Method for reclaiming optical disk substrate from abandon optical disk

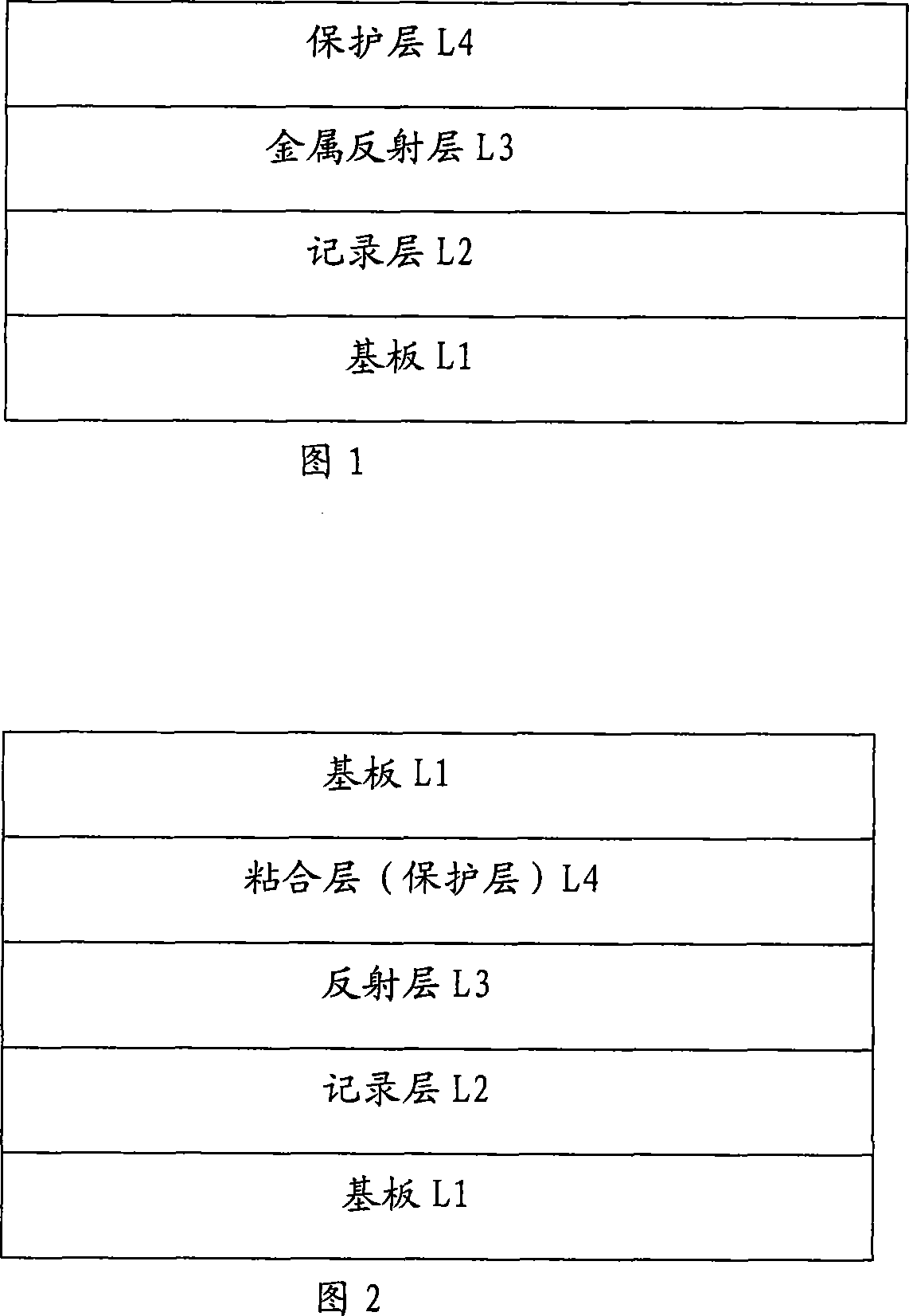

A technology for discarded optical discs and optical discs, which is applied in the fields of plastic recycling, chemical recycling, recycling technology, etc., can solve the problems of complicated process and difficult promotion, and achieve the effect of environmental protection of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

