Method for preparing straight-chain maltopentaose by using double-enzyme method

A technology of maltopentasaccharide and maltooligosaccharides, which is applied in the direction of medical preparations, applications, and pharmaceutical formulations containing active ingredients, which can solve the problems of low substrate concentration and inability to directly expand industrial production, and reduce production and processing costs , good thermal stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

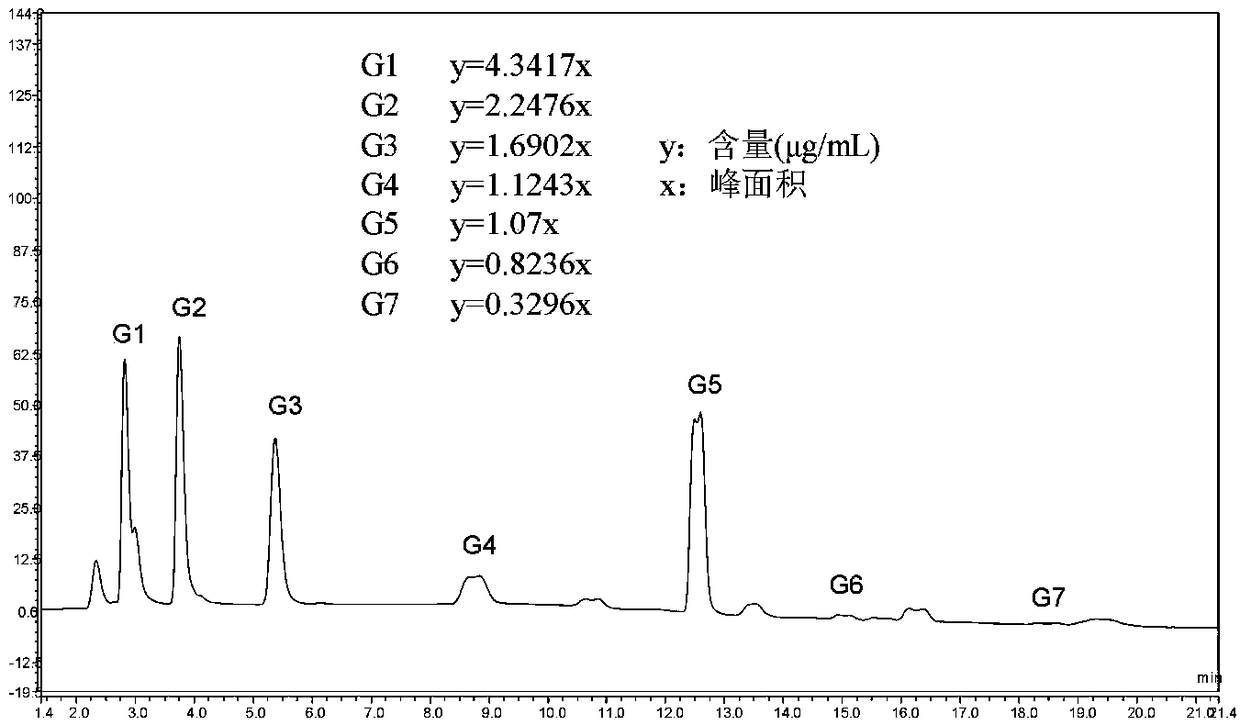

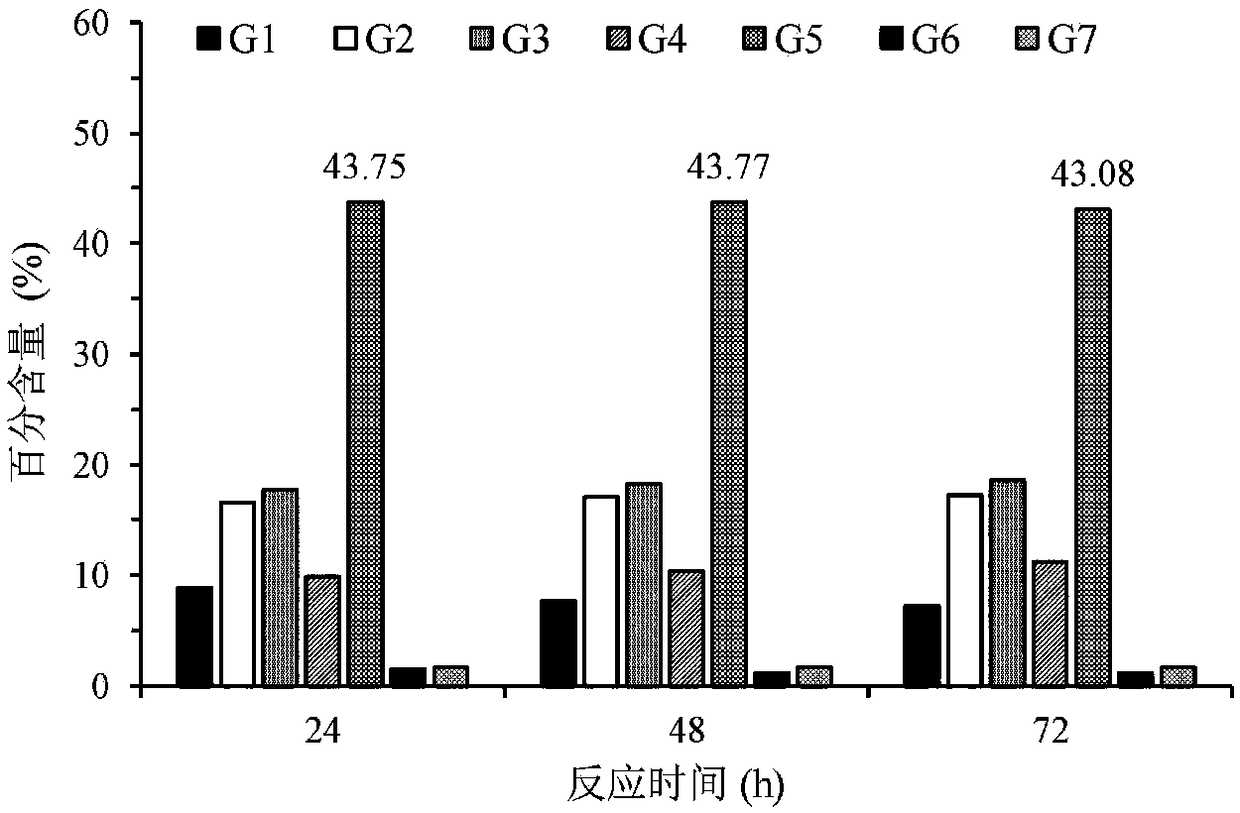

[0029] A 10% maltodextrin (DE=6) solution with pH 6.0 was prepared as a substrate, and the malto-oligosaccharide generating enzyme (the amino acid sequence numbered in GenBank is AIV43245.1) was added at a rate of 100 U / g with the enzyme added, and 2 U / g g Add the amount of enzyme and add pullulanase, react at 60°C for 24 to 72 hours. After the reaction, the enzyme is inactivated in a boiling water bath for 40 minutes, and the sample is measured by high performance anion exchange chromatography-pulse amperometric detection (HPAEC-PAD). The chromatogram of 24h reaction is as follows figure 1 Shown. The relative content of each component in the syrup corresponding to different reaction times is as follows figure 2 As shown, at this time, the main product maltopentaose content is above 43%, the substrate conversion rate is 90.2%-99.8%, and the glucose content is within 10%, and the linear oligosaccharides with a DP value of 8 and above are not detected. It shows that the substrat...

