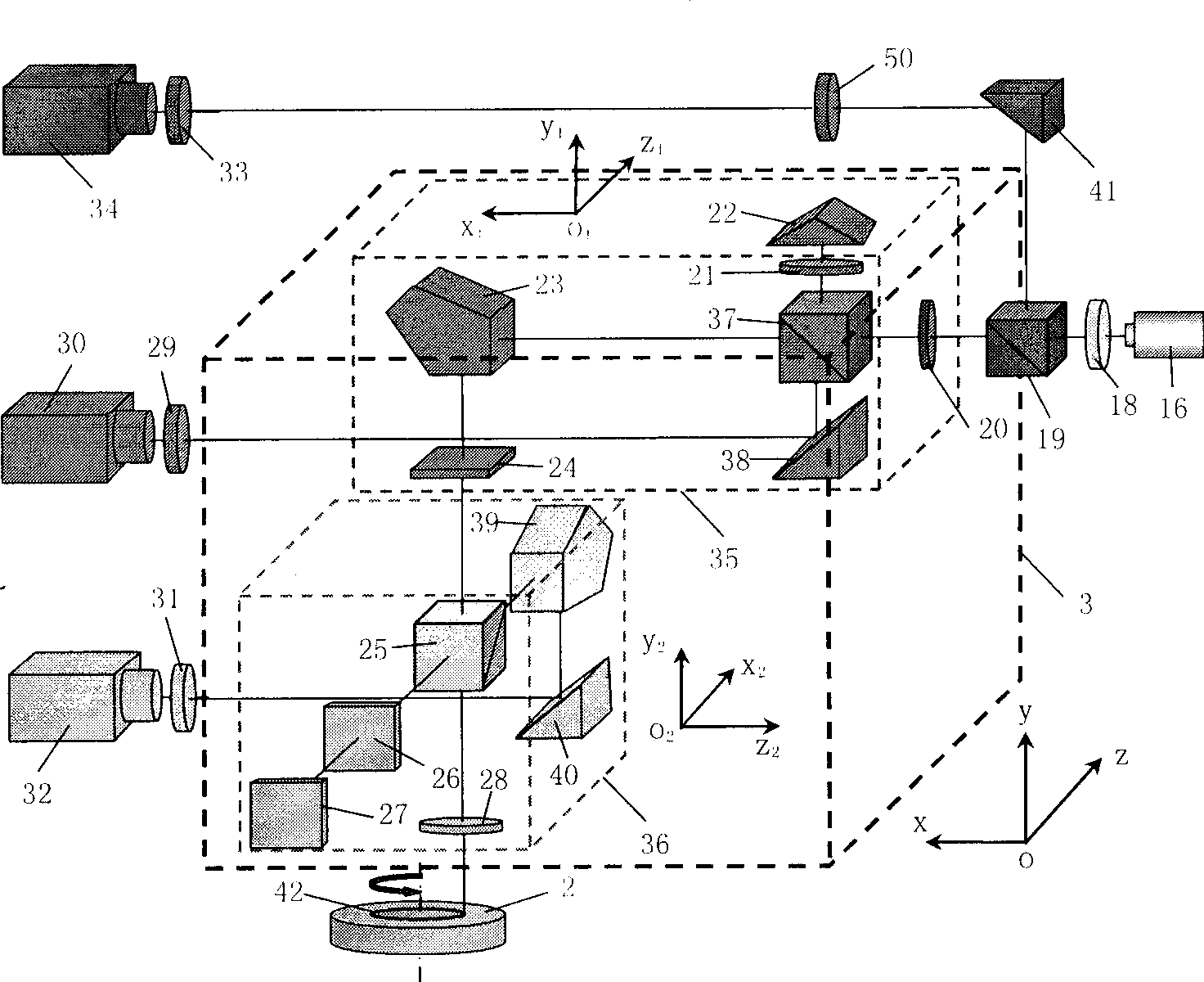

[0046] Adjust the beam splitter 37 so that the measurement light spot received by the CCD camera 30 is completely separated from the reference light spot; adjust the polarization beam splitter 25 so that the measurement light spot received by the CCD camera 32 is completely separated from the reference light spot; The spectroscope 25 is fixed, and then the component is calibrated, and after calibration, the component will not be adjusted in the subsequent rotary scanning measurement process. Adjust the linear polarizer 28 and the λ / 2 wave plate 24 so that the measurement and reference spot peak values received by the CCD camera 32 of the sub-scan head 36 are approximately equal, and are approximate to the measurement light spot peak values received by the CCD camera 30 of the sub-scan head 35 Equal; adjust the linear polarizer 21 so that the