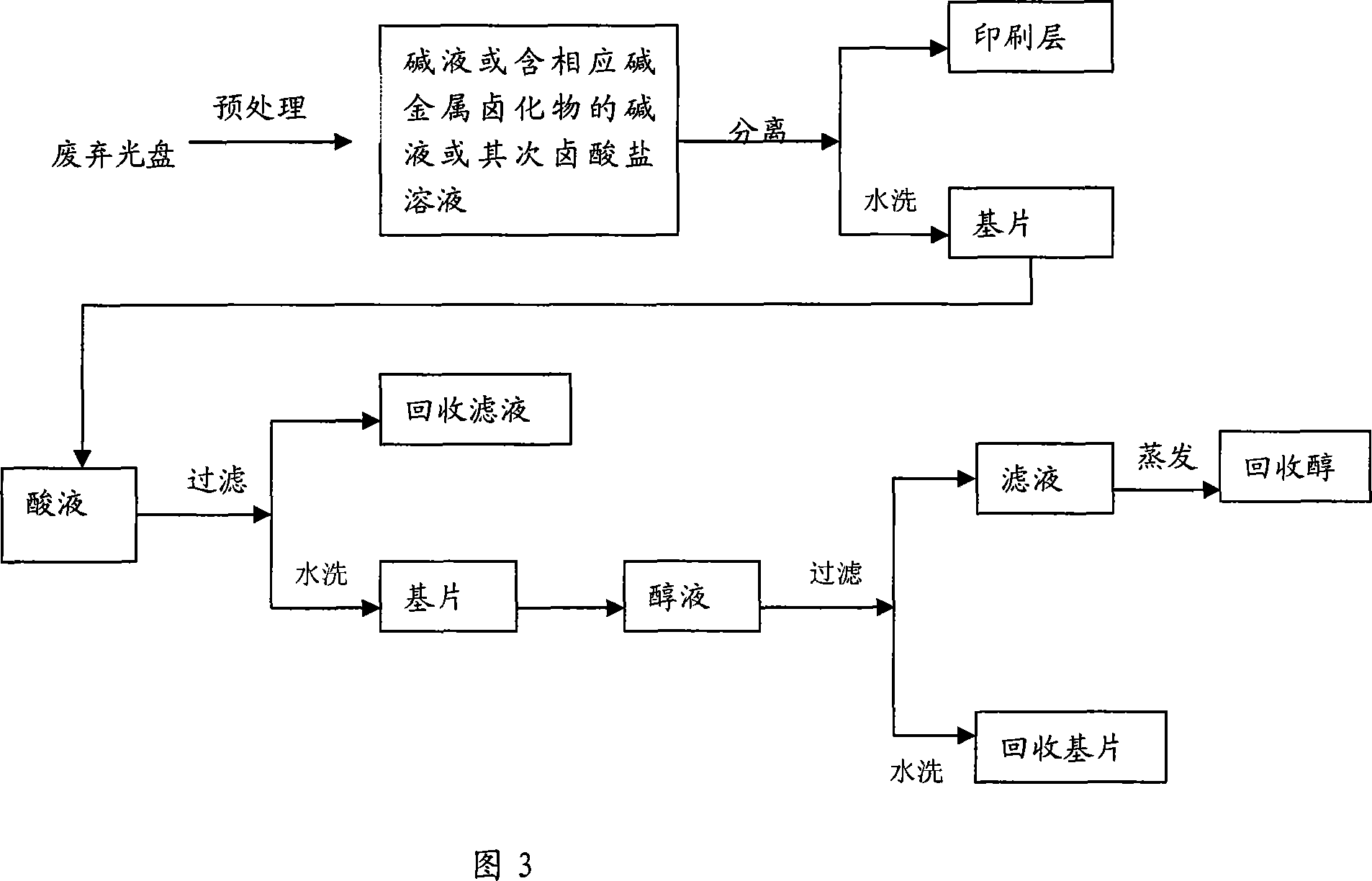

Method used

Image

Examples

Embodiment 1

[0024] Use mechanical methods such as cutters to separate the upper and lower substrates of DVD discs (except CD / VCD). Then take the above-mentioned stripped disc and place it in a pre-configured 20wt% NaOH solution (the volume of the solution is based on the complete immersion of the disc, the same below.), at 50°C and a stirring speed of 400r / min, stir 30min. Then the optical disc in the above solution was taken out and washed with water, placed in a pre-configured 10wt% hydrochloric acid solution, heated to 40°C, stirred and reacted at a stirring speed of 800r / min for 50min, and then the optical disc was taken out. Then the optical disc was washed with water and placed in 30wt% ethanol solution, allowed to stand at room temperature for 40 minutes, and then washed with water to obtain a clean and transparent plastic substrate. Finally the ethanol solution is evaporated to recover the alcohol.

Embodiment 2

[0026] The method is as in Example 1, the stripped optical disc is placed in a mixed solution of 5% NaOH and 10% NaCl or a 40% aqueous solution of KClO, and stirred for 30 min at a temperature of 65° C. and a stirring speed of 400 r / min. Other steps and obtained result are with embodiment 1.

Embodiment 3

[0028] Method is as embodiment 1, and the optical disk disc stripped is placed in 30% Na 2 CO 3 In the aqueous solution, stir for 40 min at a temperature of 60° C. and a stirring speed of 400 r / min. Other steps and obtained result are with embodiment 1.

[0029] The qualified rate of above-mentioned experimental result is all greater than 98% (wherein, qualified rate is the percentage of the completely clean and transparent plastic substrate weight that obtains after processing and the optical disc gross weight before processing); The original substrates were scanned with an electron probe, and the results were not significantly different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com