Embodiment 2

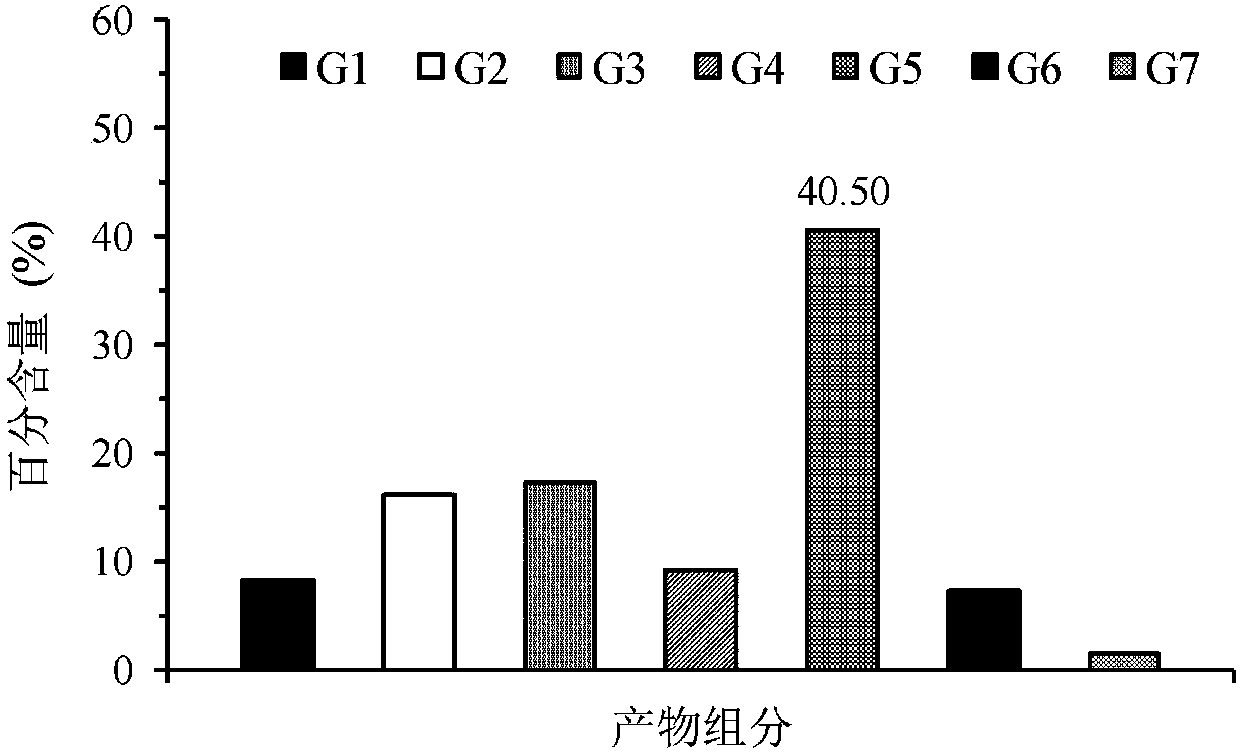

[0031] Prepare 30% maltodextrin (DE=6) solution as substrate, adjust pH 5.5, add malto-oligosaccharide-producing enzyme (amino acid sequence number in GenBank is AIV43245.1) according to 50U / g enzyme amount, press Pullulanase was added with 5U / g enzyme amount, reacted at 70℃ for 72h, after the reaction, the enzyme was killed in a boiling water bath, and the composition and content of the sample were determined by high performance anion exchange chromatography-pulse amperometric detection (HPAEC-PAD) Such as image 3 As shown, at this time, the main product maltopentaose content in the syrup is 40.5%, and the substrate conversion rate reaches 91.7%.

Embodiment 3

[0033] Prepare a 10% corn starch solution as the substrate, adjust the pH to 6.5, add the malto-oligosaccharide generating enzyme (amino acid sequence number in GenBank is AIV43245.1) according to the 100U / g enzyme amount, and add the enzyme amount according to 2U / g Add pullulanase and react at 60℃ for 48h. After the reaction, the enzyme is killed in a boiling water bath. The content of the main product maltopentaose in the syrup is 43.3% as determined by high performance anion exchange chromatography-pulse amperometric detection (HPAEC-PAD). The substrate conversion rate reached 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com