measured and reference spot peaks received by the CCD camera 30 of the sub-scanning head 35 are approximately equal. Adjust linear po...

Embodiment 2

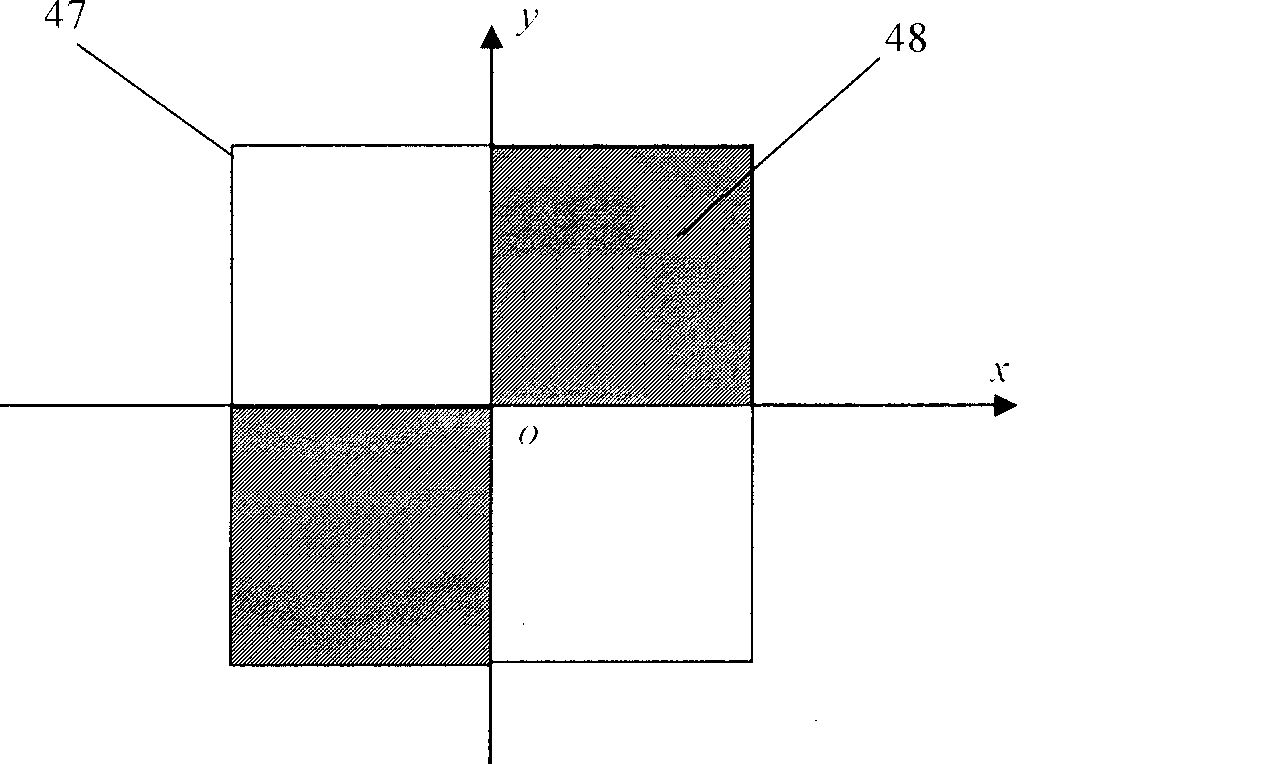

[0049] see figure 2 And Fig. 9, rectangular prism 22 also can adopt plane mirror 49, by Figure 9A It can be seen that in order to compensate the inclination measurement error caused by the angular drift in the sub-scanning head 35, it is necessary to subtract the reference signal from the measurement signal, see Figure 9B , in order to compensate the inclination measurement error caused by the vibration of the beam splitter 37 in the sub-scanning head 35, it is necessary to add the reference signal to the measurement signal. In this case, the propagation path of the light beam in the sub-scanning head 36 does not change, and does not affect its error compensation method and measurement results.

Embodiment 3

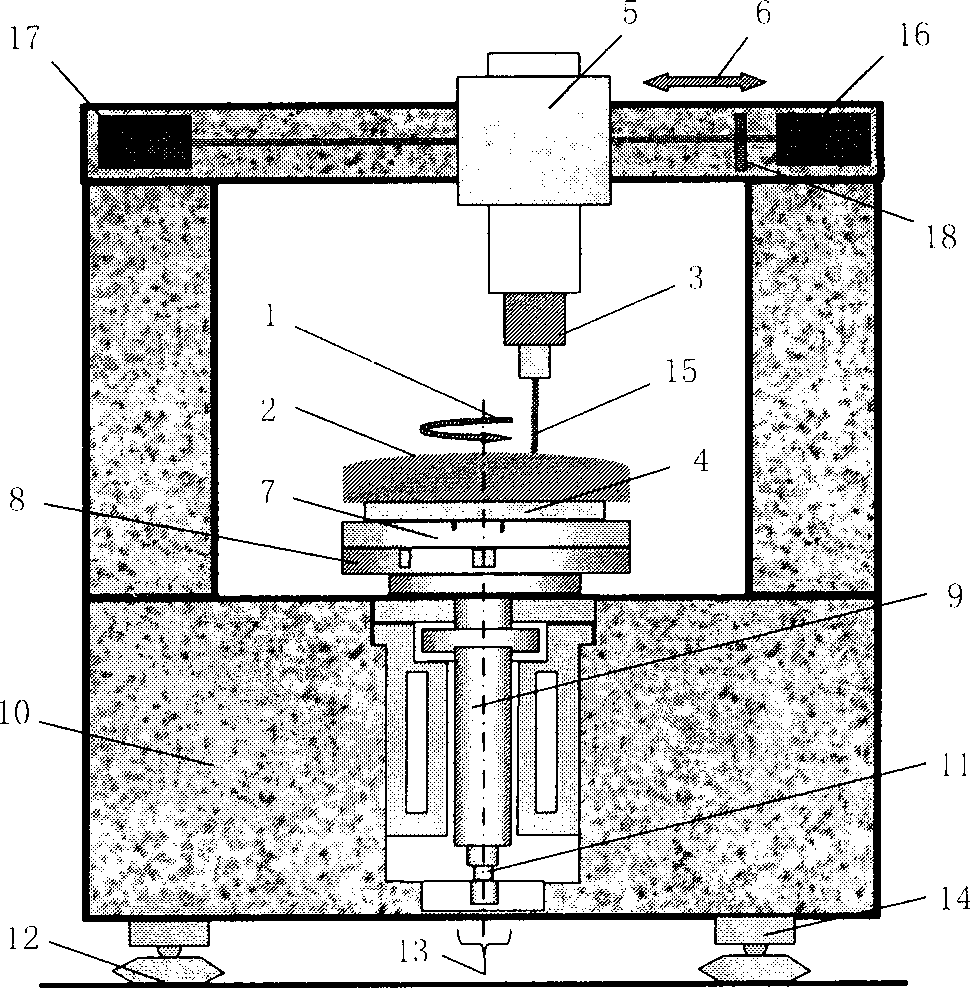

[0051] see figure 1 with Figure 10 , the linearly polarized He-Ne laser can also be a semiconductor laser, and after being collimated and thinned by a single-mode fiber collimating system, it is incident on the two-dimensional phase plate 18. The other components and working principles of this embodiment are the same as in Embodiment 1. same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com